An Airborne Scramjet Pressure Measurement System

A technology of scram stamping and measurement system, which is applied in the field of aerospace telemetry and remote sensing, can solve the problems of unfavorable integration, bulky pressure measurement system, and inability to meet multi-point synchronous measurement, and achieve the effect of light weight and small volume

Active Publication Date: 2014-04-09

NAT UNIV OF DEFENSE TECH

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And the pressure measurement system volume that is currently applied in aerospace field is generally too large, is unfavorable for integrated integration,

Or can not meet the needs of multi-point synchronization measurement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] Below in conjunction with the accompanying drawings, the present invention will be described in detail.

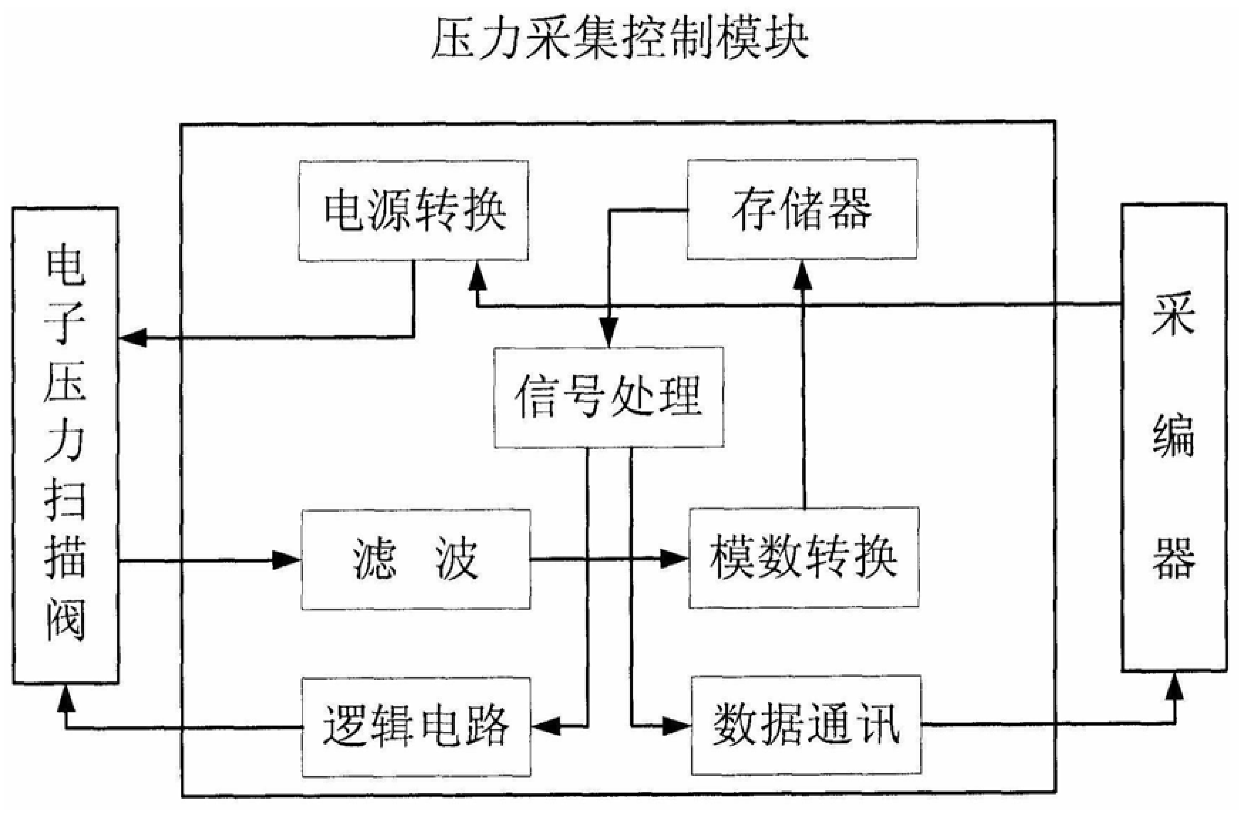

[0027] Filter selection voltage-controlled voltage source type VCVS active filter. The entire bandpass filter consists of two second-order bar

[0034] The data communication function module completes the formation of the data frame and transmits data to the serial port at a required baud rate. Pass

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

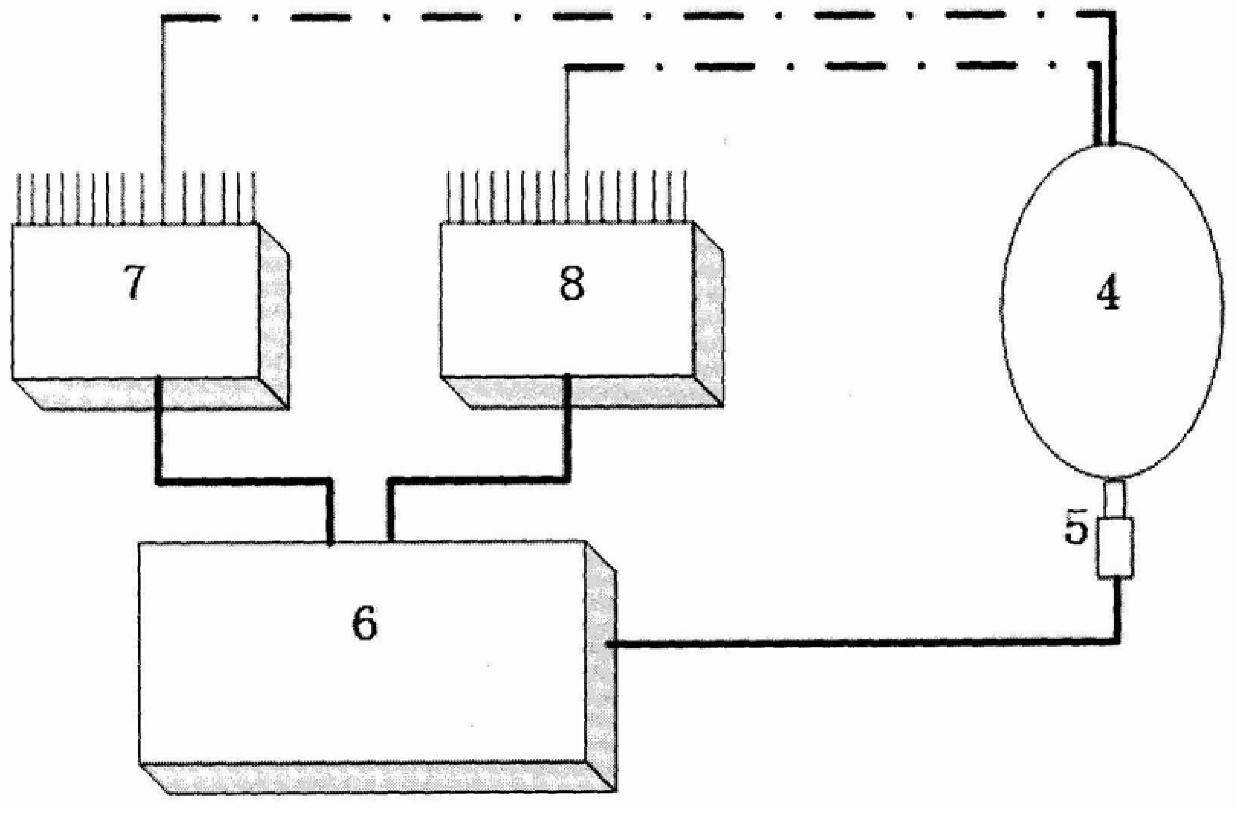

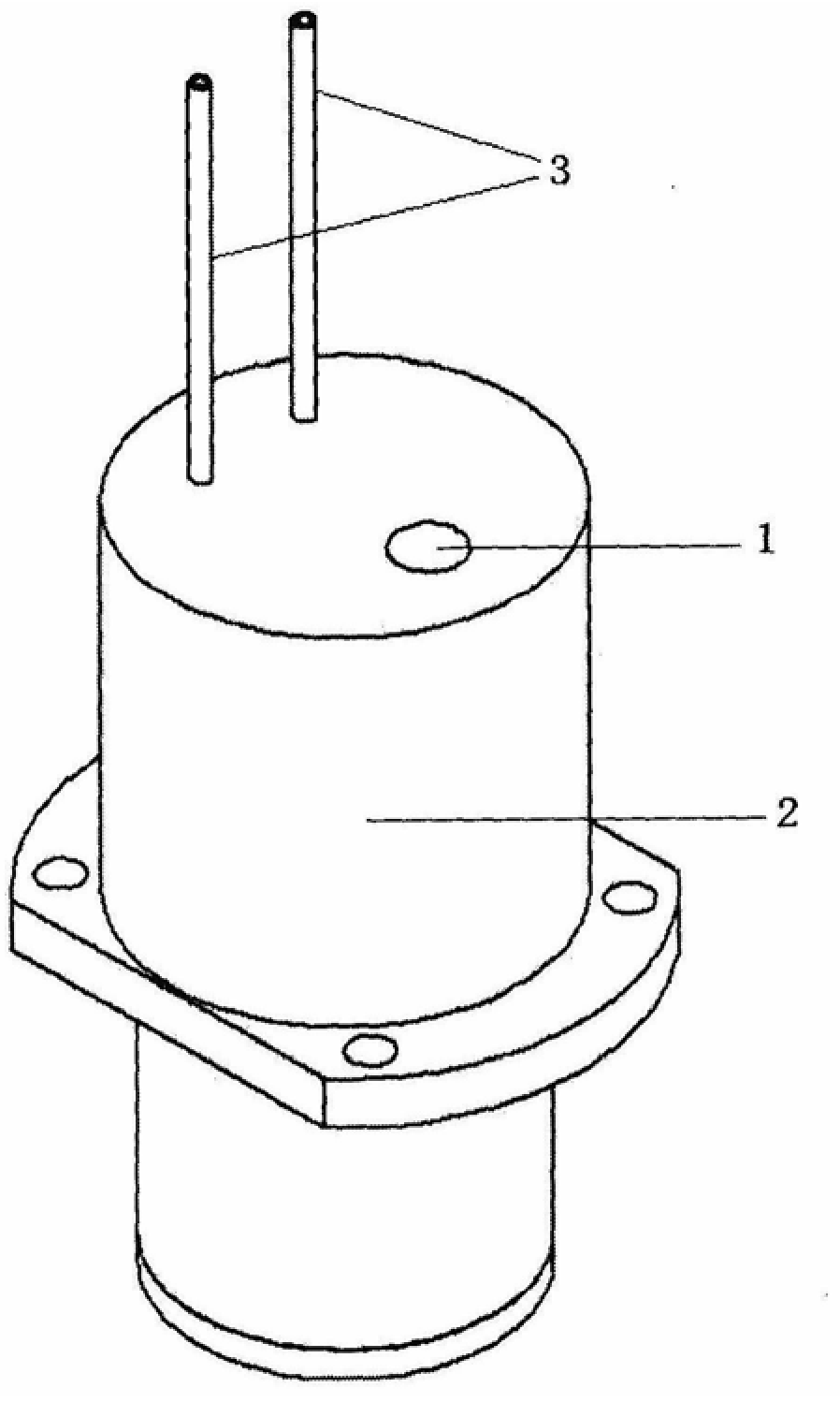

The invention provides an airborne scramjet pressure measurement system, which mainly includes an electronic pressure scanning valve, a pressure acquisition control module, a back pressure device and an absolute pressure sensor; the back pressure device provides reference pressure for the electronic pressure scanning valves 7 and 8 The absolute pressure sensor collects the pressure of the back pressure device, and the output signal of the electronic pressure scanning valve is sent to the pressure acquisition control module; the back pressure device is composed of an absolute pressure sensor interface, a back pressure device barrel and an impermeable steel pipe; the back pressure device barrel The inside is sealed with a local atmospheric pressure or evacuated; one end of the absolute pressure sensor interface is connected to the back pressure device cylinder, and the other end is connected to the absolute pressure sensor; one end of the stainless steel tube is connected to the back pressure device cylinder, and the other end is connected to the electronic pressure scanner through the pressure measuring pipeline valve. The invention is small in volume, light in weight and high in precision, helps to increase the proportion of payload in the aircraft structure, and provides an effective means of pressure measurement for hypersonic autonomous flight.

Description

An airborne scramjet pressure measurement system Technical field The present invention relates to aerospace telemetry remote sensing field, particularly, relate to a kind of airborne scramjet pressure measurement system. Background technique Mainly be used in the attitude control of spacecraft and aerospace vehicle, high-speed aircraft, jet engine in aerospace field The pressure measurement of heat-resistant cavities and surfaces of aircraft, rockets, satellites, etc., its performance is determined by the measurement range, measurement accuracy, nonlinear and working temperature. Aerospace field working environment is harsher, usually comprises thermal erosion, mainly refers to high-temperature environment; Mechanical erosion, mainly Refers to high load, vibration and impact, etc.; chemical corrosion, mainly refers to the environment with corrosive media, etc. Along with the rapid development of measurement technology, high-precision fluid dynamics test has propose...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M15/00F02K9/00

Inventor 罗世彬夏智勋曾迎生黄伟鄢小清杨乐柳军金亮曾庆华刘冰郭振云李洁颜力王德全隆清贤梁文鹏付博文杨阳

Owner NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com