Alkali resistant ceramic coating material and preparation method thereof

A ceramic coating and alkali resistance technology, applied in the field of alkali resistance ceramic coating materials and their preparation, can solve the problems of high cost, complicated preparation process, insufficient bonding strength, etc., to improve mechanical strength, reduce production cost, Effects that improve composition quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

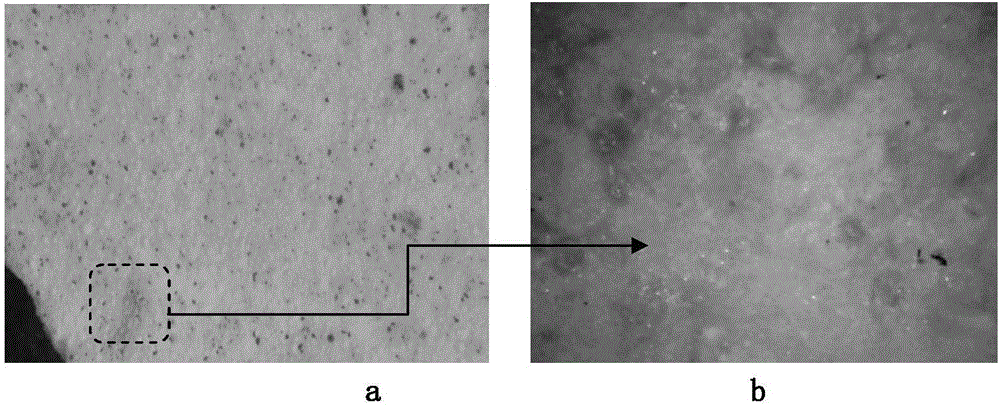

Image

Examples

Embodiment 1

[0033] A kind of anti-alkali ceramic coating material, the composition of raw material and batching are as Table 1 below (parts by mass):

[0034] Table 1 (Kg)

[0035] spinel 11.0 γ-LiAlO 2 15.0 spodumene 12.0 ZrO 2 1.0 α-Al 2 o 3 3.0 SiO 2 8.0

[0036] Composite phosphate glue (bonding agent) 19.0 Citric Acid Solution (30%) 31.0

[0037] Table 1 The spodumene in is "natural spodumene" (the same below).

[0038] The above-mentioned preparation method of an alkali-resistant ceramic coating material comprises the following steps: 1) selecting raw materials according to the ratio of the above-mentioned raw materials; 2) mixing the raw materials to obtain an alkali-resistant ceramic coating material.

[0039] When in use, the anti-alkali ceramic coating material (after the above raw materials are uniformly mixed to make a well-flowing ceramic slurry) is directly coated in various ways on the refractory ...

Embodiment 2

[0042] A kind of anti-alkali ceramic coating material, the composition of raw material and batching such as Table 2 below (parts by mass):

[0043] Table 2 (Kg)

[0044] spinel 10.0 γ-LiAlO 2 14.5 spodumene 14.0 ZrO 2 1.5 α-Al 2 o 3 3.0 SiO 2 7.0 Composite phosphate glue (bonding agent) 35.0 Citric Acid Solution (30%) 15.0 solid to liquid ratio 50.00:50.00

[0045] The above-mentioned preparation method of an alkali-resistant ceramic coating material comprises the following steps: 1) selecting raw materials according to the ratio of the above-mentioned raw materials; 2) mixing the raw materials to obtain an alkali-resistant ceramic coating material.

[0046] When in use, the anti-alkali ceramic coating material (after the above raw materials are uniformly mixed to make a well-flowing ceramic slurry) is directly coated in various ways on the refractory sagger to be used or the refractory sagger to be repai...

Embodiment 3

[0049] A kind of anti-alkali ceramic coating material, the composition of raw material and batching such as Table 3 below (parts by mass):

[0050] table 3 (Kg)

[0051] spinel 9.0 γ-LiAlO 2 18.0 spodumene 13.0 ZrO 2 2.0 α-Al 2 o 3 5.0 SiO 2 3.0 Composite phosphate glue (bonding agent) 20.0 Citric Acid Solution (30%) 30.0 solid to liquid ratio 50.00:50.00

[0052] The above-mentioned preparation method of an alkali-resistant ceramic coating material comprises the following steps: 1) selecting raw materials according to the ratio of the above-mentioned raw materials; 2) mixing the raw materials to obtain an alkali-resistant ceramic coating material.

[0053] When in use, the anti-alkali ceramic coating material (after the above raw materials are uniformly mixed to make a well-flowing ceramic slurry) is directly coated in various ways on the refractory sagger to be used or the refractory sagger to be repair...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com