Carbon-silicon negative electrode material and preparation method thereof

A technology of negative electrode material and porous carbon material, which is applied in the field of carbon silicon negative electrode material and its preparation, can solve the problems of volume expansion of silicon material and the production cost of nano-silicon easy to agglomerate, so as to ensure stability, alleviate volume expansion, and overcome production cost. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

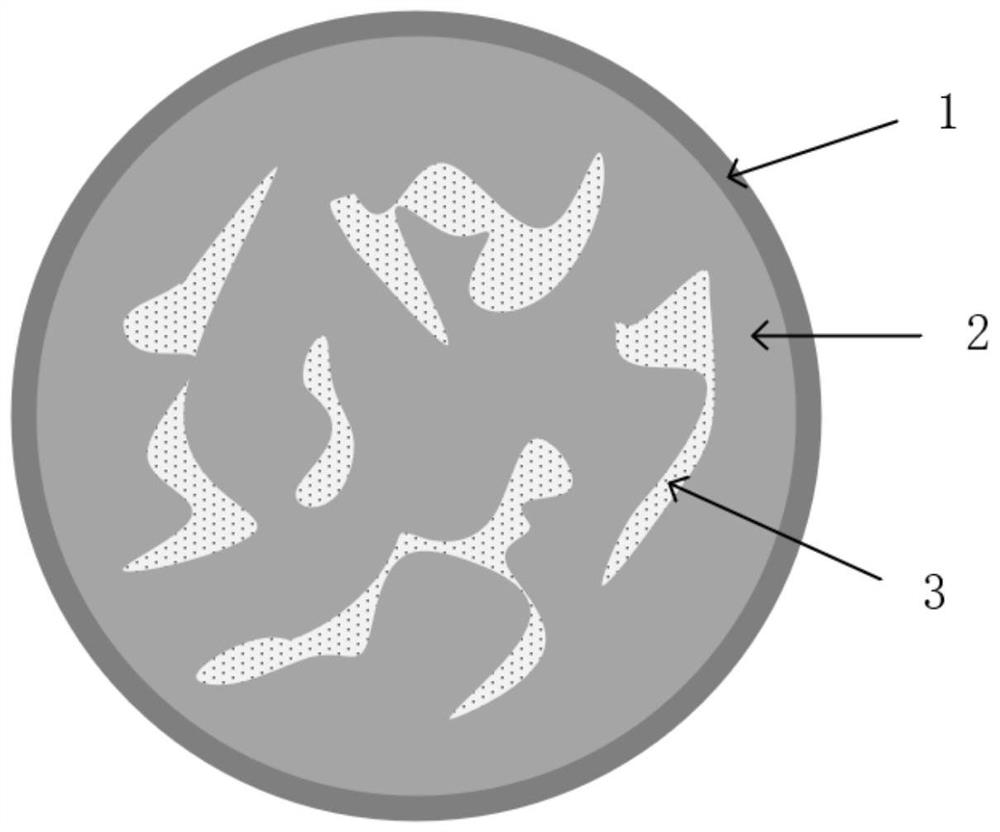

[0034] Embodiments of the present invention provide a method for preparing a carbon-silicon negative electrode material, comprising the steps of:

[0035] S1. Impregnating the porous carbon material with the organosilicon solution, adding alcohol or water to react, and drying the product after the reaction to obtain the first precursor.

[0036] Wherein, the solute concentration of the organosilicon solution is 10%-100%. Wherein, the solute of the organosilicon solution is an organosilicon compound, specifically, halosilane and / or ethyl orthosilicate can be selected, and the solvent of the organosilicon solution is an organic solvent, specifically, n-hexane, n-heptane, At least one of n-pentane and benzene.

[0037] The porous carbon material is at least one of porous artificial graphite, porous natural graphite, porous hard carbon, porous soft carbon and porous mesocarbon microspheres.

[0038] A porous carbon material having a particle diameter of 1 μm to 20 μm is preferre...

Embodiment 1

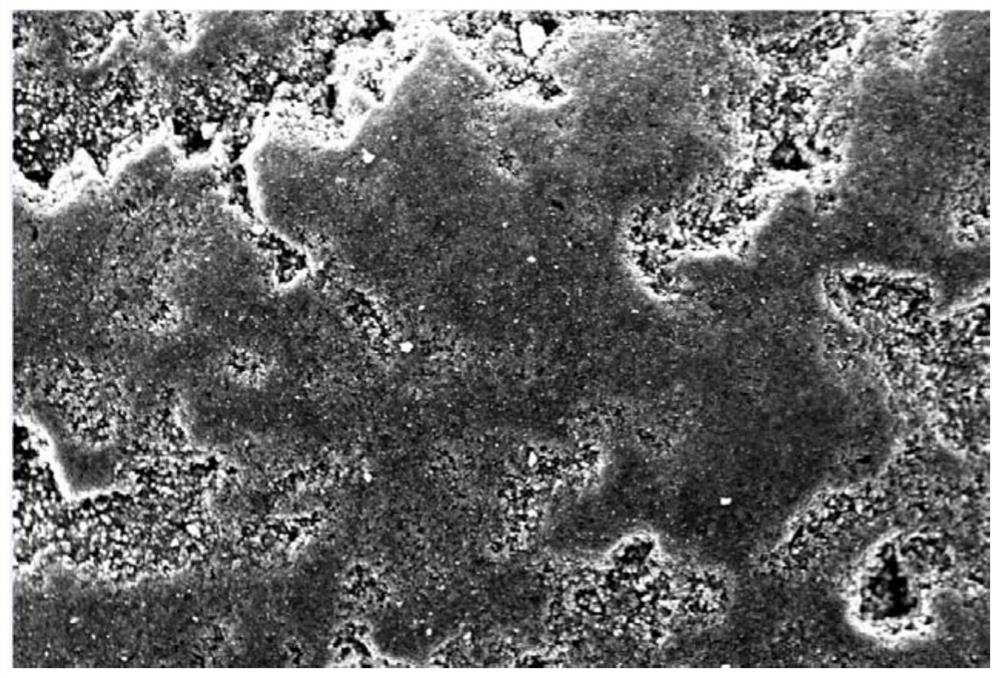

[0069] (1) Add porous artificial graphite and silicon tetrachloride (volume concentration: 99.5%) into the reaction kettle at a mass ratio of 1:0.6, stir to completely infiltrate the silicon tetrachloride solution into the pores of the graphite, and slowly add to the graphite pores during stirring. The ionized water was hydrolyzed, and after the reaction was completed, it was heated to 50°C, the residual solution was evaporated, and then the temperature was raised to 200°C, and kept for 1 hour to obtain the loaded nano-SiO 2 The graphite material is called precursor A.

[0070] (2) Mix the precursor A and magnesium powder in step (1) at a mass ratio of 1:0.8, mix evenly, place in a sintering furnace, and calcine under an argon atmosphere at a calcination temperature of 700°C. After holding for 4 hours, Cool to room temperature with the furnace. Then the resultant was washed with acid, and then washed with deionized water until neutral to obtain a graphite material loaded with...

Embodiment 2

[0075] (1) Add porous artificial graphite and silicon tetrachloride (volume concentration 99.5%) into the reaction kettle at a mass ratio of 1:3, stir to completely infiltrate the silicon tetrachloride solution into the graphite pores, and slowly add ethanol during the stirring process Carry out the hydrolysis reaction, heat to 80°C after the reaction is completed, evaporate the residual solution, then raise the temperature to 100°C, and keep it for 3 hours to obtain the loaded nano-SiO 2 The graphite material is called precursor A.

[0076] (2) Mix the precursor A of step (1) with the aluminum powder at a mass ratio of 1:4, mix evenly, place in a sintering furnace, and calcine under a mixed atmosphere of argon and hydrogen, with a hydrogen concentration of 5%, and calcine The temperature is 400°C, after 8 hours of heat preservation, it is cooled to room temperature with the furnace, and the product is washed with acid and deionized water to neutrality to obtain a graphite mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com