A kind of rigid polyvinyl chloride product and its preparation method

A technology of rigid polyvinyl chloride and polyvinyl chloride, applied in the field of polyvinyl chloride materials and its preparation, can solve the problem of affecting the appearance and performance of polyvinyl chloride decorative materials, the great difference in the refractive index of polyvinyl chloride, and the lack of decorative objects Effect and other issues, to achieve the effect of improving flow performance, good appearance performance, and blocking penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1. The preparation of rigid polyvinyl chloride product 1

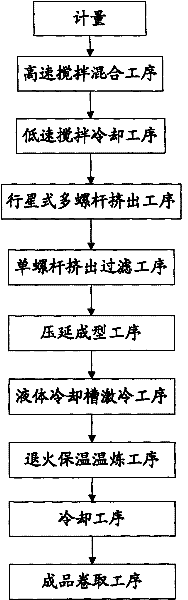

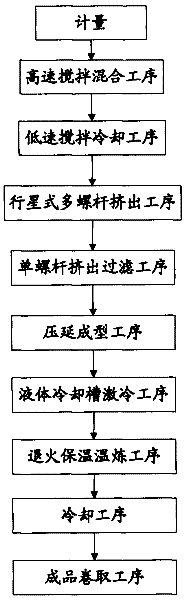

[0044] like figure 1 As shown, the preparation method of the rigid polyvinyl chloride product of the present invention includes a high-speed stirring and mixing process, a low-speed stirring and cooling process, a planetary multi-screw extrusion process, a single-screw extrusion and filtration process, a calendering process, and a liquid cooling tank. Chilling process, annealing heat preservation and warming process, cooling process and finished product coiling process; its special feature is that in this embodiment, each component of the rigid polyvinyl chloride product and the component content in parts by mass are shown in the table 1 shows:

[0045] Components and content (parts by mass) of the rigid polyvinyl chloride product of Table 1 Example 1

[0046] Polyvinyl chloride (PVC) 100 parts,

[0047] Mercaptan organotin 1.6 parts,

[0048] Acrylic ester internal lubricant 0.6 part,

[0049] A...

Embodiment 2

[0054] Embodiment 2. Preparation 2 of rigid polyvinyl chloride products

[0055] Component and content (parts by mass) of the PVC bottom film of table 2 embodiment 2

[0056] Polyvinyl chloride (PVC) 100 parts,

[0057] Mercaptan organotin 1.8 parts,

[0058] Acrylic ester internal lubricant 0.8 parts,

[0059] Acrylic external lubricant 0.3 parts,

[0060] 10 parts of methyl methacrylate-butadiene-styrene copolymer,

[0061] Hydroxy-terminated linear reactive siloxane 0.3 parts

[0062] Rutile titanium dioxide 8.0 parts

[0063] Ultramarine EP-19 0.018 parts

[0064] According to the components and contents in Table 2, the rigid polyvinyl chloride product produced by the method in Example 1, because no plasticizer is needed, and the hydroxyl-terminated linear reactive silicone containing hydrophobic group is added Alkanes can significantly block the erosion of water molecules on the film, and better solve the problem of water-sensitive whitening on the surface of plastic...

Embodiment 3

[0065] Embodiment 3. Preparation 3 of rigid polyvinyl chloride products

[0066] Component and content (parts by mass) of the PVC bottom film of table 3 embodiment 3

[0067] Polyvinyl chloride (PVC) 100 parts,

[0068] Mercaptan organotin 2.2 parts,

[0069] 1.0 part of acrylic internal lubricant,

[0070] 0.5 parts of acrylic external lubricant,

[0071] 14 parts of methyl methacrylate-butadiene-styrene copolymer,

[0072] Fluorine resin 0.5 parts

[0073] Rutile titanium dioxide 1.0 parts

[0074] P.V.19 red pigment 4.0 parts

[0075] P.R.122 red pigment 0.9 parts

[0076] According to the components and contents in Table 3, the rigid polyvinyl chloride products produced by the method in Example 1 can significantly block water due to the addition of plasticizers and the addition of fluororesins containing hydrophobic groups. The erosion effect of molecules on the film can better solve the problem of water-sensitive and whitening of the surface of plastic products. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com