Patents

Literature

42results about How to "Smooth and wear-resistant surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

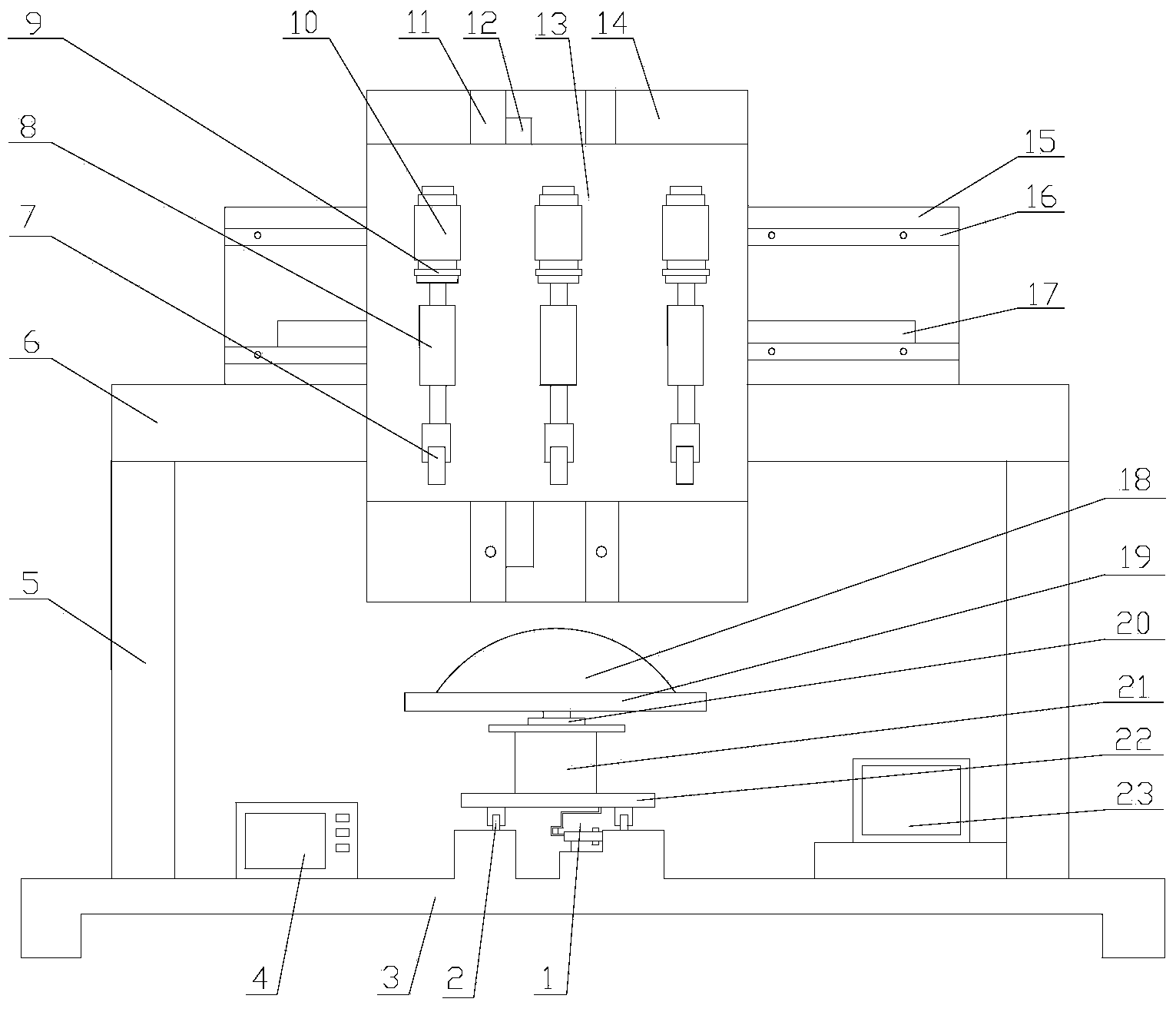

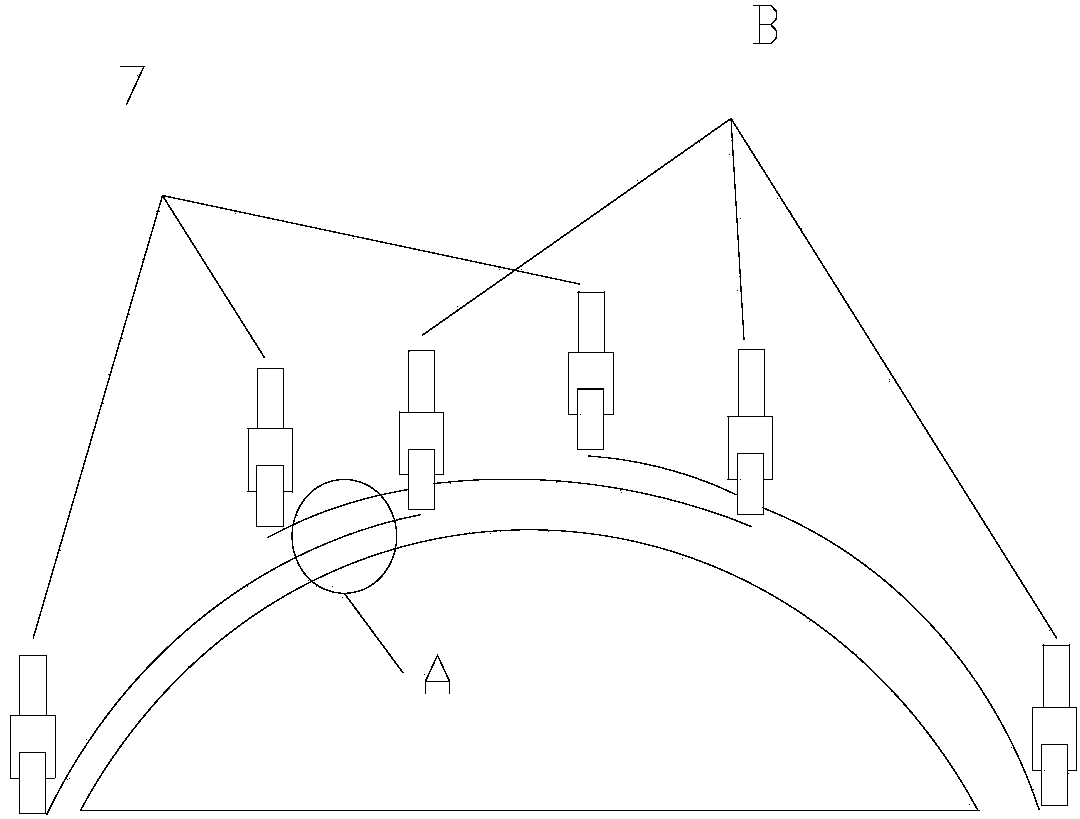

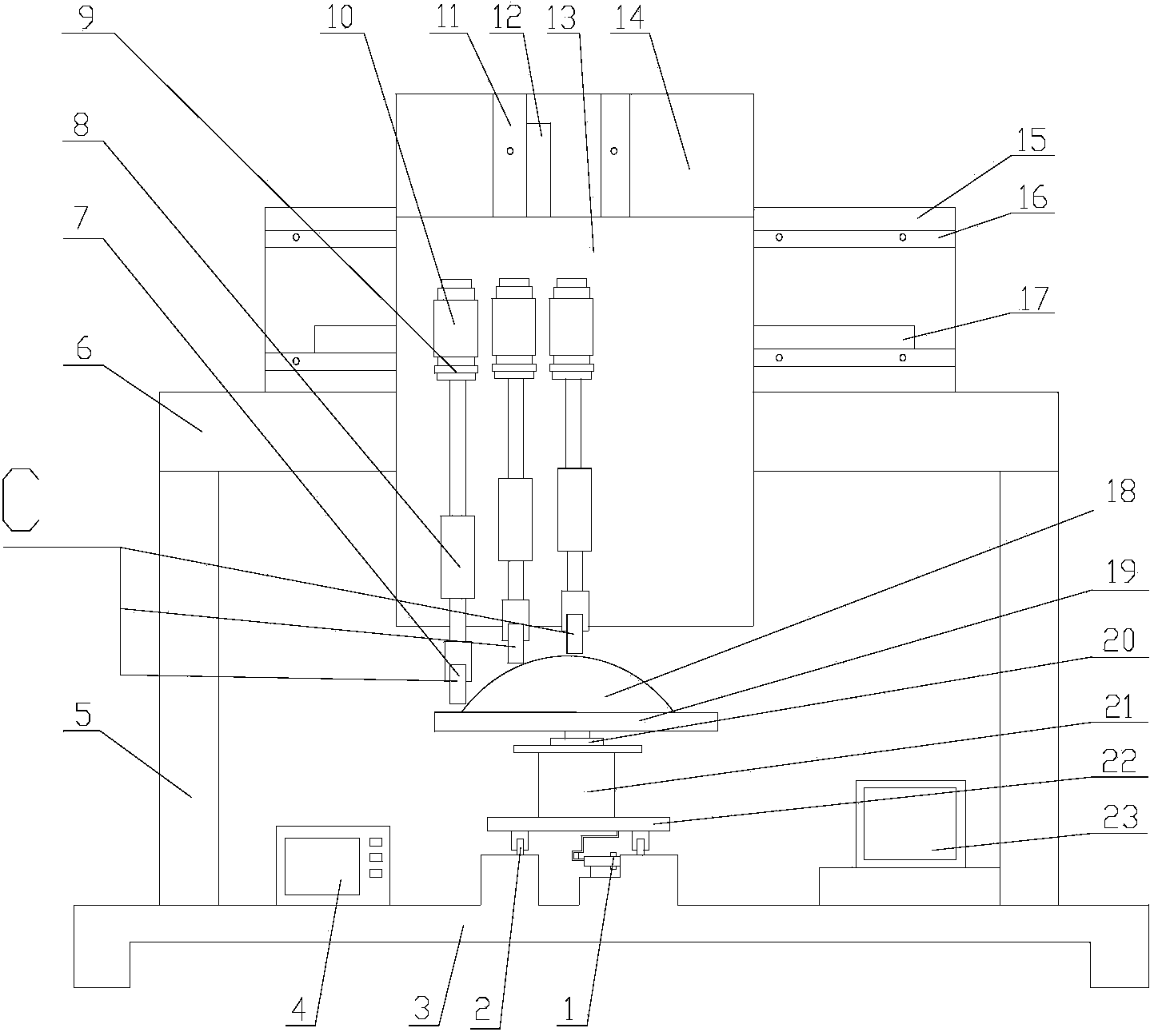

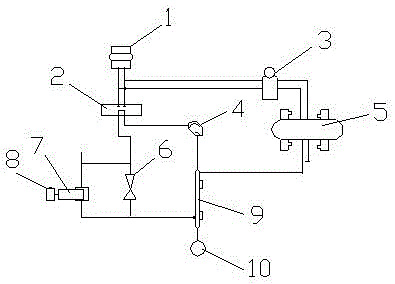

One-time splicing measurement device of large-aperture optical element profile

The invention provides a one-time splicing measurement device of a large-aperture optical element profile, relating to a measurement device of an optical element profile. The one-time splicing measurement device is provided with a Y-axis linear motor, Y-axis linear guide rails, a base, a movement controller, a stand column, a cross beam, a measurement sensor, a linear motion lead screw nut pair, a coupling, a measuring head movement driving motor, Z-axis linear guide rails, a Z-axis linear motor, a measuring head connecting base, a Z-axis workbench, an X-axis workbench, X-axis linear guide rails, an X-axis linear motor, a workpiece, a workpiece rotary table, a connecting base, a rotary motor, a Y-axis workbench and a computer. The one-time splicing measurement device can realize one-time splicing measurement; particularly specific to a large-aperture workpiece, measurement steps are reduced by adopting the measurement device; the one-time splicing measurement device is simple in measurement process, high in measurement efficiency, simple and compact in structure and convenient to operate.

Owner:XIAMEN UNIV

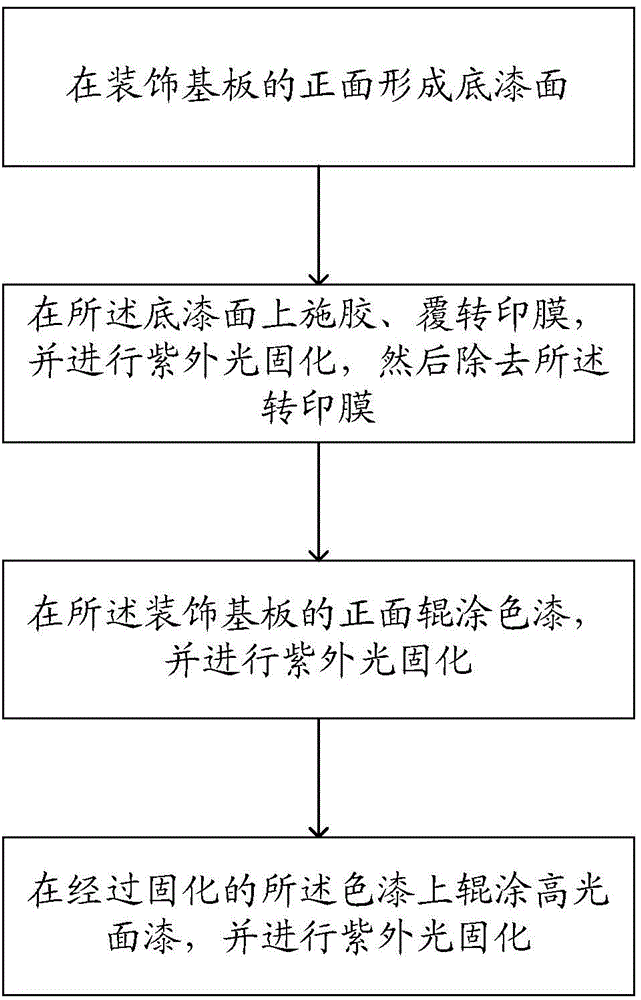

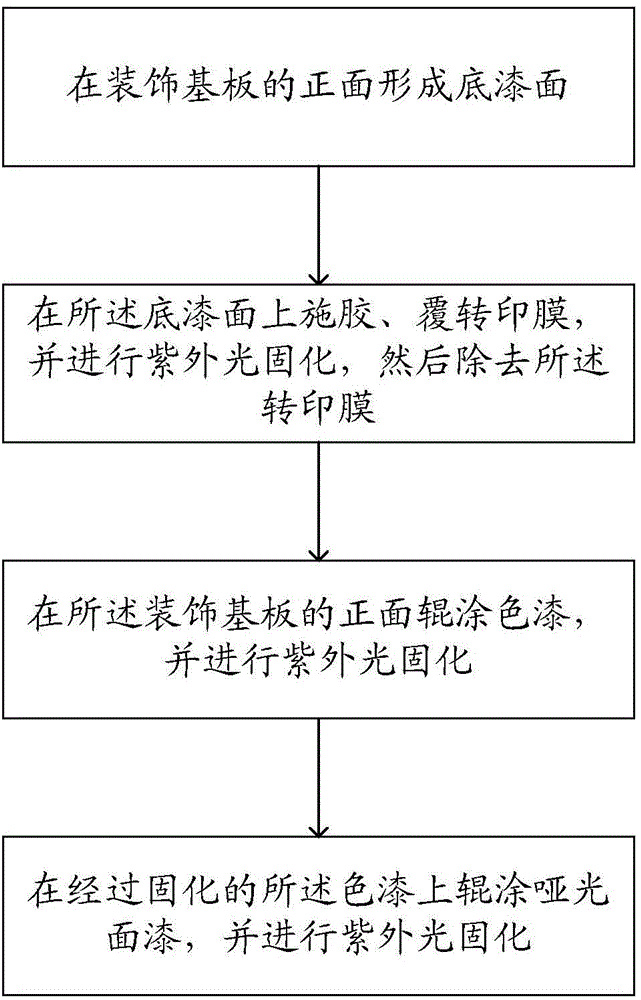

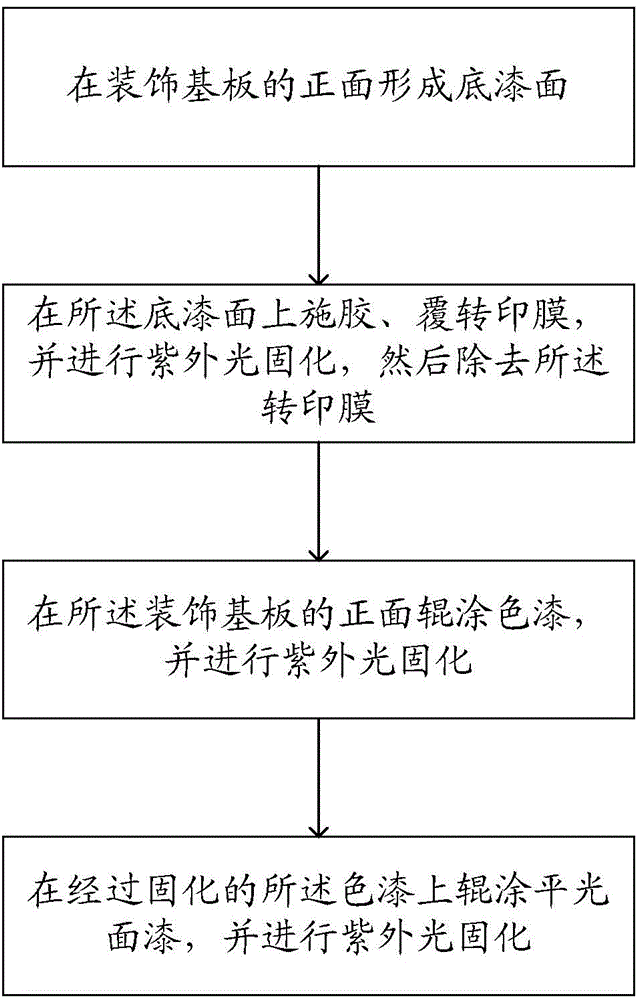

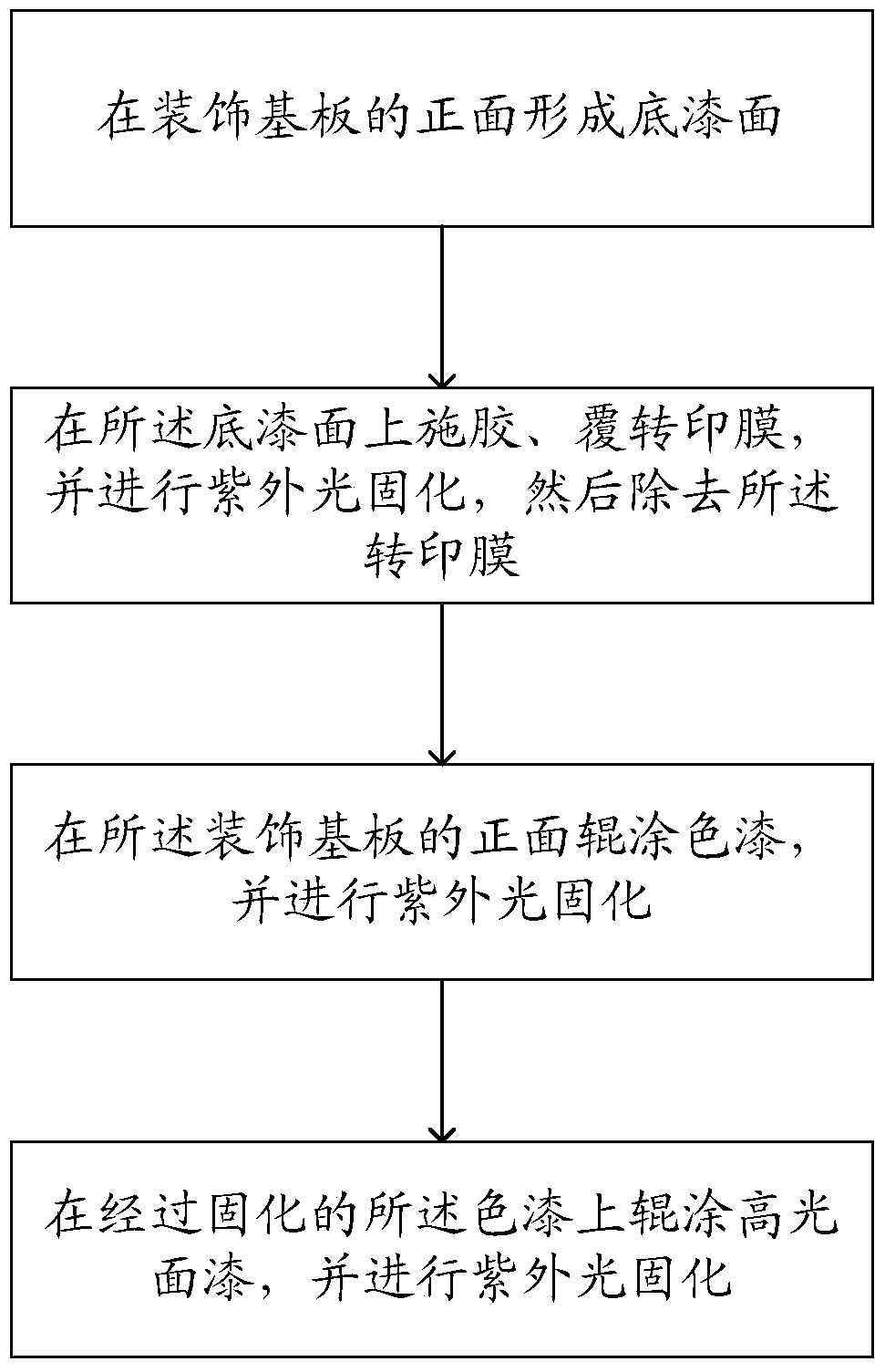

Ultraviolet curing transfer-printing high-gloss decoration plate and manufacturing method thereof

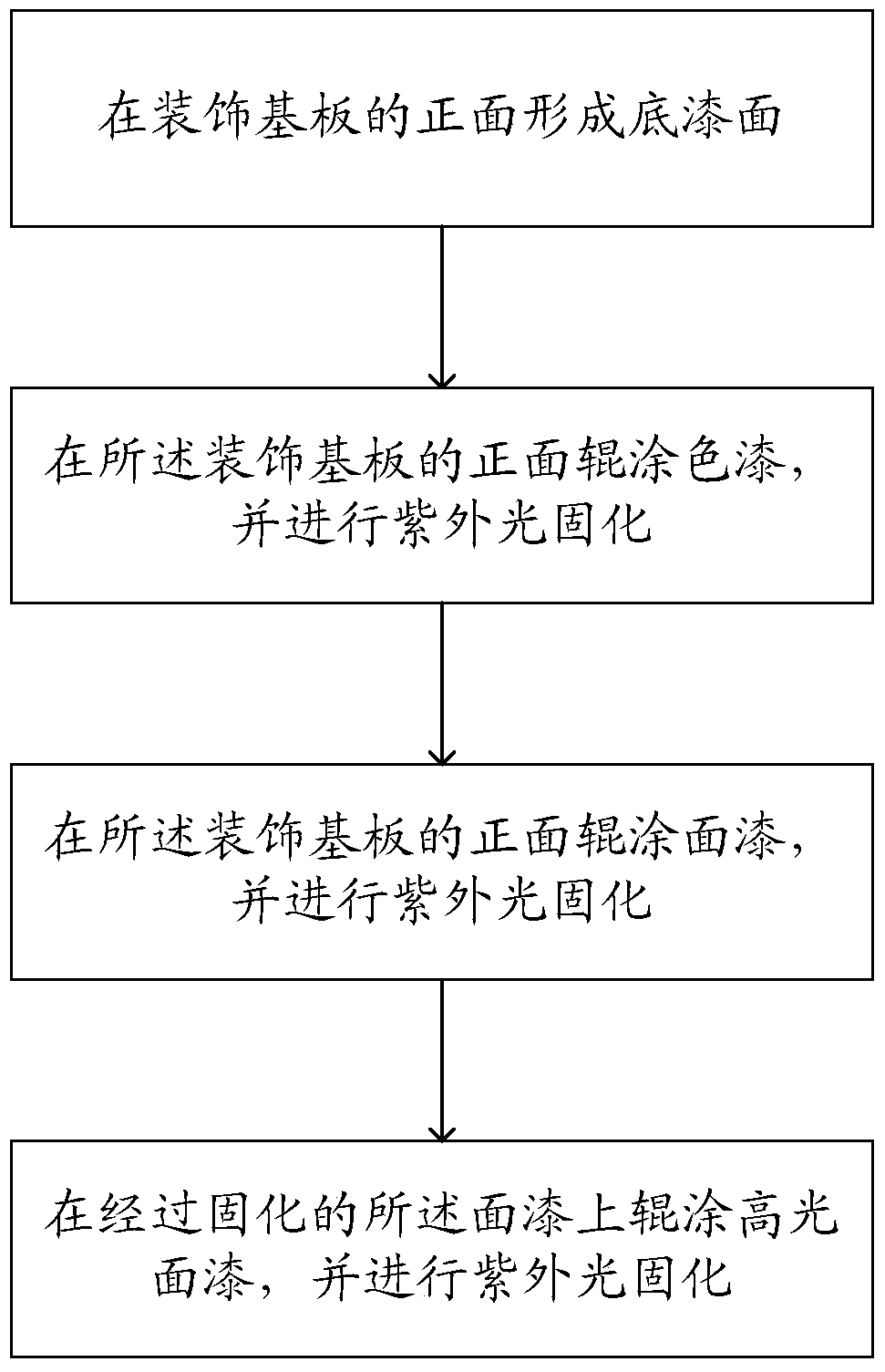

The invention provides an ultraviolet curing transfer-printing high-gloss decoration plate and a manufacturing method thereof. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing sizing and transfer film-printing of the primer surface, performing ultraviolet curing, and removing the transfer-printing film; (3) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; and (4) performing roller painting of high-gloss finishing paints on the cured colored paints and performing ultraviolet curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:中关村人居环境工程与材料研究院

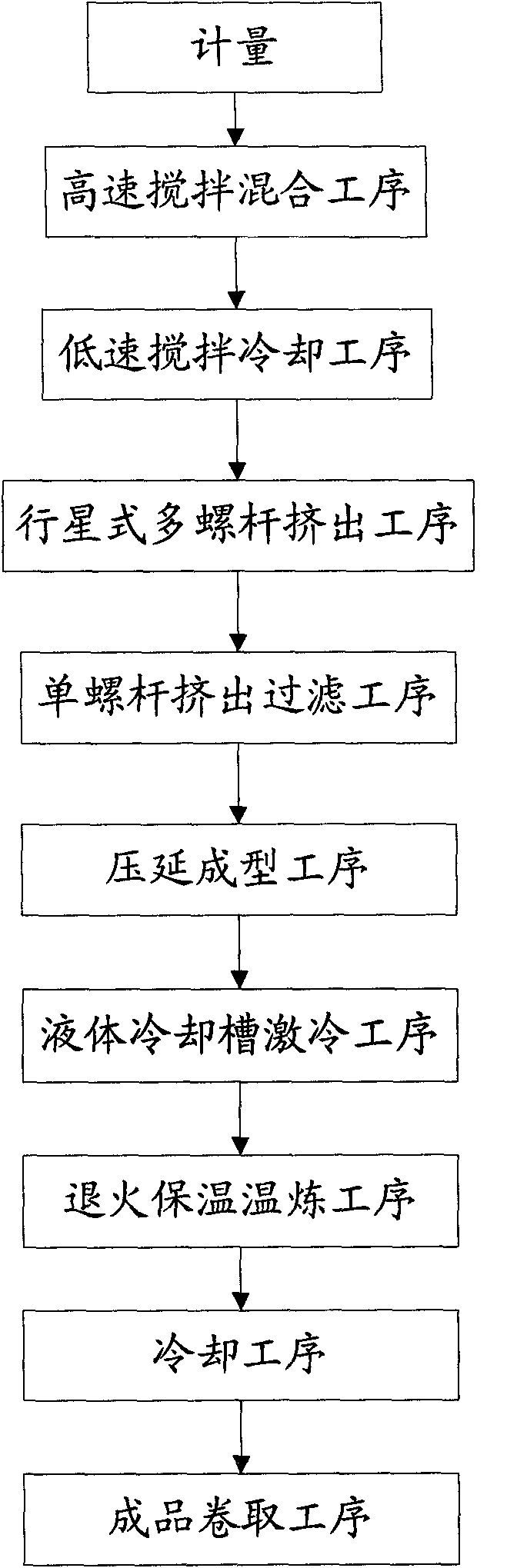

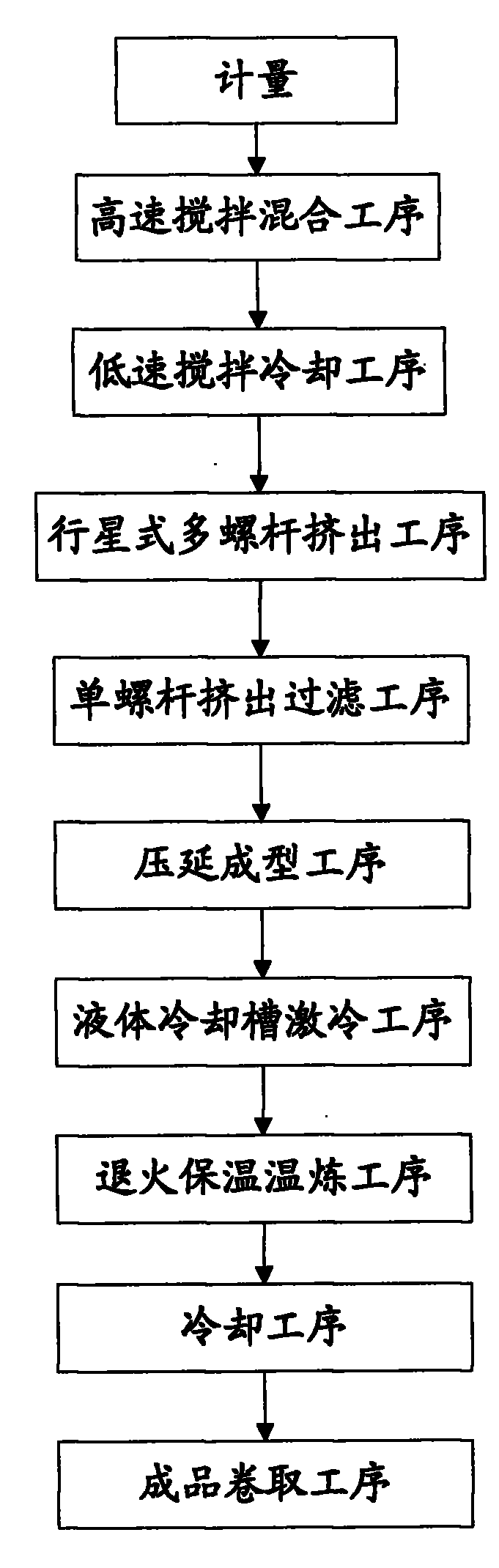

Hard polrvinyl chloride product and preparation method thereof

ActiveCN101792562AAvoid the phenomenon of surface sensitive water whiteningProtect the surfaceThiolPlasticizer

The invention discloses a hard polrvinyl chloride product, which contains the following components in parts by weight: 100 parts of polrvinyl chloride, 1.6-2.2 parts of organotin thiol, 0.6-1.0 part of internal lubricant, 0.2-0.5 part of external lubricant, 6-14 parts of impact-resistant modifier, 0.2-0.5 part of waterproof modifier, and proper amount of pigment is added. The invention also discloses a preparation method of the hard polrvinyl chloride product. The formula of the hard polrvinyl chloride product does not add any plasticizer, thus avoiding the phenomenon that the surface of the polrvinyl chloride product is water-sensitive and becomes white due to the influence of ester group of the plasticizer. In addition, the formula of the hard polrvinyl chloride product adds the waterproof modifier containing hydrophobic group, thus obviously improving the solvent resistance and the impermeability of the polrvinyl chloride product, effectively isolating the corrosion of external water or steam, protecting the surface of the polrvinyl chloride product, and leading the polrvinyl chloride product to have good appearance performance.

Owner:ANHUI TIANAN NEW MATERIAL CO LTD

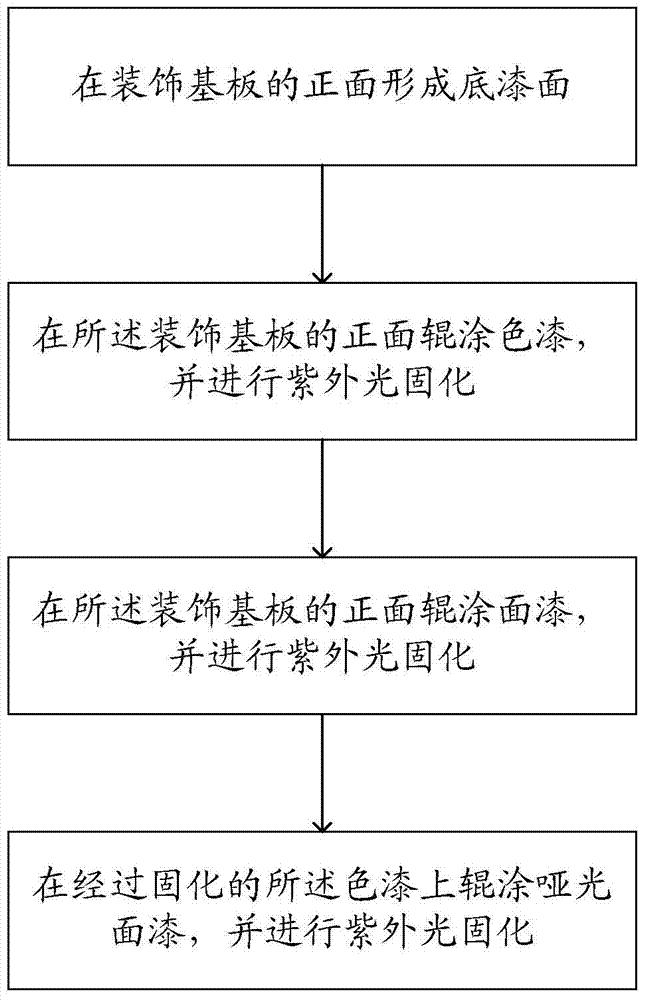

Ultraviolet curing transfer-printing matte decoration plate and manufacturing method thereof

The invention provides an ultraviolet curing transfer-printing matte decoration plate and a manufacturing method thereof. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing sizing and transfer film-printing of the primer surface, performing ultraviolet curing, and removing the transfer-printing film; (3) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; and (4) performing roller painting of matte finishing paints on the cured colored paints and performing ultraviolet curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:中关村人居环境工程与材料研究院

Method for manufacturing inner wall paint

InactiveCN101117473AEasy to transportEasy to useStarch coatingsPowdery paintsWear resistantMoisture resistance

A manufacturing method for preparing interior wall paint powder is provided, wherein 170 kg of glutinous rice with no impurity and residual shell, the purity of 95 percent and the water content of 15 percent is expanded and ground into 151 kg of 80 screen mesh expanded glutinous rice powder with 5 percent of water; 50 kg of the glutinous rice powder and 500 kg of talcum powder with the fineness of 600 screen mesh and 0.3 percent of water are fed into a mixer to be mixed uniformly and made into 550 kg of powder-shaped finished products. The present invention has the following advantages of innocuity, convenient transportation, convenience for long-term preservation, convenient use, strong adhesion, good fastness, glabrous and wear-resistant surface and moisture resistance.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

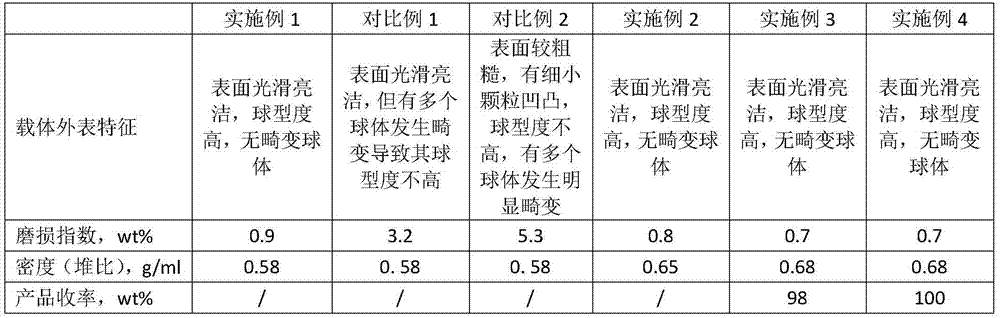

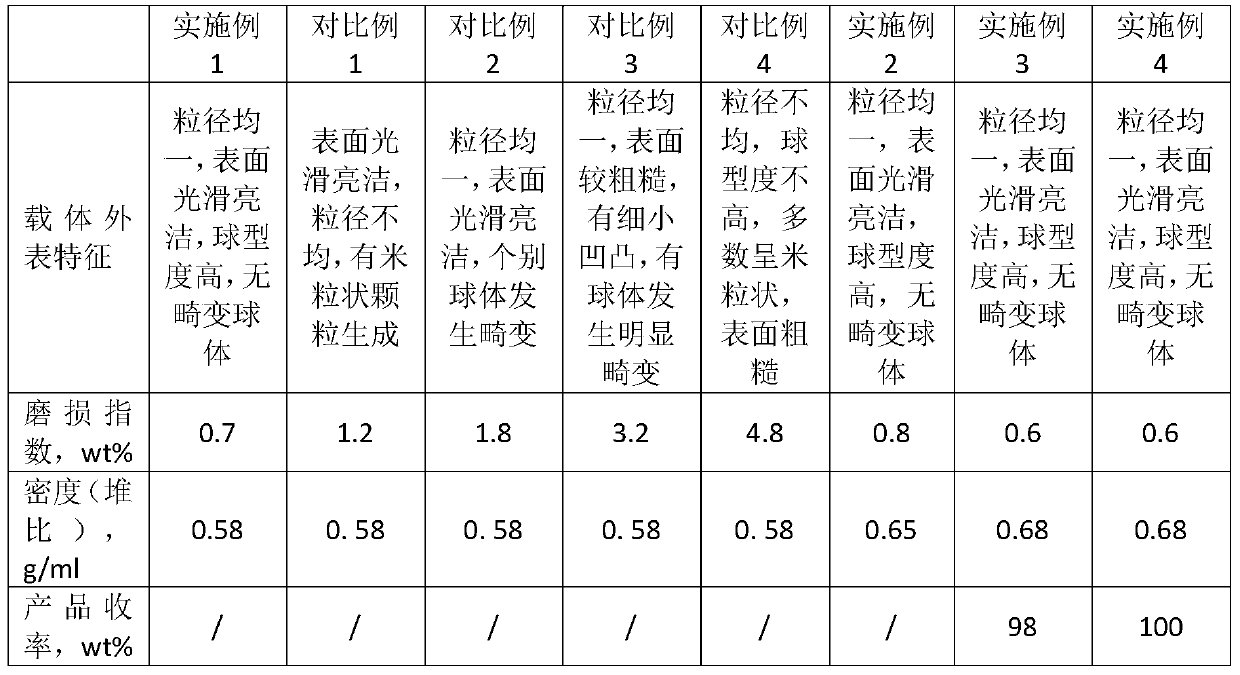

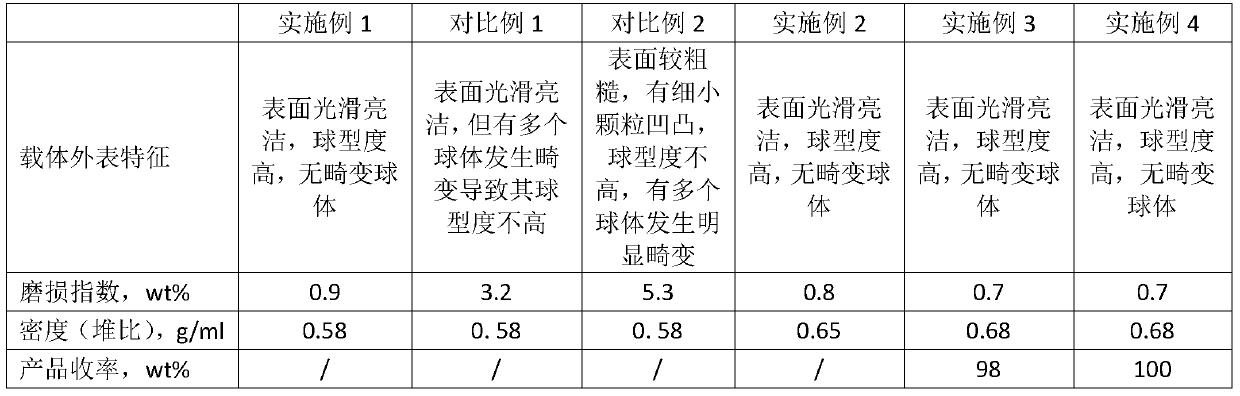

Preparation method of spherical aluminum oxide

ActiveCN106892648AHigh degree of sphericitySmooth and wear-resistant surfaceOther chemical processesAlkali metal oxides/hydroxidesPelletizingSmooth surface

The invention relates to a preparation method of spherical aluminum oxide. The method comprises the following steps: mixing pseudoboehmite powder and a forming aid, adding acid-containing deionized water, kneading, and extruding to obtain a strip plastic; putting the strip plastic in a balling device on the premise of no adhesion of the strip plastic surface to implement strip breaking and rolling granulation, spraying a misty liquid drop wetting agent while keeping the granules rotating, wetting the granule surfaces on the premise of no adhesion of the granules, stopping spraying, continuing rotation until the granules become spherical granules with smooth surfaces, changing cold air in the balling device into hot air, drying to harden the spherical granule surfaces, and stopping the rolling granulation; and drying the spherical granules, and roasting to finally obtain the aluminum oxide spherical carrier. The method solves the problems of unsmooth surface, poor sphericity and poor wear resistance in the balls prepared by the original process, and has the advantages of low preparation cost and no pollution in the preparation process.

Owner:PETROCHINA CO LTD

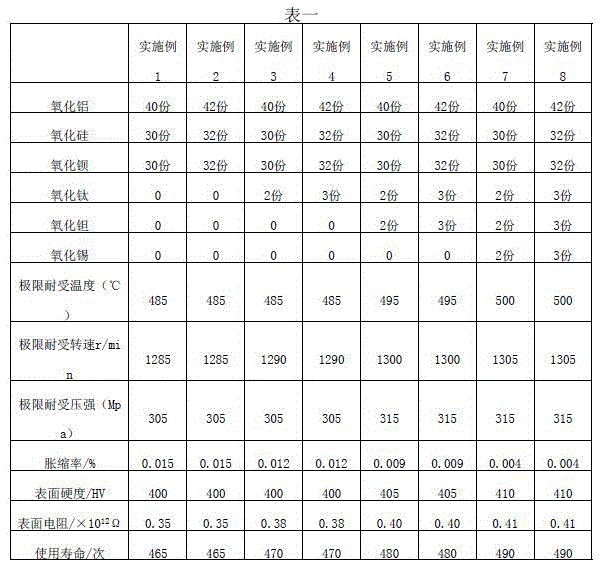

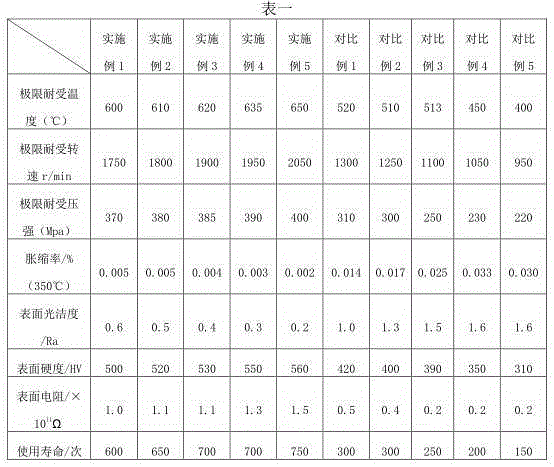

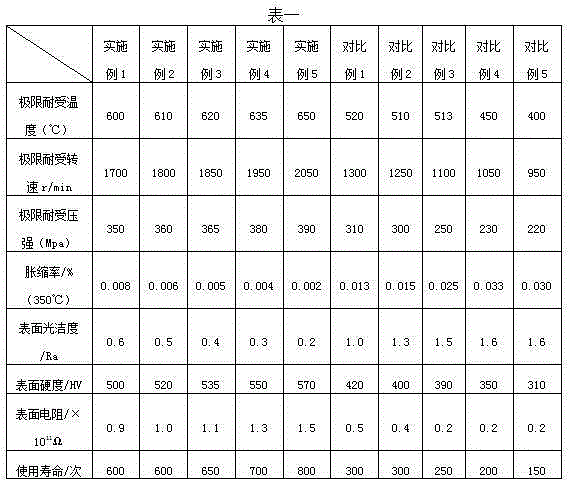

Plasma-spray-based manufacturing method of scratch-resistant insulating mirror plate

InactiveCN105568203AGuaranteed high-frequency useSmooth and wear-resistant surfaceMolten spray coatingWear resistantAcid washing

The invention discloses a plasma-spray-based manufacturing method of a scratch-resistant insulating mirror plate. The method comprises the following steps: (1) carrying out acid-washing and degreasing on a substrate to be sprayed, and then drying the substrate; (2) carrying out corona treatment on the substrate; (3) spraying coating powder onto the surface of the substrate by a plasma spraying method, wherein the coating powder is prepared from the following materials in parts by weight: 40-42 parts of aluminum oxide, 30-32 parts of silicon oxide and 30-32 parts of barium oxide. According to the method, the formula of the coating powder is newly designed according to the plasma spraying process, so that the formula is well applicable to the plasma spraying process; a layer of dense coating is formed on the surface of the substrate, and the coating is capable of enabling the insulating mirror plate to be frequently used in a hot-pressing process at high temperature and under high pressure; the insulating mirror plate also does not have expansion and shrink, and the surface of the insulating mirror plate is flat and wear-resistant, and is not sunken.

Owner:SUZHOU JIAMING MACHINERY MFG

Production process of low-dilatation and low-shrinkage insulated mirror boards based on impregnation process

InactiveCN105349929AReduce internal stressImprove stabilityHot-dipping/immersion processesCeriumStrontium

The invention discloses a production process of low-dilatation and low-shrinkage insulated mirror boards based on the impregnation process. The production process comprises the steps of S1, fusing aluminum in the atmosphere of inert gas; S2, immersing stainless steel plates into the aluminum and then taking out the stainless steel plates for cooling; S3, adding first powder into the aluminum, carrying out heating until the first powder is fused and then obtaining first fused mixed liquid; S4, immersing the stainless steel plates into the first fused mixed liquid and then taking out the stainless steel plates for cooling; S5, adding second powder into the first fused mixed liquid, carrying out heating until the second powder is fused and then obtaining second fused mixed liquid; S6, immersing the stainless steel plates into the second fused mixed liquid, then taking out the stainless steel plates for cooling and obtaining the insulated mirror boards after oxidation, wherein the first powder comprises, by weight, nickel of 50 parts and cerium of 7-8 parts, and the second powder comprises, by weight, germanium of 50 parts and strontium of 14-15 parts. According to the production process, the conventional impregnation process is improved, and therefore the prepared mirror boards can be frequently used at high temperature and high pressure and do not dilate or shrink and the surfaces are flat and resistant to wear and do not get sunken.

Owner:SUZHOU JIAMING MACHINERY MFG

Ultraviolet curing transfer-printing flat decoration plate and manufacturing method thereof

The invention provides an ultraviolet curing transfer-printing flat decoration plate and a manufacturing method thereof. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing sizing and transfer film-printing of the primer surface, performing ultraviolet curing, and removing the transfer-printing film; (3) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; and (4) performing roller painting of flat finishing paints on the cured colored paints and performing ultraviolet curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:北京天工人居科技有限公司

Fluff hand feeling powder coating

PendingCN111234658AFine coating surface structureSmooth releaseEmulsion paintsEpoxy resin coatingsPolytetrafluoroethyleneCarboxylic group

The invention belongs to the technical field of coatings, and particularly relates to a fluff hand feeling powder coating which comprises raw materials, by weight, 230-250 parts of a solid epoxy resin, 40-60 parts of a carboxyl resin, 5 parts of a fluff auxiliary agent, 8-12 parts of a leveling agent, 3-8 parts of a pigment, 120-140 parts of quartz powder, 100-120 parts of barite and 8-12 parts ofpolytetrafluoroethylene micro-powder wax. After the fluff hand feeling powder coatingis sprayed and constructed, a brand-new touch experience is given to a metal surface, and the fluff hand feeling powder coating obtained by the invention has the advantages of strong wear resistance, yellowing resistance and acid and alkali resistance, fine coating surface and stable coating performance.

Owner:FUJIAN WANAN IND

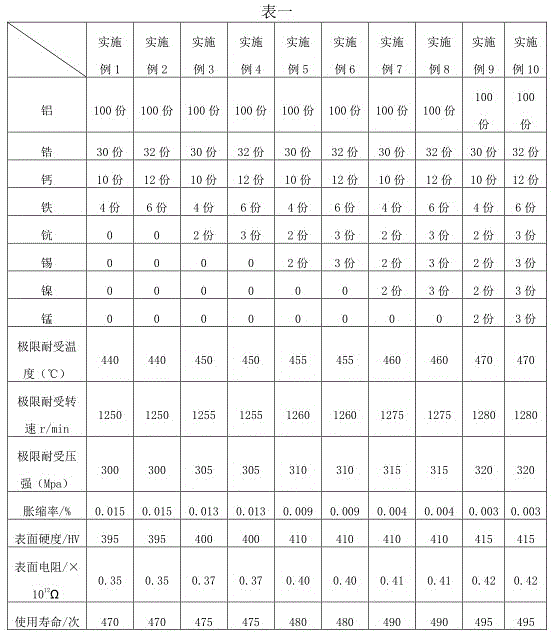

Technology for producing hot-pressing-resisting insulation mirror plate based on impregnation technology

InactiveCN105483593AGuaranteed high-frequency useSmooth and wear-resistant surfaceHot-dipping/immersion processesHigh pressureInert gas

The invention discloses a technology for producing a hot-pressing-resisting insulation mirror plate based on an impregnation technology. The technology comprises the following steps that 1, a stainless steel plate is subjected to acid pickling and degreasing and then is dried; 2, mixed powder is heated and molten in the inert gas atmosphere, and melting liquid is obtained; 3, the stainless steel plate is impregnated in the melting liquid and then taken out to be cooled, and a pre-coating plate is obtained; and 4, after the pre-coating plate is oxidized, the insulation mirror plate is obtained. The mixed powder comprises, by weight, 100 parts of aluminum, 30-32 parts of zirconium, 10-12 parts of calcium and 4-6 parts of iron. According to the scheme, the conventional impregnation technology is improved, and the brand-new technology for producing a mirror plate coating is obtained; and the formula of the molten mixed powder is improved so that high-frequency use of the manufactured mirror plate can be guaranteed under the conditions of high temperature and high pressure, no expansion or shrinkage happens, the surface is flat and resistant to wear, and no sinking happens.

Owner:SUZHOU JIAMING MACHINERY MFG

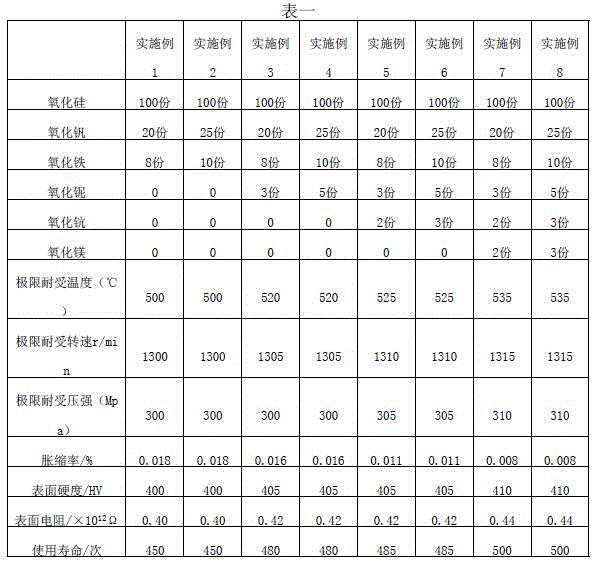

Abrasion-resistant insulating thrust runner manufacturing method based on plasma spraying

InactiveCN105420660AGuaranteed high-frequency useSmooth and wear-resistant surfaceMolten spray coatingHigh pressureIron oxide

The invention discloses an abrasion-resistant insulating thrust runner manufacturing method based on plasma spraying. The method includes the following steps of (1) drying a substrate to be sprayed after acid pickling and degreasing, (2) carrying out corona treatment on the substrate and (3) spraying coating powder to the surface of the substrate through a plasma spraying method. The coating powder comprises, by weight, 100 parts of silicon oxide, 20-25 parts of vanadium oxide and 8-10 parts of iron oxide. The formula of the coating powder is newly designed according to the plasma spraying process, the formula can well adapt to the plasma spraying process, a dense coating is formed on the surface of the substrate, and by means of the coating, a manufactured thrust runner can be used frequently when being hot-pressed under the high temperature and high pressure, the thrust runner does not expand or contract, and the surface is flat, resistant to abrasion and not concave.

Owner:SUZHOU JIAMING MACHINERY MFG

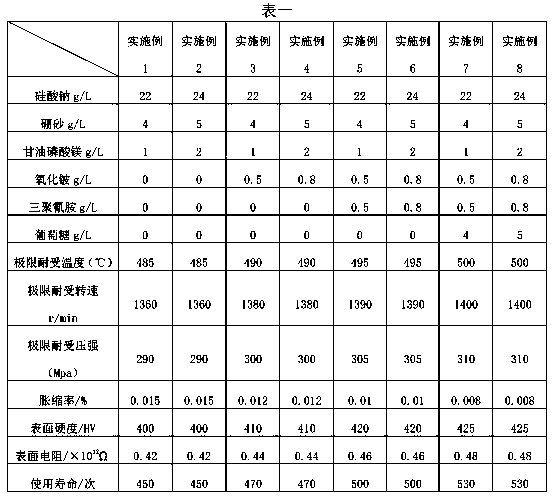

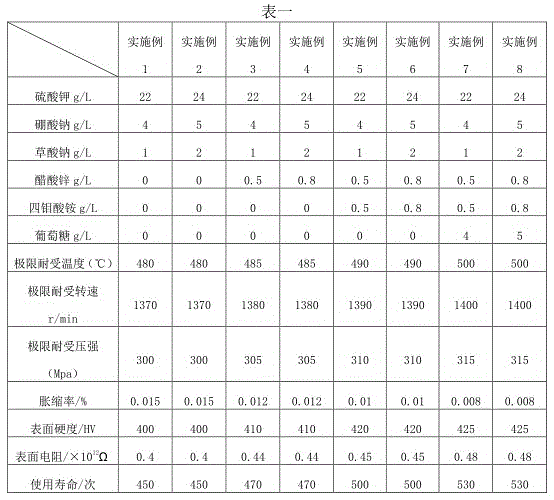

Wear-resisting insulation thrust runner collar preparation technology

The invention discloses a wear-resisting insulation thrust runner collar preparation technology. The wear-resisting insulation thrust runner collar preparation technology comprises the following steps of: immersing an aluminum plate in an electrolytic cell containing an electrolytic solution, wherein the aluminum plate serves as a positive electrode; a stainless steel plate serves as a negative electrode; and performing micro-arc oxidation under setting conditions so as to form an oxidation film on the surface of the aluminum plate, wherein the specific setting conditions are as follows: the voltage range is 520-530V, the electric current density is 16-18A / dm<2>, the temperature of the electrolytic solution is 24-26 DEG C, and the reaction time is 18-20 minutes; and the electrolytic solution comprises 22-24 g / L of sodium silicate, 4-5 g / L of borax and 1-2 g / L of magnesium glycerophosphate. According to the technical scheme of the wear-resisting insulation thrust runner collar preparation technology, a micro-arc oxidation technology is adopted for forming a compact oxidation film layer on the surface of the aluminum plate; and the oxidation film layer can ensure that when an insulation thrust runner collar is hot-pressed at high temperatures and high pressures, the high-frequency usage of the insulation thrust runner collar is realized, the insulation thrust runner collar does not swell and shrink, and the surface of the insulation thrust runner collar is flat and wear-resisting and does not hollow.

Owner:SUZHOU JIAMING MACHINERY MFG

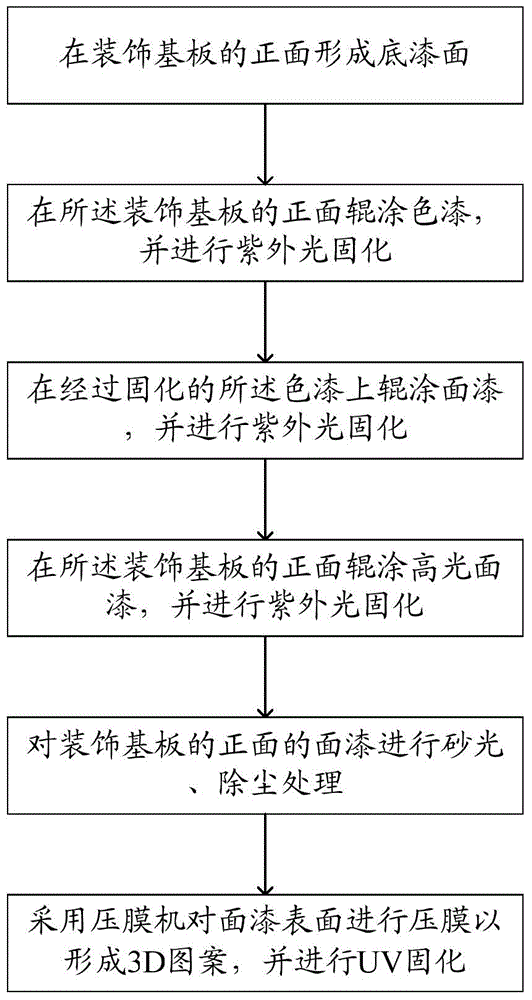

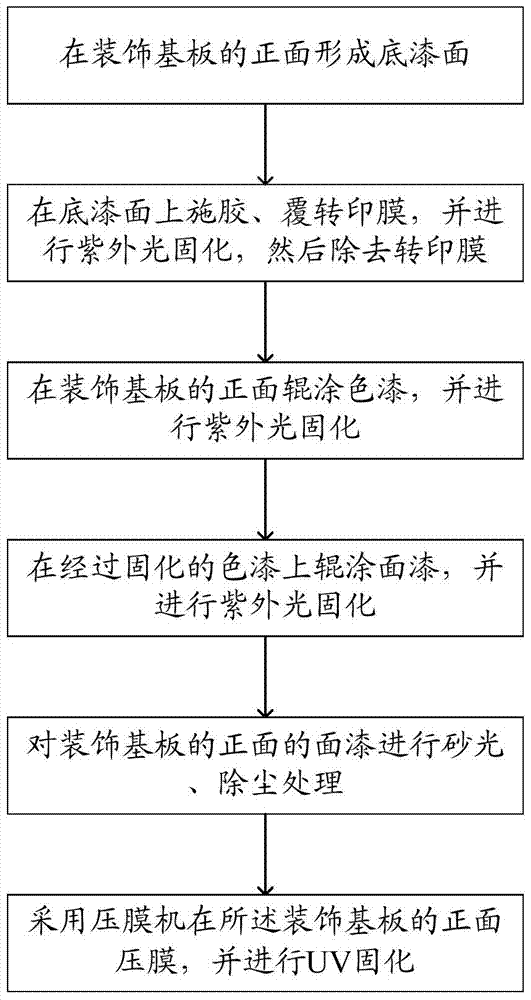

Ultraviolet curing color 3D decoration plate and manufacturing method thereof

ActiveCN104989062AHigh hardnessImprove wiping effectCovering/liningsLamination ancillary operations3d patterningUV curing

The invention provides a manufacturing method of an ultraviolet curing color 3D decoration plate. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; (3) performing roller painting of finishing paints on the cured colored paints and performing ultraviolet curing; (4) performing roller painting of high-gloss finishing paints on the front surface of the decoration substrate and performing ultraviolet curing; (5) performing sanding and dedusting processing of the finishing paints on the front surface of the decoration substrate; and (6) performing film pressing of the surface of the finishing paints by employing a laminator to form 3D patterns and performing UV curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:中关村人居环境工程与材料研究院

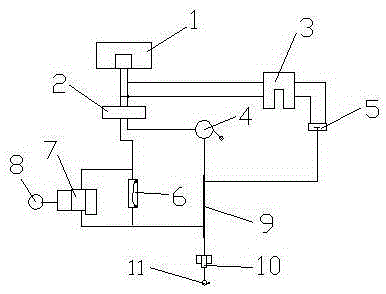

Stamping part preliminary mold mechanism

InactiveCN105936135AReasonable distributionSmooth and wear-resistant surfacePressesPower flowUv detection

The invention discloses a stamping part preliminary mold mechanism. The stamping part preliminary mold mechanism mainly comprises a tablet machine, an electromagnetic directional valve, an oil purifier, an ultraviolet detection machine, a potentiometer, a check valve, an electric appliance connector and a relay; the tablet machine is connected with the electromagnetic directional valve, the oil purifier is connected to a line branch between the tablet machine and the electromagnetic directional valve, the ultraviolet detection machine is connected to the line in the other direction of the oil purifier, a current reversing valve is mounted on one line in the other direction of the electromagnetic directional valve, and the potentiometer is mounted on the other line; and an air pressure hydraulic system is reasonable in distribution, pressed parts are hard, the surface is smooth and wear-resisting, and the quality is detected.

Owner:安徽省东至县东鑫冲压件有限责任公司

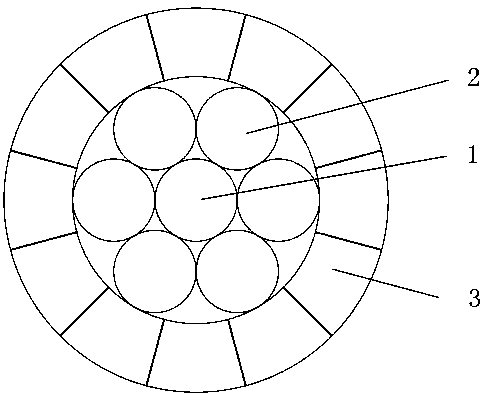

Superfine sealed steel wire rope and production process thereof

PendingCN108716151APrecise and reasonable structural designSmooth and wear-resistant surfaceCoatingsTextile cablesProcess designMetal

The invention relates to a superfine sealed steel wire rope. The superfine sealed steel wire rope is characterized by sequentially comprising a central metal core, an inner-layer round steel wire layer and an outer-layer T-shaped steel wire layer from inside to outside, wherein the central metal core is externally and annularly twisted and sleeved with the inner-layer round steel wire layer, the inner-layer round steel wire layer is externally and annularly twisted and sleeved with the outer-layer T-shaped steel wire layer, and the central metal core is a single round steel wire; the inner-layer round steel wire layer is of a structure formed by uniformly and spirally twisting the central metal core with multiple round steel wires and is uniformly arrayed on the periphery of the central metal core, and the section of the structure is round; and the outer-layer T-shaped steel wire layer is of a sealing structure formed by uniformly and spirally twisting inner-layer round steel wire withmultiple T-shaped steel wires and has a sealing effect, and the section of the structure is a round ring. The superfine sealed steel wire rope has the beneficial effects that the structural design isprecise and reasonable, and the blank in the field of small-sized sealed steel wire ropes is filled; and by utilizing a special process design, the steel wire rope is circularly sealed, the surface of the steel wire rope is smooth and wearable, and an S-shaped bend is avoided.

Owner:山东希尔电缆有限公司

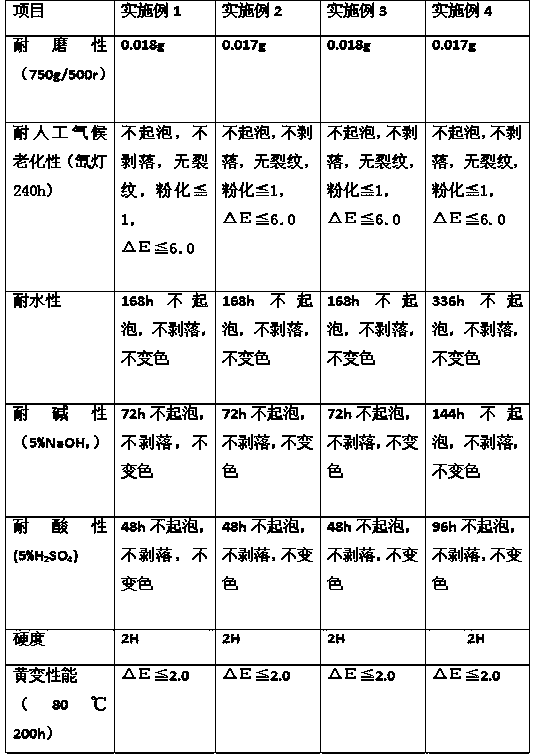

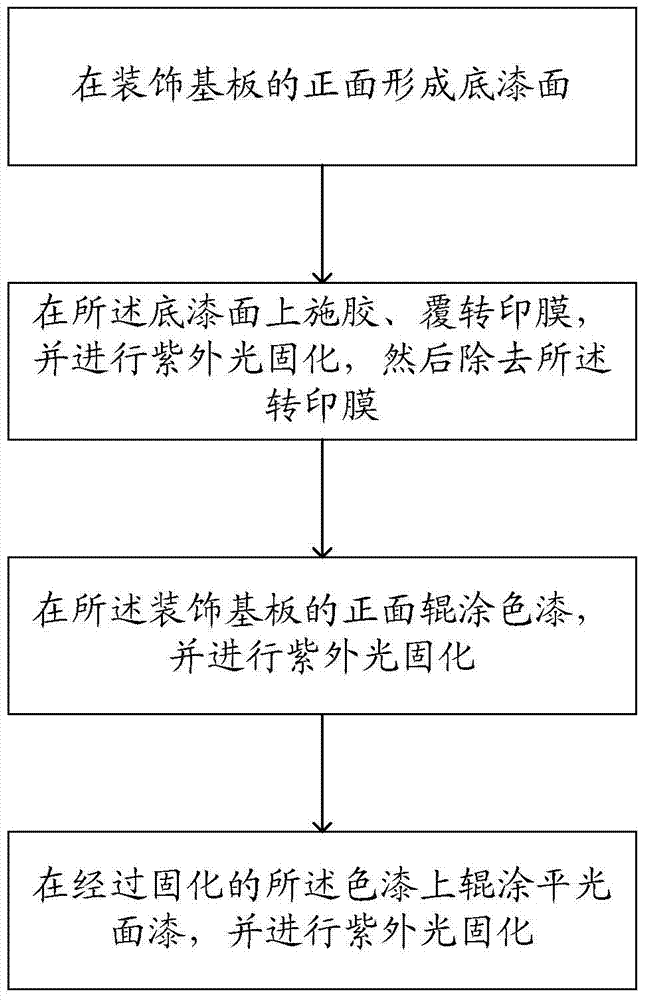

A UV-cured transfer high-gloss decorative plate and its manufacturing method

ActiveCN104989045BHigh hardnessImprove wiping effectCovering/liningsUltraviolet lightsPolymer chemistry

The invention provides an ultraviolet light curing transfer high-gloss decorative plate and a manufacturing method thereof. The manufacturing method includes: (1) forming a primer surface on the front surface of the decorative substrate; (2) sizing the primer surface, covering the transfer film, and performing ultraviolet curing, and then removing the transfer film; (3) The front surface of the substrate is coated with color paint and cured by ultraviolet light; (4) a high-gloss finish paint is rolled on the cured color paint and cured by ultraviolet light. The decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:中关村人居环境工程与材料研究院

A kind of UV-cured color matte decorative board and its manufacturing method

ActiveCN104989047BHigh hardnessImprove wiping effectCovering/liningsUltraviolet lightsPolymer chemistry

The invention provides a method for manufacturing an ultraviolet light-cured colored matte decorative board, comprising: (1) forming a primer surface on the front side of the decorative substrate; light curing; (3) roll coating a top coat on the front surface of the decorative substrate, and carry out ultraviolet light curing; (4) roll coating a matte finish paint on the cured color paint, and carry out ultraviolet light curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:北京天工人居科技有限公司

A kind of ultraviolet curing transfer printing 3D decorative plate and its manufacturing method

ActiveCN104989060BHigh hardnessImprove wiping effectCovering/liningsLamination ancillary operationsUV curingUltraviolet lights

The invention provides an ultraviolet light curing transfer printing 3D decorative plate and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) forming a primer surface on the front side of the decorative substrate; (2) sizing the primer surface, applying a transfer film, and performing ultraviolet curing, and then removing the transfer film (3) roll-coat color paint on the front surface of the decorative substrate, and carry out UV curing; (4) roll-coat topcoat on the cured color paint, and carry out UV curing; Sanding and dedusting the top coat on the front of the decorative substrate; (6) laminating a film on the front of the decorative substrate with a laminating machine, and performing UV curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:中关村人居环境工程与材料研究院

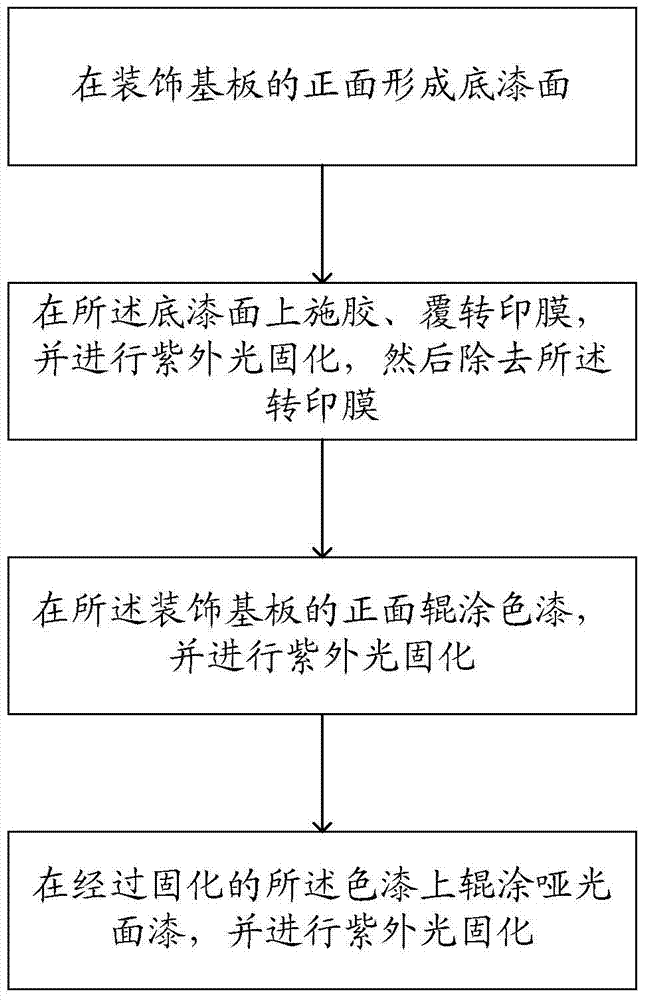

A kind of ultraviolet curing transfer printing flat decorative plate and its manufacturing method

The invention provides an ultraviolet curing transfer printing flat decorative plate and a manufacturing method thereof. The manufacturing method comprises: (1) forming a primer surface on the front surface of a decorative substrate; (2) applying glue on the primer surface, covering a transfer film, and curing with ultraviolet light, and then removing the transfer film; ( 3) Roll-coat color paint on the front surface of the decorative substrate, and perform ultraviolet light curing; (4) Roll-coat smooth topcoat on the cured color paint, and perform ultraviolet light curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated colors, smooth and wear-resistant surface, light weight and low price.

Owner:北京天工人居科技有限公司

A kind of UV curing transfer printing matte decorative board and its manufacturing method

Owner:中关村人居环境工程与材料研究院

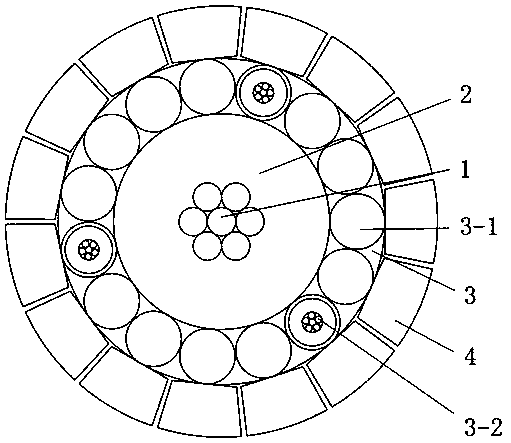

Low armored resistance load-bearing detection cable

PendingCN109243680AAvoid performanceAvoid lifeInsulated cablesDetails of conductive coresWear resistantEngineering

The invention belongs to the technical field of load-bearing detection cable, in particular to a low armored resistance bearing detection cable, which includes one or more sets of centrally located copper strands, the outer ring of the copper strand is covered with an insulating layer, The outer stranded ring of the insulating layer is sheathed with an inner steel wire armor layer, the inner steelwire armor layer is surrounded by a group of steel wires with circular cross-section and micro-steel pipe cables into a sealed circular ring, the inner steel wire armor layer is sheathed with an outer steel wire armor layer, and the outer steel wire armor layer is surrounded by a group of steel wires with fan-trapezoid cross-section into a sealed circular ring. The invention has the beneficial effects that the low armor resistance bearing detection cable of the invention is ingenious in structure design, smooth and wear-resistant in surface, and is suitable for popularizing and using.

Owner:山东希尔电缆有限公司

A kind of ultraviolet light curing color high-gloss decorative board and its manufacturing method

ActiveCN104989059BHigh hardnessImprove wiping effectLamination ancillary operationsCovering/liningsUltraviolet lightsLight cure

The invention provides a method for manufacturing an ultraviolet light-cured colored high-gloss decorative board, comprising: (1) forming a primer surface on the front side of the decorative substrate; curing; (3) roll-coating a top coat on the front surface of the decorative substrate, and performing ultraviolet curing; (4) rolling coating a high-gloss top coat on the cured top paint, and performing ultraviolet curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:中关村人居环境工程与材料研究院

Inner-wall paint

The invention discloses inner-wall paint. The inner-wall paint comprises, by weight, 10-35% of titanium dioxide, 4-10% of extinction powder, 6-10% of light calcium carbonate and the balance water.

Owner:郭公甫

Ink slab mold preforming pneumatic mechanism

InactiveCN105351261AReasonable distributionSmooth and wear-resistant surfaceServomotorsPower controllerEngineering

The invention discloses an ink slab mold preforming pneumatic mechanism. The ink slab mold preforming pneumatic mechanism mainly comprises a power controller, an electromagnetic exchange valve, a pre-pressing cylinder, a one-way overflowing valve, an electromagnetic two-way valve, a relay, a condenser pipe and a small-sized air cylinder, wherein the power controller is connected with the electromagnetic exchange valve; the pre-pressing cylinder is connected to a branch of one line between the power controller and the electromagnetic exchange valve; the one-way overflowing valve is connected with the line of the pre-pressing cylinder in the other direction; a burglary alarm is mounted on one path of the line of the electromagnetic exchange valve in one direction, and the electromagnetic two-way valve is mounted on the other path of the line of the electromagnetic exchange valve in the other direction; the line of the electromagnetic exchange valve in the other direction and the line of the relay in the other direction are combined into one line with the condenser pipe at the terminal end; and the terminal end of the other line of the one-way overflowing valve and the terminal end of the other line of the burglary alarm are connected with the condenser pipe. The distribution of the pneumatic hydraulic system is reasonable, ink slabs obtained through pressing are hard and attractive, and the surfaces of the ink slabs are smooth and resistant to abrasion.

Owner:李晓勤

A kind of preparation method of spherical alumina

The invention relates to a preparation method of spherical aluminum oxide. The method comprises the following steps: mixing pseudoboehmite powder and a forming aid, adding acid-containing deionized water, kneading, and extruding to obtain a strip plastic; cutting the strip plastic in the radial direction to obtain the granules with the length-diameter ratio of 0.5-2, putting the granules in a balling device on the premise of no adhesion of the granule surfaces to implement rotary balling, spraying a misty liquid drop wetting agent, wetting the granule surfaces on the premise of no adhesion of the granules, stopping spraying, continuing rotation until the granules become spherical granules with smooth surfaces, and stopping the rolling granulation; and drying the spherical granules, and roasting to finally obtain the aluminum oxide spherical carrier. The method solves the problems of nonuniform size, unsmooth surface, poor sphericity and poor wear resistance in the balls prepared by the original forming granulation process, and has the advantages of low preparation cost and no pollution in the preparation process.

Owner:PETROCHINA CO LTD

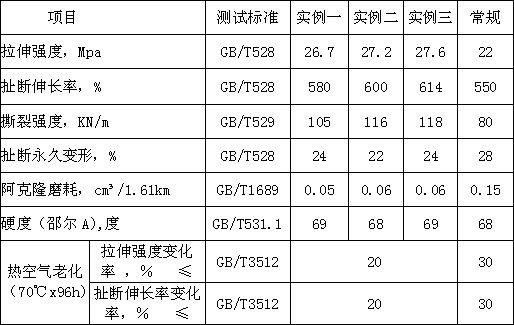

High-wear-resistance tractor rubber track rubber material and manufacturing method thereof

The invention discloses a high-wear-resistance tractor rubber track rubber material and a manufacturing method thereof. The formula comprises the following components in parts by weight: 85-70 parts of polyisoprene, 15-30 parts of rare earth butadiene rubber, 2.7-3.5 parts of a vulcanization accelerator, 3-4 parts of zinc oxide, 1-2 parts of stearic acid, 3-4 parts of an anti-aging agent, 1.5-2.5parts of a homogenizing agent, 1.2-2.2 parts of a flowing exhaust agent, 46-55 parts of carbon black, 5-10 parts of nano silicon dioxide and 0.8-2 part of a coupling agent. The material has the advantages of achieving the advantage of wear resistance, thereby greatly prolonging the service life. According to the invention, the tensile strength can be improved, meanwhile, the prepared rubber trackhas good wear resistance, the strength of a rubber material is improved, the friction coefficient between rubber and the ground is reduced, the phenomenon that the surface of the rubber is prone to foaming is prevented, the smoothness of the contact area is enhanced, the wear resistance is improved, and the problem of better mixing uniformity during blending is solved. In the preparation process,the prepared rubber track has very high wear resistance and tearing strength, and the service life is further prolonged.

Owner:镇江同立橡胶有限公司

Manufacturing technology of expansion and shrinkage resisting insulation mirror plate

The invention discloses a manufacturing technology of an expansion and shrinkage resisting insulation mirror plate. The manufacturing technology comprises the steps that an aluminum plate is immersed into an electrolytic cell with an electrolyte and serves as an anode, a stainless steel plate serves as a cathode, micro-arc oxidation is carried out under the set conditions so that an oxidation film can be formed on the surface of the aluminum plate, and according to the specific set conditions, the voltage ranges from 480 V to 500 V, the current density ranges from 18 A / dm<2> to 20 A / dm<2>, the temperature of the electrolyte ranges from 32 DEG C to 35 DEG C, and the reaction time ranges from 20 min to 25 min; and the electrolyte comprises 22-24 g / L of potassium sulphate, 4-5 g / L of sodium borate and 1-2 g / L of sodium oxalate. According to the scheme, the micro-arc oxidation technology is adopted so that a compact oxidation film layer can be formed on the surface of the aluminum plate, high-frequency use of the insulation mirror plate can be guaranteed during hot pressing at a high temperature and a high pressure through the oxidation film layer, no expansion or shrinkage happens, the surface is flat and resistant to wear, and no sinking happens.

Owner:SUZHOU JIAMING MACHINERY MFG

A kind of preparation method of spherical alumina

ActiveCN106892648BAdd surface dry hardening stepHigh degree of sphericityOther chemical processesAlkali metal oxides/hydroxidesCold airWear resistance

The invention relates to a preparation method of spherical aluminum oxide. The method comprises the following steps: mixing pseudoboehmite powder and a forming aid, adding acid-containing deionized water, kneading, and extruding to obtain a strip plastic; putting the strip plastic in a balling device on the premise of no adhesion of the strip plastic surface to implement strip breaking and rolling granulation, spraying a misty liquid drop wetting agent while keeping the granules rotating, wetting the granule surfaces on the premise of no adhesion of the granules, stopping spraying, continuing rotation until the granules become spherical granules with smooth surfaces, changing cold air in the balling device into hot air, drying to harden the spherical granule surfaces, and stopping the rolling granulation; and drying the spherical granules, and roasting to finally obtain the aluminum oxide spherical carrier. The method solves the problems of unsmooth surface, poor sphericity and poor wear resistance in the balls prepared by the original process, and has the advantages of low preparation cost and no pollution in the preparation process.

Owner:PETROCHINA CO LTD

Insulating thrust runner production process based on impregnation process

InactiveCN105420655AReduce internal stressImprove stabilityHot-dipping/immersion processesHigh pressureCobalt

The invention discloses an insulating thrust runner production process based on an impregnation process. The production process includes the steps that S1, aluminum is melted in an inert gas atmosphere; S2, a stainless steel plate is immersed in the molten aluminum and then taken out and cooled; S3, first powder is added into the aluminum and heated to be molten, so that first molten mixed liquor is obtained; S4, the stainless steel plate is immersed in the first molten mixed liquor and then taken out and cooled; S5, second powder is added into the first molten mixed liquor and heated to be molten, so that second molten mixed liquor is obtained; and S6, the stainless steel plate is immersed in the second molten mixed liquor, taken out, cooled and subjected to acid pickling and passivation, so that an insulating thrust runner is obtained. The first powder comprises, by weight, 50 parts of zirconium and 2-4 parts of cobalt; the second powder comprises, by weight, 50 parts of calcium and 10-12 parts of magnesium. According to the scheme, the conventional impregnation process is improved so that the manufactured thrust runner can be used frequently under high-temperature and high-pressure-intensity conditions, the thrust runner does not expand or contract, and the surface is flat, resistant to abrasion and not concave.

Owner:SUZHOU JIAMING MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com