A kind of UV-cured color matte decorative board and its manufacturing method

A manufacturing method and technology of decorative panels, applied in building construction, covering/lining, construction, etc., to achieve high production efficiency, good hardness and wiping performance, and bright and saturated colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

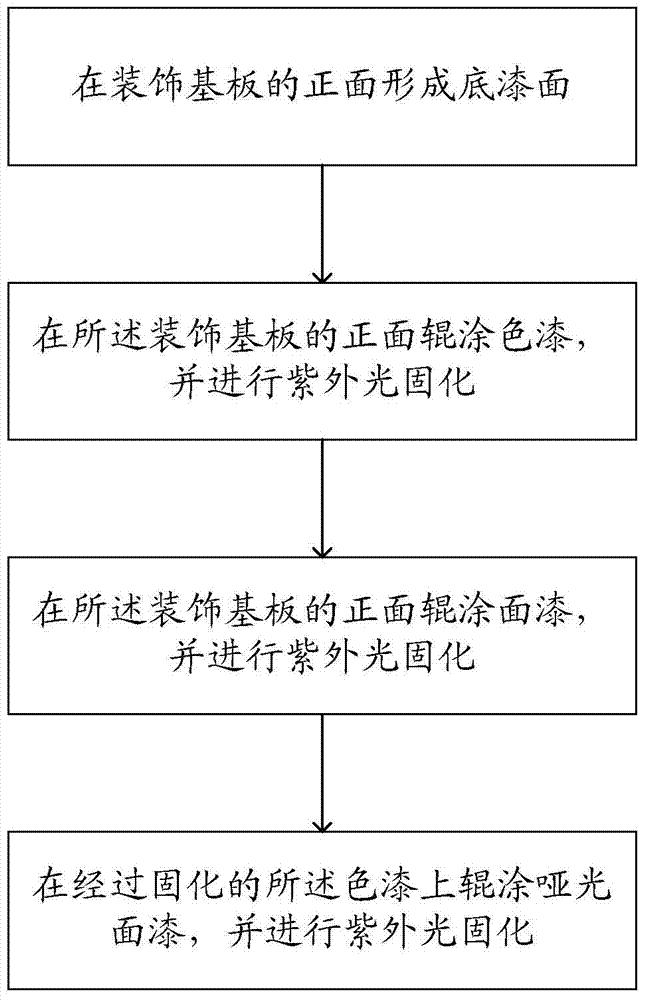

[0066] The manufacture method of UV-cured colored matte decorative plate according to the present invention comprises the following steps:

[0067] 1) Dedusting the back of the plasterboard;

[0068] 2) Apply a 0.05mm thick sealing paint on the back of the plasterboard by single roller coating, and use a double mercury lamp curing machine for 3s UV curing;

[0069] 3) Turn over the board, and carry out dust removal treatment on the front of the plasterboard;

[0070] 4) Apply a 0.05mm-thick adhesion primer to the front of the plasterboard by means of forward and reverse roller coating, and use a gallium gallium lamp curing machine for 3s UV curing;

[0071] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the plasterboard;

[0072] 6) Apply a 0.05mm thick white primer with a single roller, and use a double gallium lamp curing machine for 3s UV curing;

[0073] 7) Apply a 0.05mm thick sealing primer with positive and negative ro...

Embodiment 2

[0085] The manufacture method of UV-cured colored matte decorative plate according to the present invention comprises the following steps:

[0086] 1) Dedusting the back of the plasterboard;

[0087] 2) Apply a 0.08mm thick sealer paint on the back of the plasterboard with a single roller coating method, and use a double mercury lamp curing machine for 6s UV curing;

[0088] 3) Turn over the board, and carry out dust removal treatment on the front of the plasterboard;

[0089] 4) Apply a 0.08mm-thick adhesion primer to the front of the plasterboard by means of forward and reverse roller coating, and use a gallium gallium lamp curing machine for 6s UV curing;

[0090] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the plasterboard;

[0091] 6) Apply a 0.08mm thick white primer with a single roller, and use a double gallium lamp curing machine for 6s UV curing;

[0092] 7) Apply a 0.08mm thick sealing primer with positive and n...

Embodiment 3

[0104] The manufacture method of UV-cured colored matte decorative plate according to the present invention comprises the following steps:

[0105] 1) Dedusting the back of the plasterboard;

[0106] 2) Apply a 0.12mm thick sealer paint on the back of the plasterboard with a single roller coating method, and use a double mercury lamp curing machine for 10s of UV curing;

[0107] 3) Turn over the board, and carry out dust removal treatment on the front of the plasterboard;

[0108] 4) Apply a 0.12mm-thick adhesion primer to the front of the plasterboard by means of forward and reverse roller coating, and use a gallium-gallium lamp curing machine for 10s of UV curing;

[0109] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the plasterboard;

[0110] 6) Apply a 0.12mm thick white primer with a single roller, and use a double gallium lamp curing machine for 10s of UV curing;

[0111] 7) Apply a 0.12mm thick sealing primer with po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com