Production process of low-dilatation and low-shrinkage insulated mirror boards based on impregnation process

A production process and mirror plate technology, applied in the direction of hot-dip plating process, metal material coating process, coating, etc., can solve the problems of mirror plate failure, surface depression, immature coating preparation process, etc., to reduce the internal Effects of stress, surface flatness and wear resistance, and improvement of stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

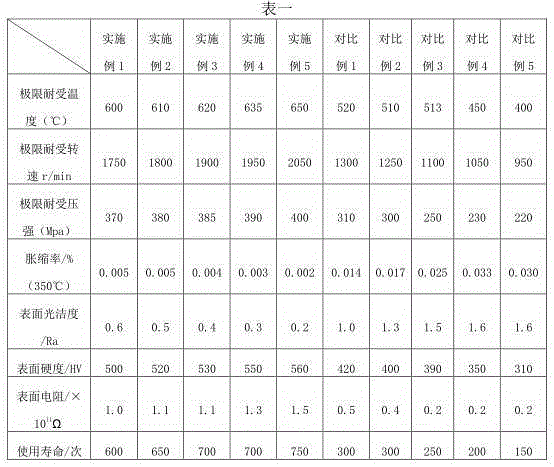

Examples

Embodiment 1

[0026] This case proposes an embodiment of a production process for a low-expansion-shrinkage insulating mirror plate based on an impregnation process, including:

[0027] S1: In an inert gas atmosphere, heat aluminum to a molten state;

[0028] S2: Immerse the stainless steel plate completely in the molten aluminum, then take it out and cool it;

[0029] S3: Add the first powder to the molten aluminum, and continue heating until the first powder melts, and mix well to obtain the first molten mixture; wherein, the weight ratio of the first powder to aluminum is 15-16: 100;

[0030] S4: immerse the stainless steel plate completely in the first molten mixture, then take it out and cool it;

[0031] S5: Add the second powder into the first molten mixture, and continue heating until the second powder is melted, and mix well to obtain the second molten mixture; wherein, the weight ratio of the second powder to aluminum is 7~ 8:100;

[0032] S6: Immerse the stainless steel plate...

Embodiment 2

[0046] On the basis of Example 1, the first powder further includes 2-4 parts by weight of yttrium. This process is relatively harsh on the formulation of the first powder, allowing only a limited amount of yttrium to be introduced. Yttrium can adjust the solidification rate of the coating and reduce the shrinkage potential energy of the coating during cooling, thereby reducing the expansion and contraction rate of the mirror plate. However, if yttrium is placed in the second powder, the stress of the coating will increase sharply.

Embodiment 3

[0048]On the basis of Example 2, the first powder further includes 6-8 parts by weight of beryllium. The introduction of beryllium will not cause an increase in the stress of the coating, and can effectively improve the compressive performance of the coating at high temperature, so that the number of times of hot pressing of the mirror plate is greatly increased. However, if beryllium is placed in the second powder, it will increase the stress of the coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com