Technology for producing hot-pressing-resisting insulation mirror plate based on impregnation technology

A production process, heat-resistant technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve problems such as surface depression, mirror plate failure, immature coating preparation process, etc., and achieve surface smoothness Wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0022] This case proposes an embodiment of a production process for a heat-resistant and pressure-resistant insulating mirror plate based on an impregnation process, including the following steps:

[0023] 1) Dry the stainless steel plate after pickling and degreasing;

[0024] 2) Heat and melt the mixed powder in an inert gas atmosphere to obtain a molten liquid;

[0025] 3) Immerse the stainless steel plate in the molten liquid, then take it out and cool it to get the pre-coated plate;

[0026] 4) The insulating mirror plate is obtained after the pre-coated plate is oxidized;

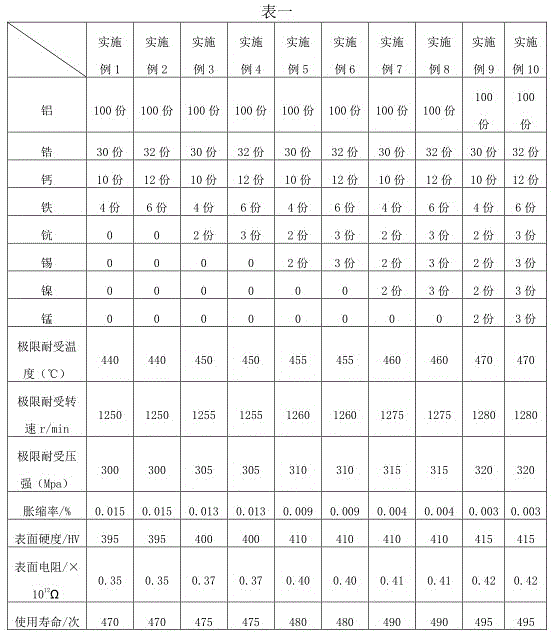

[0027] Wherein, the mixed powder comprises the following materials by weight:

[0028] 100 parts by weight of aluminum;

[0029] 30-32 parts by weight of zirconium;

[0030] 10-12 parts by weight of calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com