Plasma-spraying-based manufacturing method for high-strength insulation mirror plate

A manufacturing method and plasma technology, which are applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of surface depression, mirror plate failure, immature coating preparation process, etc., and achieve smooth and wear-resistant surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0021] This case proposes an embodiment of a method for manufacturing a high-strength insulating mirror plate based on plasma spraying, including the following steps:

[0022] 1) Dry the substrate to be sprayed after pickling and degreasing;

[0023] 2) corona treatment of the substrate;

[0024] 3) Spray the coating powder onto the surface of the substrate by plasma spraying method;

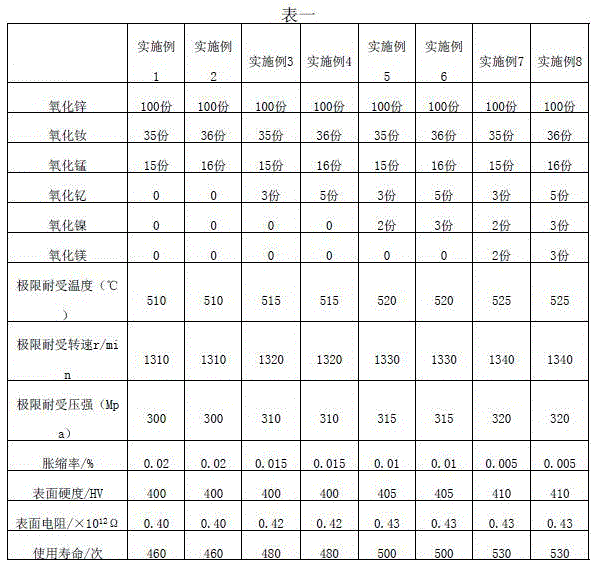

[0025] Wherein, the coating powder comprises the following materials by weight:

[0026] Zinc oxide 100 parts by weight;

[0027] Neodymium oxide 35~36 parts by weight;

[0028] 15-16 parts by weight of manganese oxide.

[0029] In the above embodiments, the substrate is an aluminum plate or a stainless steel plate.

[0030] In the above embodiments, the coating powder further includes 3-5 parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com