One-time splicing measurement device of large-aperture optical element profile

An optical element and measuring device technology, which is applied in the field of one-time splicing measuring devices for the outline of large-diameter optical elements, and achieves the effects of small roughness value, stable accuracy and reduction of measuring steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

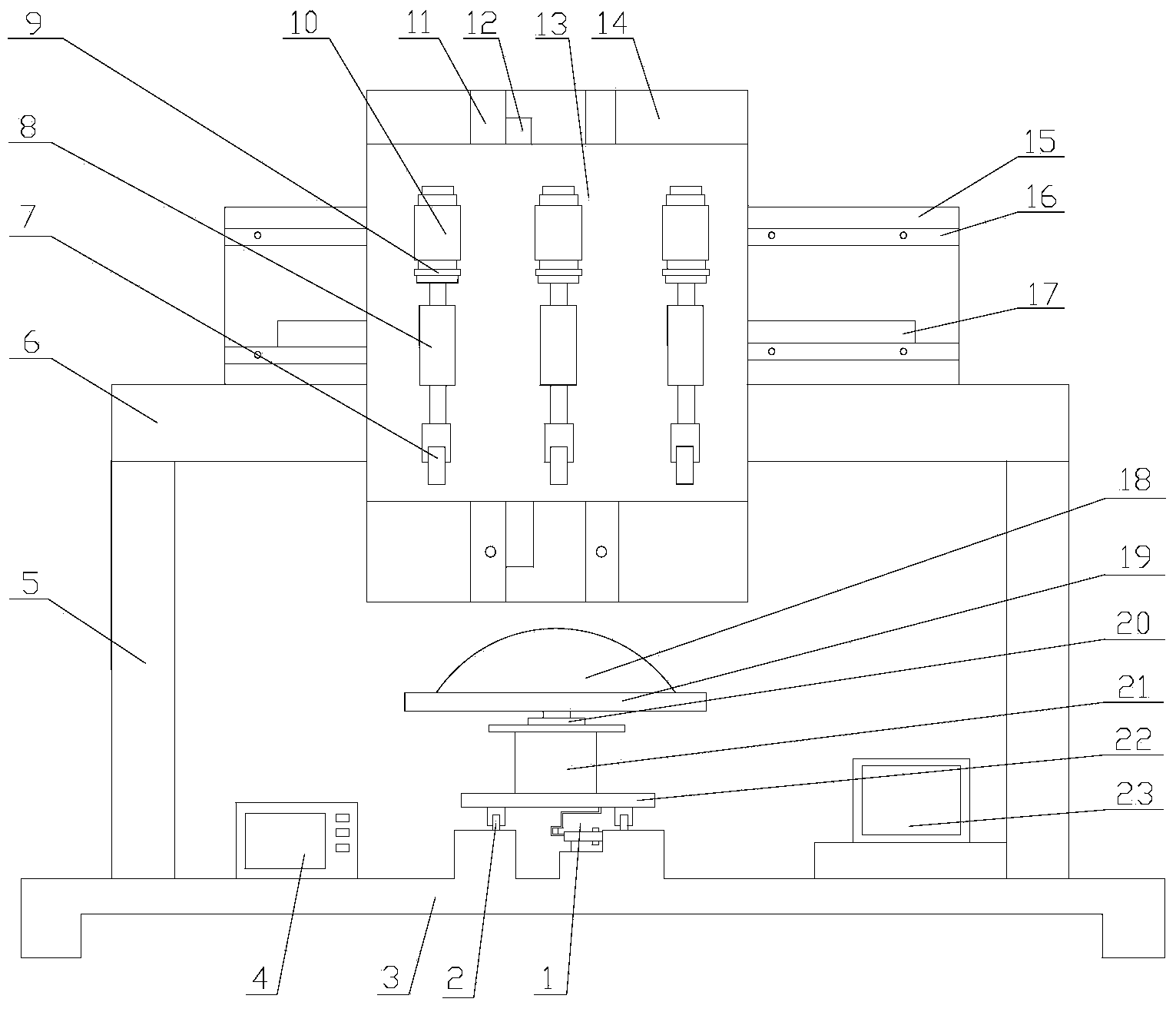

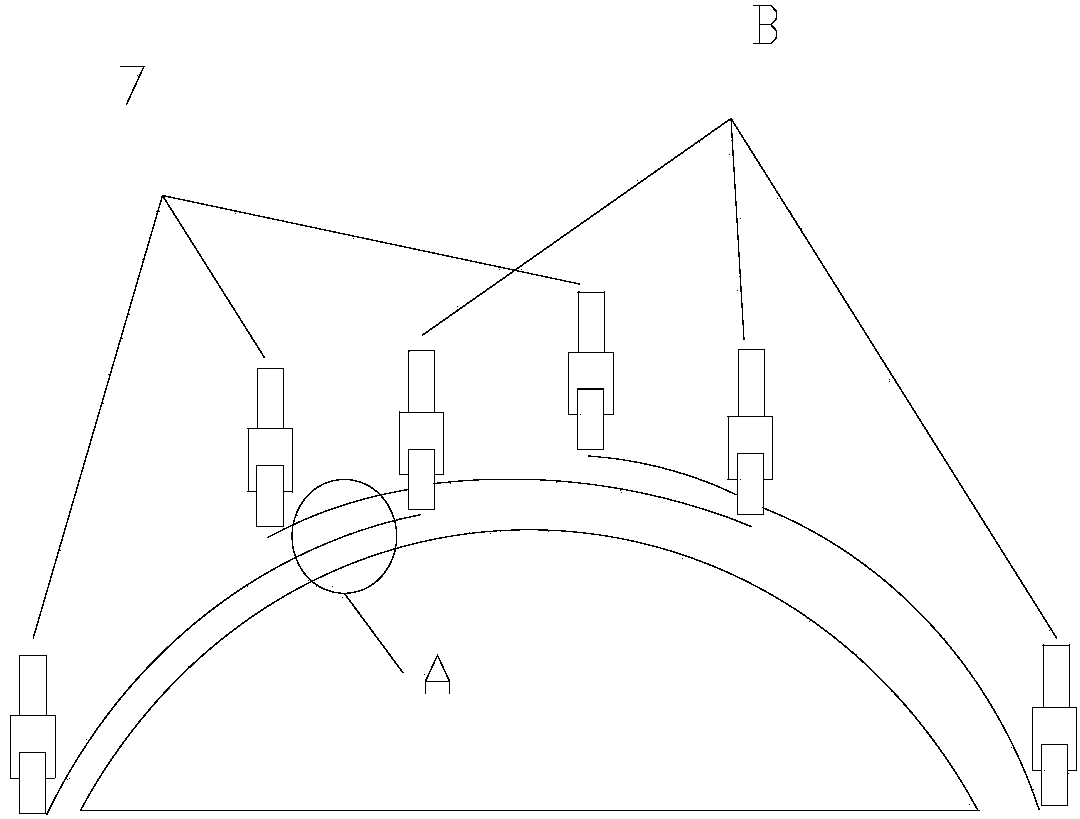

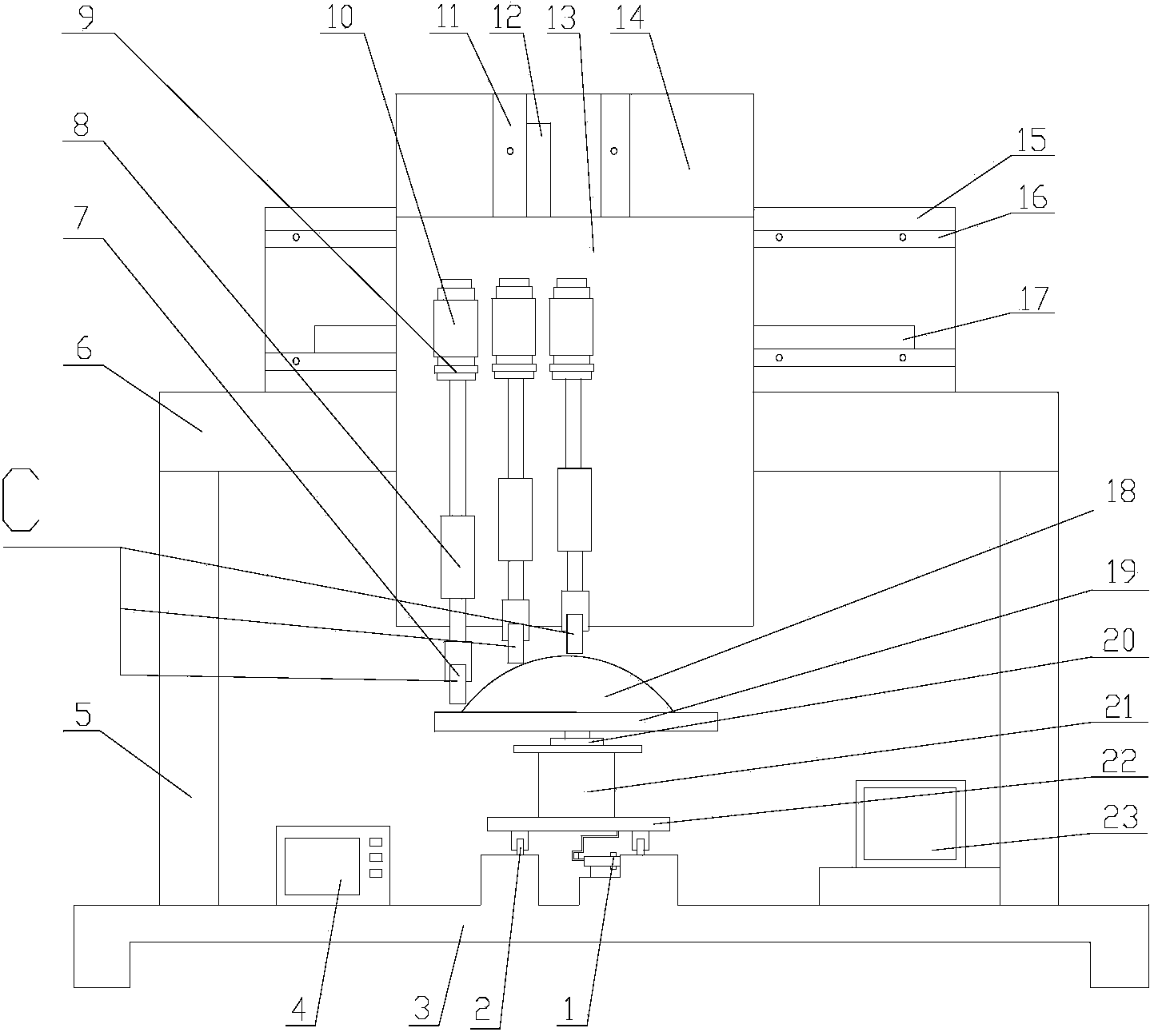

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0023] The embodiment of the present invention is provided with a Y-axis linear motor 1, a Y-axis linear guide rail 2, a base 3, a motion controller 4, a column 5, a beam 6, a measuring sensor 7, a linear motion screw nut pair 8, a shaft coupling 9, a measuring Head movement drive motor 10, Z-axis linear guide rail 11, Z-axis linear motor 12, probe connection seat 13, Z-axis worktable 14, X-axis worktable 15, X-axis linear guide rail 16, X-axis linear motor 17, workpiece 18 , the workpiece turntable 19, the connection seat 20, the rotating motor 21, the Y-axis table 22 and the computer 23.

[0024] The Y-axis linear motor 1 and the Y-axis linear guide rail 2 are set on the base 3, and the column 5 is located on the base 3 to support the beam 6, and the X-axis workbench 15 is fixed on the beam 6 and driven by the X-axis linear motor 17 , the X-axis li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com