Ink slab mold preforming pneumatic mechanism

A mold and pre-mold technology, which is applied in the field of inkstone mold pre-mold pneumatic mechanism, can solve the problems of easy breakage, unsatisfactory quality, and unadvanced, etc., and achieve the effect of hard inkstone, reasonable distribution of air pressure and hydraulic system, and smooth and wear-resistant surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

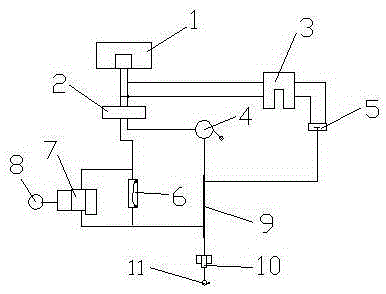

[0009] The specific embodiment: an anti-theft alarm 4 is installed on one line of the other direction line of the electromagnetic reversing valve 2, and an electromagnetic two-way valve 6 is installed on the other line. A relay 7 is installed, and the respective other direction circuits of the electromagnetic two-way valve 6 and the relay 7 are combined in one circuit, and the end of this circuit is connected with the condensation pipe 9, and the respective one-way overflow valve 5 and the anti-theft alarm 4 The end of the line in the other direction is connected to the condensation pipe 9 .

[0010] Further, a small air cylinder 10 and a fire alarm 11 are sequentially installed on the line at the end of the condensation pipe 9, and the condensation pipe 9 is straight and tubular.

[0011] A motor 8 is installed at one end of the relay 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com