Superfine sealed steel wire rope and production process thereof

A steel wire rope and steel wire technology, applied in the field of steel wire rope, to achieve the effect of smooth and wear-resistant surface, precise and reasonable structural design, and no serpentine bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

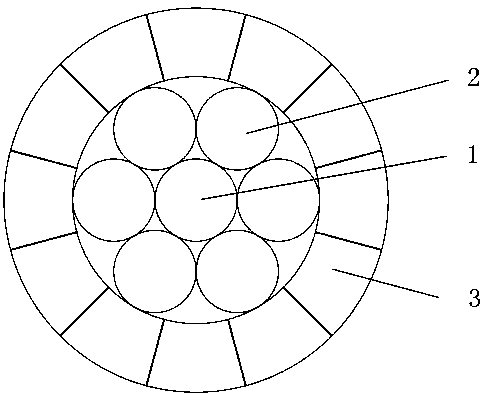

[0021] Accompanying drawing is a kind of specific embodiment of the present invention.

[0022] attached figure 1 It is a specific embodiment of the present invention. Such as figure 1 As shown, the micro-sealed steel wire rope is sequentially composed of a central metal core 1, an inner round steel wire layer 2, an outer T-shaped steel wire layer 3, and the inner round steel wire layer of the outer stranded ring of the central metal core 1. 2. The outer layer of T-shaped steel wire layer 3 is twisted and looped outside the inner layer of round steel wire layer 2; the inner layer of round steel wire layer 2 is made of a plurality of 0.6mm round steel wires 6 that are uniformly helically twisted around the central metal core to form a section It is a ring-shaped structure; the outer T-shaped steel wire layer 3 is a ring-shaped sealing structure formed by a plurality of T-shaped steel wires with a height of 0.5mm twisted uniformly and helically around the inner round steel wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com