A kind of preparation method of spherical alumina

A technology of spherical alumina and spherical particles, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc. It is prone to deformation and other problems, and achieves the effects of high sphericity, no pollution in the preparation process, and good hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a kind of preparation method of spherical aluminum oxide, comprises the steps:

[0041] Step 1: Mix pseudo-boehmite powder and molding aids, then add acid-containing deionized water, knead and extrude to make a long plastic body;

[0042] Step 2: On the premise that the surface of the strip-shaped plastic body does not stick, place it in the ball forming device to realize strip breaking and rolling granulation. After breaking the strip and granulating, keep the particles rotating while spraying the mist liquid Drops of wetting agent, on the premise that there is no adhesion between the particles, wet the surface of the particles, stop spraying and continue to rotate, when the particles become spherical particles with smooth surface, the cold air in the ball forming device is changed to hot air, and the spherical particles The surface dries and hardens, then the tumbling granulation is stopped; and

[0043] Step 3: Dry the spherical particles at a...

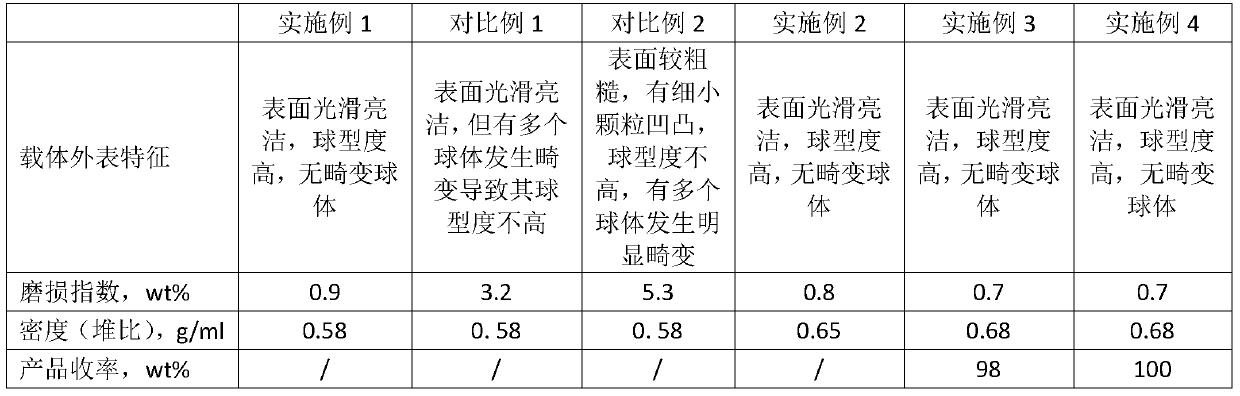

Embodiment 1

[0059] Take by weighing 100g of pseudo-boehmite powder (Sasol SB powder) prepared by the commercially available alcohol-aluminum method, take by weighing 2 g of safflower rubber powder, fully mix in a kneader; take by weighing 2 g of nitric acid (in terms of pure nitric acid weight), After adding 60g of deionized water to dilute, add it to a kneader and knead it into a block-shaped plastic body; use a low-pressure extruder and a clover-shaped orifice plate with a 4mm aperture to extrude the block-shaped plastic body into a bar-shaped plastic body. The cross-section is Clover shape, let it dry at room temperature for 2 hours; under the premise that the surface of the strip-shaped plastic body does not stick, place the strip-shaped plastic body in a high-speed ball forming device, set the speed at 100 rpm, and the strip-shaped plastic body completes strip breaking and rolling granulation ;Keep the rotating state, spray the ethanol wetting agent liquid from the external spray gun ...

Embodiment 2

[0065] Take by weighing commercially available pseudoboehmite powder (Sasol SB powder) 1000g prepared by aluminum alcohol method, take by weighing carbon black powder 50g, citric acid 50g, fully mix in kneader; Take by weighing nitric acid 40g (with pure nitric acid weight), add 400g of deionized water to dilute, add to the kneader together, and knead into a block-shaped plastic body; use a high-pressure extruder, 0.4mm hole diameter circular orifice plate, extrude the block-shaped plastic body into a bar-shaped plastic The cross-section is circular, and it is left to air at room temperature for 0.2h; on the premise that the surface of the strip-shaped plastic body does not stick, place the strip-shaped plastic body in a high-speed ball forming device, set the speed at 1500 rpm, and the strip-shaped plastic body is completed Strip breaking and rolling granulation; keep the rotating state, spray distilled water from the external spray gun in the high-speed ball forming device, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com