Stamping part preliminary mold mechanism

A technology of stamping parts and pre-molds, which is applied in the field of stamping parts pre-mold mechanisms, can solve the problems of parts such as insufficient hardness, unsatisfactory quality, and non-wear resistance, and achieve the effect of hard parts, reasonable distribution, and smooth and wear-resistant surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

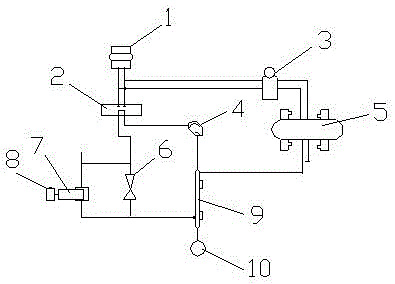

[0009] Specific embodiments: a current reversing valve 4 is installed on one circuit of the other direction circuit of the electromagnetic reversing valve 2, and a potentiometer 6 is installed on the other circuit. The check valve 7 is installed, the respective lines of the other direction of the potentiometer 6 and the check valve 7 are combined into one line, and the end of this line is connected to the electrical connector 9, the ultraviolet detector 5 and the current reversing valve 4 The ends of the respective lines in the other direction are connected to electrical connectors 9.

[0010] Further, a relay 10 is installed on the circuit at the end of the electrical connector 9 , and the electrical connector 9 is straight and tubular.

[0011] A stereoscopic mirror 8 is installed at one end of the check valve 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com