Ultraviolet curing transfer-printing flat decoration plate and manufacturing method thereof

A manufacturing method and ultraviolet light technology, applied in building construction, covering/lining, construction, etc., to achieve the effects of high production efficiency, wide application range, good hardness and wiping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

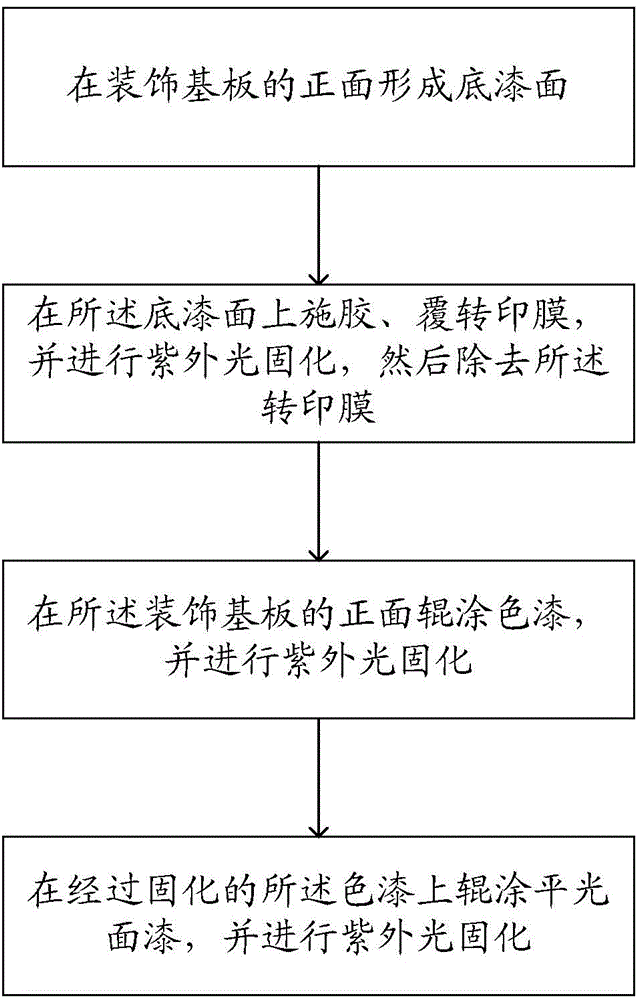

[0057] The manufacture method of UV-cured transfer printing flat decorative plate according to the present invention comprises the following steps:

[0058] 1) Dedusting the back of the plasterboard;

[0059] 2) Apply a 0.05mm thick sealing paint on the back of the plasterboard by single roller coating, and use a double mercury lamp curing machine for 3s UV curing;

[0060] 3) Turn over the board, and carry out dust removal treatment on the front of the plasterboard;

[0061] 4) Coat the front of the plasterboard with a 0.05mm thick adhesion primer by means of forward and reverse roller coating, and use a double gallium lamp curing machine for 3s UV curing;

[0062] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the plasterboard;

[0063] 6) Apply a 0.05mm thick white primer with a single roller, and use a double gallium lamp curing machine for 3s UV curing;

[0064] 7) Apply a 0.05mm thick sealing primer with positive and ne...

Embodiment 2

[0074] The manufacture method of UV-cured transfer printing flat decorative plate according to the present invention comprises the following steps:

[0075] 1) Dedusting the back of the plasterboard;

[0076] 2) Apply a 0.08mm thick sealer paint on the back of the plasterboard with a single roller coating method, and use a double mercury lamp curing machine for 6s UV curing;

[0077] 3) Turn over the board, and carry out dust removal treatment on the front of the plasterboard;

[0078] 4) Coat the front of the plasterboard with a 0.08mm thick adhesion primer by means of forward and reverse roller coating, and use a double gallium lamp curing machine for 6s UV curing;

[0079] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the plasterboard;

[0080] 6) Apply a 0.08mm thick white primer with a single roller, and use a double gallium lamp curing machine for 6s UV curing;

[0081] 7) Apply a 0.08mm thick sealing primer with posit...

Embodiment 3

[0091] The manufacture method of UV-cured transfer printing flat decorative plate according to the present invention comprises the following steps:

[0092] 1) Dedusting the back of the plasterboard;

[0093] 2) Apply a 0.12mm thick sealer paint on the back of the plasterboard with a single roller coating method, and use a double mercury lamp curing machine for 10s of UV curing;

[0094] 3) Turn over the board, and carry out dust removal treatment on the front of the plasterboard;

[0095] 4) Apply a 0.12mm-thick adhesion primer to the front of the plasterboard by means of forward and reverse roller coating, and use a double-gallium lamp curing machine for 10s of UV curing;

[0096] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the plasterboard;

[0097] 6) Apply a 0.12mm thick white primer with a single roller, and use a double gallium lamp curing machine for 10s of UV curing;

[0098] 7) Apply a 0.12mm thick sealing primer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com