A kind of ultraviolet curing transfer printing 3D decorative plate and its manufacturing method

A manufacturing method and technology of decorative boards, applied in chemical instruments and methods, lamination devices, building structures, etc., to achieve good hardness and wiping performance, smooth and wear-resistant surface, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

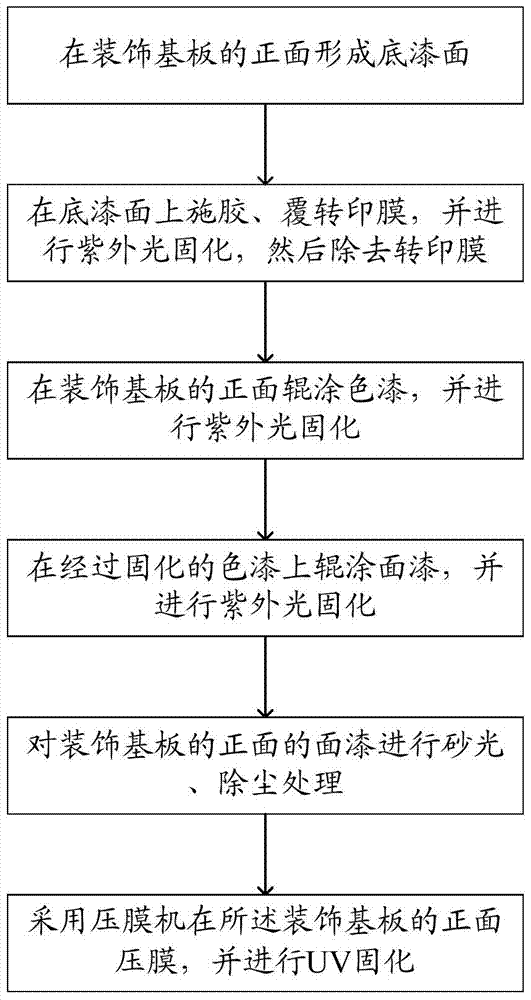

[0061] The manufacturing method of the UV-curing transfer printing 3D decorative board according to the present invention comprises the following steps:

[0062] 1) Dust removal treatment on the back of the gypsum board;

[0063] 2) Apply a 0.05mm thick sealer on the back of the paper-faced gypsum board by single-roller roller coating, and use a double mercury lamp curing machine for UV curing for 3s;

[0064] 3) Turn over the board, and carry out dust removal treatment on the front of the gypsum board;

[0065] 4) Apply a 0.05mm thick adhesion primer on the front of the gypsum board by means of forward and reverse roller coating, and use a dual gallium lamp curing machine for UV curing for 3s;

[0066] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the gypsum board;

[0067] 6) Apply a 0.05mm thick white primer with a single roller, and use a dual gallium lamp curing machine for 3s UV curing;

[0068] 7) Apply a 0.05mm thick...

Embodiment 2

[0080] The manufacturing method of the UV-curing transfer printing 3D decorative board according to the present invention comprises the following steps:

[0081] 1) Dust removal treatment on the back of the gypsum board;

[0082] 2) Apply a 0.08mm thick sealer on the back of the paper-faced gypsum board by single-roller roller coating, and use a double mercury lamp curing machine for 6s of UV curing;

[0083] 3) Turn over the board, and carry out dust removal treatment on the front of the gypsum board;

[0084] 4) Apply a 0.08mm thick adhesion primer on the front of the gypsum board by means of forward and reverse roller coating, and use a dual gallium lamp curing machine for UV curing for 6s;

[0085] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the gypsum board;

[0086] 6) Apply a 0.08mm thick white primer with a single roller, and use a dual gallium lamp curing machine for 6s UV curing;

[0087] 7) Apply a 0.08mm thick ...

Embodiment 3

[0099] The manufacturing method of the UV-curing transfer printing 3D decorative board according to the present invention comprises the following steps:

[0100] 1) Dust removal treatment on the back of the gypsum board;

[0101] 2) Apply a 0.12mm thick sealer on the back of the paper-faced gypsum board by single-roller roller coating, and use a double mercury lamp curing machine for 10s of UV curing;

[0102] 3) Turn over the board, and carry out dust removal treatment on the front of the gypsum board;

[0103] 4) Apply a 0.12mm thick adhesion primer on the front of the gypsum board by means of forward and reverse roller coating, and use a dual gallium lamp curing machine to perform UV curing for 10s;

[0104] 5) After the curing is completed, fine sanding and dust removal are performed on the surface of the gypsum board;

[0105] 6) Apply a 0.12mm thick white primer with a single roller, and use a dual gallium lamp curing machine for 10s UV curing;

[0106] 7) Apply a 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com