Fluff hand feeling powder coating

A powder coating and fluff technology, applied in epoxy resin coatings, coatings, latex paints, etc., can solve problems such as low elasticity, poor wear resistance and scratch resistance on the surface of the coating, poor recovery and softness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

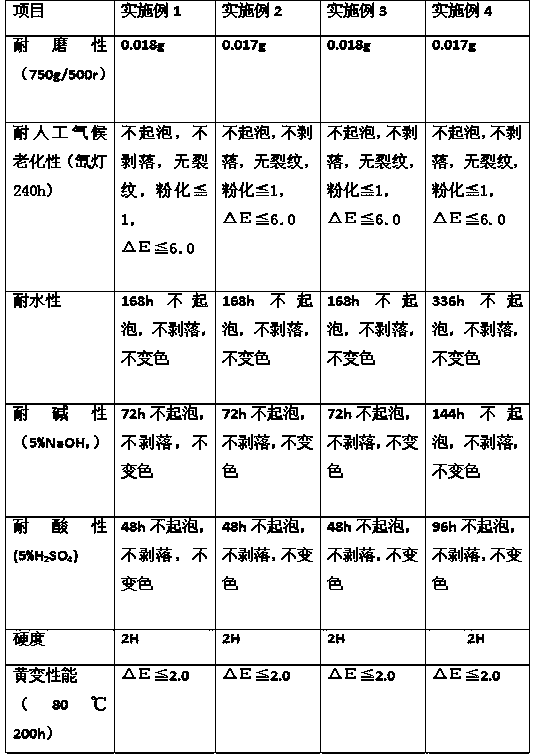

Examples

Embodiment 1

[0033] A kind of fluffy feel powder coating, its raw material comprises by weight:

[0034] 230 parts of solid epoxy resin

[0035] Carboxylic resin 40 parts

[0036] Fluff additive 5 parts

[0037] Leveling agent 8 parts

[0038] 3 parts of paint

[0039] Quartz powder 120 parts

[0040] Barite 100 parts

[0041] 8 parts of polytetrafluoroethylene micronized wax.

Embodiment 2

[0043] A kind of fluffy feel powder coating, its raw material comprises by weight:

[0044] 240 parts of solid epoxy resin

[0045] Carboxylic resin 50 parts

[0046] Fluff additive 5 parts

[0047] Leveling agent 10 parts

[0048] Pigment 5 parts

[0049] Quartz powder 100 parts

[0050] Barite 80 parts

[0051] 10 parts of polytetrafluoroethylene micronized wax.

Embodiment 3

[0053] A kind of fluffy feel powder coating, its raw material comprises by weight:

[0054] 250 parts of solid epoxy resin

[0055] Carboxylic resin 60 parts

[0056] Fluff additive 5 parts

[0057] Leveling agent 12 parts

[0058] Pigment 8 parts

[0059] Quartz powder 140 parts

[0060] Barite 120 parts

[0061] 12 parts of polytetrafluoroethylene micronized wax.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com