Intelligent mineral insulated cable

A mineral insulated cable, intelligent technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of poor information and power transmission, high risk of data loss, etc., achieve excellent fire resistance and improve safety and reliability , Good effect of fire and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

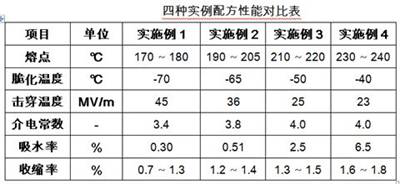

Embodiment 1

[0024] Embodiment 1: a kind of anti-rodent-ant wear-resistant non-toxic environment-friendly nylon sheath material preparation method and its characteristics comprise the following steps:

[0025] Step 1. Put 52.9 parts of polyamide resin PA66, 19 parts of hindered phenolic antioxidant, 9 parts of thiodipropionate diester, 7.5 parts of calcium stearate, and 4 parts of hindered amine light stabilizer into the high-speed mixer Agent, 3 parts of ethylene bis stearamide, 1.8 parts of silicone powder, 2.8 parts of nanometer talcum powder, mixed for 5 minutes to obtain a blended material;

[0026] Step 2. Put the blended material obtained in Step 1 into a screw extruder at a temperature of 300° C. and a rotation speed of 200 r / min, and extrude after melting and kneading;

[0027] Step 3: After cooling, cutting, sieving, and packaging, the rodent-proof, wear-resistant, non-toxic and environmentally friendly nylon sheath material can be obtained.

Embodiment 2

[0028] Embodiment 2: a kind of anti-rodent-ant wear-resistant non-toxic environment-friendly nylon sheath material preparation method and its characteristics include the following steps:

[0029] Step 1. Put 59 parts of polyamide resin PA6, 15 parts of hindered phenolic antioxidant, 8 parts of thiodipropionate diester, 7 parts of calcium stearate, and 3 parts of hindered amine light stabilizer into the high-speed mixer Agent, 3 parts of ethylene bis stearamide, 2 parts of silicone powder, 3 parts of nanometer talcum powder, mixed for 5 minutes to obtain a blended material;

[0030] Step 2. Put the blended material obtained in Step 1 into a screw extruder at a temperature of 220° C. and a rotation speed of 300 r / min, and extrude after melting and kneading;

[0031] Step 3: After cooling, cutting, sieving, and packaging, the rodent-proof, wear-resistant, non-toxic and environmentally friendly nylon sheath material can be obtained.

Embodiment 3

[0032] Embodiment 3: a kind of anti-rodent-ant wear-resistant non-toxic environment-friendly nylon sheath material preparation method and its characteristics include the following steps:

[0033] Step 1. Put 76 parts of polyamide resin PA12, 5 parts of hindered phenolic antioxidant, 4 parts of thiodipropionate diester, 5 parts of calcium stearate, and 3 parts of hindered amine light stabilizer into the high-speed mixer Agent, 2 parts of ethylene bis stearamide, 2 parts of silicone powder, 3 parts of nanometer talcum powder, mixed for 5 minutes to obtain a blended material;

[0034] Step 2. Put the blended material obtained in Step 1 into a screw extruder at a temperature of 228° C. and a rotation speed of 200 r / min, and extrude after melting and kneading;

[0035] Step 3: After cooling, cutting, sieving, and packaging, the rodent-proof, wear-resistant, non-toxic and environmentally friendly nylon sheath material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com