Super self-cleaning inorganic fireproof tunnel coating and preparation method thereof

A super self-cleaning, inorganic technology, applied in fire-retardant coatings, antifouling/underwater coatings, chemical instruments and methods, etc., can solve the problems of reducing the quality of coatings, wrong material ratio, residual materials, etc., to improve flame retardant effect, low surface tension, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

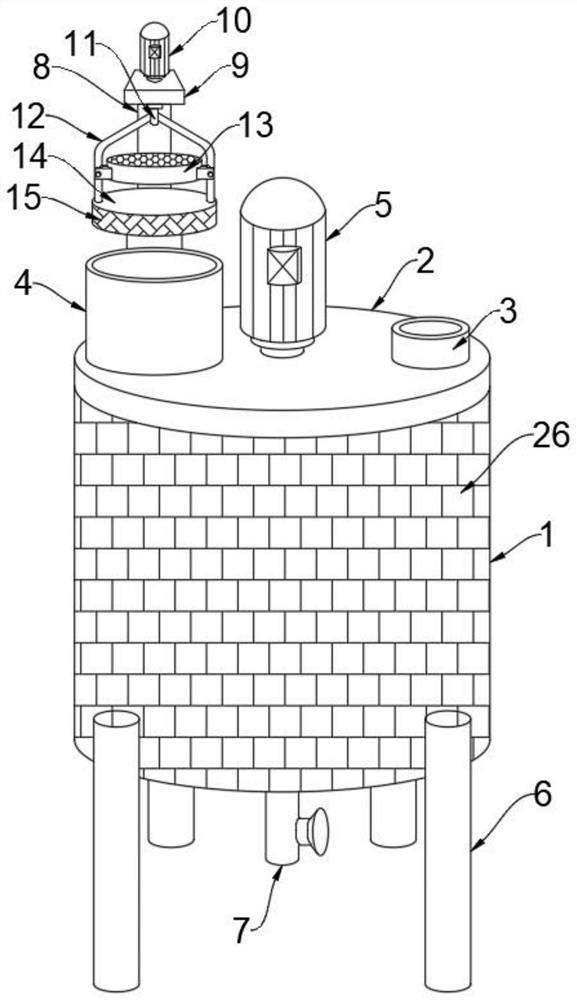

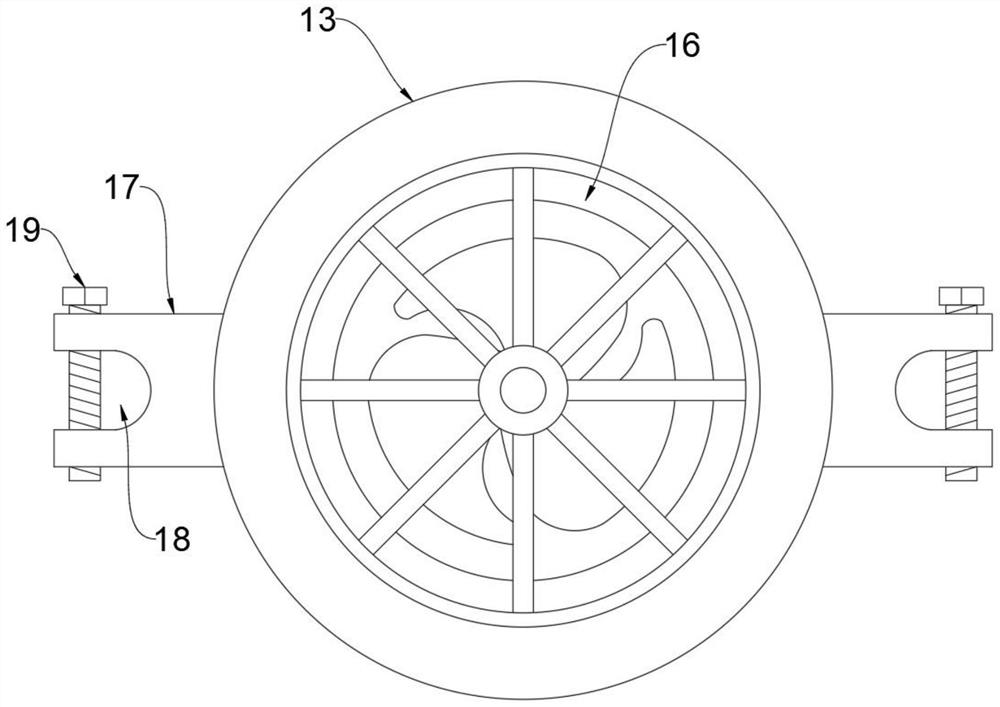

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0037] see Figure 1-5 , an embodiment provided by the present invention: super self-cleaning inorganic fire-proof tunnel coating is a multi-group powdery mixture, and the powdery mixture is made of the following raw materials in proportion by weight: inorganic alkali metal silicate 20%, modified silica sol 15%, kaolin 10%, expanded vermiculite 6%, vitrified microspheres 14%, glass microspheres 3%, aluminum hydroxide 8%, ammonium polyphosphate APP3%, melamine 2%, nitrogen - Vanadium co-doped nano-TiO 28%, organosilicon modifier 12%, additives 4%.

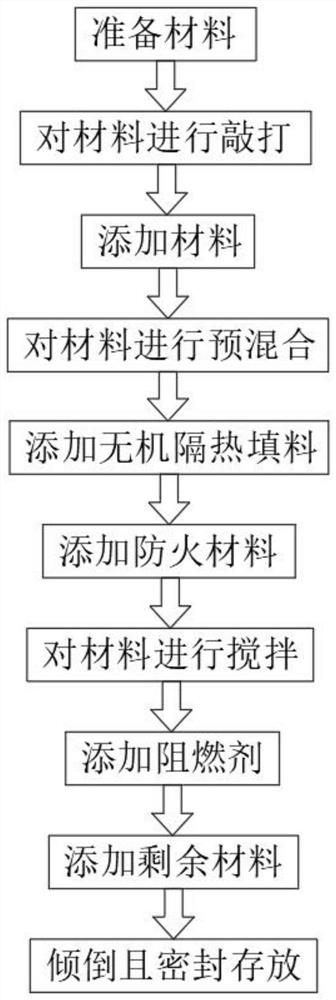

[0038] Further: super self-cleaning inorganic fireproof tunnel coating and preparation method thereof, comprising the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com