Industrial automation control cabinet dustproof and anti-corrosion ventilation system and method

An industrial automation and ventilation system technology, which is applied in the direction of cooling/ventilation/heating transformation, casing/cabinet/drawer parts, etc. Gas protection, overheating of components in the cabinet during running time, etc., to eliminate external hidden dangers, improve equipment safety and reliability, and increase economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

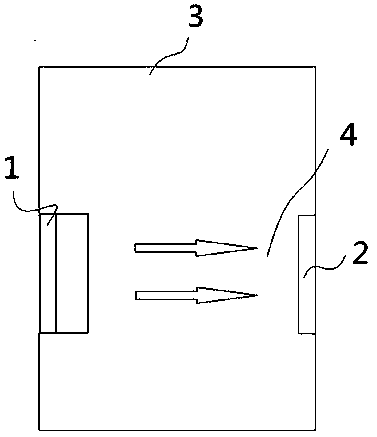

[0023] Such as figure 1 , an industrial automation control cabinet dust-proof and anti-corrosion ventilation system and method, at least comprising: a dust-proof air inlet unit 1, a dust-proof air outlet unit 2, the dust-proof air inlet unit 1 and the dust-proof air outlet unit 2 are fixed on the industrial automation control The two ends of the ventilation and heat dissipation channel 4 of the cabinet 3.

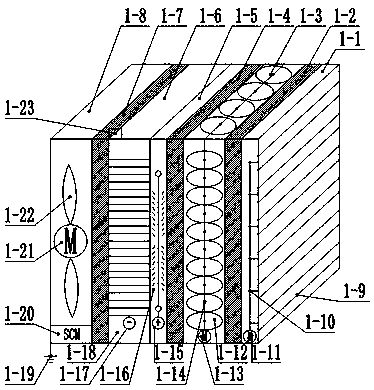

[0024] Such as figure 2As shown, the dust-proof air inlet unit 1 at least includes: an air inlet module 1-1, an air inlet module mosquito isolation device 1-2, an internal and external circulation conversion module 1-3, a dust filter module 1-4, and an electrostatic precipitator positive electrode Module 1-5, electrostatic precipitator negative electrode module 1-6, activated carbon adsorption module 1-7, fan module 1-8, air inlet module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com