Method for processing porous material by hydrogenated silicon oil

A technology of hydrogenated silicone oil and porous materials, which is applied in the treatment of dyed organic silicon compounds and fibrous fillers. It can solve the problems of porous material erosion, high porosity, high air permeability, and reduced material performance, and achieve excellent market prospects and maintain environmental protection. , better durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

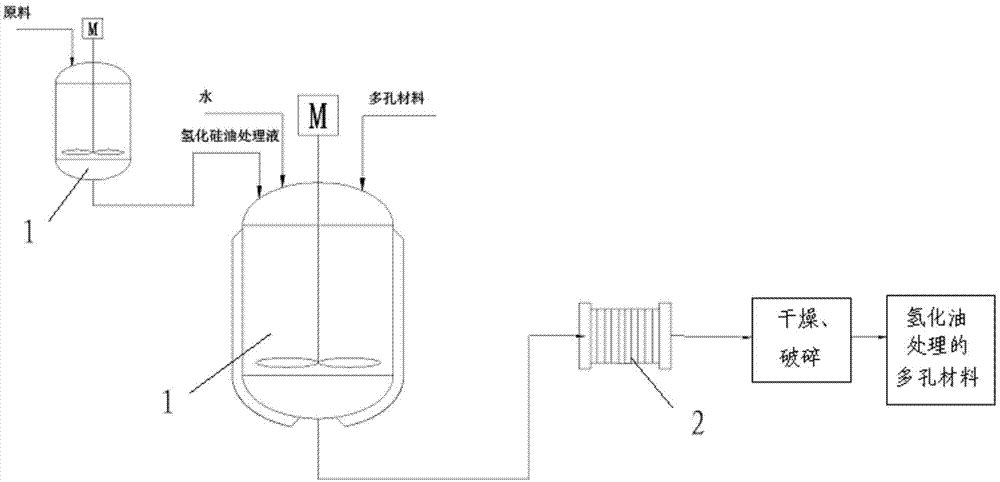

Method used

Image

Examples

Embodiment 1

[0015] The formula and processing technology are as follows:

[0016] In terms of mass fraction, add 20 parts of hydrogenated silicone oil with a hydrogen content of 0.8%, 0-5 parts of siloxane coupling agent, 2 parts of methacryloxypropyl trimethoxysilane, and 30 parts of acetone into the stirred tank , 48 parts of butanol, stirred and dissolved to obtain hydrogenated silicone oil treatment agent.

[0017] Add water 10 times the amount of porous filler to be treated into the kettle with a stirring and heating device, start stirring, and at the same time slowly put in the porous silicate material to be treated (feeding process is about 15-25min), and drop evenly at 20°C Add the pretreatment agent, stir for 30 minutes after adding, then filter, dry, and crush to the required particle size to obtain a porous material treated with hydrogenated silicone oil. The pores of the porous silicate material are not closed after treatment, and the water contact angle is 158 °, with superh...

Embodiment 2

[0019] The formula and process are as follows:

[0020] In terms of mass fraction, add 30 parts of hydrogenated silicone oil with a hydrogen content of 0.5%, 1 part of methacryloxypropyltrimethoxysilane, 40 parts of methyl ethyl ketone, and 29 parts of ethanol into the stirred tank, stir and dissolve to obtain hydrogenated Silicone oil treatment agent.

[0021] Add water 15 times the amount of porous filler to be treated into the kettle with a stirring and heating device, start stirring, and slowly put in the porous silicate material to be treated (feeding process is about 15-25min), and drop evenly at 30°C Add the pretreatment agent, stir for 30 minutes after adding, then filter, dry, and crush to the required particle size to obtain a porous material treated with hydrogenated silicone oil. The pores of the porous material are not closed after treatment, and the water contact angle is 158°. Hydrophobic.

Embodiment 3

[0023] The formula and process are as follows:

[0024] In terms of mass fraction, add 10 parts of hydrogenated silicone oil with a hydrogen content of 0.1%, 3 parts of glycidyltrimethoxysilane, 60 parts of acetone, and 27 parts of ethanol into the stirred tank, and stir and dissolve to obtain a hydrogenated silicone oil treatment agent; Add water 5 times the amount of porous filler to be treated into the kettle with a stirring and heating device, start stirring, and slowly put in the porous silicate material to be treated at the same time (feeding process is about 15-25min), and drop evenly at 80°C After adding the pretreatment agent, stir for 60 minutes, suction filter the porous material dispersion, dry it, and crush it to the required particle size to obtain the porous silicate material treated with hydrogenated silicone oil. The pores of the porous material are not closed after treatment, and the water The contact angle is 150°, and it is superhydrophobic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com