Flexible main cable protection material

A technology of protective materials and main cables, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problem of the increasingly high requirements for the sealing of main cables, and achieve the effect of isolating erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

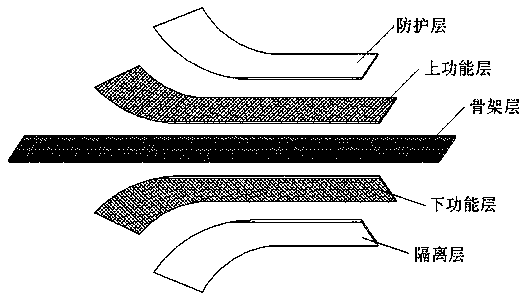

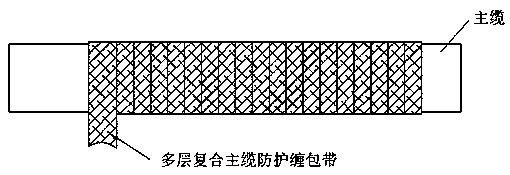

[0017] Embodiment: The protective layer (1) of the present invention adopts colorless transparent saturated polyolefin thermoplastic elastomer as the main material, which has a good isolation effect and can prevent external air and ultraviolet rays from aging the flexible main cable protective material. The skeleton layer (2) is a polyester fiberglass cloth with pores of 2-8mm, which provides strength for the flexible main cable protective material. The film layer (3) is made of modified ethylene propylene rubber, which has excellent weather resistance and elasticity, and can ensure that the wrapping tape moves with the main cable when the main cable is displaced, and at the same time ensures the sealing performance of the main cable.

[0018] The thickness of the protective layer is 0.3-1.0mm. The thickness of the skeleton layer is 0.1-0.3mm. The thickness of the film layer is 0.3-1.0mm. The protective material of the flexible main cable is designed to be white as a whole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com