Preparation method of cover plate for polycrystalline ingot furnace thermal field

A technology of polycrystalline ingot and cover plate, which is applied in the field of preparation of carbon/carbon composite material cover plate for polycrystalline ingot casting furnace, can solve the problems of delamination cracking, carbon fiber damage, overall performance reduction, etc., and prolong the service life , good coating effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

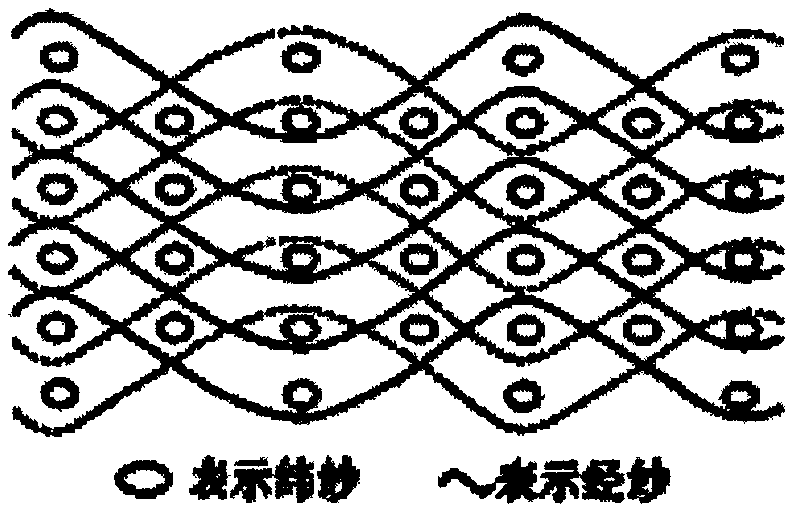

[0026] (1) Select Toray T700-12K polyacrylonitrile-based carbon fiber, weave and shape it in a 2.5D shallow cross-linking method to form a carbon fiber preform; the preform density is 0.50g / cm 3 ;The size of the preform is 1000×1000×10mm;

[0027] (2) Select a thermosetting phenolic resin with a solid content of about 60% as the impregnating agent, put the carbon fiber preform into a vacuum impregnation tank, and inhale the phenolic resin after vacuuming for 30 minutes until the resin completely covers the preform;

[0028] (3) Place the resin-impregnated carbon fiber prefabricated body on a flat-plate hot press for hot-press curing, the curing temperature is 150°C, and the curing time is 3 hours; before curing, adjust the distance between the press platen and press the thickness of the prefabricated body to 8.5mm;

[0029] (4) Put the cured finished product into a carbonization furnace for carbonization treatment. During the treatment, the temperature is raised to 800 °C at a...

Embodiment 2

[0035] (1) Select Toray T700-6K polyacrylonitrile-based carbon fiber, and weave and shape it in a 2.5D shallow cross-linking method to form a carbon fiber prefabricated body; the prefabricated body density is 0.60g / cm 3 ;The size of the preform is 1000×1000×10mm;

[0036] (2) Select a thermosetting phenolic resin with a solid content of about 55% as the impregnating agent, put the carbon fiber preform into a vacuum impregnation tank, and inhale the phenolic resin after vacuuming for 30 minutes until the resin completely submerges the preform;

[0037] (3) Place the resin-impregnated carbon fiber prefabricated body on a flat-plate hot press for hot-press curing, with a curing temperature of 130°C and a curing time of 5 hours; before curing, adjust the distance between the press plates of the press to press the thickness of the prefabricated body to 9mm;

[0038] (4) Put the solidified finished product into a carbonization furnace for carbonization treatment. During the treatmen...

Embodiment 3

[0044] (1) Select Toray T700-12K polyacrylonitrile-based carbon fiber, weave and shape it in a 2.5D shallow cross-linked way to form a carbon fiber preform; the preform density is 0.40g / cm 3 ;The size of the preform is 1000×1000×10mm;

[0045] (2) Select a thermosetting phenolic resin with a solid content of about 65% as the impregnating agent, put the carbon fiber preform into a vacuum impregnation tank, and inhale the phenolic resin after vacuuming for 30 minutes until the resin completely submerges the preform;

[0046] (3) Place the resin-impregnated carbon fiber prefabricated body on a flat-plate hot press for hot-press curing, the curing temperature is 160°C, and the curing time is 1h; before curing, adjust the distance between the press platen and press the thickness of the prefabricated body to 8mm;

[0047] (4) Put the cured finished product into a carbonization furnace for carbonization treatment. During the treatment, the temperature is raised to 700°C at a heating ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com