A metal mesh composite plastic-steel component

A technology of metal holes and components, which is applied in the field of metal hole mesh composite plastic-steel components, can solve the problems of different thermal expansion coefficients, layered cracking, etc., and achieve the effects of increasing physical properties, preventing expansion, and increasing overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

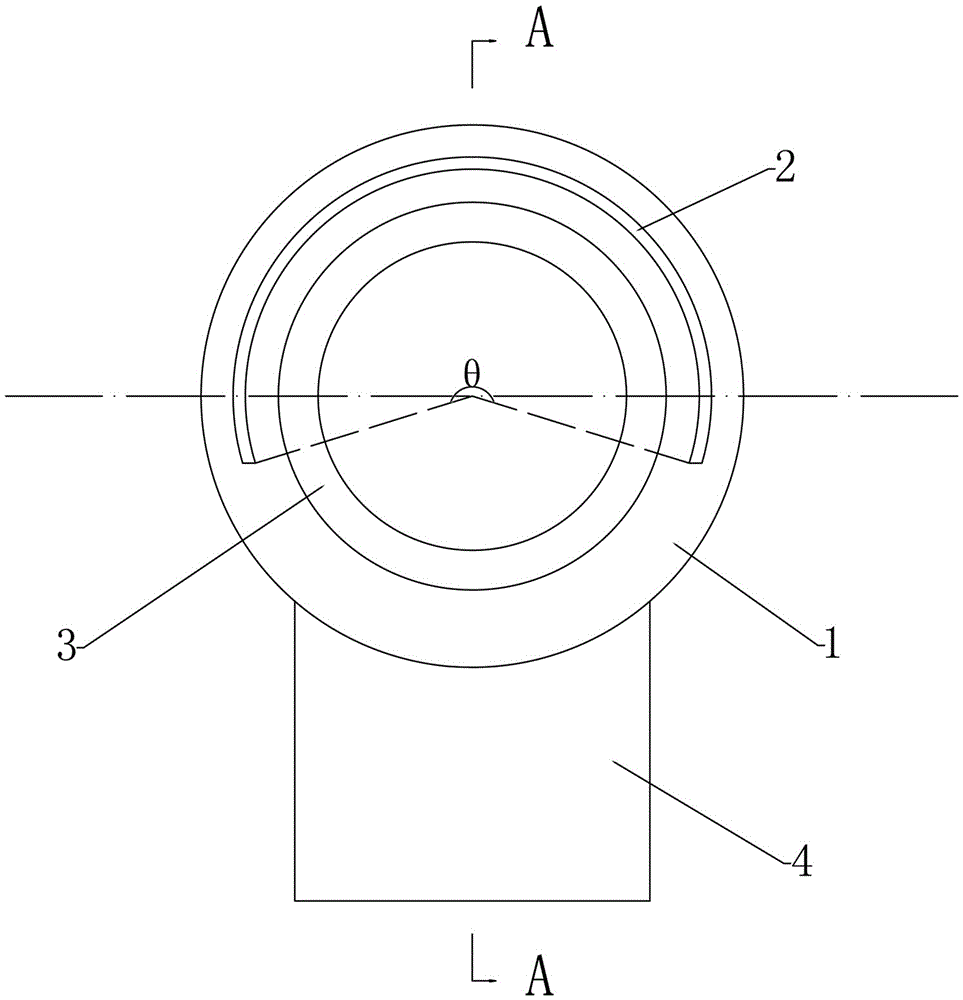

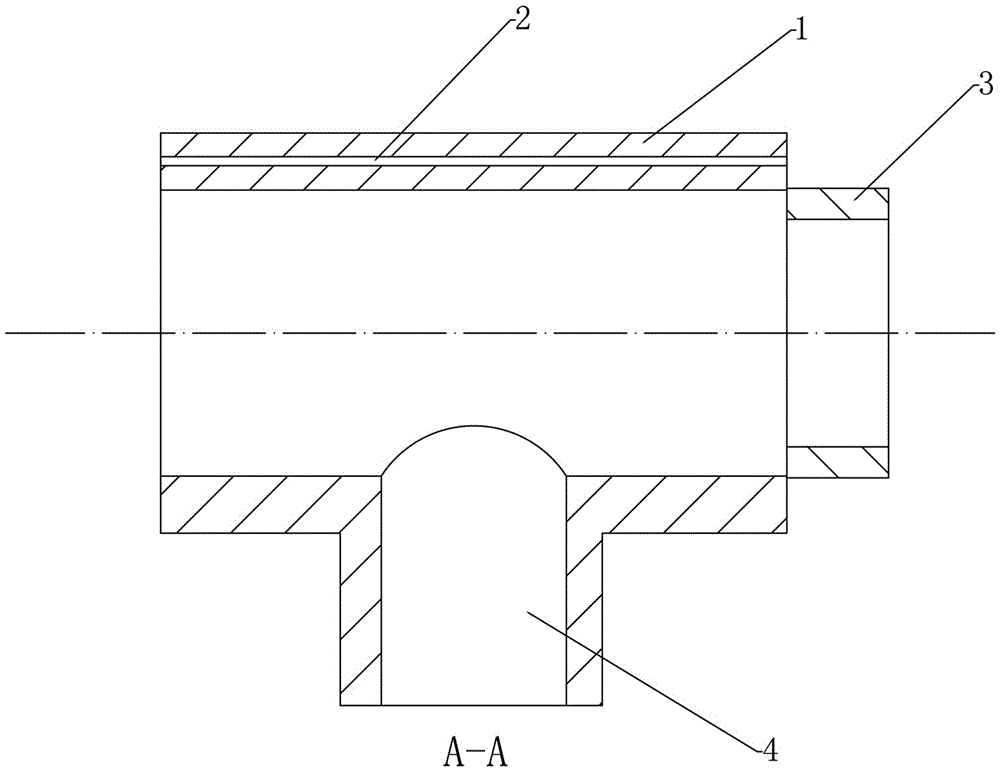

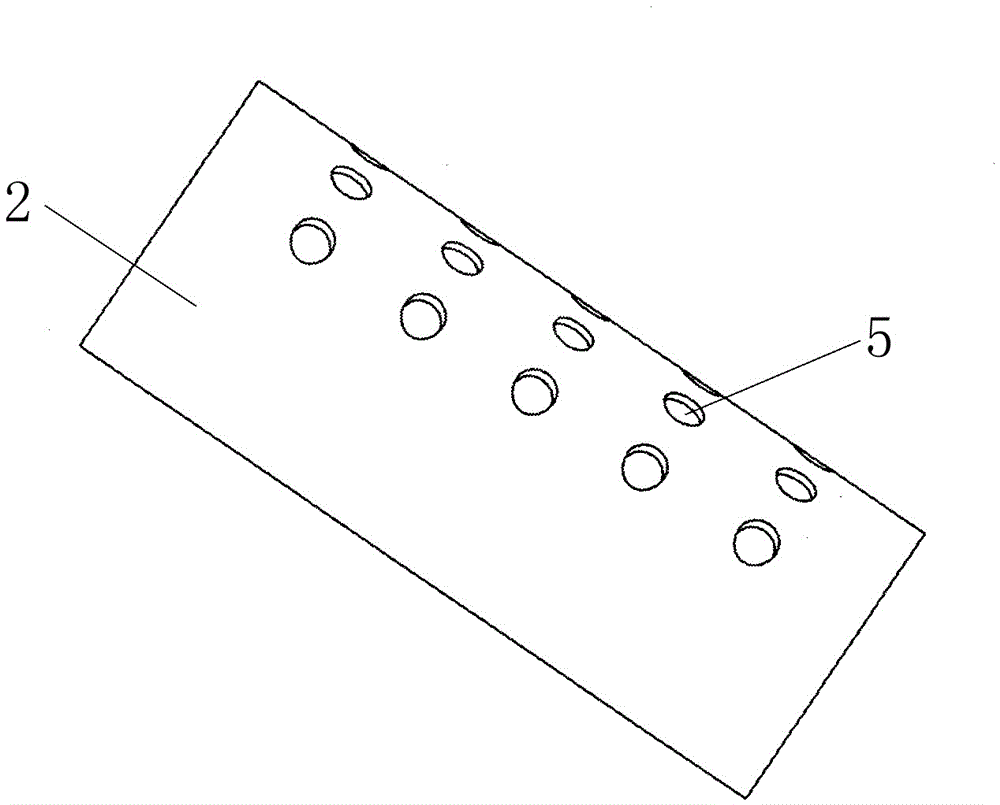

[0022] Example 1 consists of Figure 1 to Figure 3 It can be seen that the structure of the present invention is a metal mesh composite plastic-steel member, comprising a PERT pipe 1 and a metal hole mesh 2, wherein the inside of the PERT pipe 1 is provided with a metal hole mesh 2, and the metal hole mesh 2 is provided with holes 5, The lower part of the longitudinal part of the PERT tube 1 is provided with an opening 4, and one side of the lateral part of the PERT tube 1 is provided with a connection end 3. The metal mesh 2 is located at the transverse part of the PERT pipe 1, and the arc end point circle center of the arc structure of the metal hole mesh 2 is Angle θ, 180°<θ<360°.

Embodiment 2

[0023] Example 2 consists of Figure 3 to Figure 5 It can be seen that the structure of the present invention is a metal mesh composite plastic-steel member, comprising a PERT pipe 1 and a metal hole mesh 2, wherein the inside of the PERT pipe 1 is provided with a metal hole mesh 2, and the metal hole mesh 2 is provided with holes 5, The lower part of the longitudinal part of the PERT tube 1 is provided with an opening 4, and one side of the lateral part of the PERT tube 1 is provided with a connection end 3. The metal mesh 2 is located at the transverse part of the PERT pipe 1, and the arc end point circle center of the arc structure of the metal hole mesh 2 is Angle θ=360°.

Embodiment 3

[0024] Example 3 consists of image 3 , Figure 4 and Figure 6 It can be seen that the structure of the present invention is a metal mesh composite plastic-steel member, comprising a PERT pipe 1 and a metal hole mesh 2, wherein the inside of the PERT pipe 1 is provided with a metal hole mesh 2, and the metal hole mesh 2 is provided with holes 5, The lower part of the longitudinal part of the PERT tube 1 is provided with an opening 4, the side of the lateral part of the PERT tube 1 is provided with a connection end 3, and the metal mesh 2 is located at the lateral part and the longitudinal part of the PERT tube 1.

[0025] Depend on Figure 7 It can be seen that, for the application of the components of Examples 1-3 on the heating radiator, the above components are connected to each other by thermal fusion to form the horizontal tube of the heating radiator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com