Herring-bone wall body construction method of large-span concrete herring-bone continuous girder bridge and structure thereof

A concrete, long-span technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of multi-prestressed material consumption, inability to provide compressive stress, complex construction process, etc., to achieve less shrinkage cracks and reduce construction complexity , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

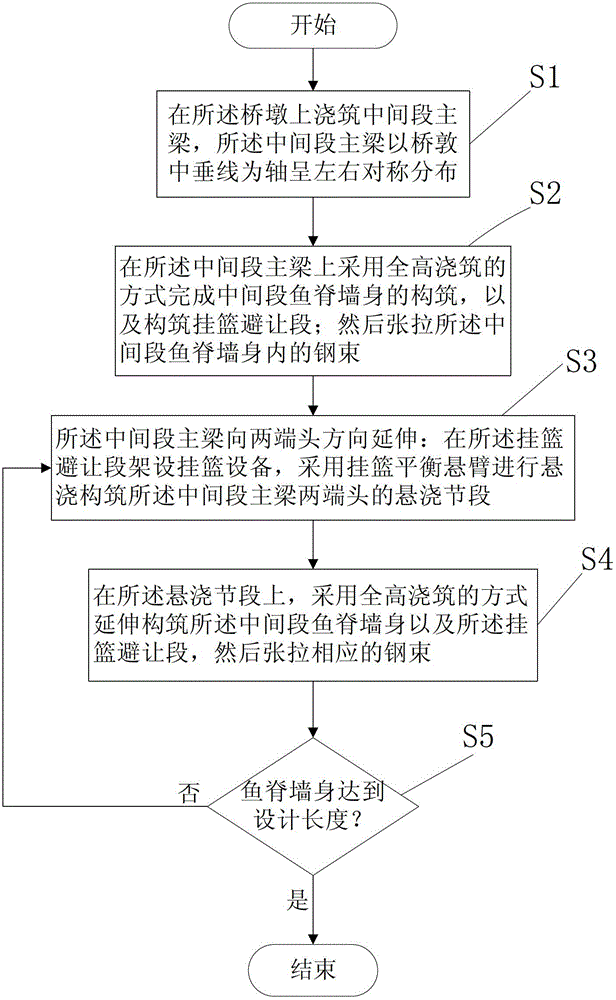

[0040] Such as figure 1 As shown, a specific embodiment of the present invention is a fish ridge wall construction method of a large-span concrete fish ridge continuous girder bridge. The fish ridge wall 5 is arranged in the same direction as the main girder of the continuous bridge, and the fish ridge wall The position of the top of 5 corresponds to the pier 1 of the continuous bridge, wherein the fish ridge wall body 5 and the main girder adopt the construction method of intermediate symmetrical segmental pouring, including the following steps:

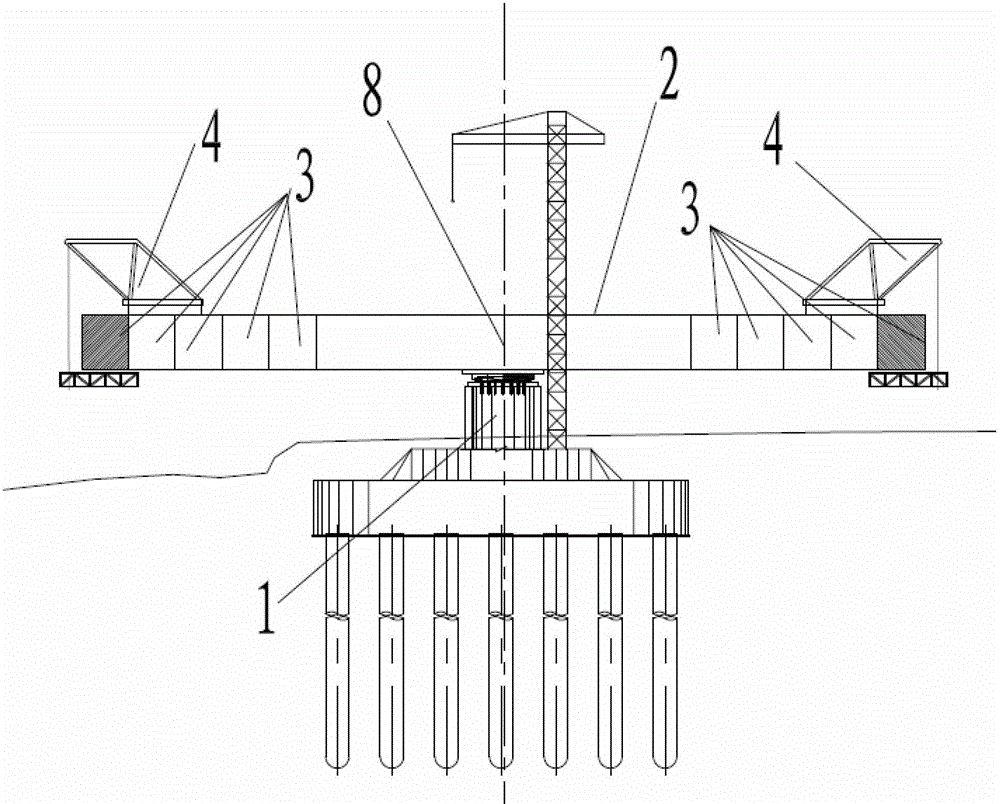

[0041] Step S1, combining figure 2 As shown, the main girder 2 of the middle section is poured on the pier 1, and the main girder 2 of the middle section is symmetrically distributed with the vertical line of the bridge as the axis.

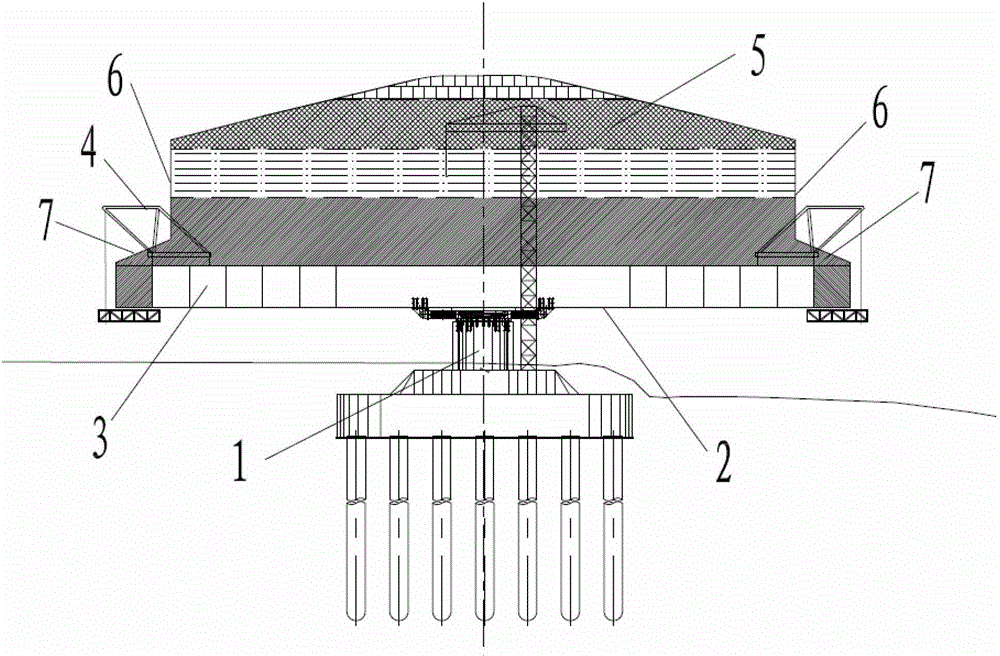

[0042] Step S2, combining image 3 As shown, the construction of the fish-ridge wall 5 in the middle section is completed by full-height pouring on the main beam 2 in the middle section. The fish-ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com