Trenchless large-caliber water supply pressure pipeline rehabilitation construction method

A technology for water supply pressure and pipeline repair, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., it can solve the problems of inconvenient connection of branch pipes, large loss of hot water, affecting construction quality, etc. The effect of small resistance of conveying liquid and mature construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific implementation modes, and various modifications or changes can be made to the details in this specification based on different viewpoints and applications without departing from the spirit of the present invention.

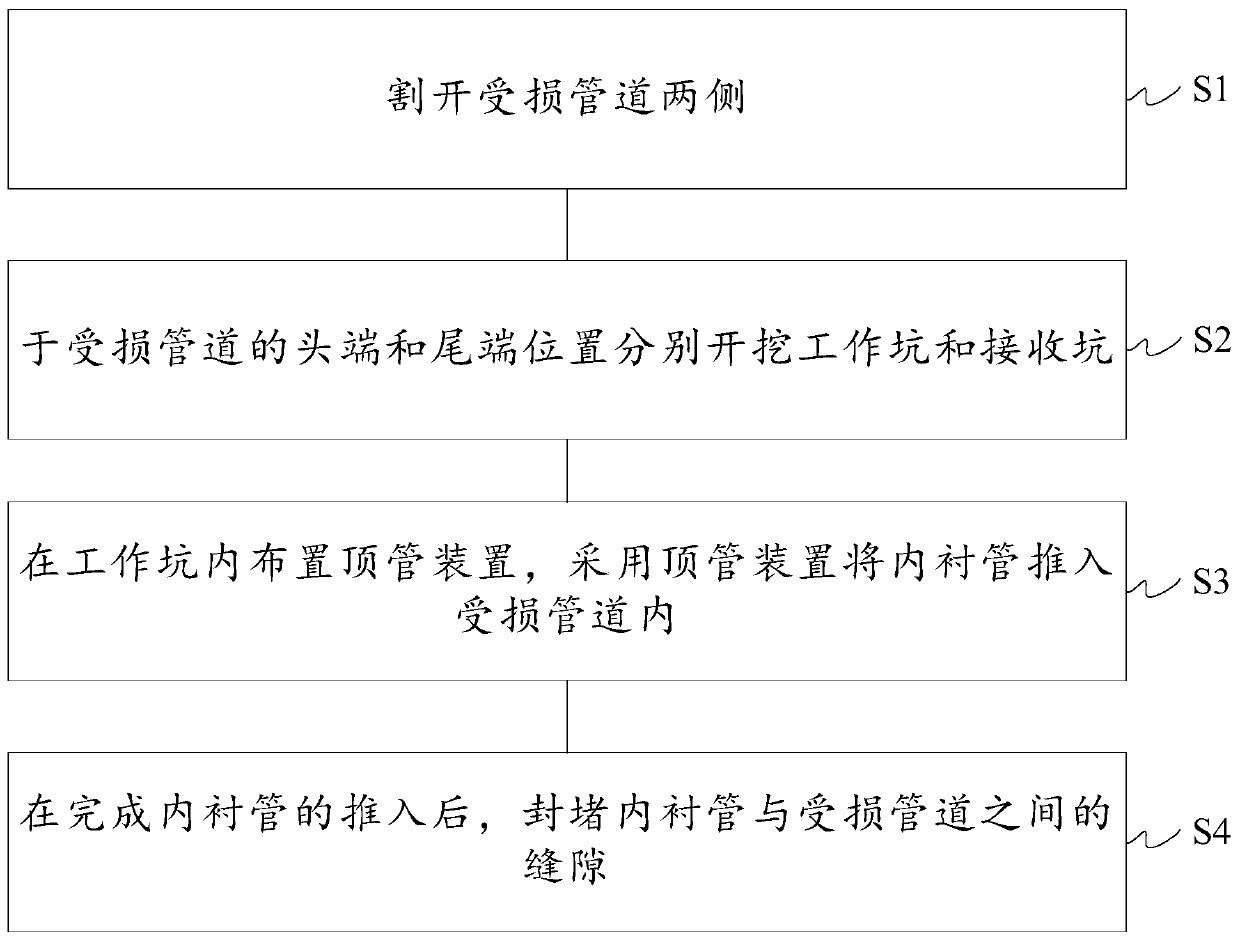

[0028] The present invention mainly provides a non-excavation large-diameter water supply pressure pipeline repair construction method, the method includes old pipe scale cleaning, lining pipe laying, pipeline connection, inspection and pressure test and other processes, and its characteristics are: the internal The laying of the liner is to penetrate the FRP sand-filled pipe and steel pipe with a diameter slightly smaller than that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com