Beam bar anchoring sleeve pre-embedded in thin wall and construction method thereof

A sleeve and anchoring technology, applied in the direction of construction and building structure, can solve the problems of inconvenient processing technology, high cost input, complicated construction, etc., and achieve the effects of mature construction technology, improved construction efficiency and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

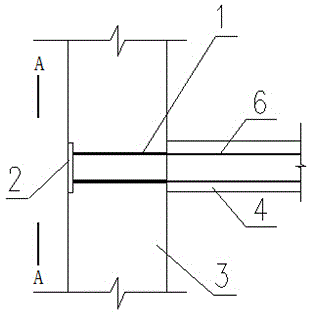

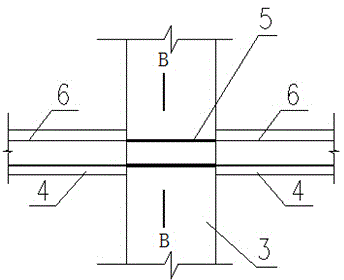

[0039] see Figure 1-5 and Figure 7 , in an embodiment of the present invention, a beam anchoring sleeve reserved in thin walls in advance, including a single-sided threaded sleeve 1 and two-sided threaded sleeves 5, one side of the single-sided threaded sleeve 1 An anchoring end plate 2 is provided, and the length of the single-sided threaded sleeve 1 plus the thickness of the anchoring end plate 2 is the same as the thickness of the thin concrete wall 3, wherein the anchoring end plate 2 is located on the other side of the thin concrete wall 3 opposite to the concrete beam 4, and the two sides The side threaded sleeve 5 is located in the thin concrete wall 3 , and its length is the same as the thickness of the thin concrete wall 3 . The inner diameter of the one-side threaded sleeve 1 and the two-sides threaded sleeve 5 is the same as the diameter of the main reinforcement 6 of the concrete beam. The material of the threaded sleeve 1 on one side and the threaded sleeve 5 ...

Embodiment 2

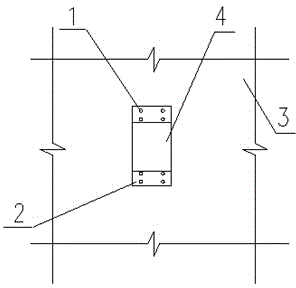

[0048] see Figure 6 , a beam anchoring sleeve reserved in thin walls in advance, the number of single-sided threaded sleeves 1 on the anchoring end plate 2 is multiple, and the distance between the single-sided threaded sleeves 1 is based on the current correlation As determined by the specification, the rest are the same as in Embodiment 1.

[0049]The construction method of the beam reinforcement anchor sleeve reserved in advance in the thin wall, the steps are as follows:

[0050] Step 1, binding the steel bars of the thin concrete wall 3 to the floor where the concrete beam 4 is located;

[0051] Step 2. According to the situation of each concrete beam 4 in this layer, determine the anchoring form of the main reinforcement 6 of the concrete beam, and weld the anchoring end plate 2 and the single-side threaded sleeve 1 into a whole in advance;

[0052] Step 3, measure and determine the position of the main reinforcement 6 of the concrete beam in each concrete beam 4, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com