Suspension cable bridge pier abutment type pre-stress anchorage

A prestressed and bridge pier technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of difficult construction of gravity anchors, large excavation of gravity anchors, and low efficiency, and shorten the construction period of anchorages. , The effect of reducing the cost of the project and reducing the cost of the anchorage project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing:

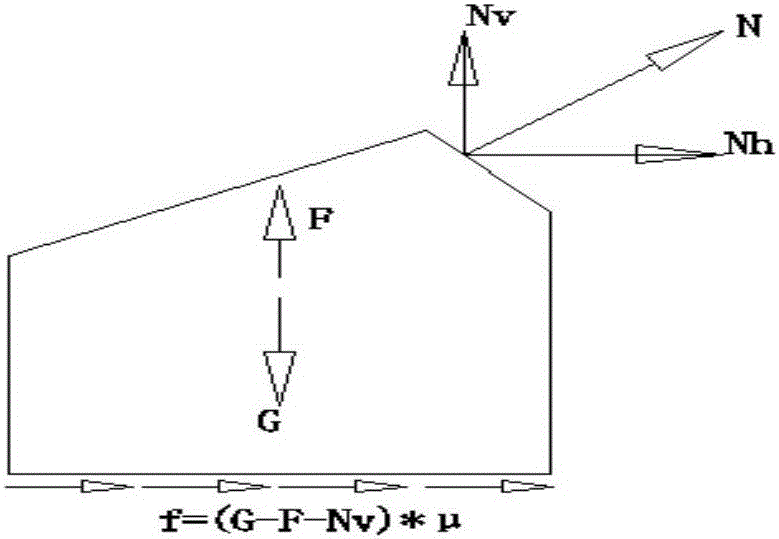

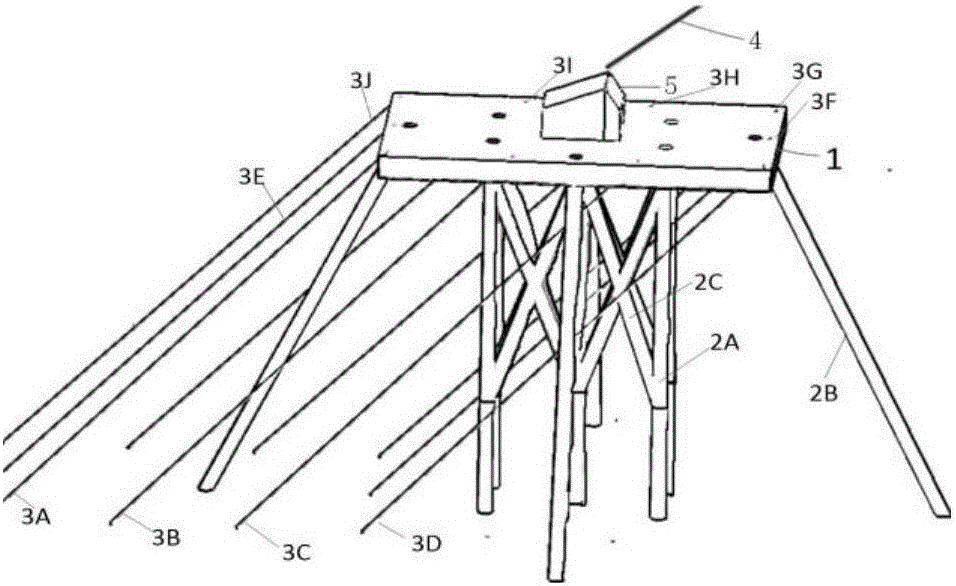

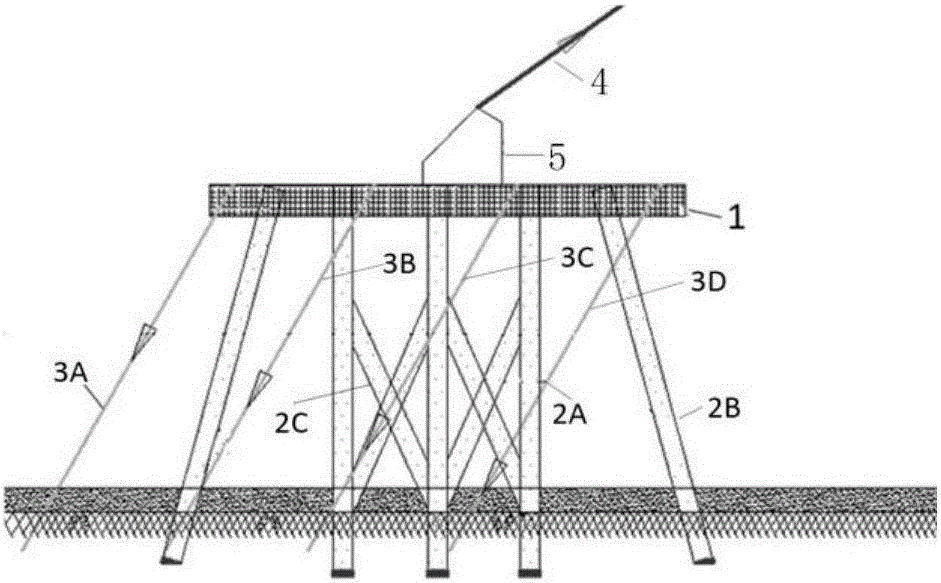

[0030] A suspension bridge pier platform prestressed anchorage, which is composed of a steel structure concrete cap 1, a steel pipe pile group 2, a prestressed anchor cable group 3, a main cable 4, and a main cable anchorage system 5. It is characterized in that: the steel pipe pile group 2 is composed of a steel pipe pile group vertical pile 2A and a steel pipe pile group inclined pile 2B, and the steel pipe pile group vertical pile 2A is composed of 8 or 13 or 18 steel pipes with a diameter of 2m; The steel pipe pile group inclined pile 2B is composed of 4 or 6 or 8 steel pipes with a diameter of 2m and an inclination angle of 5° or 10° or 15°; one end of the steel pipe pile group vertical pile 2A and the steel pipe pile group inclined pile 2B Extending into the bedrock, the other end of the vertical pile 2A of the steel pipe pile group and the inclined pile 2B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com