A surface-modified composite active al 2 o 3 -The preparation method of zno carrier spherical particles

A technology of surface modification and spherical particles, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems that activated alumina is not suitable and the adsorption capacity is not as good as activated carbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

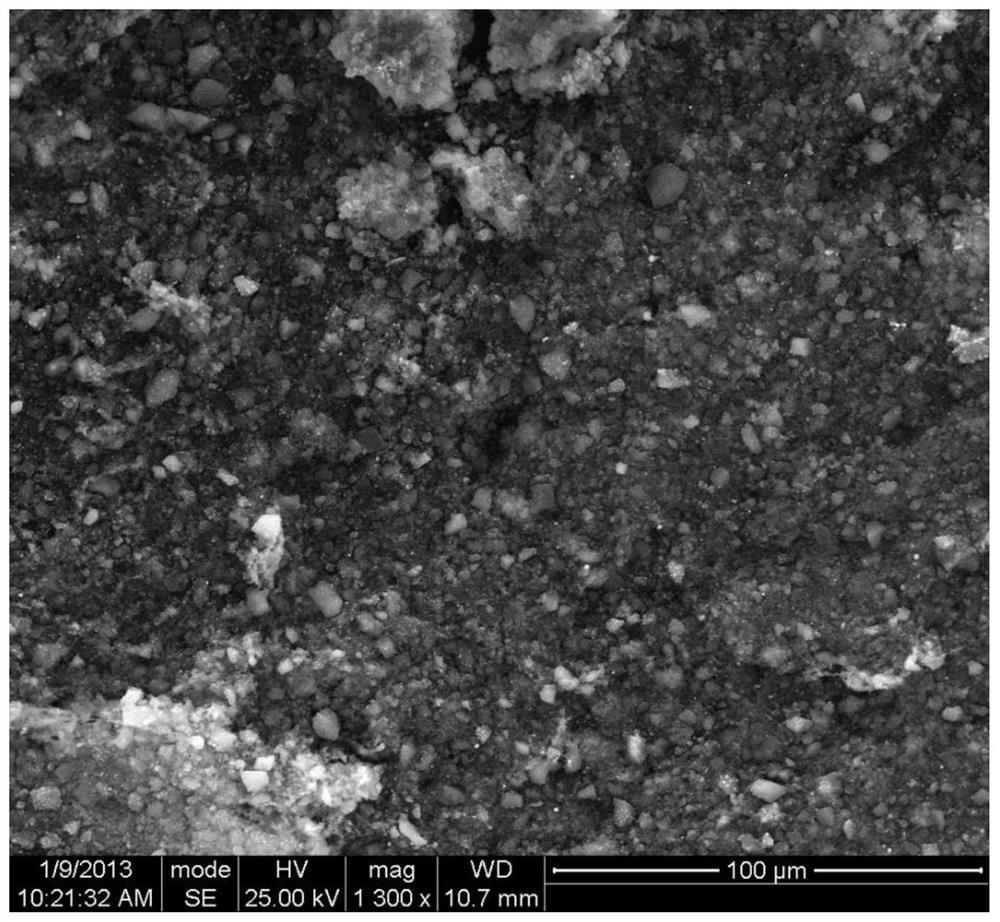

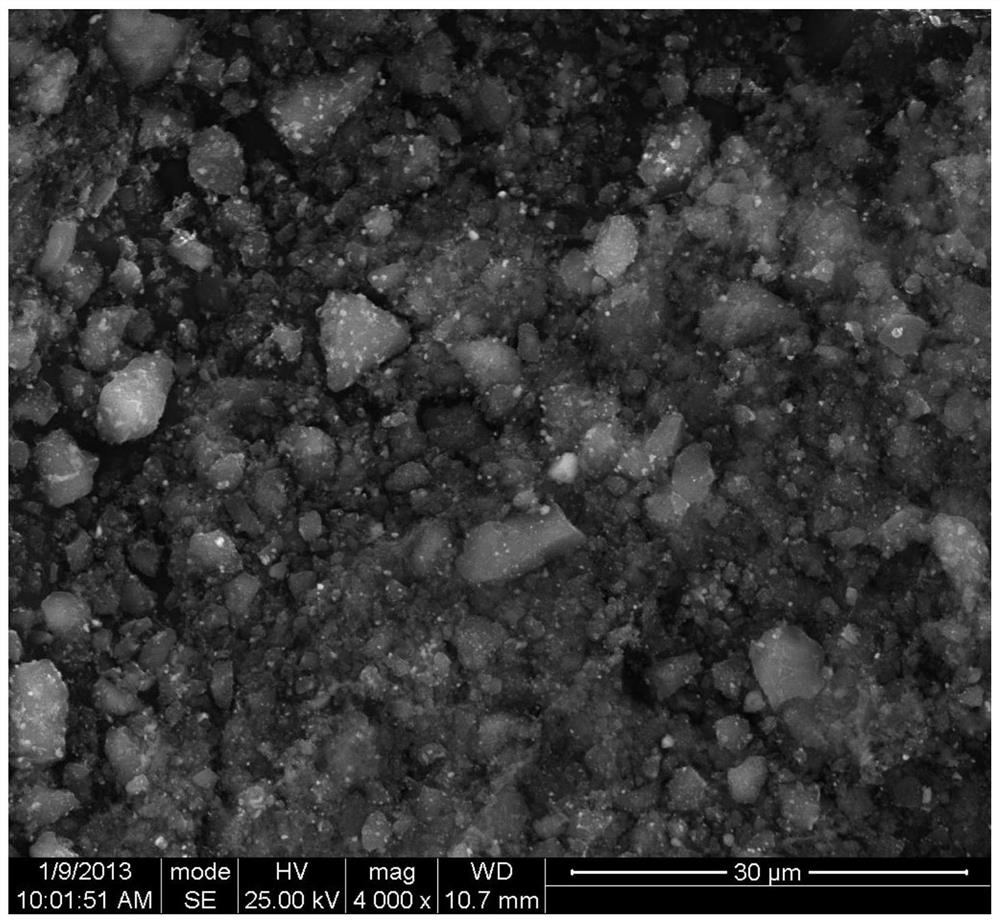

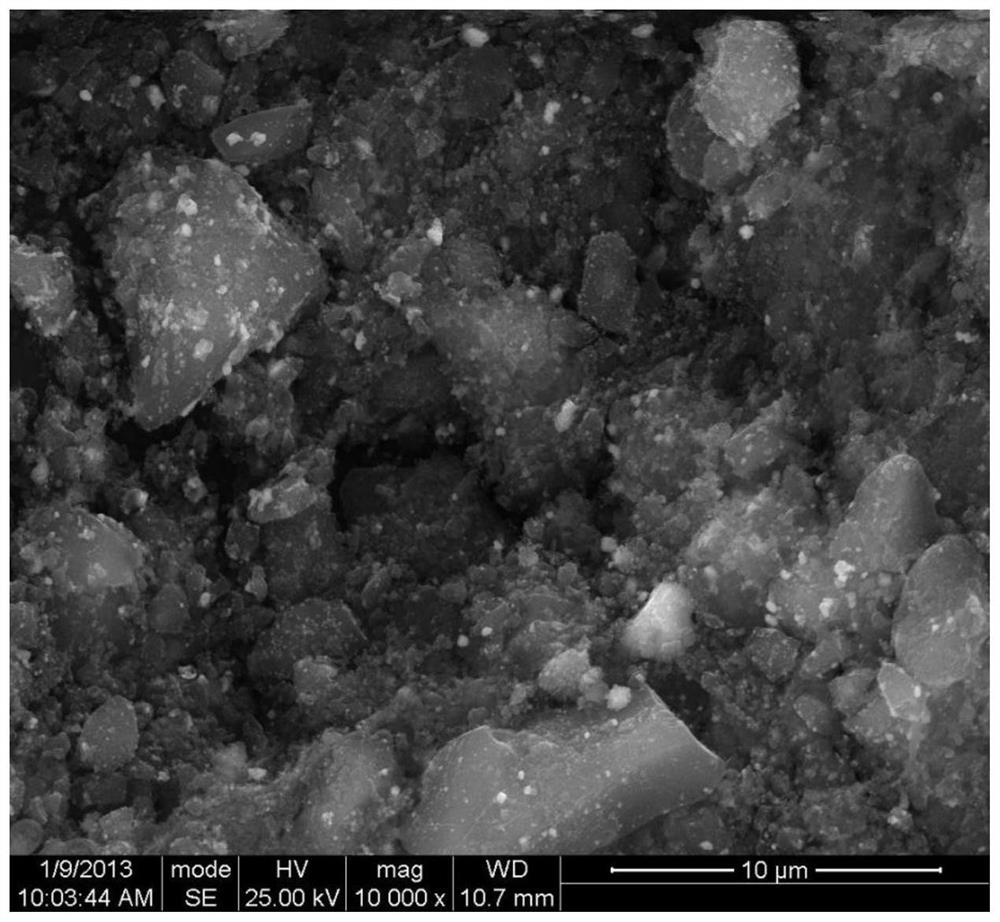

Image

Examples

Embodiment 1

[0032] ① Ball mill the active aluminum oxide that meets the standard to an average particle size of 0.8-1.0 μm to obtain alumina micropowder; ball-mill qualified zinc oxide to an average particle size of 1-1.5 μm to obtain zinc oxide micropowder; mix sodium bicarbonate , silver nitrate and carboxymethyl cellulose are mixed, and ball milled to an average particle size of 0.8-1.0 μm to obtain binder powder;

[0033] ② Mix the three micropowders prepared in step ① in a powder disperser and spray or extrude granules. After granulation, sieve out 5.0-7.0mm particles, and then press 130-150Mpa in an autoclave to form. Then put it into the mixed gas of ethanol, carbon dioxide and water vapor for fumigation for 3 to 4 hours for passivation;

[0034] ③ Activate and modify the particles obtained in step ② in a tunnel kiln at a temperature of 350°C-450°C, a heating rate of 35°C-40°C / h, keep warm for 2.5-3.5 hours, and obtain composite active particles after cooling.

[0035] The mass of...

Embodiment 2

[0040] ① Ball mill the active aluminum oxide that meets the standard to an average particle size of 0.8-1.0 μm to obtain alumina micropowder; ball-mill qualified zinc oxide to an average particle size of 1-1.5 μm to obtain zinc oxide micropowder; mix sodium bicarbonate , silver nitrate and carboxymethyl cellulose are mixed, and ball milled to an average particle size of 0.8-1.0 μm to obtain binder powder;

[0041] ② Mix the three micropowders prepared in step 1 in a powder disperser and spray or extrude to granulate. After granulation, sieve out 5.0-7.0mm particles, and then press 130-150Mpa in an autoclave to form. Then put it into ethanol, carbon dioxide and water vapor for fumigation for 3 to 4 hours for passivation;

[0042] ③ Activate and modify the particles in step ② in a tunnel kiln at a temperature of 350°C-450°C, a heating rate of 35°C-40°C / h, keep warm for 2.5-3.5 hours, and obtain composite active particles after cooling.

[0043] The mass of each component in ste...

Embodiment 3

[0048] ① Ball mill the active aluminum oxide that meets the standard to an average particle size of 0.8-1.0 μm to obtain alumina micropowder; ball-mill qualified zinc oxide to an average particle size of 1-1.5 μm to obtain zinc oxide micropowder; mix sodium bicarbonate , silver nitrate and carboxymethyl cellulose are mixed, and ball milled to an average particle size of 0.8-1.0 μm to obtain binder powder;

[0049] ②Mix the three micropowders prepared in step ① in a powder disperser and spray or extrude to granulate. After granulation, sieve out 5.0-7.0mm particles, and then press 130-150Mpa in an autoclave to form. Then put it into ethanol, carbon dioxide and water vapor for fumigation for 3 to 4 hours for passivation;

[0050] ③The particles in step ② are activated and modified in a tunnel kiln, the activation temperature is 350°C-450°C, the heating rate is 35°C-40°C / h, the temperature is kept for 2.5-3.5 hours, and the composite active particles are obtained after cooling. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com