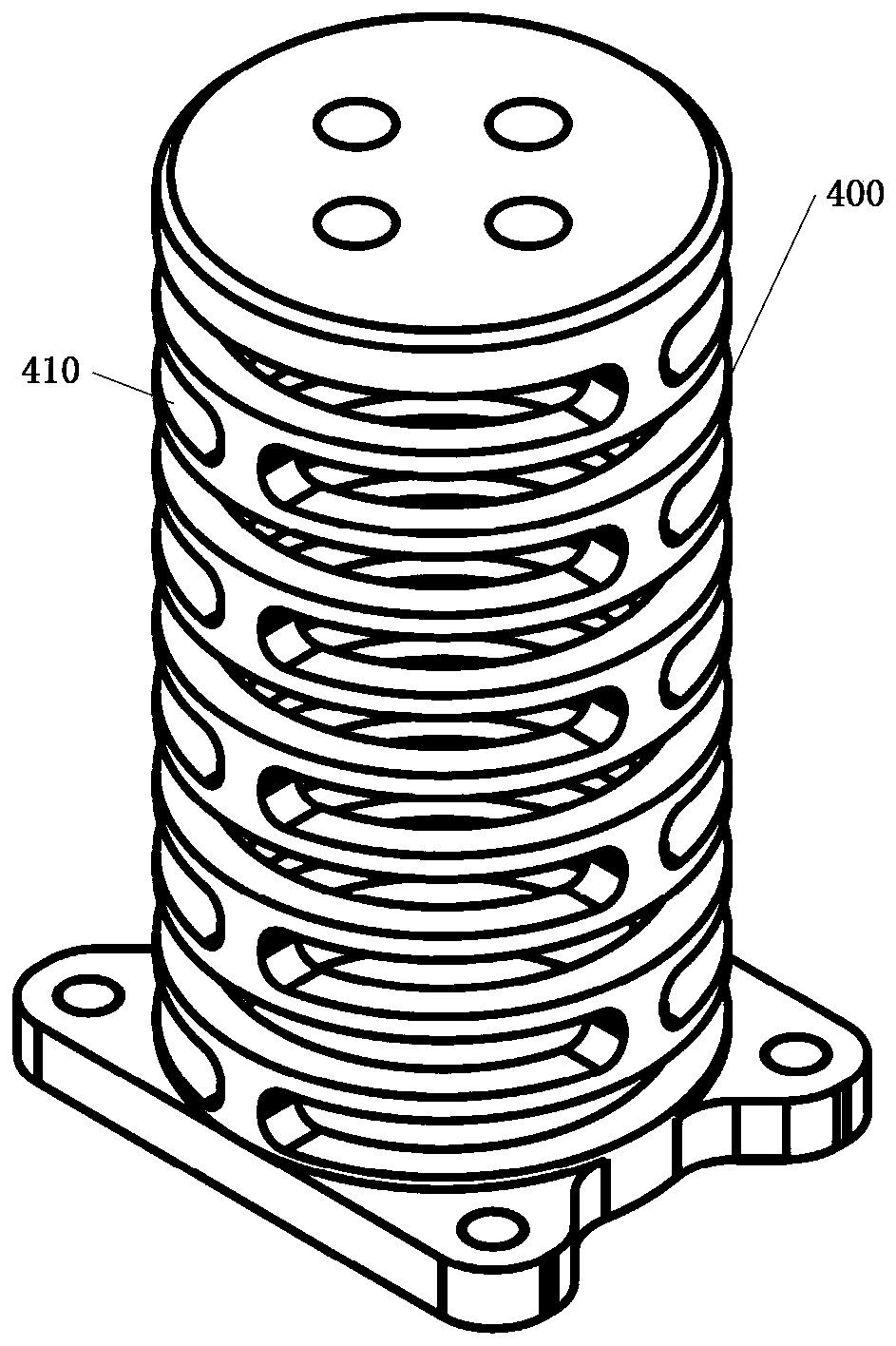

A flexible fitting

An adaptive device and flexible technology, applied in the direction of shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of extra space occupation, reduced static bearing capacity, reduced diameter, etc., to achieve flexible distribution, compact structure, The effect of high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention proposes a flexible adapting device, which is described in detail in conjunction with embodiments and drawings as follows:

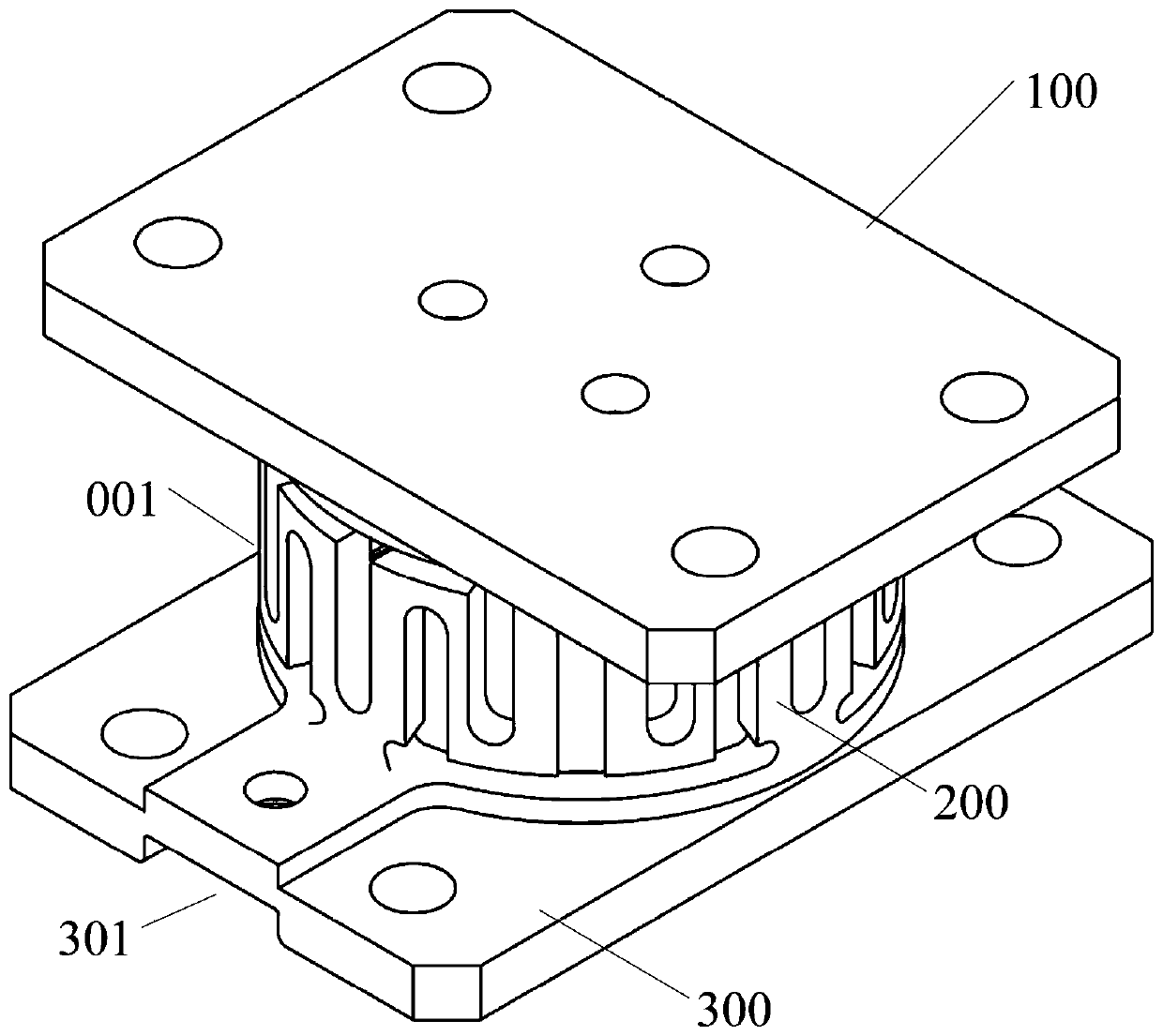

[0024] The overall structure of the flexible adapter device in this embodiment is as follows: figure 2 As shown, the flexible adapter device 001 includes an upper installation connection structure 100, a slotted circular pipe structure 200, and a lower installation connection structure 300. The device adopts bearing steel or titanium alloy to be processed by turning, milling, pliers and wire cutting. , an integral structure; wherein the upper installation connection structure 100 and the lower installation connection structure 300 are respectively located at the upper and lower ends of the slotted circular pipe structure 200 .

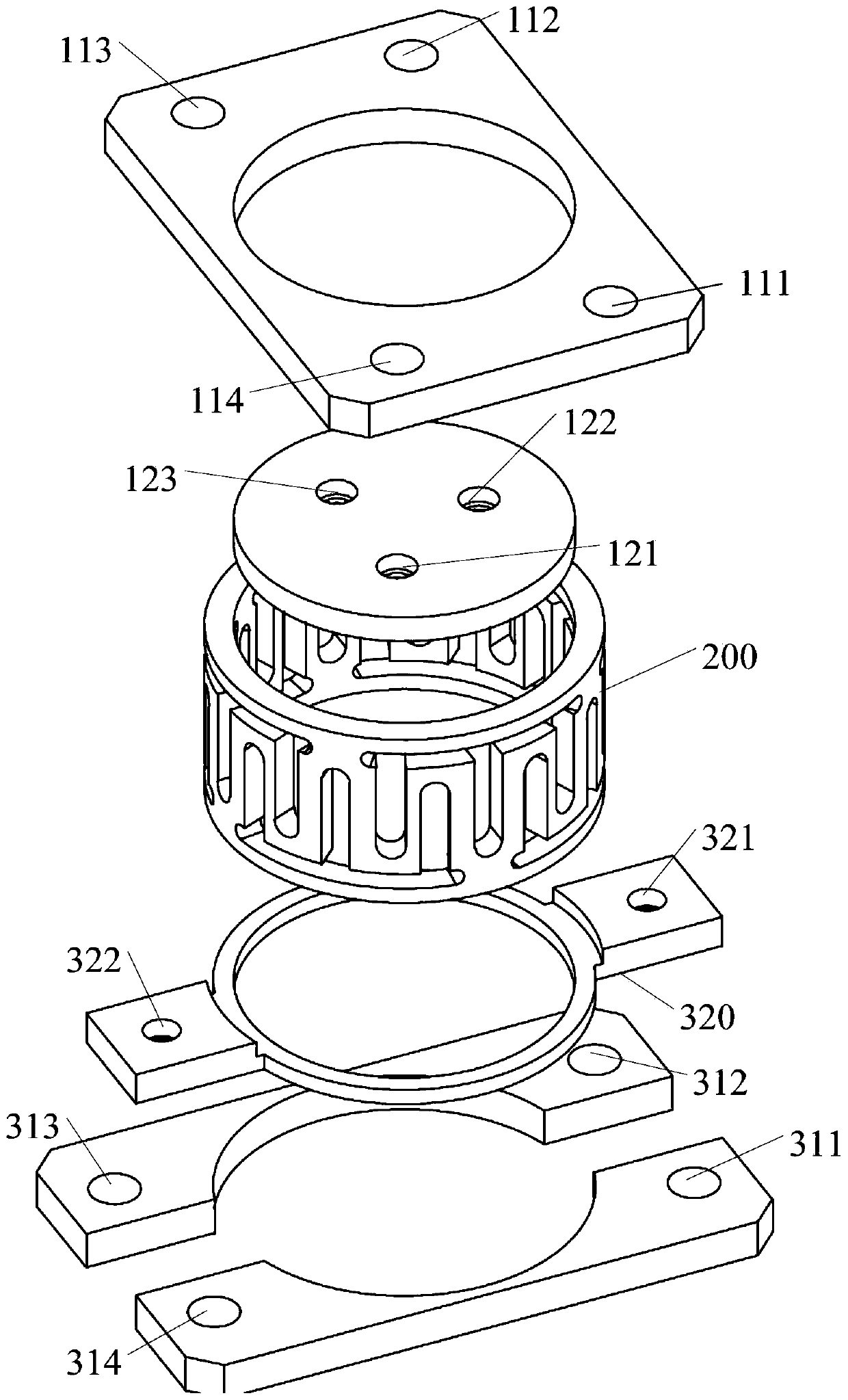

[0025] For an exploded view of the flexible fitting device of this embodiment, see image 3 On the wall of the slotted round pipe 200, grooves are made along the axial direction and the circumferent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com