Hub made of light carbon fiber composite material

A technology of composite materials and carbon fiber, which is applied in the direction of wheels, non-metallic materials, wheels, rims, etc., can solve the problems of heavy wheel materials and high production costs of carbon fiber wheels, so as to improve structural strength, overcome production difficulties, and improve use. Effects on Lifetime and Structural Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

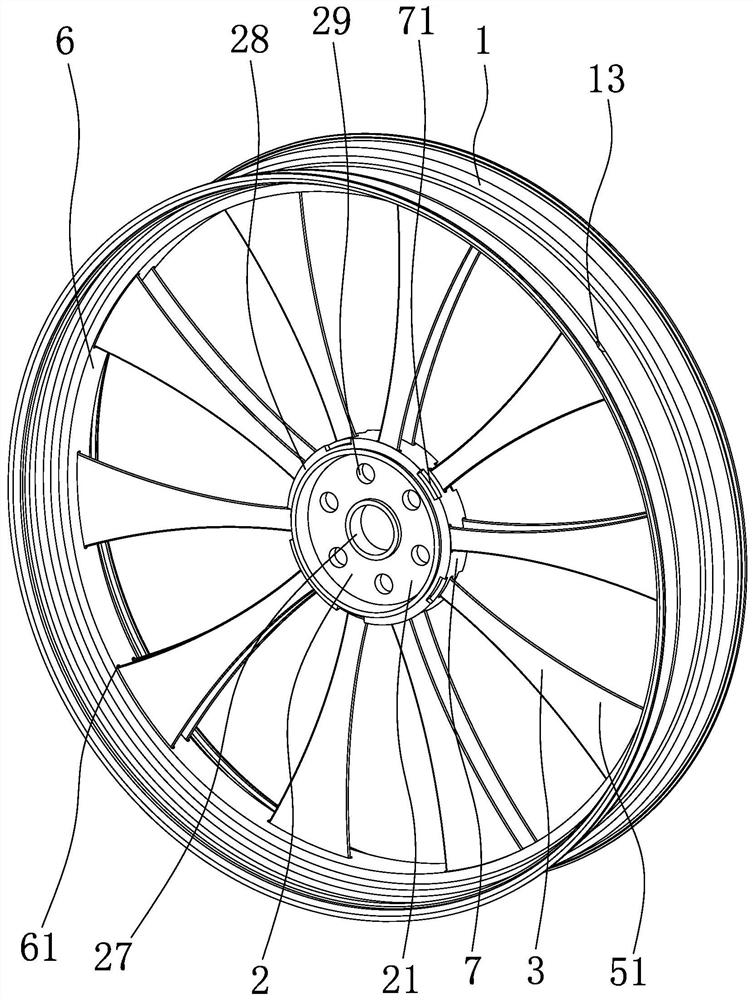

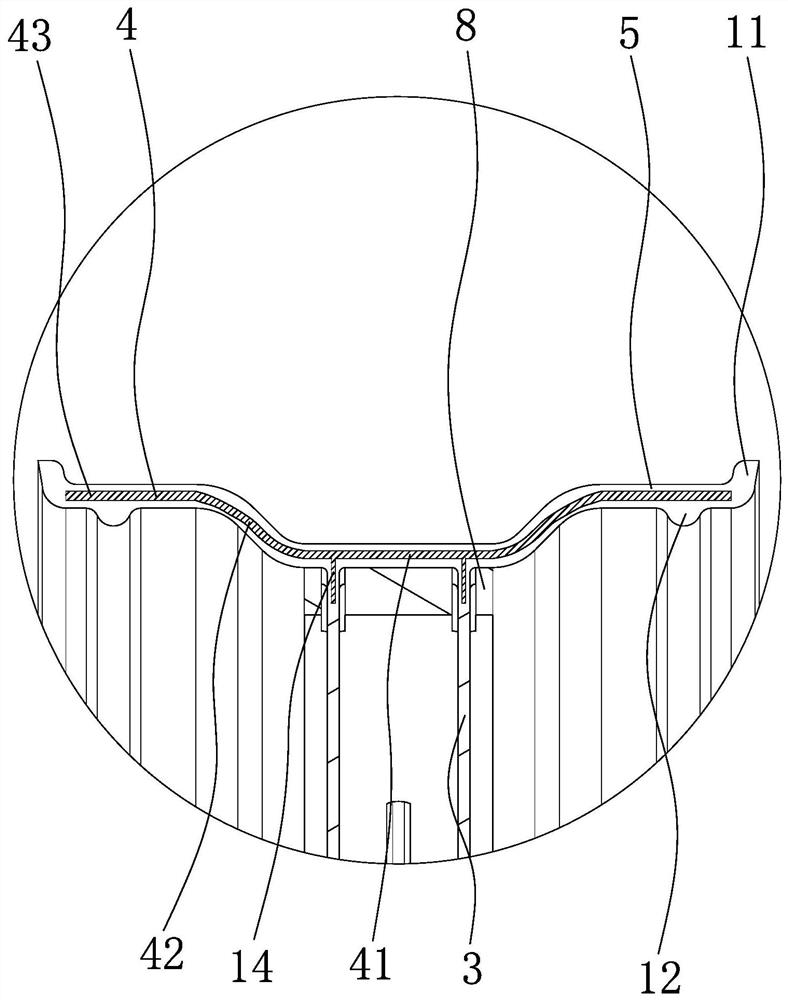

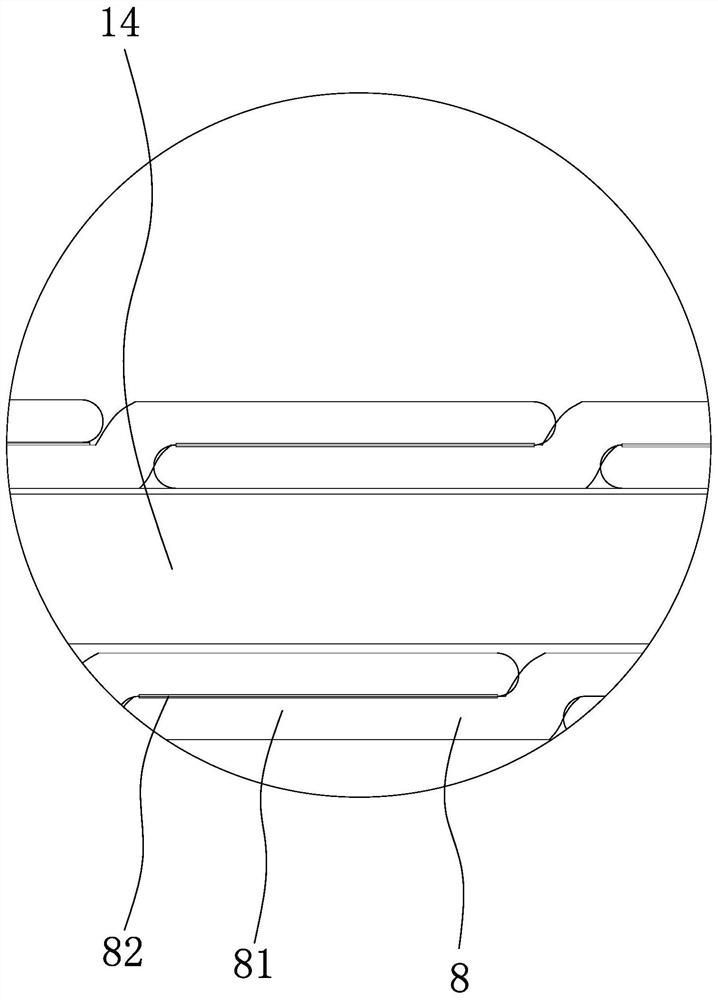

[0036] Such as Figure 6-7 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference is that the spokes 3 in this embodiment are made of aluminum alloy and are connected with the inner layer 4 of the rim 1 and the axle mounting seat 2. In one piece, the spokes 3 are arranged symmetrically with respect to the center of the axle mount 2 , and honeycomb-shaped through holes 31 are distributed on the spokes 3 . Aluminum alloy spokes 3, axle mounts 2 and the inner layer 4 of the rim 1 are used as the basic skeleton, and the outer layer 5 of the rim 1 is still made of carbon fiber composite material, which further reduces the production cost, and adopts a honeycomb structure to greatly reduce the weight of the rim 1 Weight, to meet the lightweight requirements of the wheel hub.

[0037] To sum up, the principle of this embodiment is that the sheet-like spokes 3 facilitate the processing and molding of carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com