Efficient energy-saving evaporator connecting pipe assembly and manufacturing method thereof

A high-efficiency energy-saving, evaporator technology, applied in chemical instruments and methods, separation methods, pipes/pipe joints/fittings, etc., can solve problems affecting the use of devices, low joint strength, deformation and looseness, etc., to facilitate disassembly and installation Easy to disassemble and easy to clamp and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

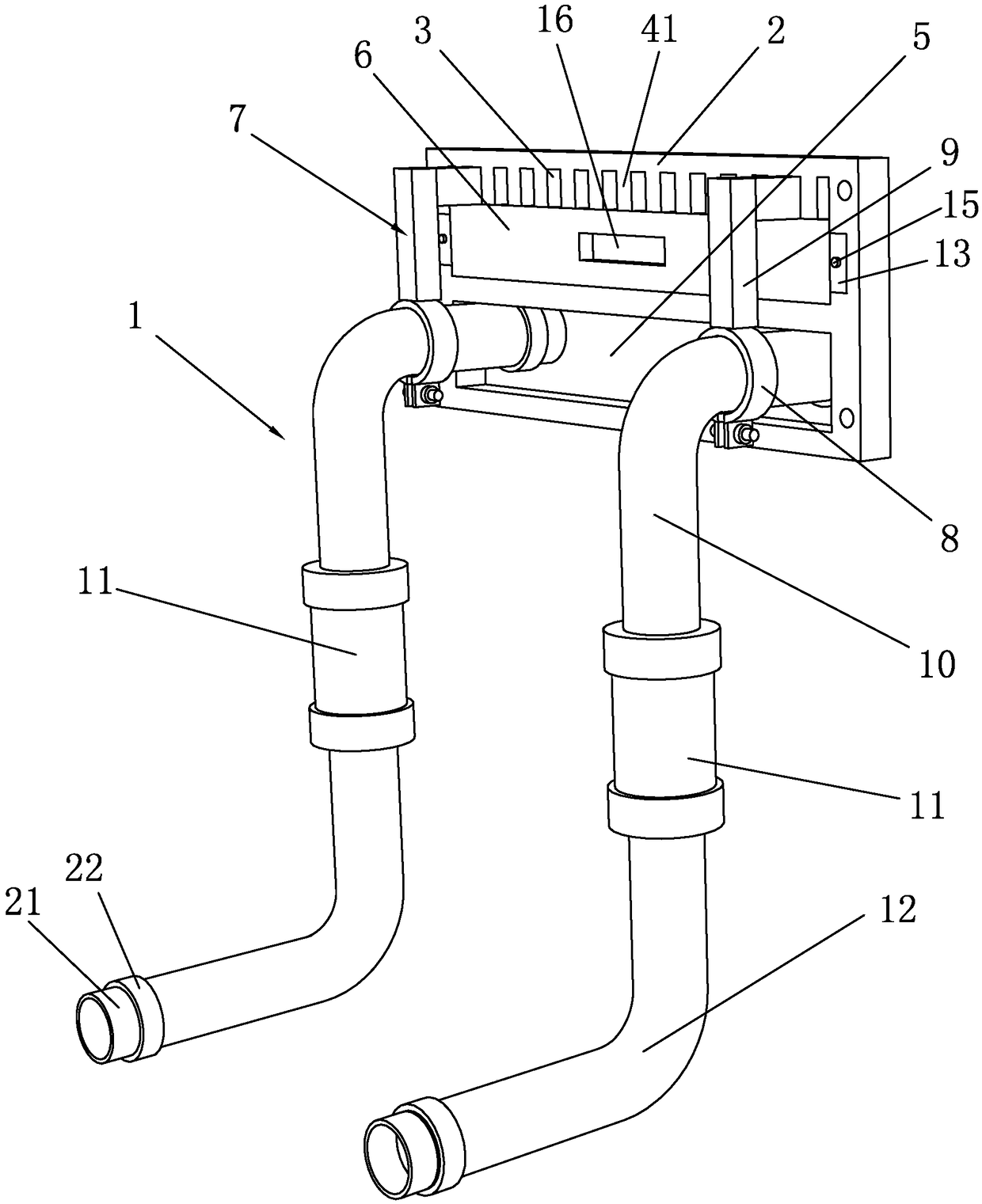

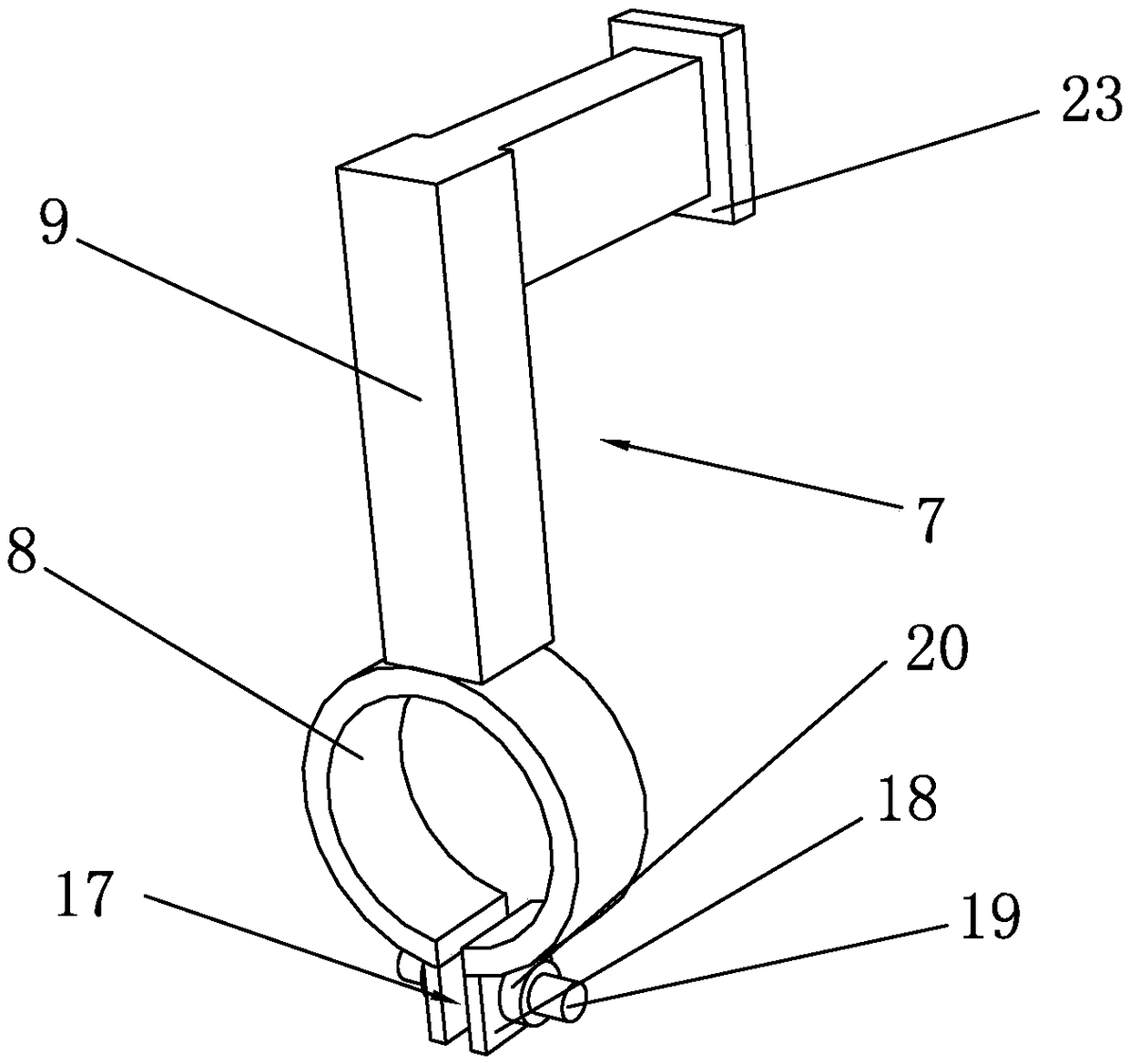

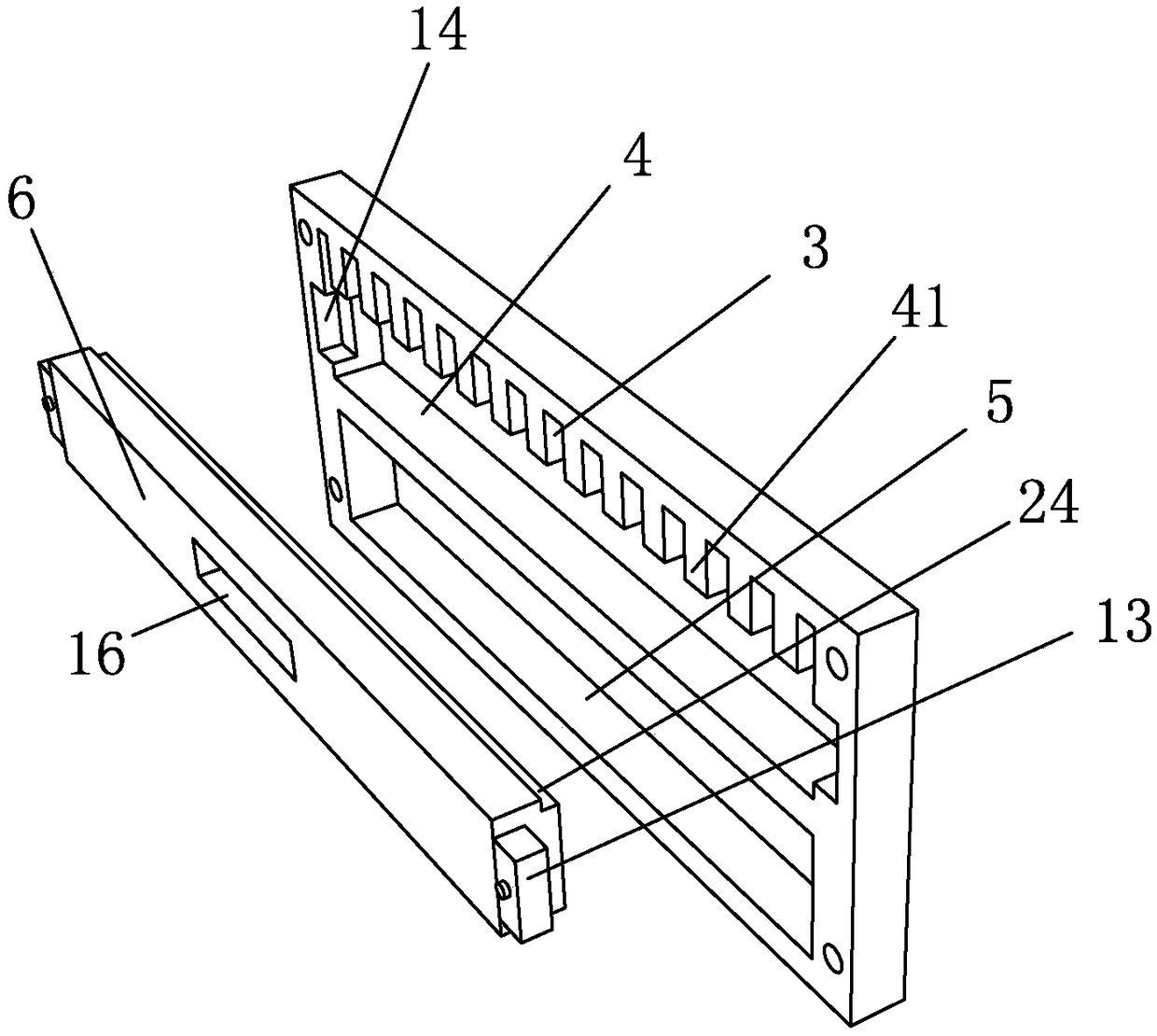

[0051] Such as Figure 1 to Figure 7 As shown, it is the connection pipe assembly of the high-efficiency energy-saving evaporator of the present invention, including the connection main pipe 1, the end of the connection main pipe 1 connected to the evaporator is provided with a reinforced pressure plate 2, and the reinforced pressure plate 2 is evenly provided with an adjustment block 41, adjacent two An adjustment groove 3 is formed between the two adjustment blocks 41, and a limit groove 4 and a clamping groove 5 are arranged on the reinforcing plate 2, the limit groove 4 communicates with the adjustment groove 3, and the limit groove 4 is clamped with a matching limit groove. Position plate 6, limit plate 6 is fixedly connected with reinforcing platen 2, both ends of limit plate 6 are provided with extension plate 13, both sides of limit groove 4 are all provided with extension groove 14, extension groove 14 and extension plate 13, the extension plate 13 is clamped in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com