Convenient-to-assemble steel structure beam-column connecting joint

A technology of beam-column connection and steel structure, which is applied in the direction of building structure and construction, can solve the problems of low joint strength and support strength, limited application of steel structure buildings, and single connection structure, so as to achieve stable and firm connection and improve Connection stability, effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

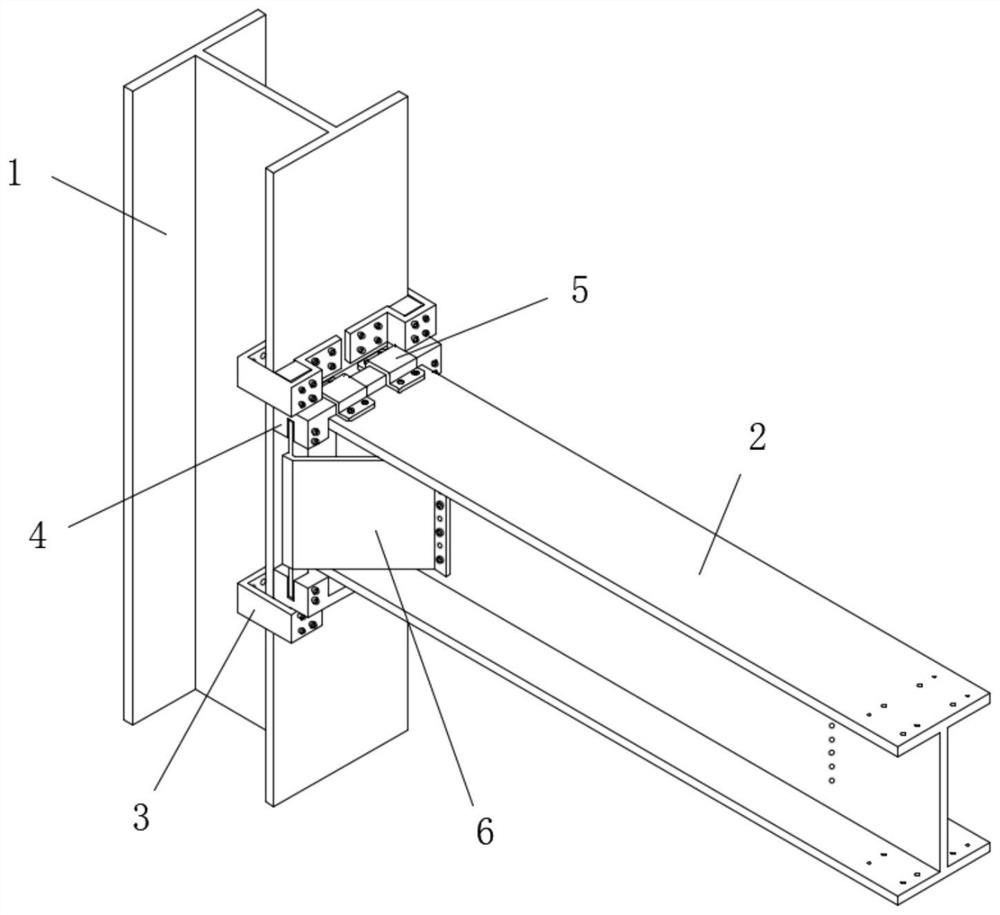

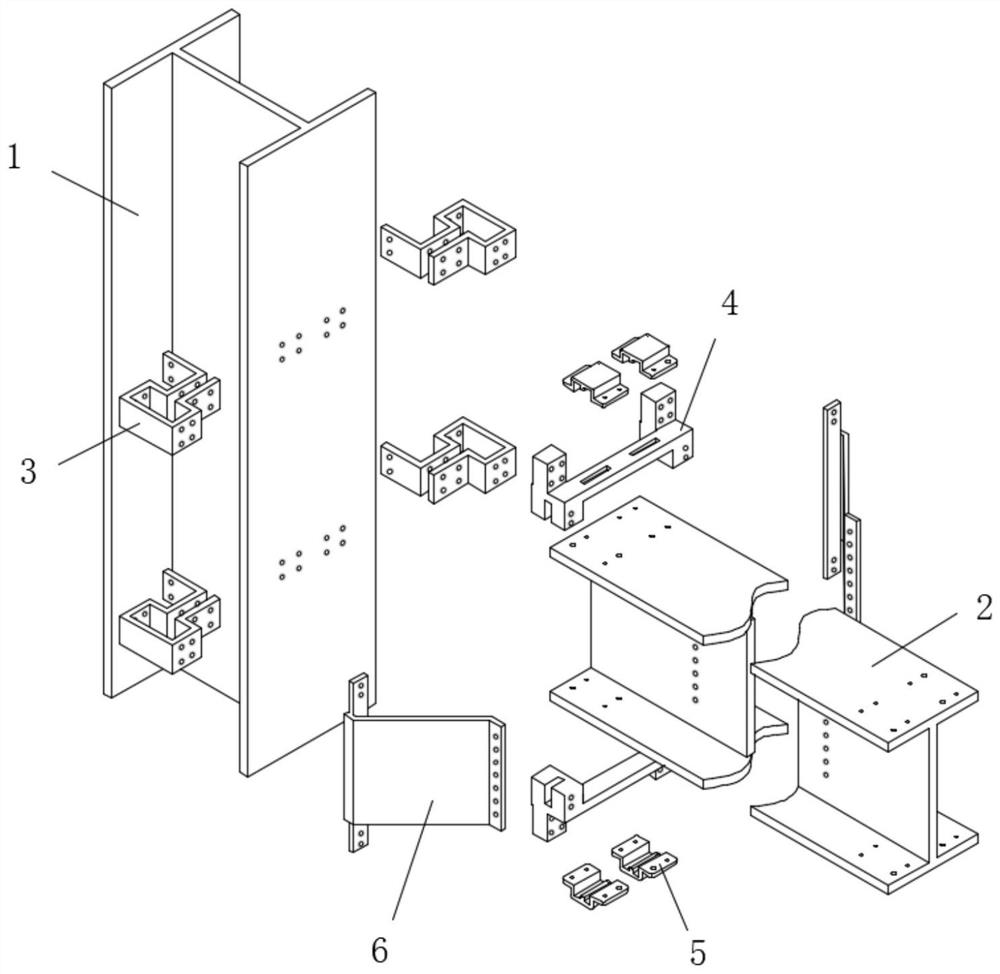

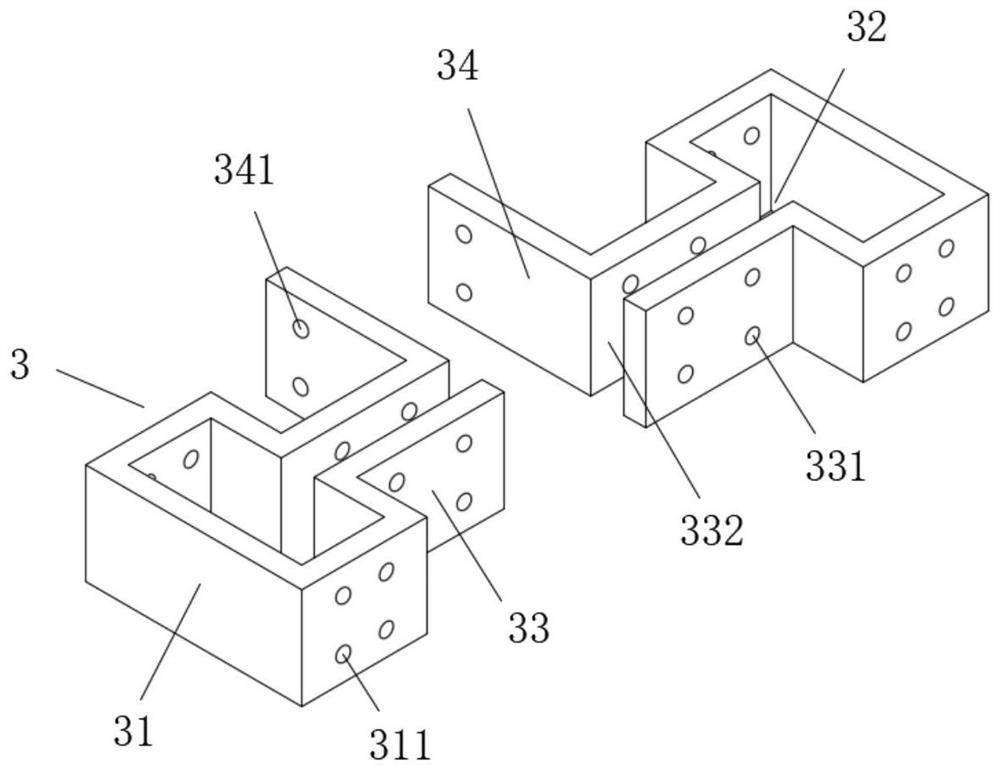

[0040] Such as Figure 1-7 As shown, a beam-to-column connection node of a steel structure that is easy to assemble includes H-shaped steel columns 1 and H-shaped steel beams 2 connected to each other. The side flange of the H-shaped steel column 1 is rectangular and symmetrically connected with four sets of support mechanisms 3 Two groups of connecting mechanisms 4 are symmetrically connected to the sides of the two flange plates of the H-shaped steel beam 2 that are far away from each other, and the two groups of connecting mechanisms 4 are respectively connected to the two groups of supporting mechanisms 3 located at the same level. The connection mechanism 4 is connected to the flange plate on one side of the H-shaped steel beam 2 through two connecting pieces 5, and the two sides of the web of the H-shaped steel beam 2 are respectively arranged between two sets of support mechanisms 3 located in the same vertical direction. There is the same set of reinforcement bodies6. ...

Embodiment 2

[0049] This embodiment is as a further improvement of the previous embodiment: as Figure 1-7 As shown, a beam-to-column connection node of a steel structure that is easy to assemble includes H-shaped steel columns 1 and H-shaped steel beams 2 connected to each other. The side flange of the H-shaped steel column 1 is rectangular and symmetrically connected with four sets of support mechanisms 3 Two groups of connecting mechanisms 4 are symmetrically connected to the sides of the two flange plates of the H-shaped steel beam 2 that are far away from each other, and the two groups of connecting mechanisms 4 are respectively connected to the two groups of supporting mechanisms 3 located at the same level. The connection mechanism 4 is connected to the flange plate on one side of the H-shaped steel beam 2 through two connecting pieces 5, and the two sides of the web of the H-shaped steel beam 2 are respectively arranged between two sets of support mechanisms 3 located in the same ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com