Patents

Literature

62results about How to "Reduce complex process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Orthopedic robot navigation device and positioning system

ActiveCN101700184BSolve the problem of errors caused by inaccurate positioningAvoid blocking interferenceProgramme-controlled manipulatorSurgical robotsEngineeringSelf positioning

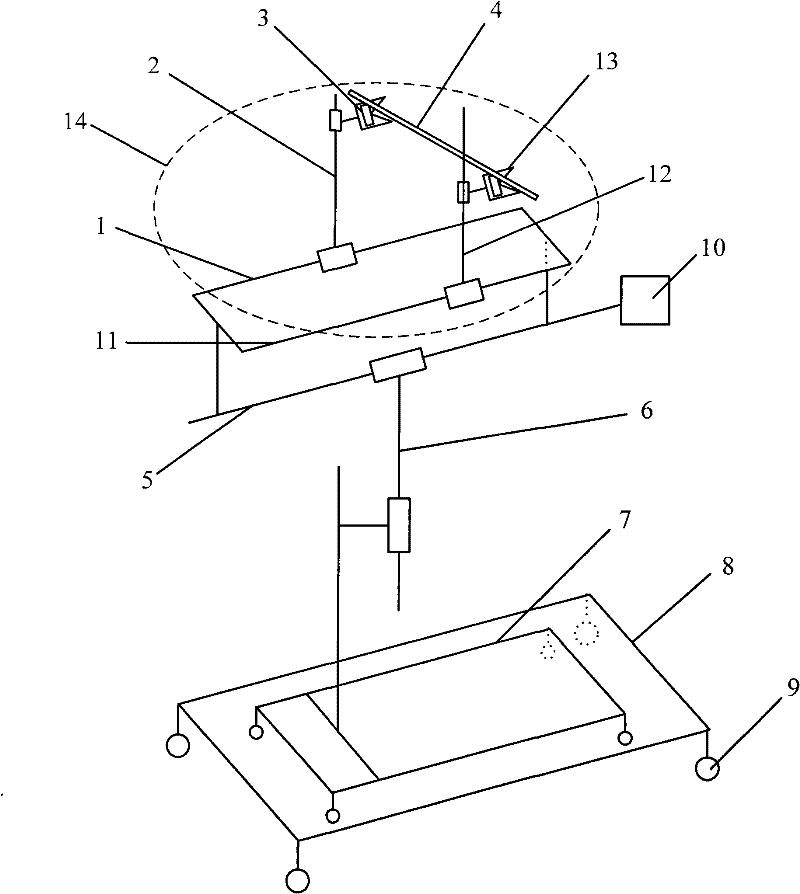

The invention relates to an orthopedic robot navigation device and a positioning system. The orthopedic robot navigation device comprises a machine seat and a four-freedom degree biplane positioning mechanism, wherein the four-freedom degree biplane positioning mechanism is arranged on the machine seat and connected with the machine seat. The four-freedom degree biplane positioning mechanism comprises a first series connection mechanical arm, a second series connection mechanical arm and a straight lever-shaped guide device, wherein the first series connection mechanical arm comprises a firsthorizontal motion assembly, a first vertical motion assembly and a first cardan joint which are connected in series; the second series connection mechanical arm comprises a second horizontal motion assembly, a second vertical motion assembly and a second cardan joint which are connected in series; both the first horizontal motion assembly and the second first horizontal motion assembly are connected with the machine seat; and the straight lever-shaped guide device realizes the self positioning by being clamped with the first cardan joint and the second cardan joint respectively. The device isarranged at the side surface of the wounded limb, realizes the accurate positioning by the straight lever-shaped guide device and is suitable for a bone fixing operation of any wounded limb part, thereby more favorably meeting the requirement of the operation.

Owner:BEIJING TINAVI MEDICAL TECH

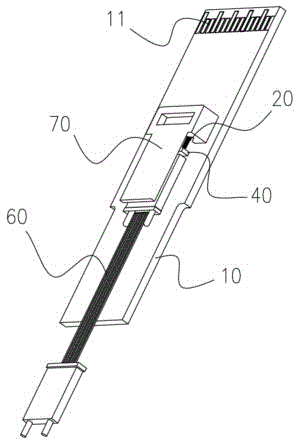

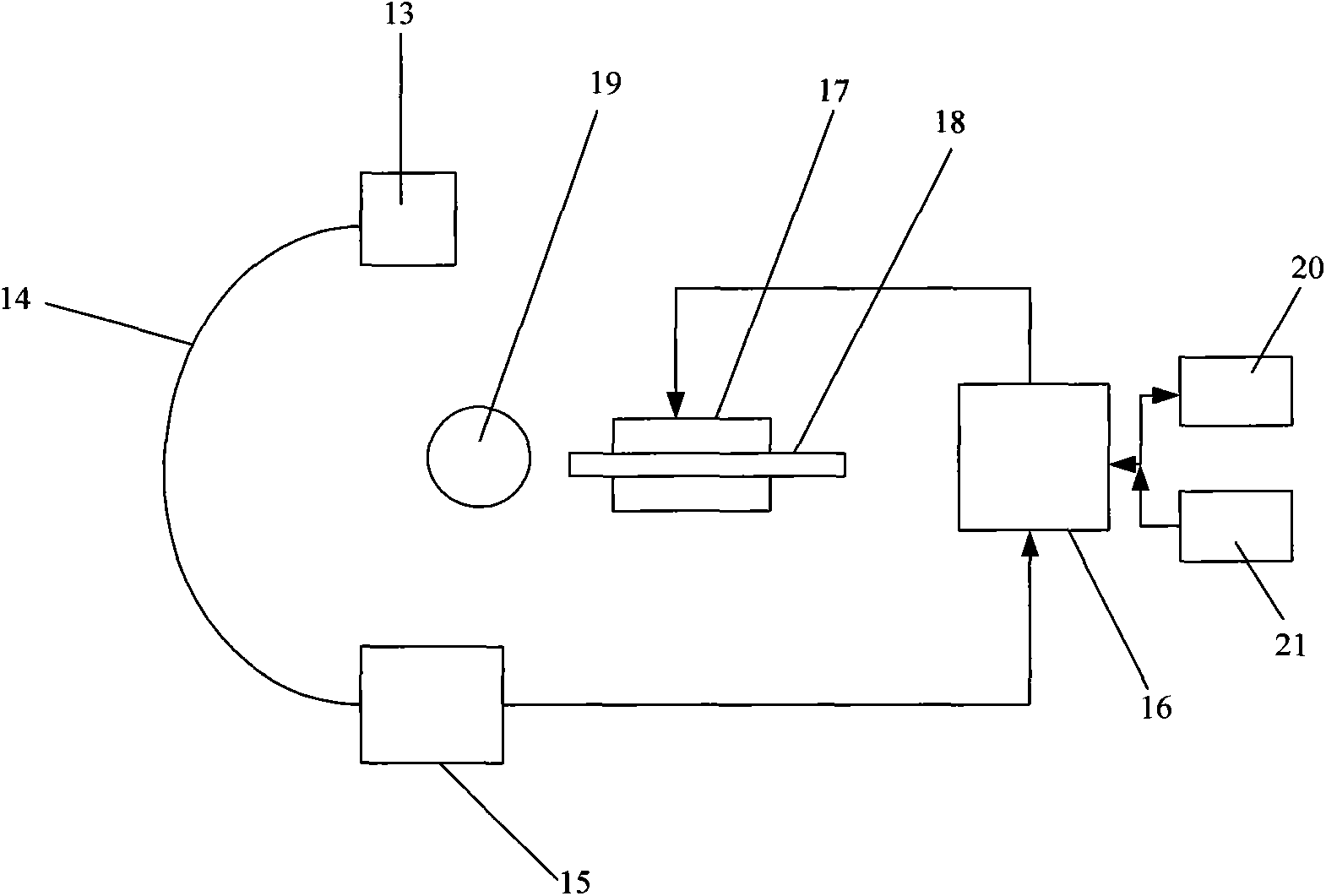

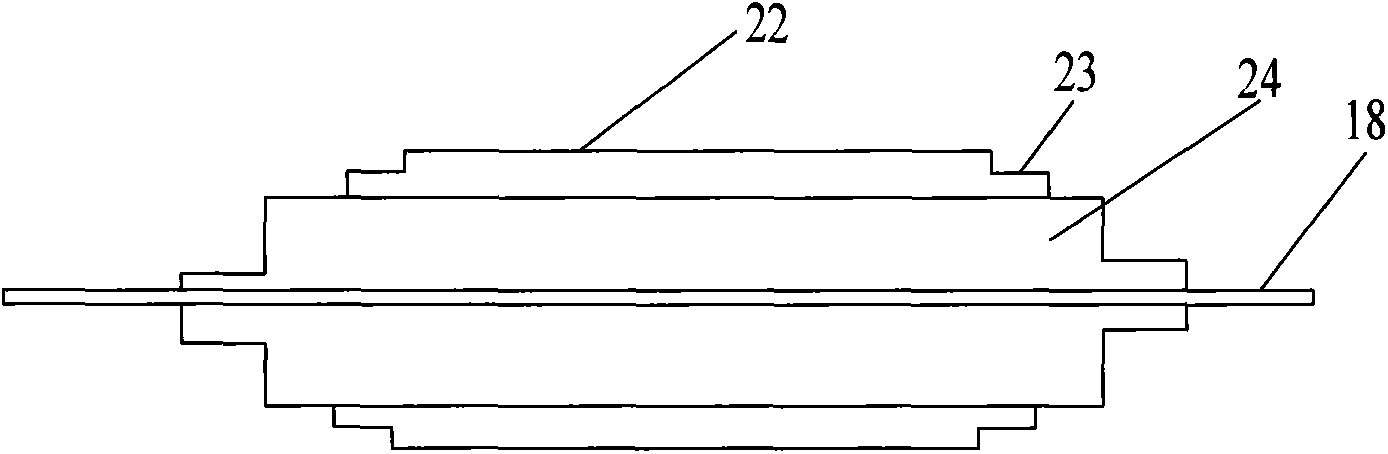

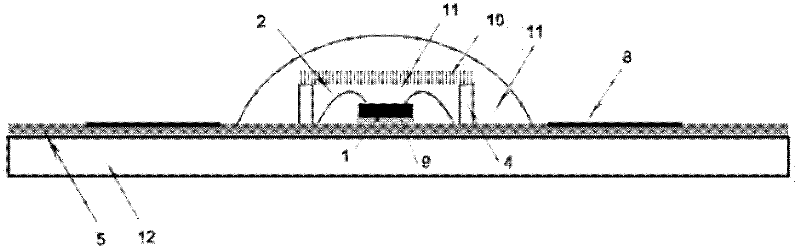

Optical interconnection assembly

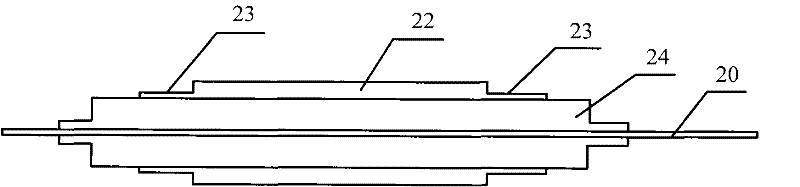

The present invention provides an optical interconnection assembly. The optical interconnection assembly comprises a PCB board, an IC chip with the PCB board as a carrier and a heat sink adhere to transition blocks and a VCSEL chip. The transition block includes a single-channel gold-plated layer and a multi-channel gold-plated layer, the single-channel gold-plated layer includes a whole top face gold-plated layer and a whole side face gold-plated layer connected with the whole top face gold-plated layer, and the multi-channel gold-plated layer includes multi-channel top face gold-plated layers which have top faces arranged at intervals and multi-channel side face gold-plated layers which are respectively connected with the multi-channel top face gold-plated layers with sides arranged at intervals; and the top of the heat sink is provided with a concave part, and when the transition blocks of the single-channel gold-plated layer or the multi-channel gold-plated layer is selected, two transitions on the range may be held, wherein the top face gold-plated layers on the transition blocks are connected with the IC chip through golden wires and the side face gold-plated layers on the transition blocks are connected with the VCSEL chip through the golden wires. According to the invention, the technical problem is solved that gold-plated layers are used for replacing a soft circuit or a lens conduction bending optical path, so that the manufacture is convenient, the cost is low and the yield of the products is improved.

Owner:WUHAN TELECOMM DEVICES

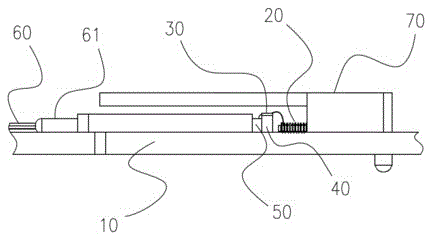

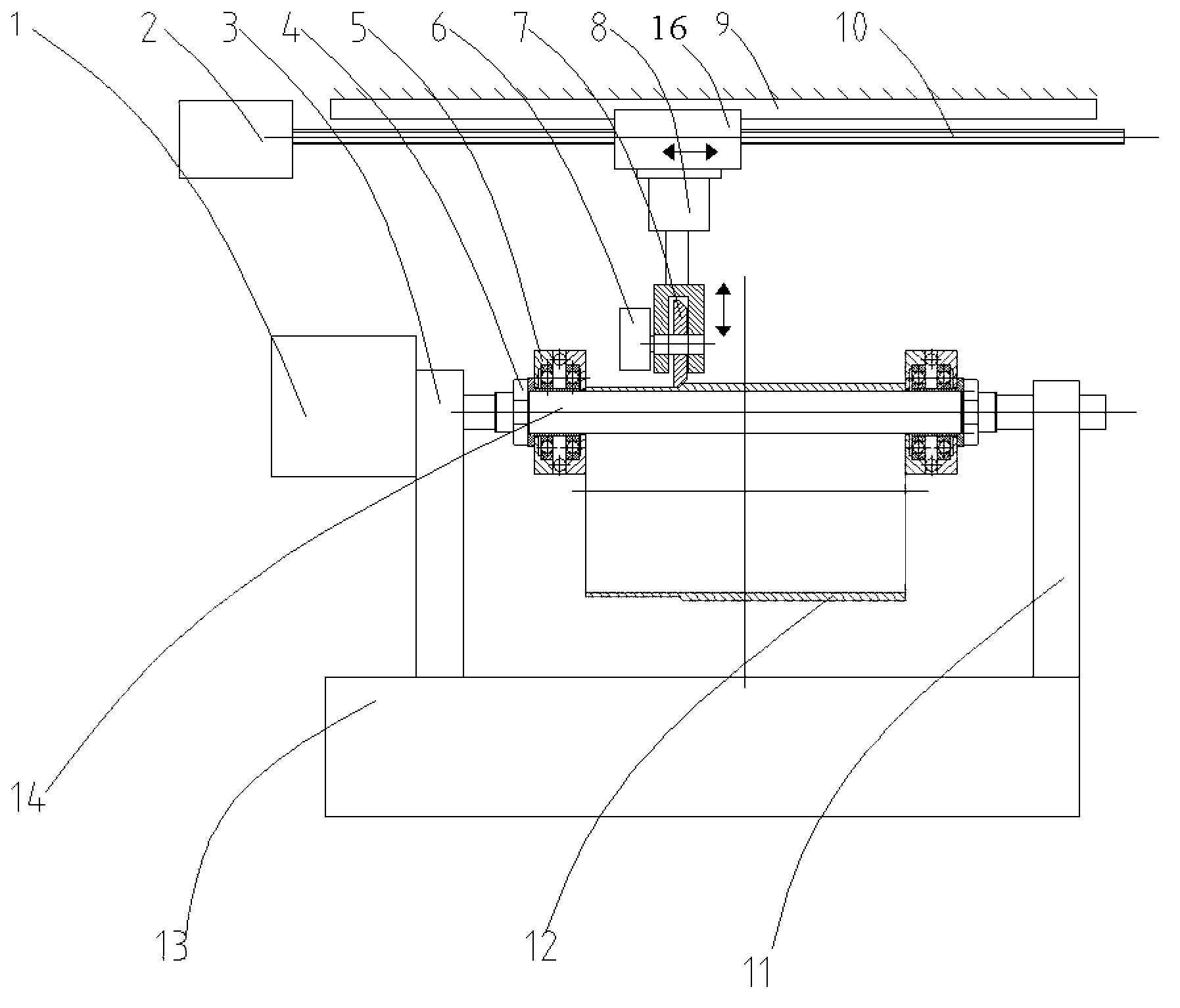

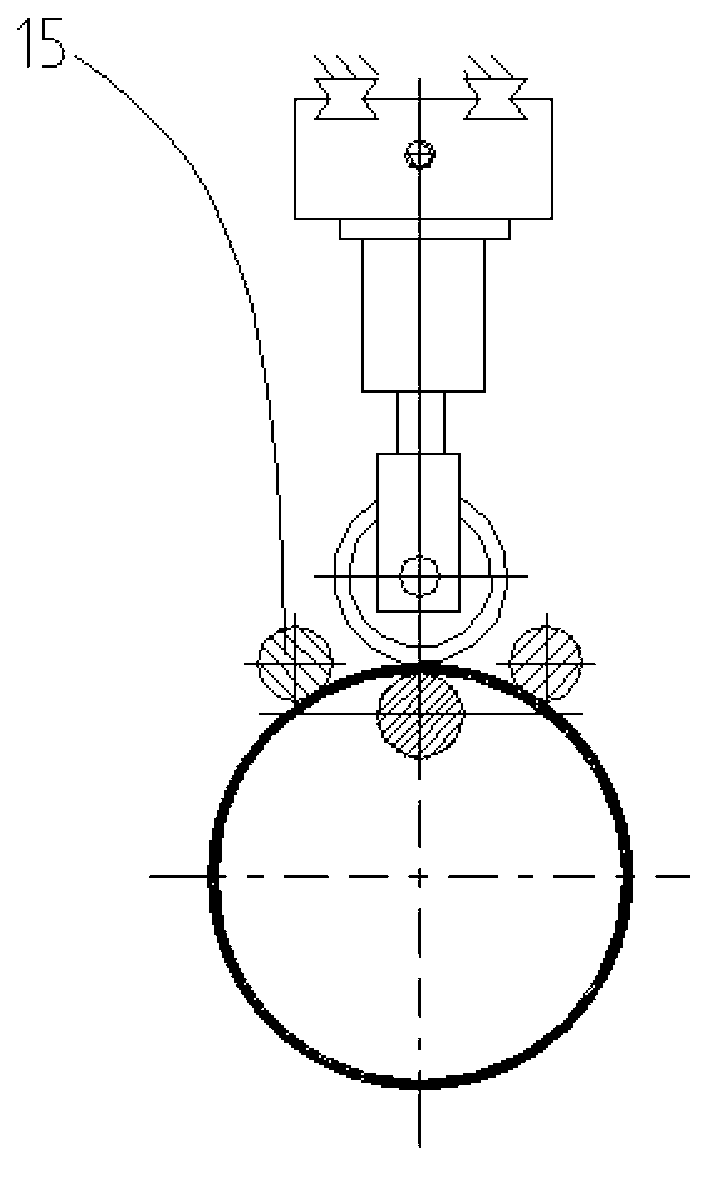

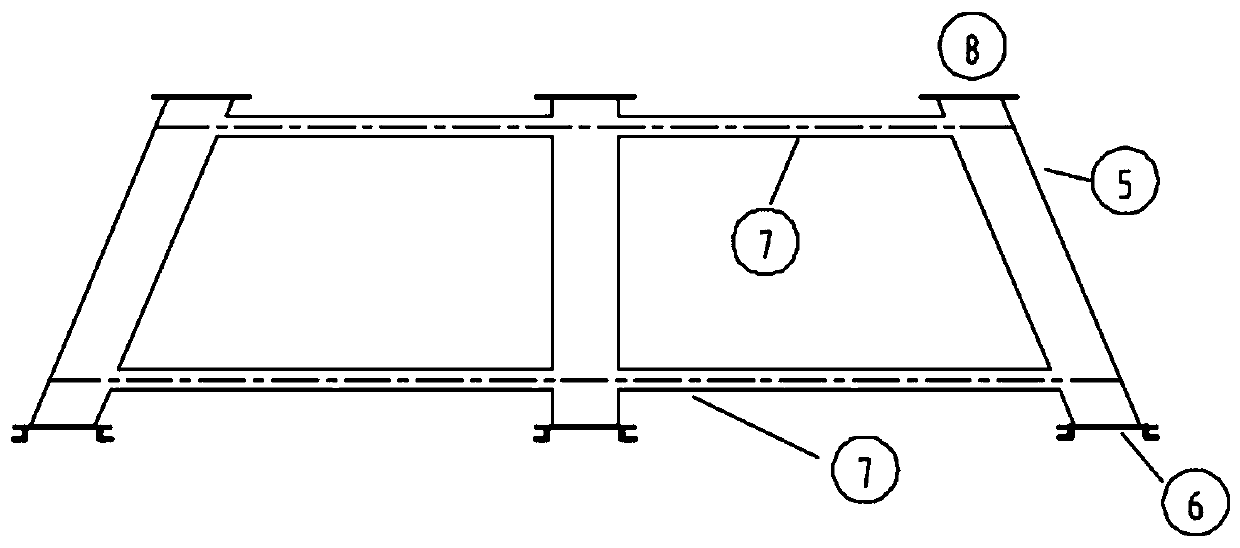

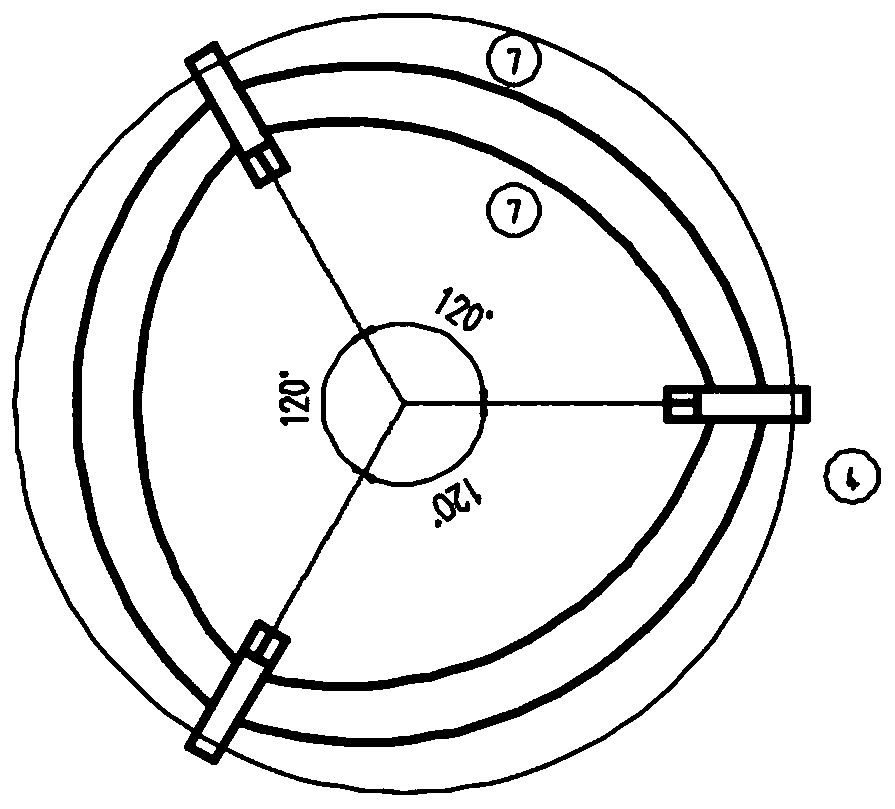

Method and device for measuring normal vector of free surface at any point

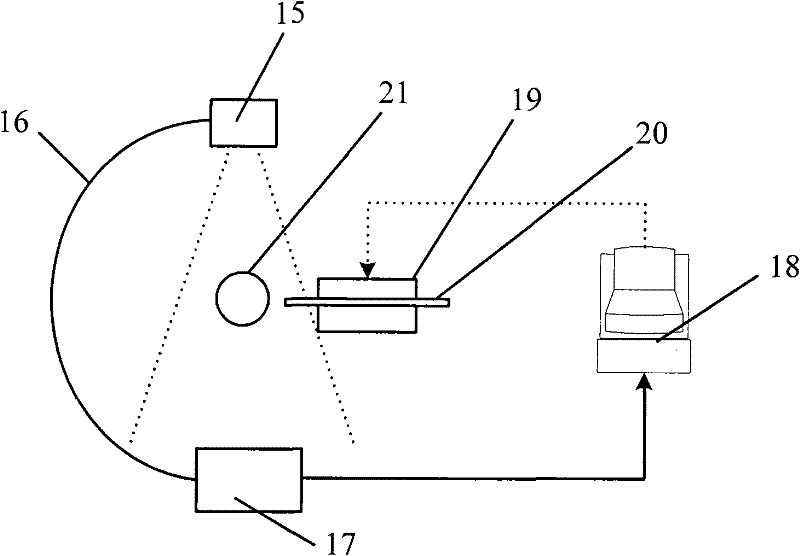

PendingCN107957234AReduce complex processSimple structureDrilling/boring measurement devicesUsing optical meansPhysicsHole making

The invention discloses a device for measuring the normal vector of a free surface at any point, including a longitudinal driving device, a longitudinal guide rail, a fixed frame, a hole making device, a longitudinal slide table, a transverse driving device, a rotating cylinder, a linear laser sensor, a transverse slide table and a transverse guide rail. The top end of the fixed frame is fixedly connected with the longitudinal driving device. The longitudinal guide rail is fixedly connected inside the fixed frame. The longitudinal guide rail is connected in a sliding manner with the matching longitudinal slide table. The hole making device is installed at the bottom end of the longitudinal slide table. The output end of the longitudinal driving device is fixedly connected with the top endof the longitudinal slide table. The bottom end of the fixed frame is fixedly connected with the transverse guide rail. The right side of the bottom end of the fixed frame is fixedly connected with the transverse driving device. The complex process of surface fitting is omitted. The problem that the precision of measurement of the normal vector will be affected when there is an interference factorsuch as a crossbeam or a step near a point to be measured for the mainstream rectangular surface patch method at present can be solved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

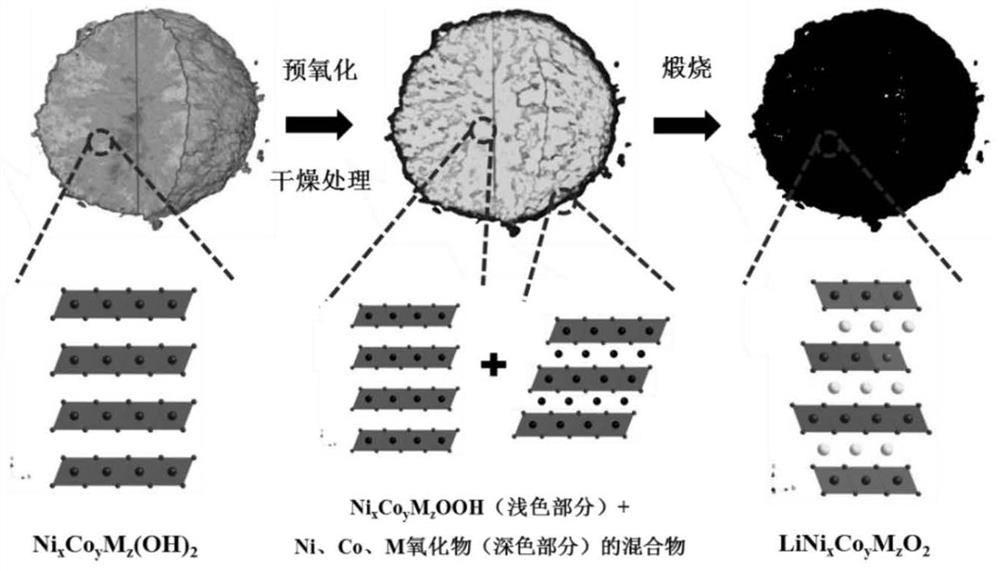

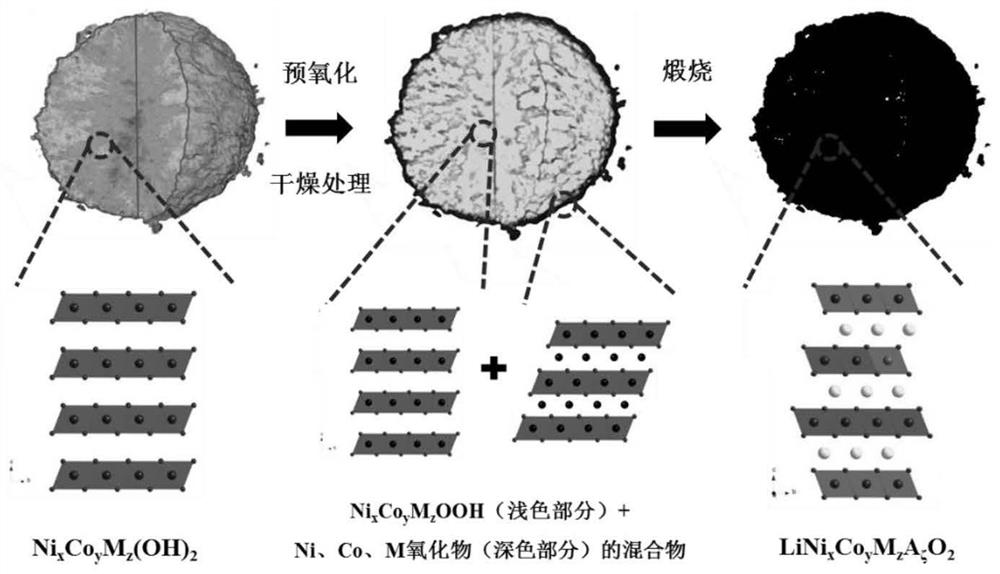

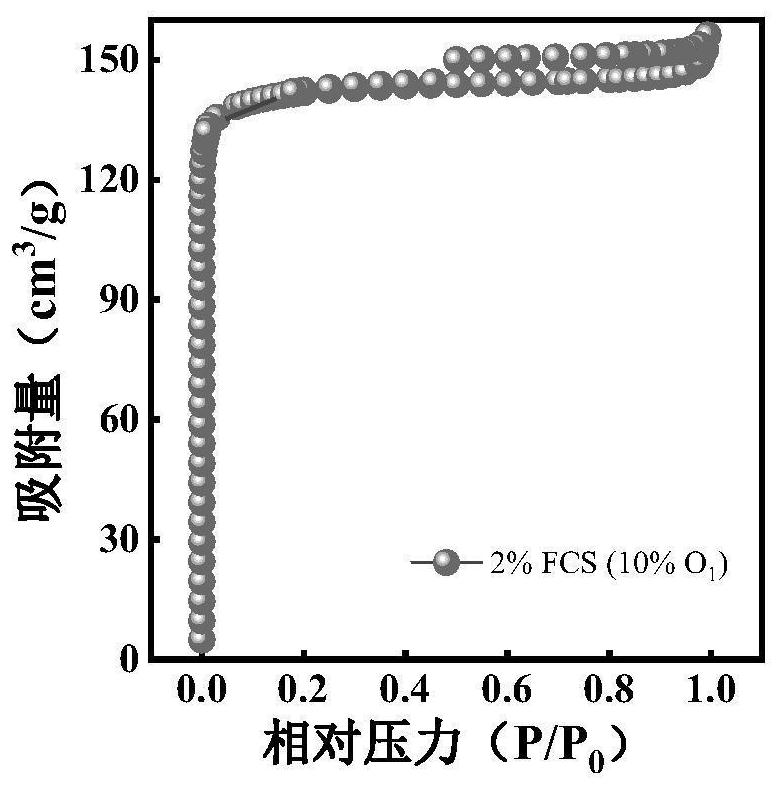

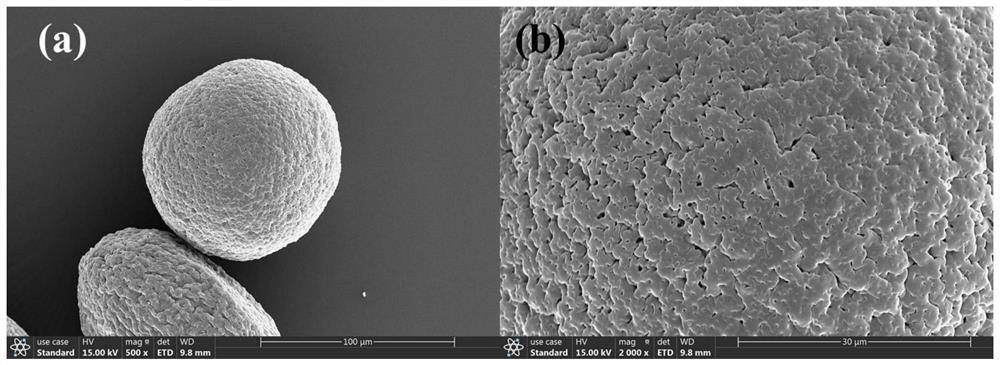

Preparation method of lithium ion battery high-nickel cathode material

ActiveCN111834631AReduce complex processNo releaseSecondary cellsPositive electrodesSlurryCrystallinity

The invention belongs to the technical field of lithium ion battery cathode materials, and specifically relates to a preparation method of a lithium ion battery high-nickel cathode material. An oxidizing agent is added into precursor alkaline slurry prepared through a coprecipitation method for precursor pre-oxidation, then the pre-oxidized precursor is converted into a polycrystalline mixture byadjusting a drying process, and then the polycrystalline mixture and a lithium source are mixed in air or a low-oxygen-concentration mixed atmosphere to be sintered at a time to obtain a target product. According to the preparation method disclosed by the invention, alkali liquor can be recycled to realize precursor pre-oxidation, the sintering time and temperature are shortened, the residual alkali value is reduced, and the crystallinity of the material is improved. In the calcining process, oxygen demand is low, safety is good, and the method is more suitable for industrial large-scale production.

Owner:WANHUA CHEM GRP CO LTD

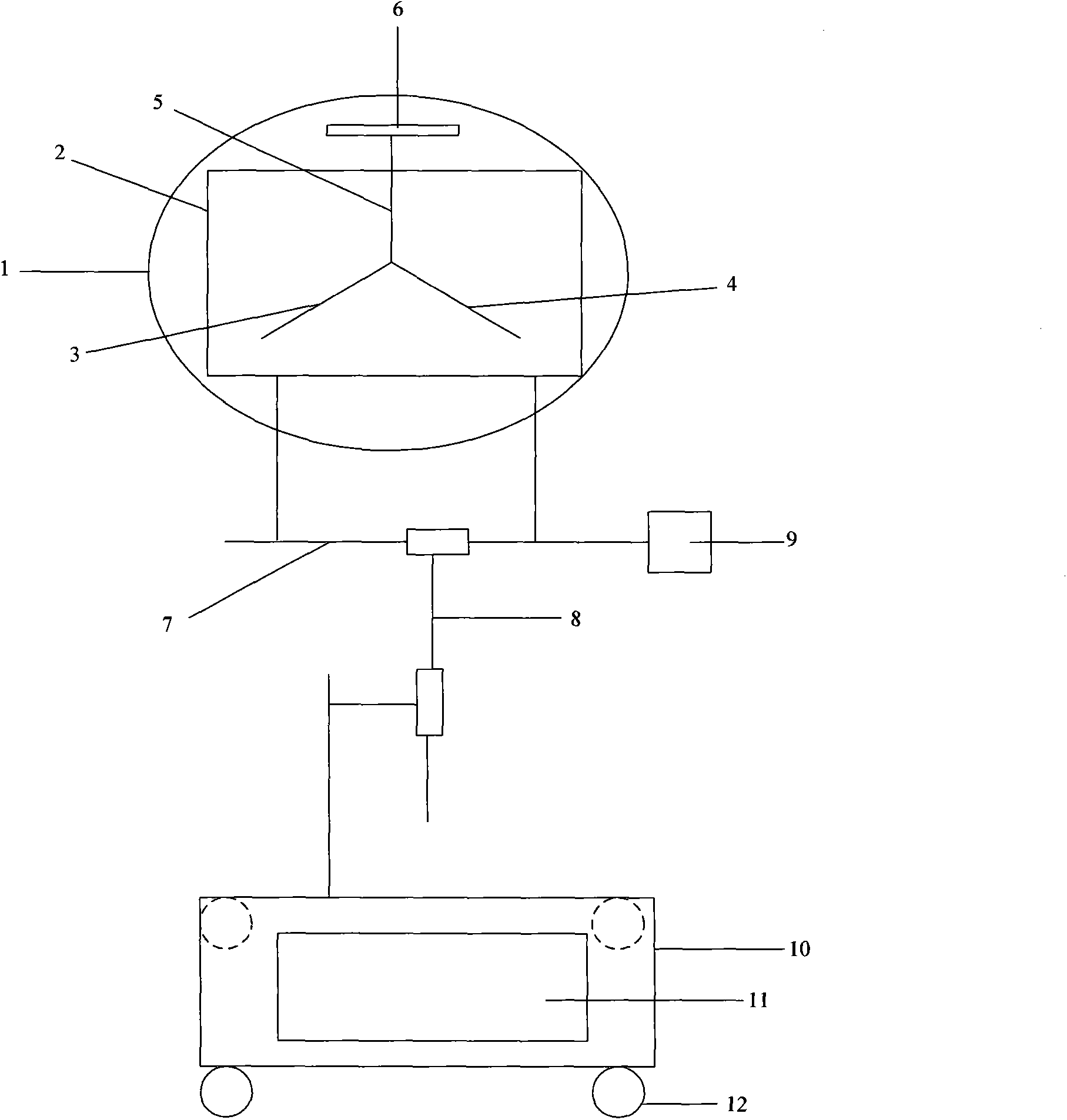

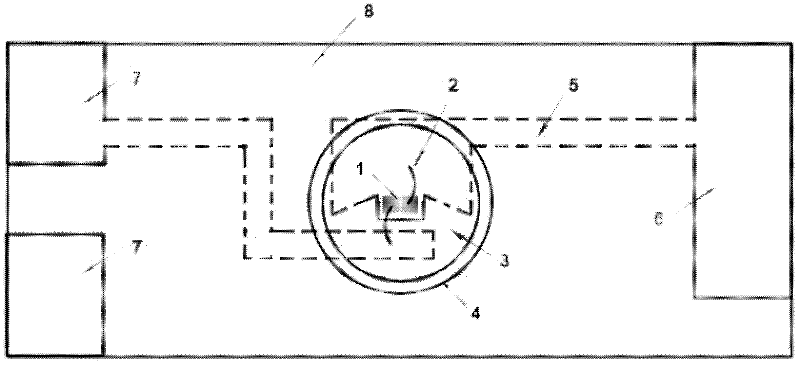

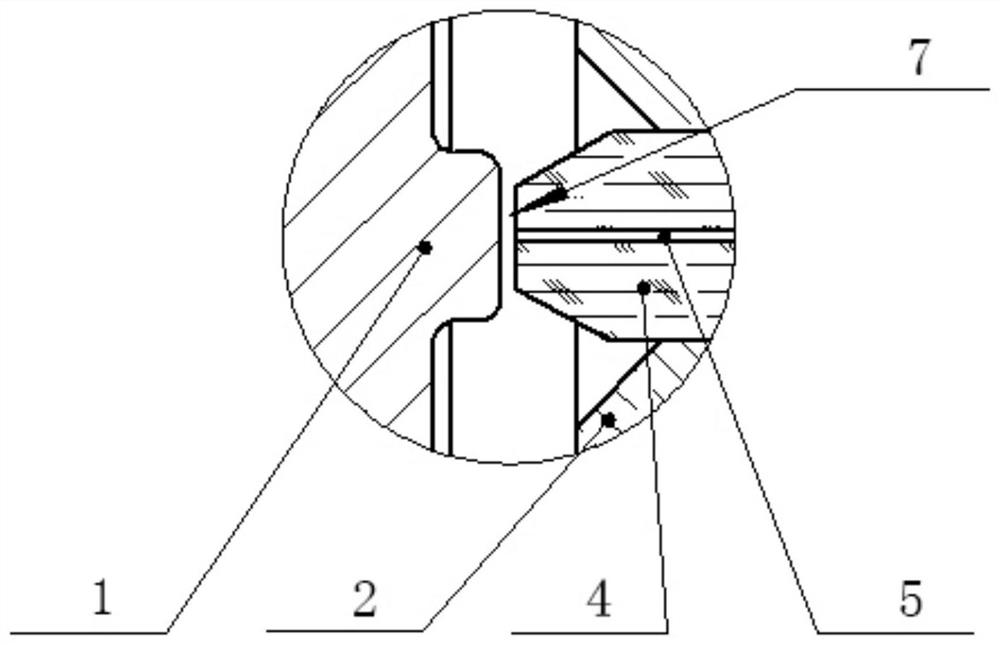

Orthopaedic robot navigation locating device

InactiveCN103919611ASolve the problem of errors caused by inaccurate positioningAvoid blocking interferenceDiagnosticsSurgeryImaging processingThree degrees of freedom

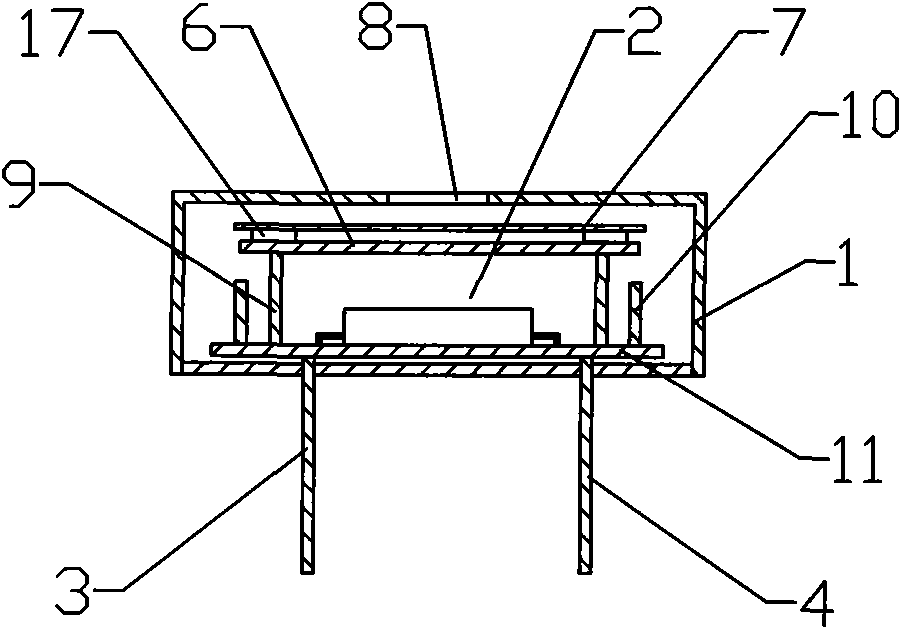

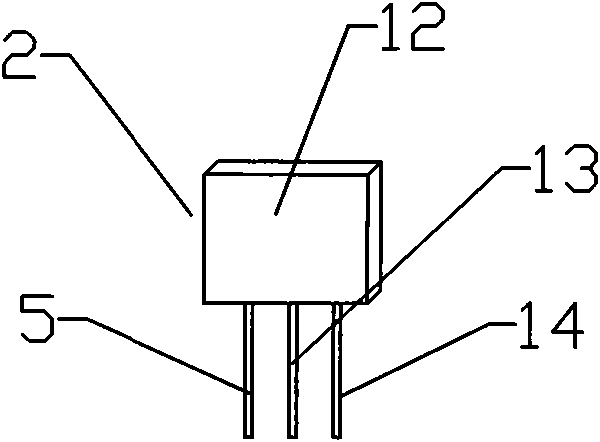

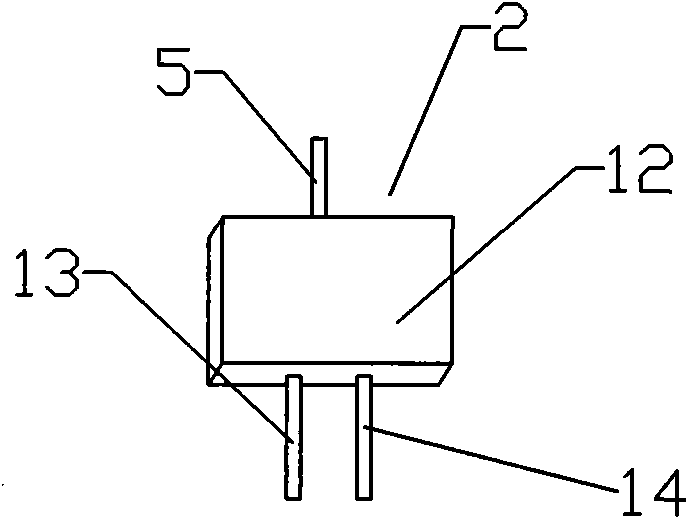

The invention discloses an orthopaedic robot navigation locating device. The orthopaedic robot navigation locating device is provided with a three-freedom-degree and double-plane locating mechanism, a horizontal adjusting assembly, a height adjusting assembly and a control panel, wherein the three-freedom-degree and double-plane locating mechanism is composed of a locating platform, an X-direction locating device, a Y-direction locating device, a Z-direction locating device and a straight rod type guide device. The height adjusting assembly and the horizontal adjusting assembly are arranged, so that adjustment of the three-freedom-degree and double-plane locating mechanism in the horizontal direction and height direction is achieved as a whole, flexibility of the orthopaedic robot navigation locating device is greatly improved, operation duration is shortened, and an operation is more convenient. A mechanical arm of the orthopaedic robot navigation locating device has three degrees of freedom, can capture position information of a navigation tool in an all-directional mode, and therefore the orthopaedic robot navigation locating device is safe and reliable. The navigation tool reflects infrared rays, passive infrared optical localization is achieved, and operation is simple. An image processing module of the locating system can convert infrared data acquired by a camera with the infrared acquisition function into data points in a three-dimensional coordinate, so that locating precision is improved.

Owner:张文峰 +1

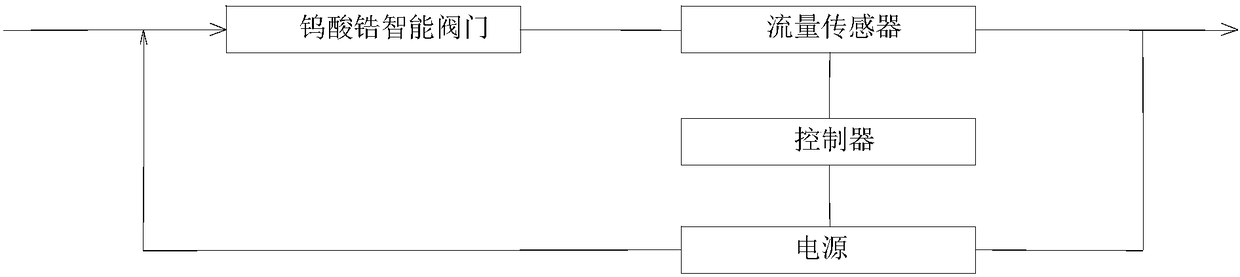

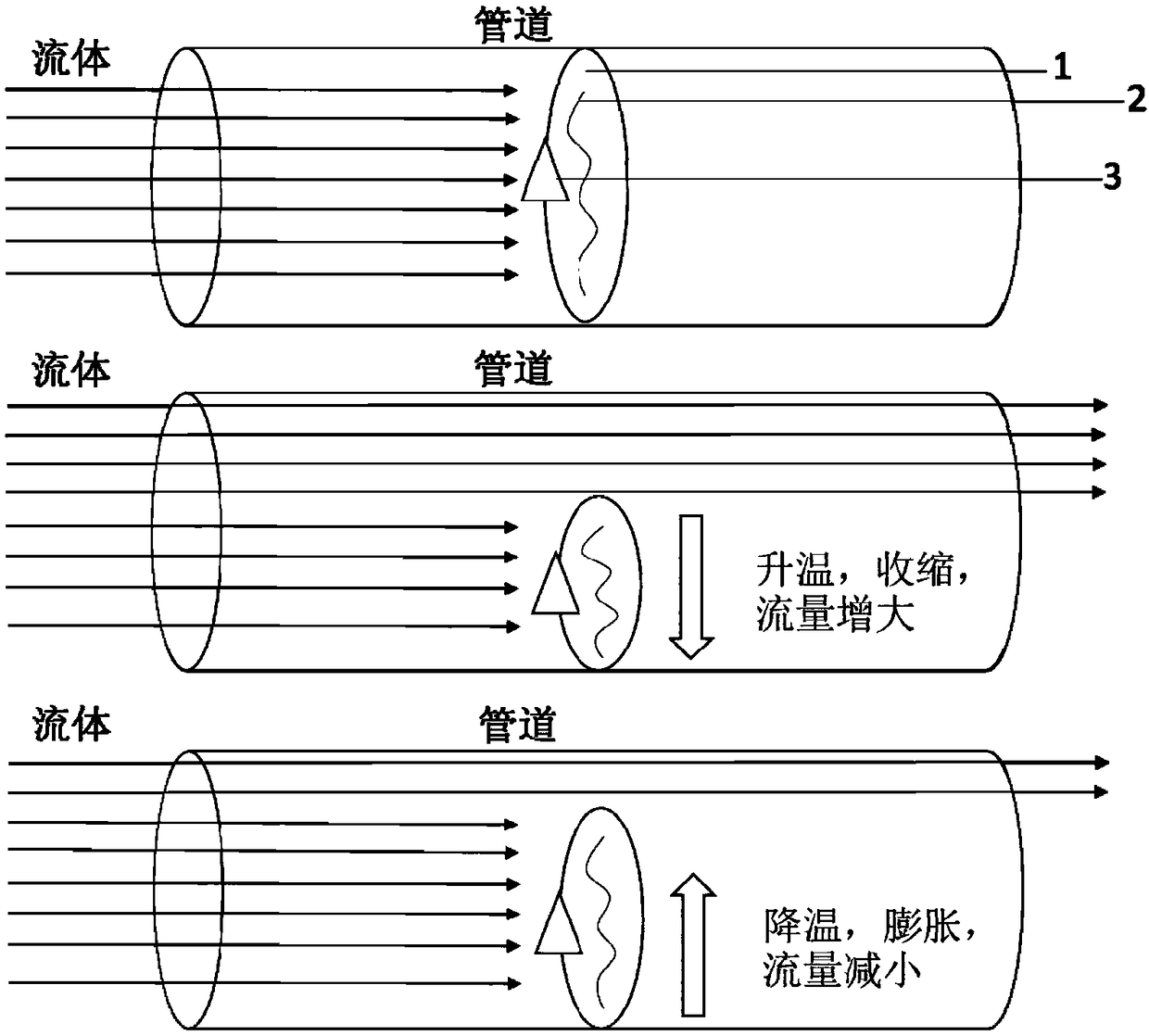

Intelligent valve made of zirconium tungstate negative thermal expansion material

PendingCN108167469APrecise TuningHigh temperature resistantDiaphragm valvesOperating means/releasing devices for valvesEngineeringTemperature resistance

The invention discloses an intelligent valve made of a zirconium tungstate negative thermal expansion material. The intelligent valve is made of the composite material formed by combining zirconium tungstate and graphene. An electric heating wire is arranged in the valve, and the valve is connected to a control circuit. The valve is prepared through a 3D printing technology. A flow sensor is installed in the pipeline, and a controller is arranged and connected with the flow sensor. When the flow in a pipeline reaches a lower threshold, a variable voltage power source supplies electricity to the valve made of the intelligent material, the valve structure is heated, the material structure is driven to generate a heat-shrinkable effect, a channel is opened, and the flow is increased. The novel material serve as the core structure of the valve, the zirconium tungstate negative thermal expansion material and a graphene ultralight material are combined to achieve high temperature resistance,high conductivity and good mechanical properties, the effect of accurately regulating the flow in the pipeline can be achieved, and thus the intelligent valve can be applied to flow control of the pipeline under various environments and has good industrial application prospects.

Owner:LANZHOU UNIVERSITY

Method for preparing magnetic microspheric alumina support

ActiveCN101172255AReduce complex processLow manufacturing costCatalyst carriersCatalyst activation/preparationMagnetic coreFerrite powder

The invention relates to a preparation method for a magnetic microsphere type alumina carrier. The invention is characterized in that spinel ferrite magnetic core is roasted at the high temperature, ground into ferrite powder, processed with acid, then washed, dried, and dispersed into alumina sol, and then shaped into the magnetic microsphere type aluminum oxide carrier by an oil column.

Owner:CHINA PETROLEUM & CHEM CORP +1

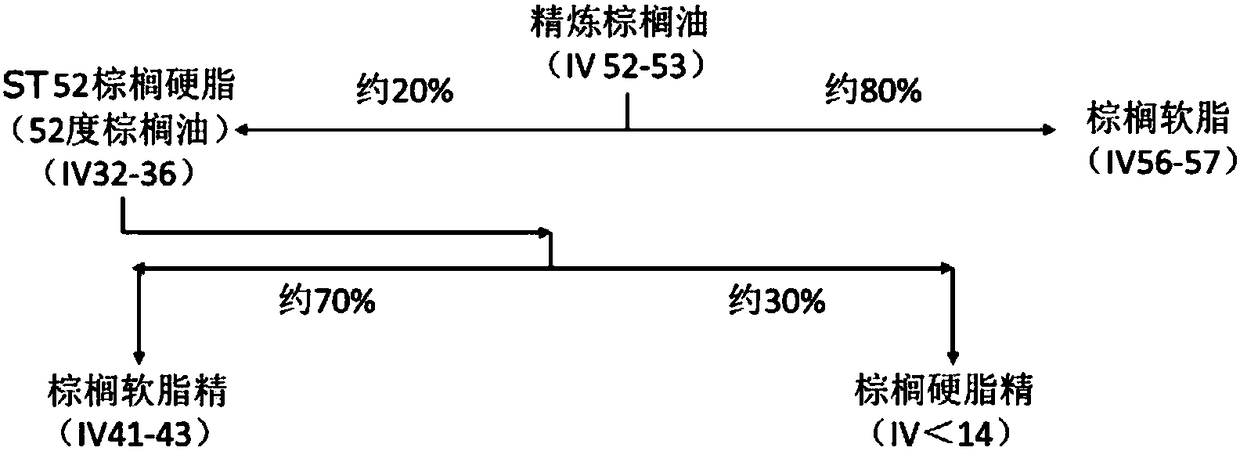

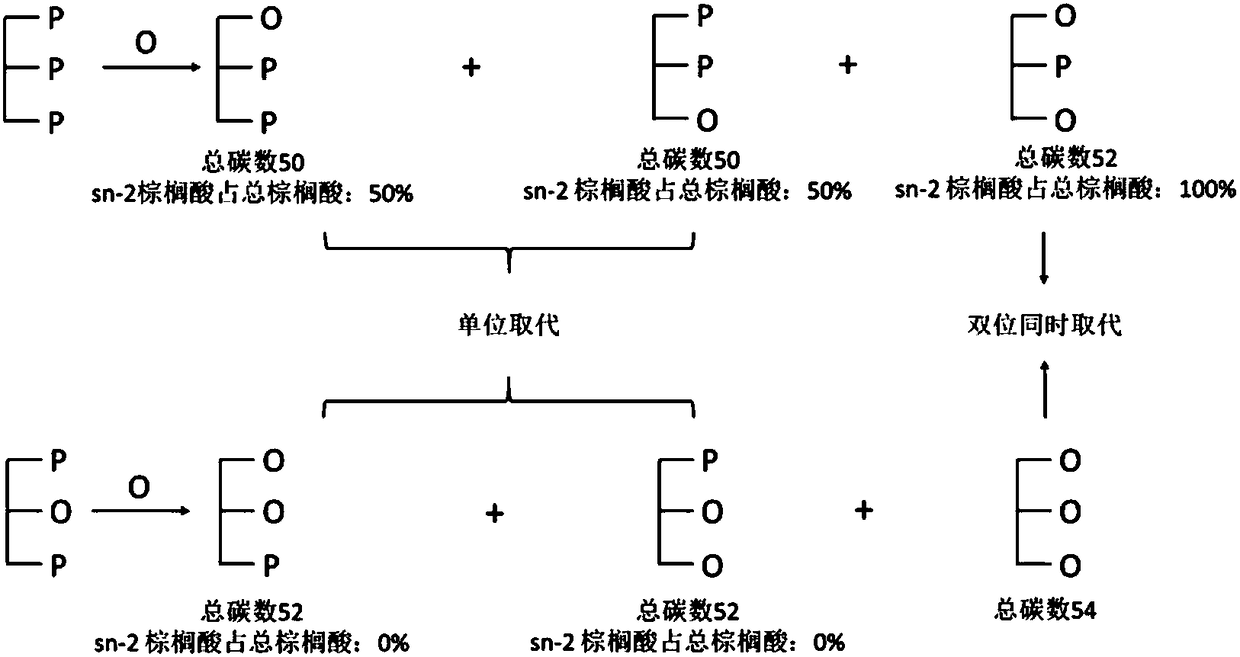

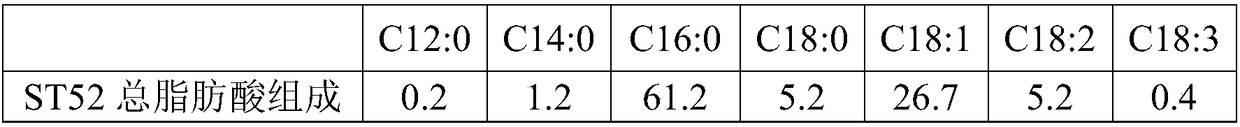

Grease composition containing 1, 3-dioleic acid-2-palmitic acid triglyceride and preparation method of grease composition

ActiveCN108265089AReduce difficultyLow costFatty acid esterificationFermentationPalm stearinTG - Triglyceride

The invention relates to a method for preparing a grease composition containing 1, 3-dioleic acid-2-palmitic acid triglyceride (OPO). According to the method, an industrial conventional product ST52 palm stearin of grease is taken as a raw material and subjected to sn-1, 3 directed ester exchange reaction with greatly excessive oleic acid mixture in the presence of enzymic preparations in batch, and separation and purification are performed to obtain the grease composition containing the OPO and recyclable fatty acid mixture.

Owner:COFCO GROUP +3

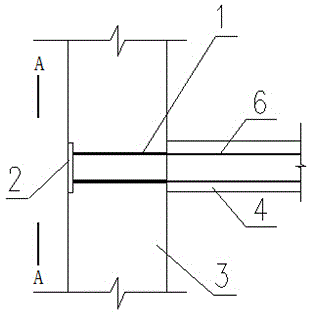

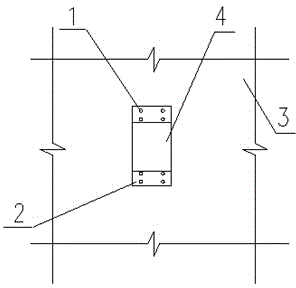

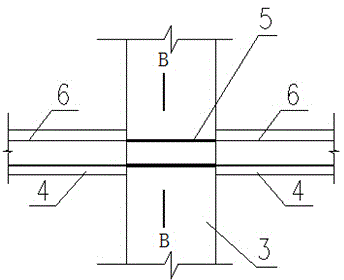

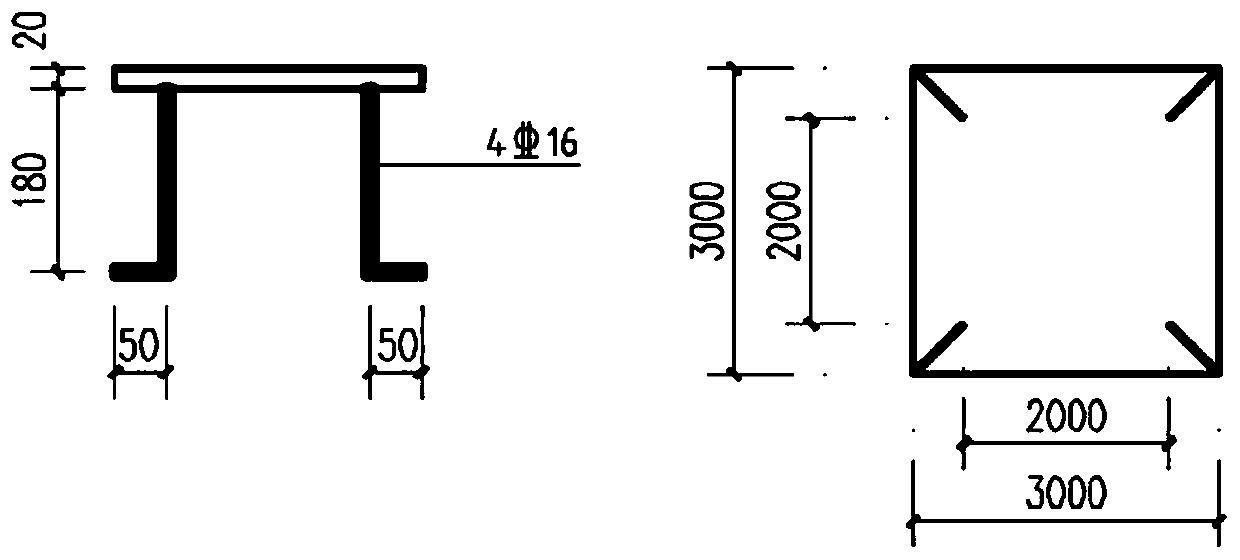

Beam bar anchoring sleeve pre-embedded in thin wall and construction method thereof

ActiveCN104452978AMature construction technologyEasy to operateBuilding constructionsConcrete beamsRebar

The invention discloses a beam bar anchoring sleeve pre-embedded in a thin wall and a construction method of the beam bar anchoring sleeve pre-embedded in the thin wall. The beam bar anchoring sleeve comprises a unilateral thread sleeve body and a bilateral thread sleeve body. One side of the unilateral thread sleeve body is provided with an anchoring end plate. The sum of the length of the unilateral thread sleeve body and the thickness of the anchoring end plate is the same as the thickness of the concrete thin wall. The anchoring end plate is located on the side, opposite to the concrete thin wall, of a concrete beam. The bilateral thread sleeve body is located in the concrete thin wall. The length of the bilateral thread sleeve body is the same as the thickness of the concrete thin wall. The center position of the bilateral thread sleeve body is the same as the center position of concrete beam main bars on the two sides of the concrete thin wall. According to the beam bar anchoring sleeve, the anchoring end plate and the sleeve are welded into an anchoring whole, the defect that in a conventional construction process, when a beam bar is pre-embedded, two-end thread machining cannot be conducted due to an excessively short steel bar is overcome, the anchoring problem of a horizontal structural beam subsequently constructed in the thin wall is solved, and the beam bar anchoring sleeve can be widely applied to the process that nodes are pre-embedded in a beam bar when a shear wall is not synchronous with the concrete beam in the construction process.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

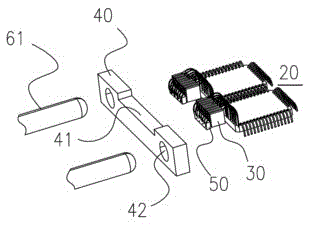

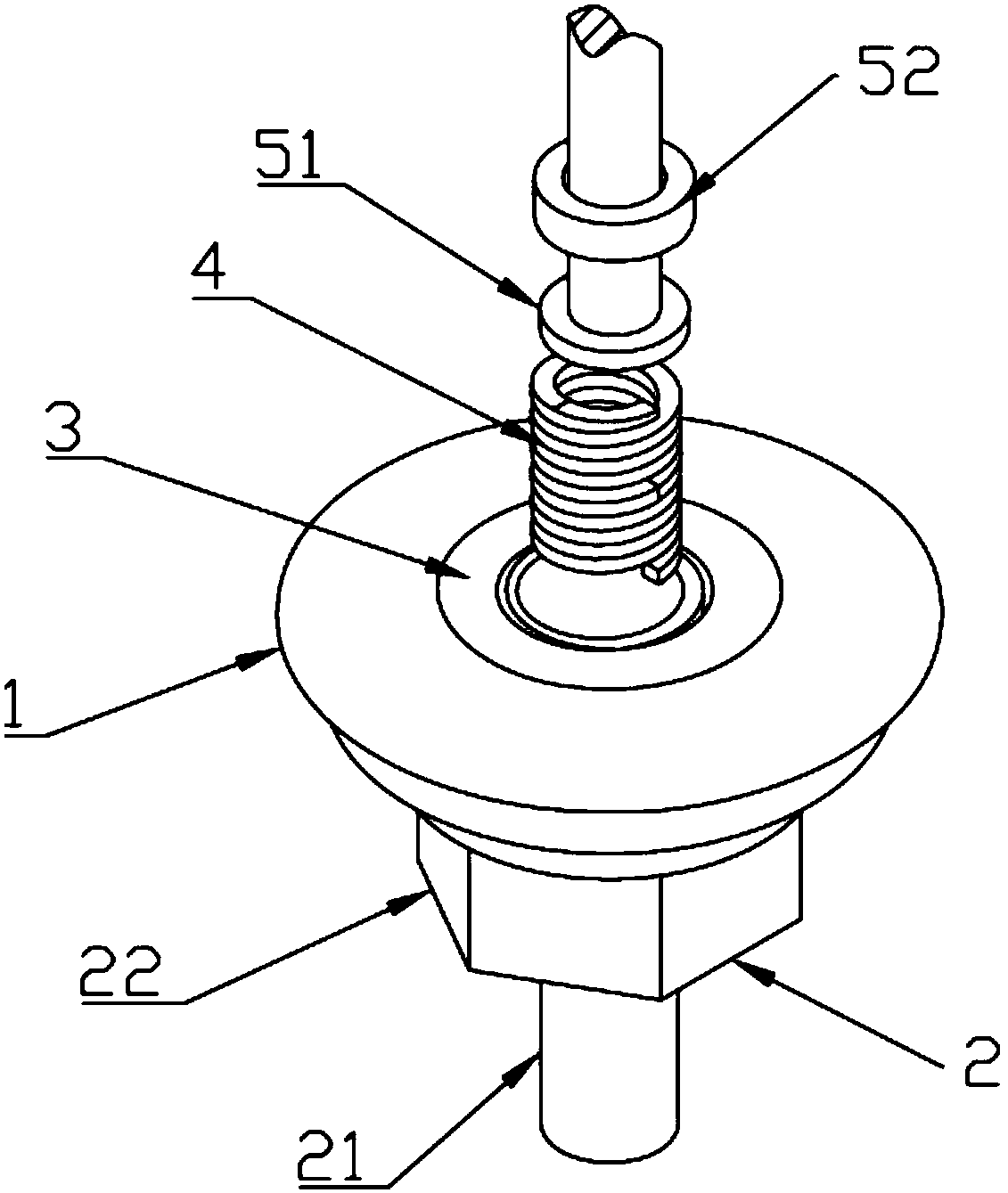

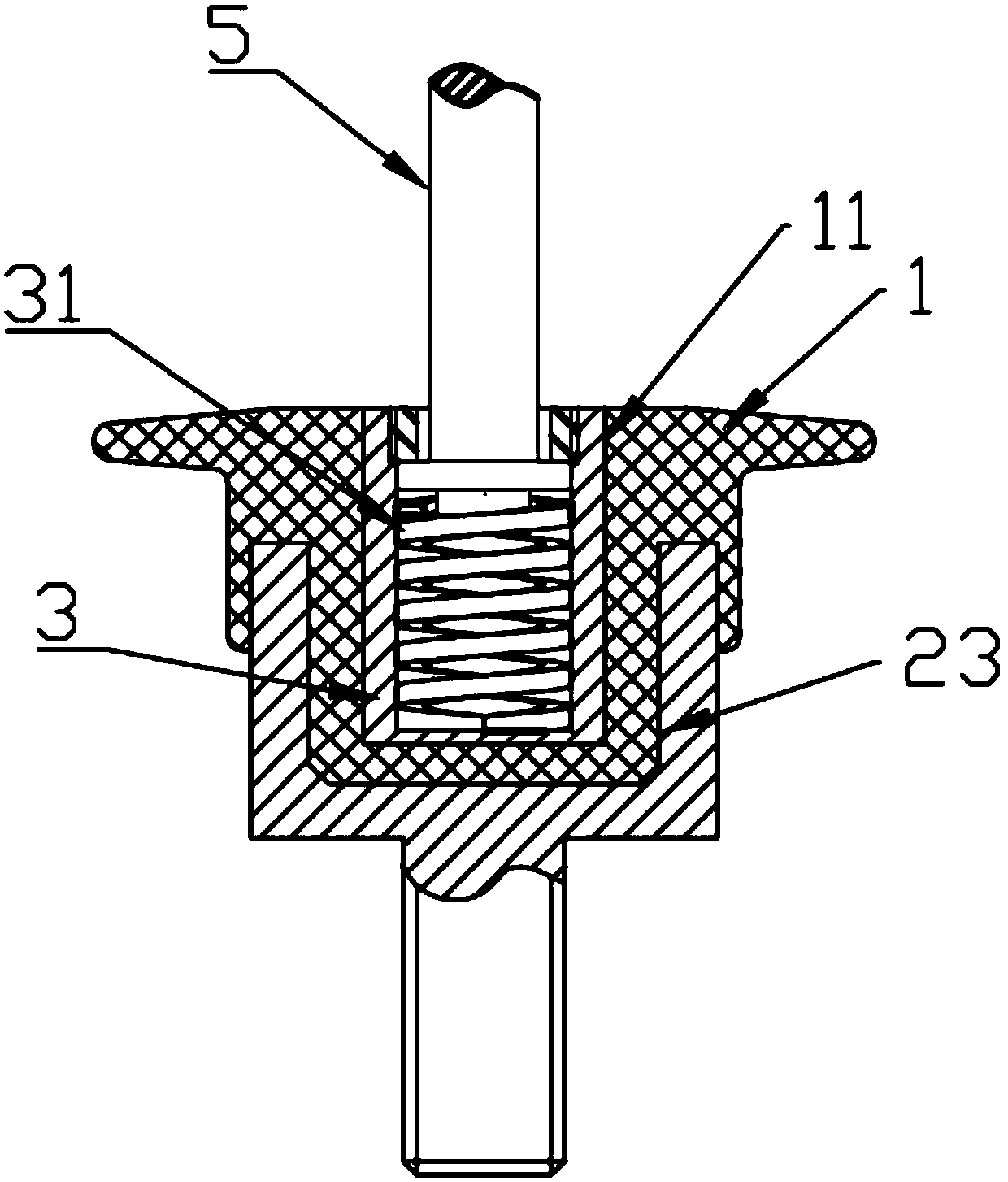

Integrated insulator

PendingCN109545626AConcentricity satisfiesReduce in quantityElectromagnetic relay detailsEngineeringMachining process

The invention discloses an integrated insulator. The integrated insulator includes an insulator, a bolt, a spring seat, a contact spring and a pull bar, wherein the lower end of the bolt is a screw with an external thread, and the upper end of the bolt is a polygonal head; a first groove is formed in the polygonal head of the bolt; the lower end of the insulator is received in the first groove; the upper end surface of the insulator is provided with a second groove; the spring seat is fixed in the second groove; the spring seat is provided with a spring mounting hole; the contact spring is installed in the spring mounting hole, and the lower end of the contact spring is fixed at the bottom of the spring mounting hole; and movement of the lower end of the pull bar is limited in the spring mounting hole and is fixedly connected to the upper end of the contact spring. The integrated insulator fixes the contact spring and the pull bar by means of cooperation of the lock nut and the insulator, and satisfies the characteristic that the insulator is small in size. The axial positioning of the pull bar and the bolt is to utilize mutual cooperation between the pull bar, the spring and the spring seat, so as to satisfy the coaxiality of the pull bar and the bolt, and the number of parts and the complex machining processes of the parts are reduced.

Owner:KUSN RUIPU ELECTRIC

Block-shaped flavoring

InactiveCN103222608AMake it fastReduce complex processFood shapingFood preparationBiotechnologySalty taste

The invention relates to a block-shaped flavoring. According to the invention, Pi-county bean paste, prickly ash seed, Sichuan chili powder, flavoring essential oil, animal product, and various spices are adopted as raw materials, and the block-shaped flavoring is prepared with a novel technical process. The flavoring has the advantages that: with the flavoring, complicated processes for preparing authentic traditional Sichuan dishes are eliminated, and dishes with authentic traditional Sichuan flavors can be rapidly prepared by more families and catering staffs; the flavoring has red color, rich fragrance, and delicious spicy, numbing, and salty taste; with the flavoring, living costs and procurement time are saved, and catering processing cost and preparation time are saved; the flavoring is convenient and clean during a cooking process, and provides good functions for the color, fragrance, and taste for the dishes.

Owner:SHANGHAI GENIFOODS CO LTD

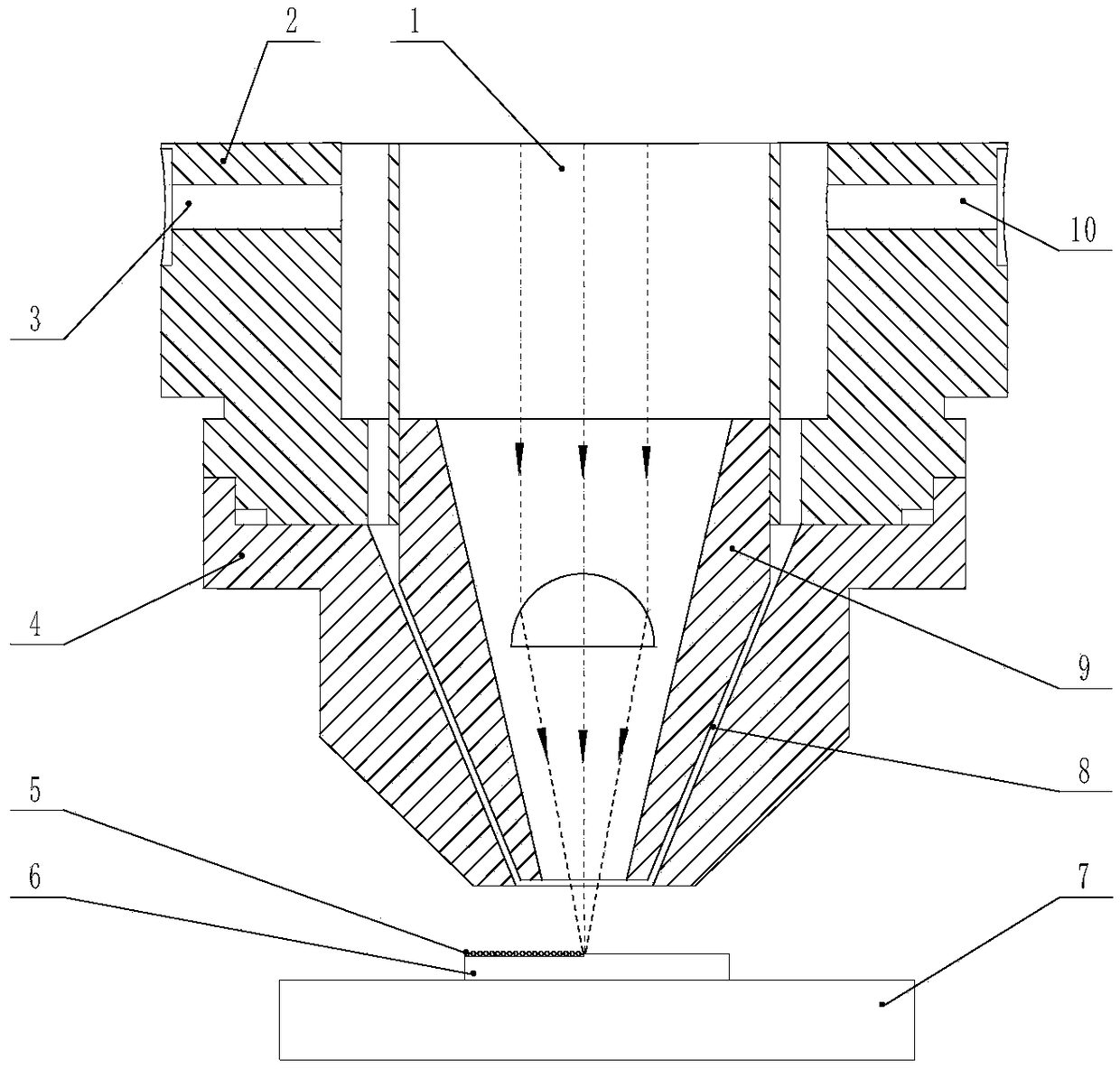

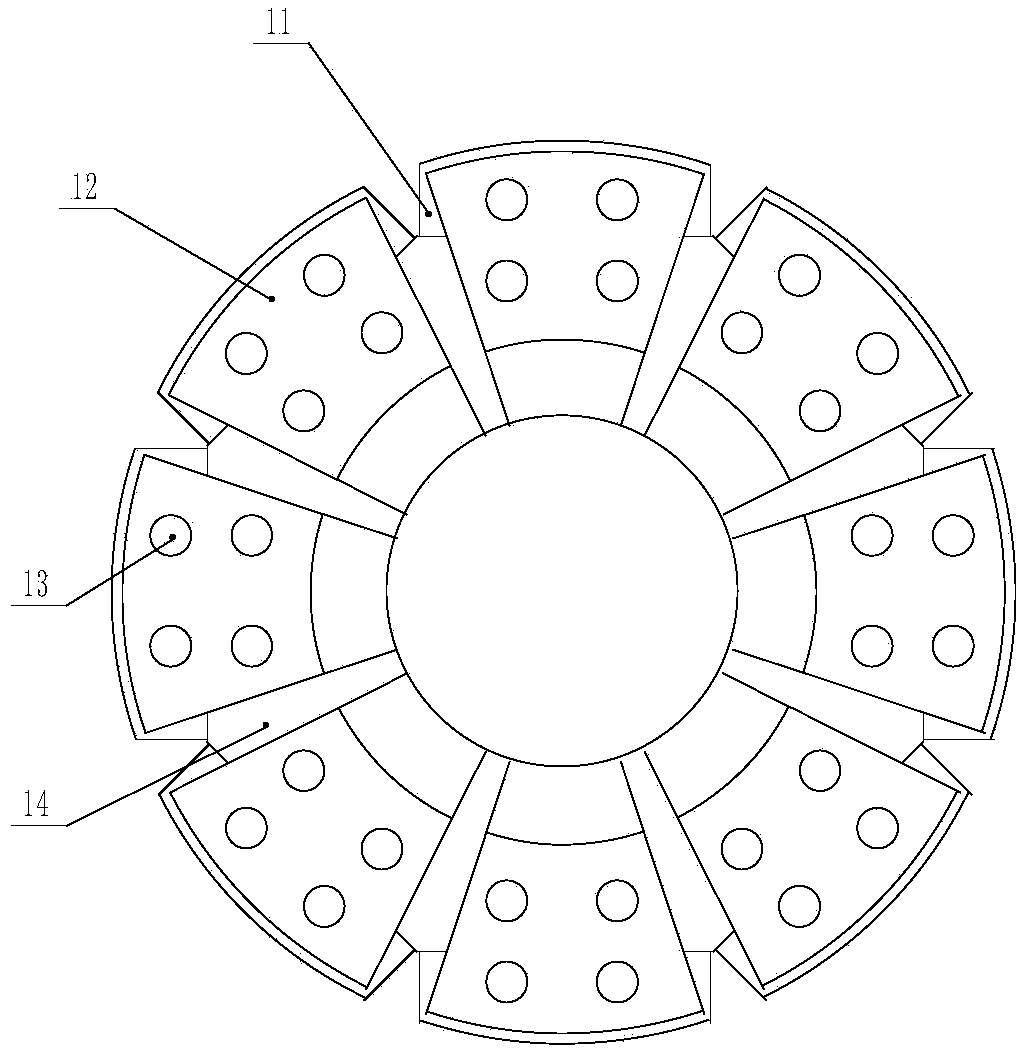

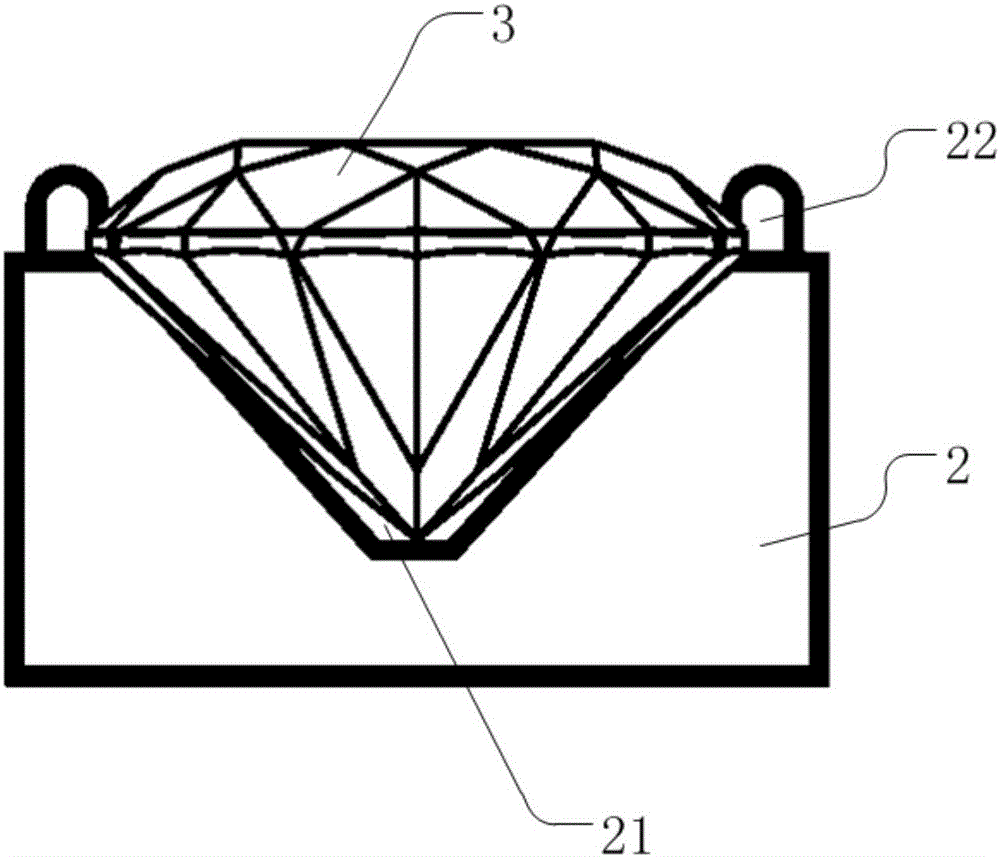

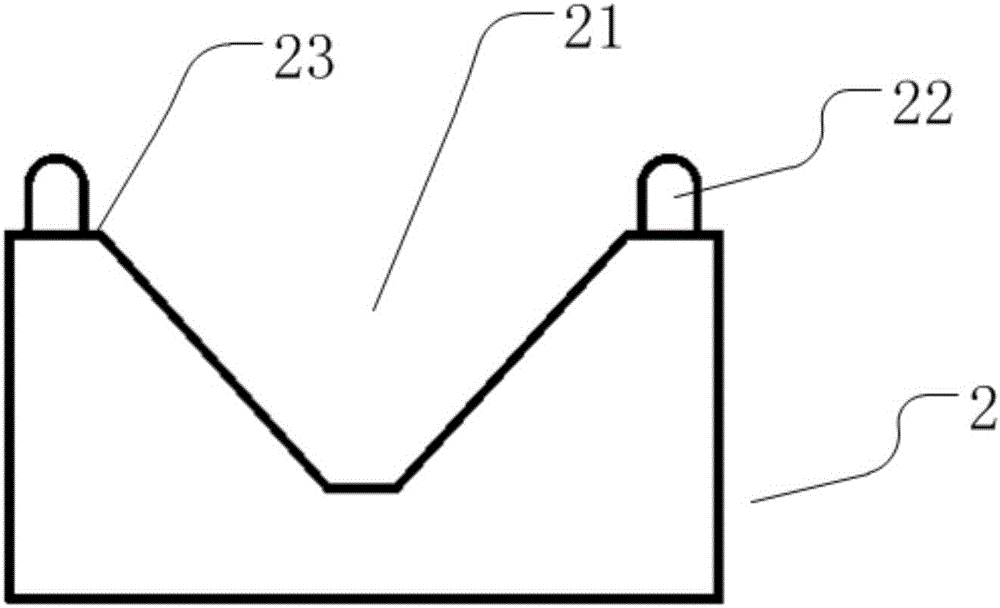

Preparation and trimming method of laser near-net forming structured diamond excircle grinding wheel

ActiveCN108655970AReduce complex processFlexible structureAbrasion apparatusGrinding devicesLaser technologyAdamite

The invention discloses a preparation and trimming method of a laser near-net forming structured diamond excircle grinding wheel. The preparation and trimming method comprises the following steps thatdiamond and metal bonding agent powder are mixed in a material mixing bottle according to a certain mass fraction ratio, are subjected to ball grinding, are screened by a screening mesh, and are putinto a drying box for drying; a segment with a bright and clean to-be-machined metal matrix is obtained; diamond grinding material mixed powder obtained after drying is added into a powder feeding device; the segment with the bright and clean to-be-machined metal matrix is subjected to laser near-neat forming machining of a diamond grinding tool according to certain laser technology parameters andscanning paths, and the obtained segment is reinstalled in the excircle grinding wheel; the excircle grinding wheel is subjected to sharpening treatment; and the excircle grinding wheel after the sharpening treatment is trimmed by combination of a steel block and an oilstone. The machining time is saved, the machining cost is reduced, a required grinding wheel structure can be flexibly machined out, relative distribution positions of diamond grinding particles are effectively controlled, the flowability of cutting scraps is improved, cutting force is reduced, and the cutting temperature is lowered.

Owner:NORTHEASTERN UNIV

A kind of white light led packaging structure and packaging method

InactiveCN102270729AImprove uniformityEasy to controlSolid-state devicesSemiconductor devicesPhosphorEngineering

The invention relates to a white light LED packaging structure and packaging method. The packaging structure includes a double-layer substrate; at least one light-emitting chip, and at least two connecting wires; the double-layer substrate includes an insulating substrate and a conductive pattern to form a bonded area and several electrode areas, the top of the double-layer substrate avoids the bonding area and several electrode areas and is coated with isolation glue; the double-layer substrate also has an insulating bracket and at least one fluorescent film for tiled on an insulating support; the bonding area is jointly formed by an insulating substrate, an insulating support and a conductive pattern. The invention adopts the fluorescent film to replace the traditional fluorescent powder, avoids the mixing of the fluorescent powder in the resin, and provides the possibility of further improving the light efficiency and white light uniformity of the white light LED.

Owner:DONGHUA UNIV

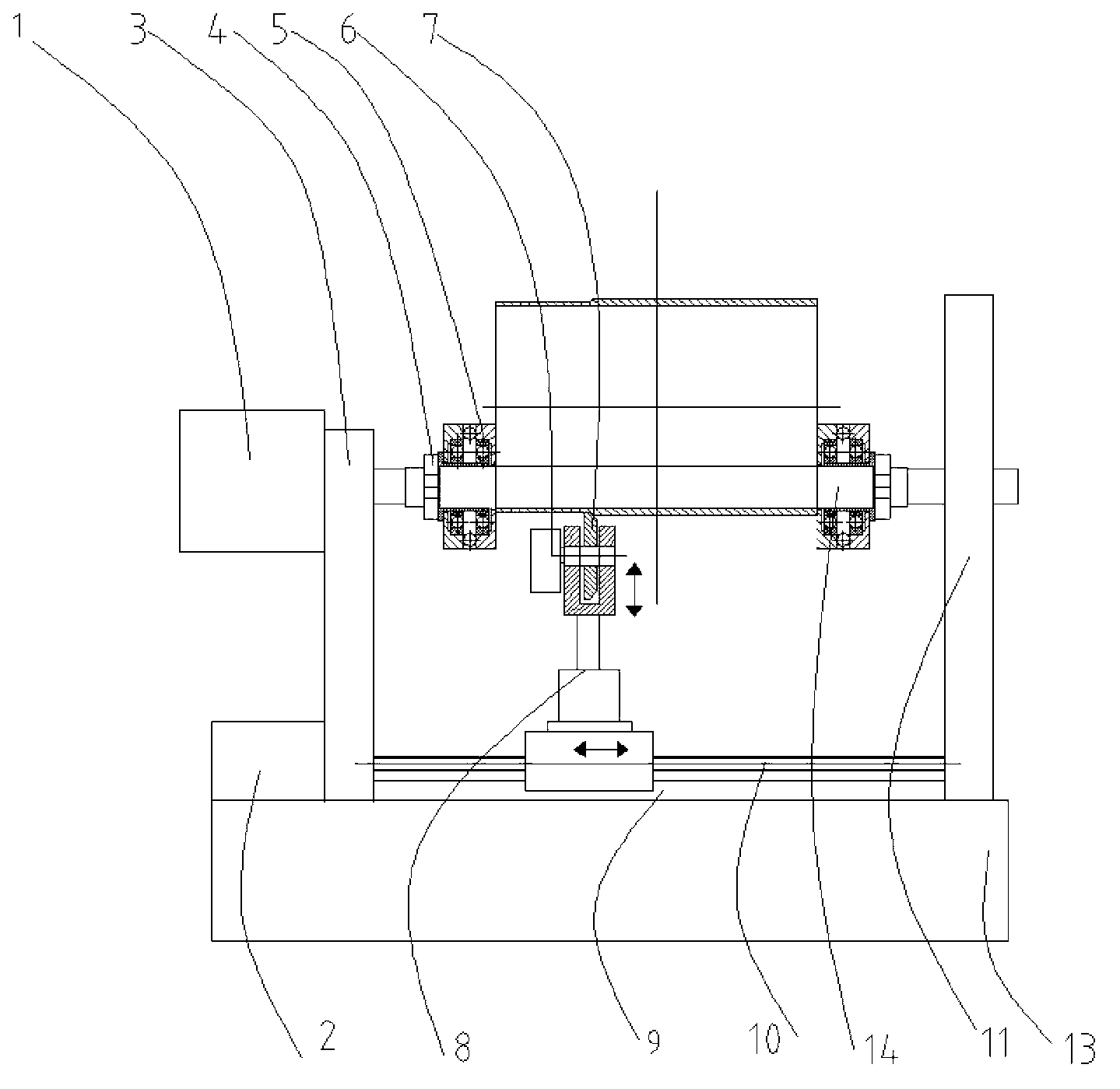

Spinning and forming device of cylindrical part with inner strengthening and outer thinning

InactiveCN103157716AReduce complex processSolve puzzlesMetal-working feeding devicesPositioning devicesDrive shaft

The invention relates to a spinning and forming device of a cylindrical part with inner strengthening and outer thinning. The spinning and forming device of the cylindrical part with inner strengthening and outer thinning is suitable for manufacturing a cylindrical part with especially big diameter to enable uniformity of wall thickness of a workpiece to be thinned, the manufacturing cost is reduced, and the purpose of efficient forming of cylindrical parts with different diameters is achieved. The spinning and forming device of the cylindrical part with inner strengthening and outer thinning comprises an actuating device, a holding device, a feeding device and working rolls. The working rolls are formed by a main roll, a plurality of auxiliary supporting rolls and a rotating roll. The main roll is supported by a drive variable speed reversing mechanism which is arranged on a tool body and a tail portion supporting seat body and driven to rotate by an actuating device I through the drive variable speed reversing mechanism. A guide rail and a drive shaft are arranged on the tool body, a sliding rail machine is arranged on the drive shaft, and the drive shaft is driven to rotate by an actuating device II to enable the sliding rail machine to move along the guide rail in a right and left mode. A radial feed device is arranged on the sliding rail machine, and the rotating roll is arranged at the top of the radial feed device. The holding device which is used for holding the cylindrical workpiece is arranged on the main roll. Clamping nuts are arranged at two ends of the holding device. The inner wall of the cylindrical workpiece is attached to the main roll, and the cylindrical workpiece rotates as the main roll rotates.

Owner:JILIN UNIV

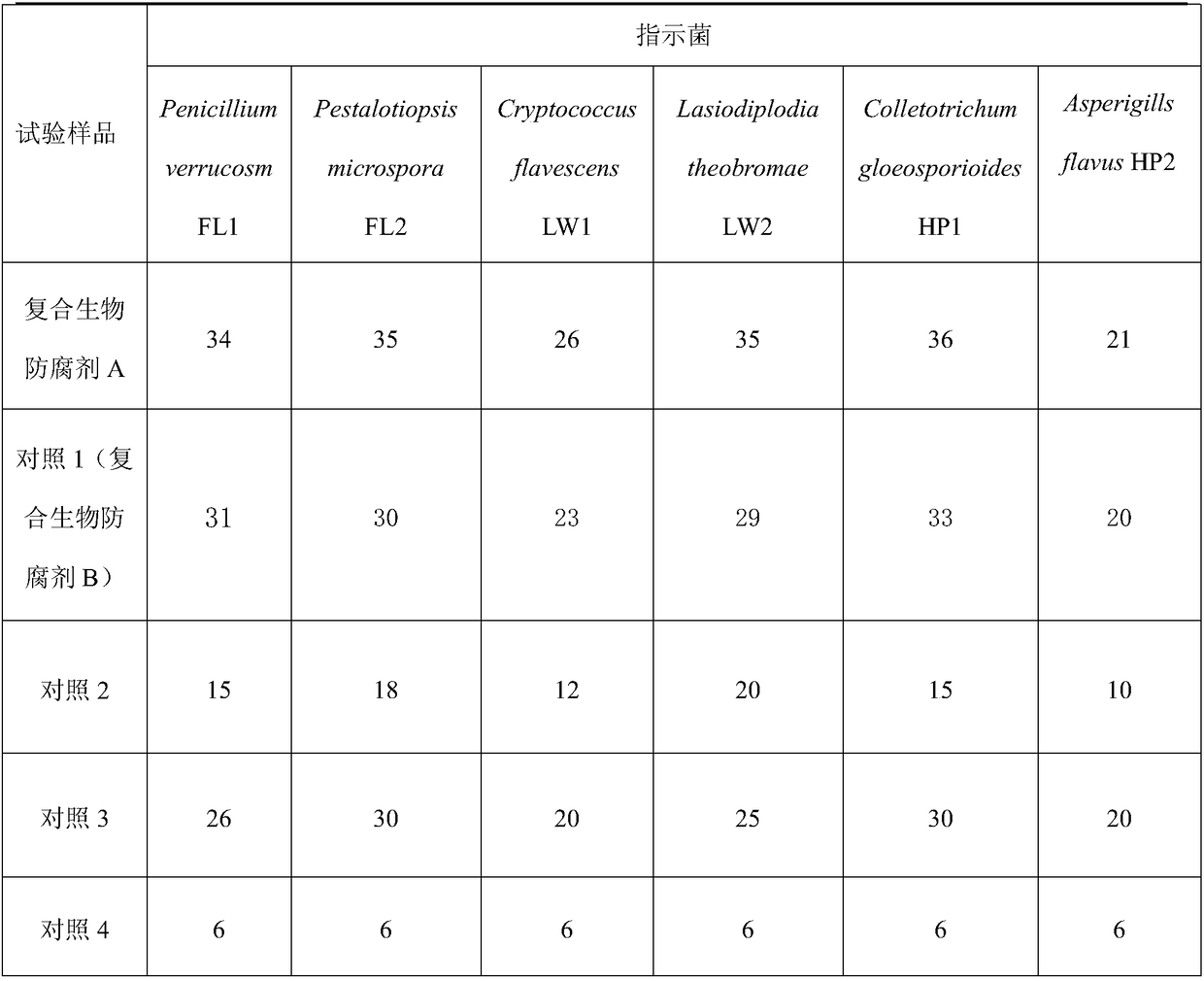

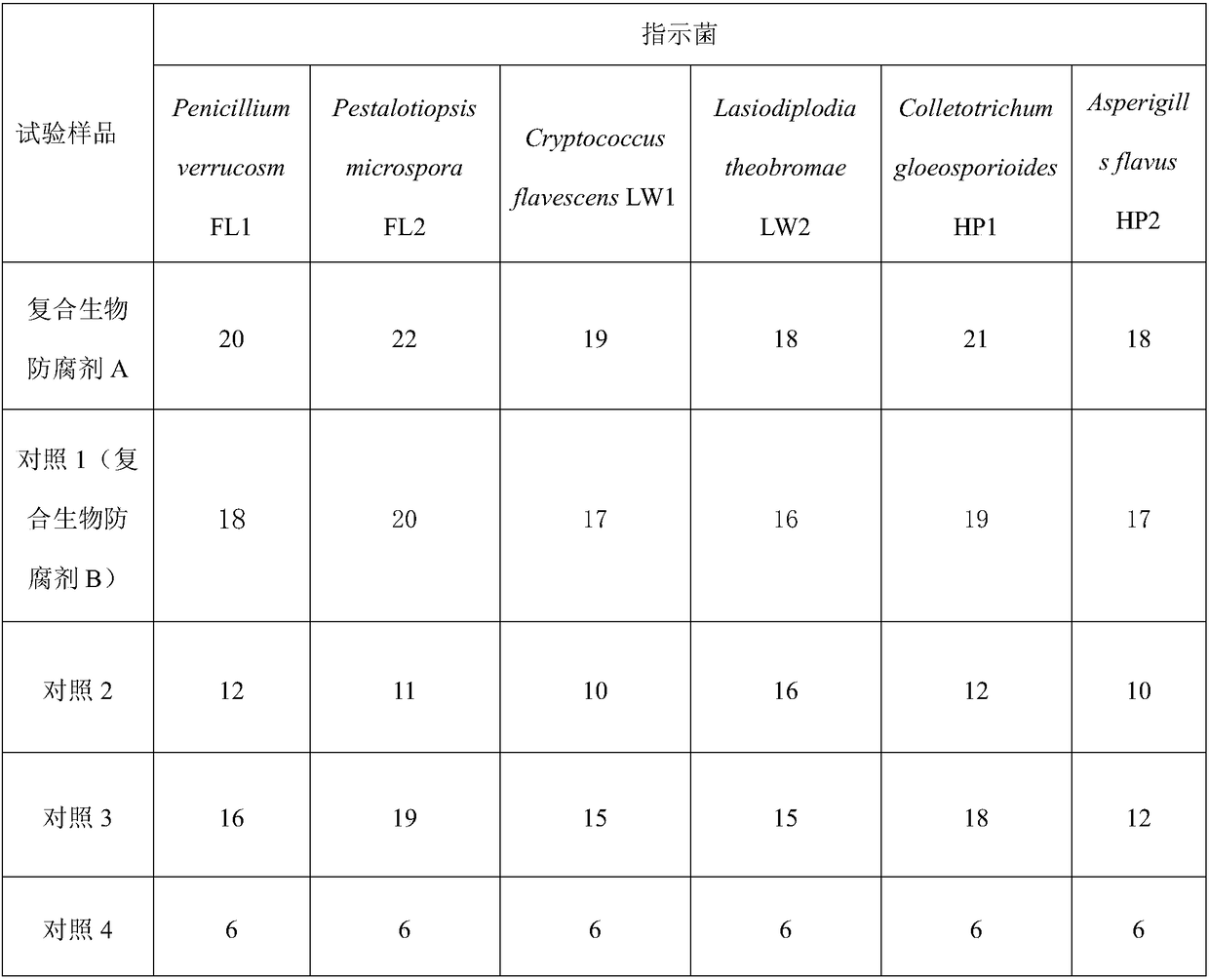

Composite biological preservative fresh keeping agent based on epsilon-polylysine-containing fermentation liquid

PendingCN108157493AGood antibacterial effectLow costFruit and vegetables preservationFermentationEpsilon-PolylysineMicroorganism

The invention discloses a composite biological preservative fresh keeping agent based on epsilon-polylysine-containing fermentation liquid. Each 100ml of the composite biological preservative fresh keeping agent comprises an epsilon-polylysine-containing microbial fermentation supernatant with the addition quantity meeting the following requirements that the content of epsilon-polylysine is 0.05-0.3g, the content of L-malic acid is 0.5-2g, the cotnent of L-lactamic acid is 0.05-0.5g, the content of natamycin is 0.05-0.3g and the balance of water. According to the composite biological preservative fresh keeping agent based on epsilon-polylysine-containing fermentation liquid, the epsilon-polylysine-containing microbial fermentation supernatant is directly used for preparation, and a complextechnology for separation and extraction of a biological preservative namely epsilon-polylysine is omitted, so that the cost of the biological preservative is greatly reduced. The method is simple and easy to operate. Experiment proves that the made composite biological fresh keeping agent is better in bacterial effect than a contrast group of directly adding pure epsilon-polylysine.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

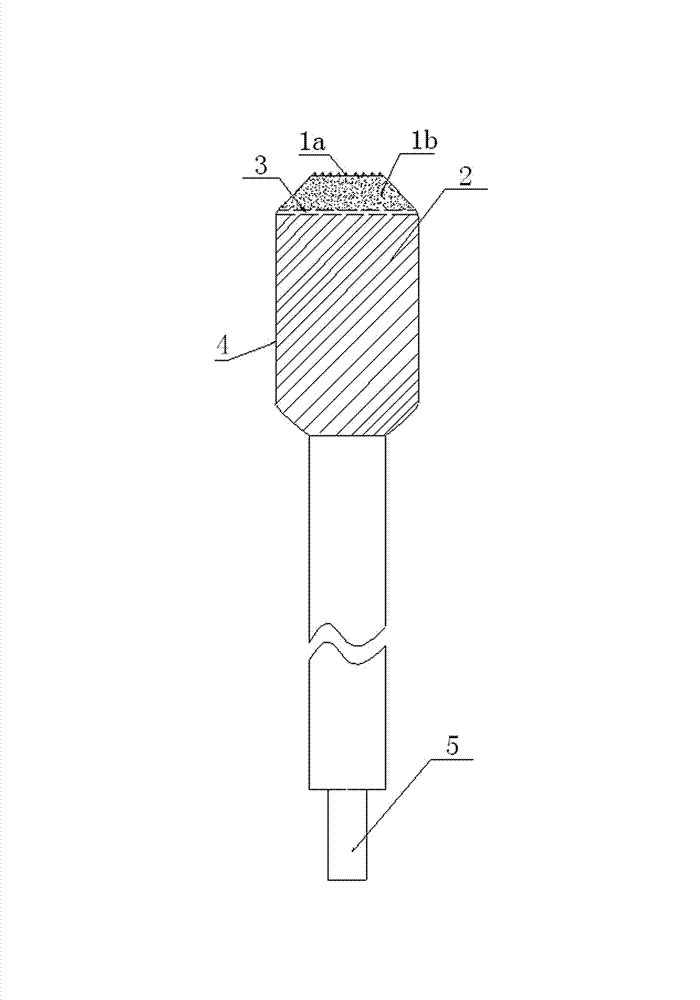

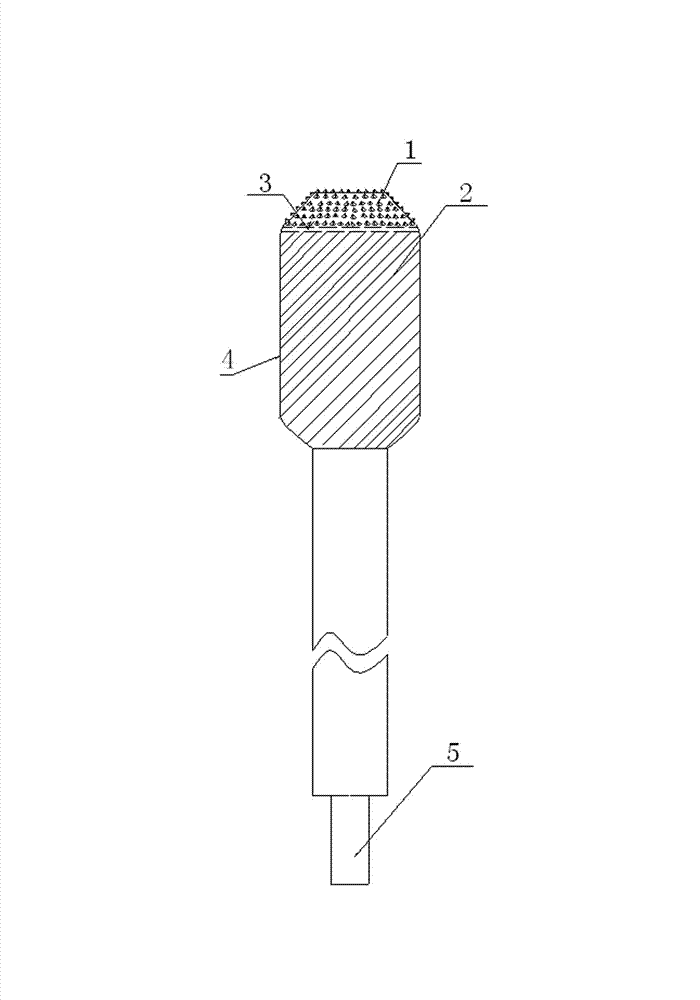

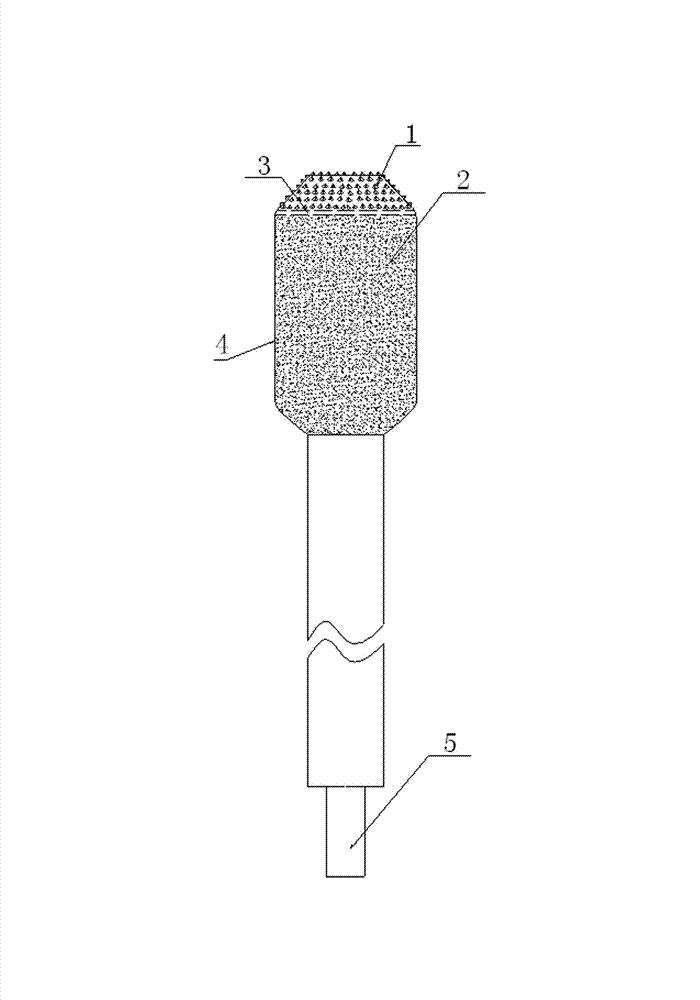

Medical multifunctional operating bit

The invention provides a medical multifunctional operating bit. A bit is arranged at the front end of a rod-shaped body, and the rear end of the rod-shaped body is provided with a connecting handle; a cone frustum is arranged in the front part of the spindle shaped bit, and a first blade area is arranged on the surface of the cone frustum and accounts for one seventh of the spindle shaped bit; a cylinder is arranged on the rear part of the spindle shaped bit, and a second blade area is arranged on the surface of the cylinder and accounts for six sevenths of the spindle shaped bit; and a plurality of triangular cut blades or corundum are arranged on the first blade area, and a plurality of arc cut blades or corundum are arranged on the second blade area. The medical multifunctional operating bit can be used for perforating bone tissues in an operation, or cutting and polishing the bone tissues in the operation, so that the problem of repeatedly changing single-function operating bits in the operation can be solved, massive time for changing bits can be saved, adjacent critical nerves and blood vessels are protected, and clinical risks are effectively reduced.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

Production process of electroacoustic component

InactiveCN101674521AReduce processing stepsReduce complex processMicrophone structural associationSemiconductor/solid-state device manufacturingAdhesiveEngineering

The invention relates to a production process of an electroacoustic component which comprises a shell, a field effect transistor, a polar plate, a vibrating diaphragm, a first terminal pin, a second terminal pin and a spacing ring, wherein a sound conducting hole is arranged at the upper part of the shell. The production process comprises the following steps: manufacturing the field effect transistor, assembling the polar plate, arranging conductive adhesive, assembling the spacing ring, installing the vibrating diaphragm and finally packaging. A drain electrode of the field effect transistorforms the first terminal pin of the electroacoustic component, a source electrode forms the second terminal pin of the electroacoustic component, the polar plate is assembled on a bearing end surfaceof the grid electrode, the bearing end surface of the grid electrode performs the function of supporting the polar plate, and the drain electrode and the source electrode can directly form the terminal pins of the electroacoustic component, thereby saving the steps in a traditional processing method, decreasing components and parts, simplifying the structure, lowering the cost, additionally decreasing the processing working procedures, improving the processing efficiency and easily realizing automatic production.

Owner:WEIFANG ANJING ELECTRONICS

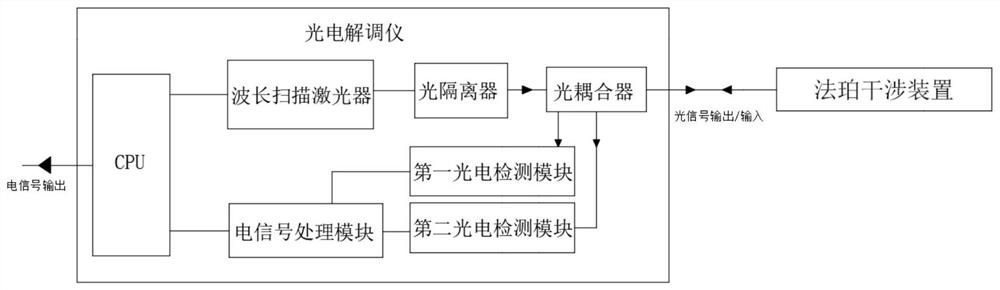

Extrinsic optical fiber Fabry-Perot interference pressure sensor

PendingCN112903154AReduce complex processReduce investmentForce measurement by measuring optical property variationConverting sensor output opticallyEngineeringMaterials science

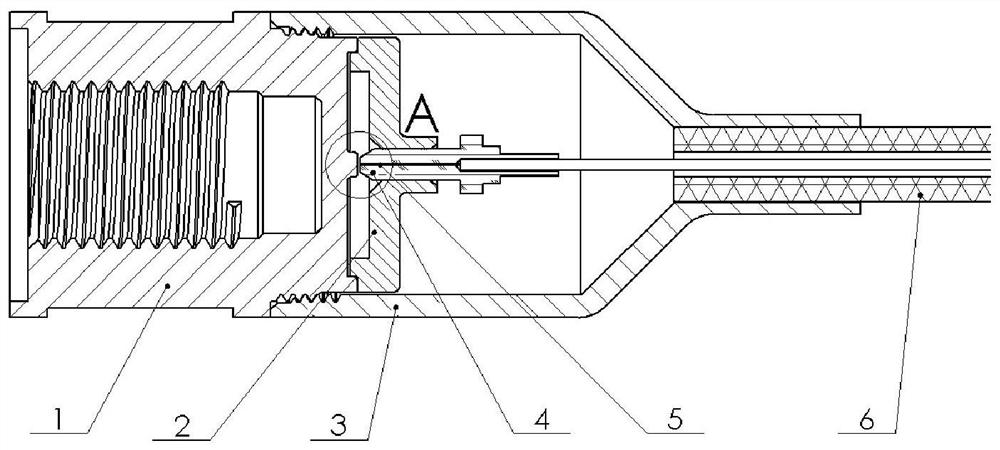

The invention relates to the technical field of optical fiber sensing, in particular to an extrinsic optical fiber Fabry-Perot interference pressure sensor which comprises a stress cylinder, a shell, a supporting ring and an insertion core with an optical fiber. One end face of the stress cylinder is in threaded connection with the shell, the end face penetrates into the shell and is fixedly connected with the supporting ring, a cavity is reserved between the end face and the supporting ring, and the FC / UPC ceramic ferrule is fixed to a center hole of the supporting ring; and the optical fiber in the insertion core is perpendicular to the end face of the stress cylinder, and the end face of the stress cylinder, the optical fiber in the insertion core and a gap between the stress cylinder and the insertion core form a Fabry-Perot cavity of the extrinsic Fabry-Perot interference pressure sensor. The extrinsic optical fiber Fabry-Perot interference pressure sensor is insensitive to a measured medium, can meet the capability of simultaneously monitoring liquid and gas, and is applied to the technical field of optical fiber sensing.

Owner:重庆拜安科技有限公司

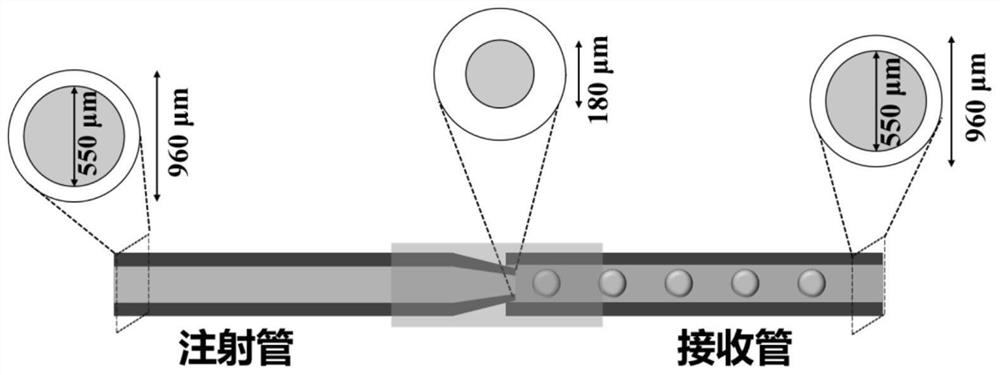

Microporous granular carbon and preparation method thereof

ActiveCN112169756AIncrease the content of basic functional groupsImprove adsorption capacityProductsGas treatmentOil emulsionPolyvinyl alcohol

The invention belongs to the field of environment-friendly materials, and particularly relates to microporous granular carbon and a preparation method thereof. The technical problem to be solved by the invention is to provide microporous granular carbon and the preparation method thereof. The preparation method comprises the following steps: A, emulsifying a chitosan solution or a polyvinyl alcohol solution, an oil-in-water emulsifier and an organic solvent to obtain an internal phase solution; mixing a water-in-oil emulsifier and an organic solvent to obtain an external phase solution; mixinga cross-linking agent and the external phase solution to obtain a curing bath; B, respectively injecting the internal phase solution and the external phase solution into an injection tube and a collection tube of a capillary micro-fluidic chip to form a monodisperse water-oil emulsion, and injecting the monodisperse water-oil emulsion into the curing bath to be subjected to a cross-linking reaction with the cross-linking agent to obtain particles; and C, washing, drying and carbonizing the particles to obtain the microporous granular carbon. The method can be used for obtaining the microporous granular carbon, and is simple, easy to operate and pollution-free.

Owner:SICHUAN UNIV

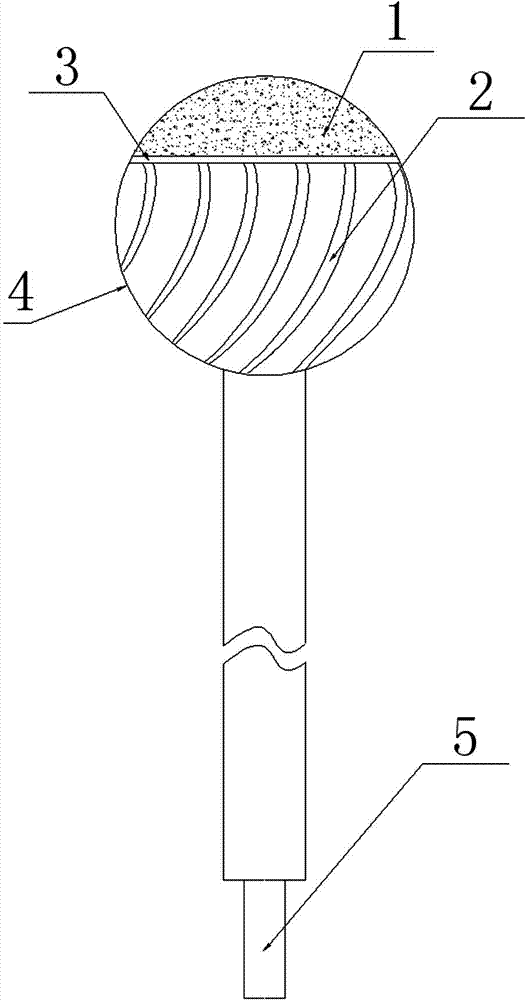

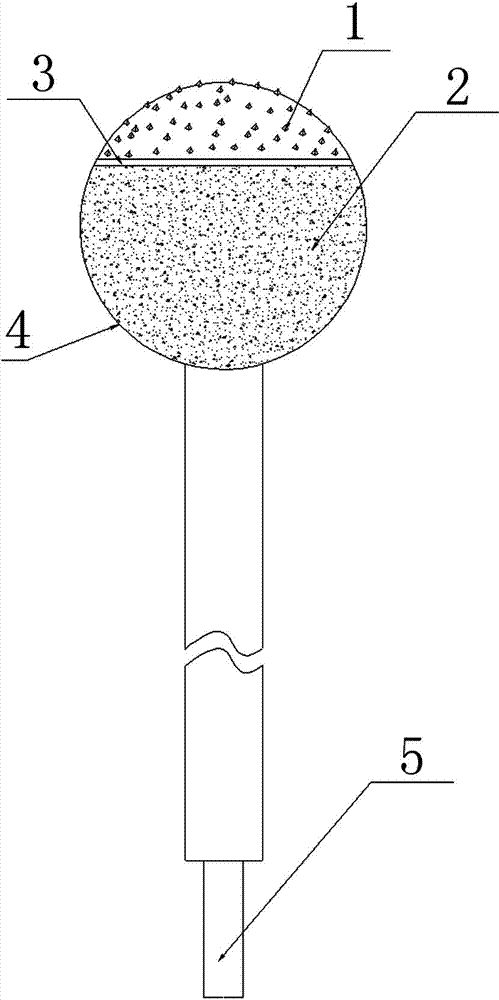

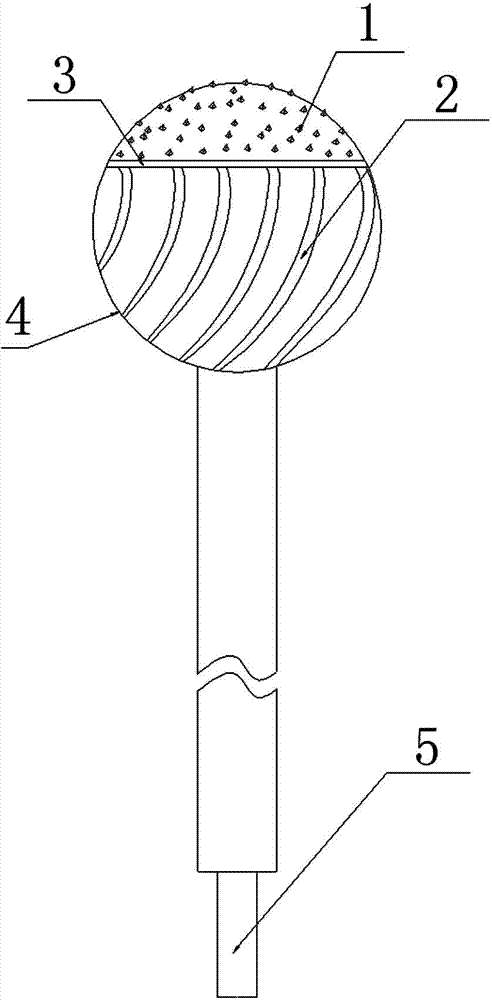

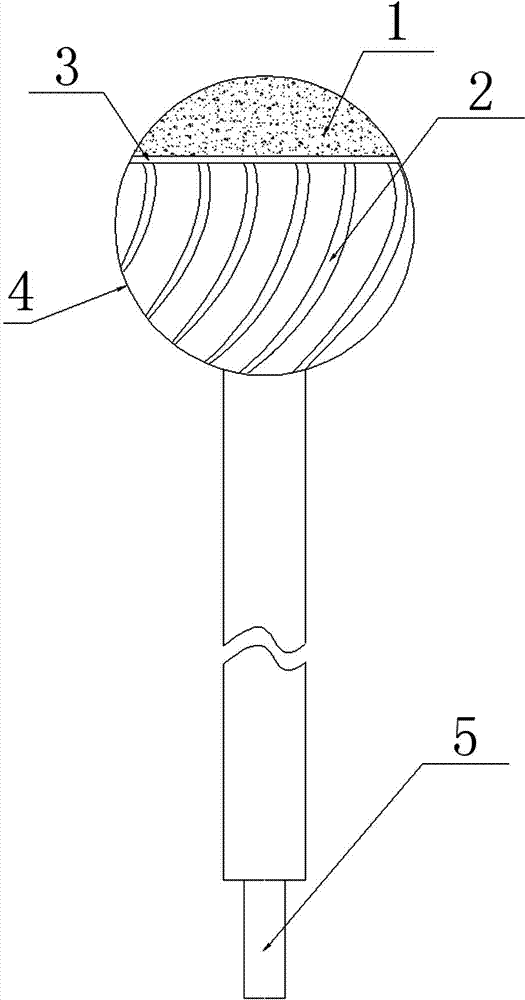

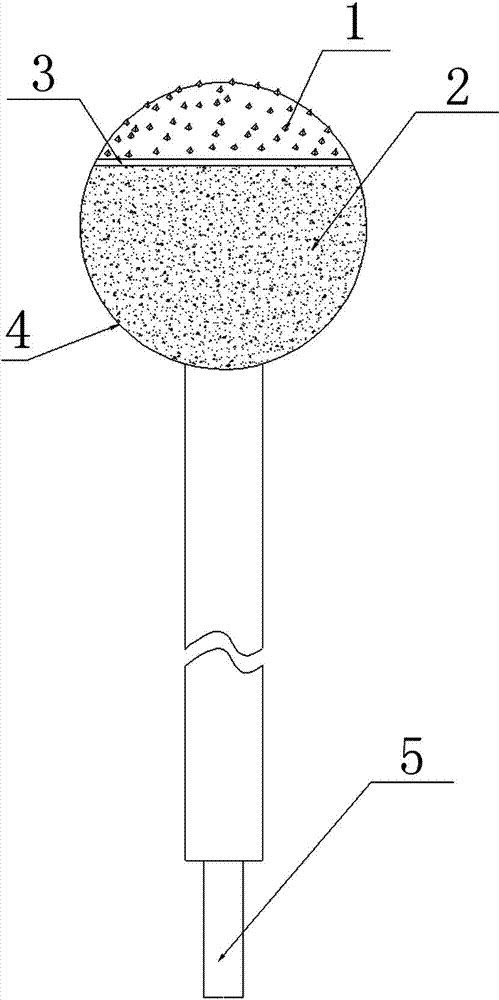

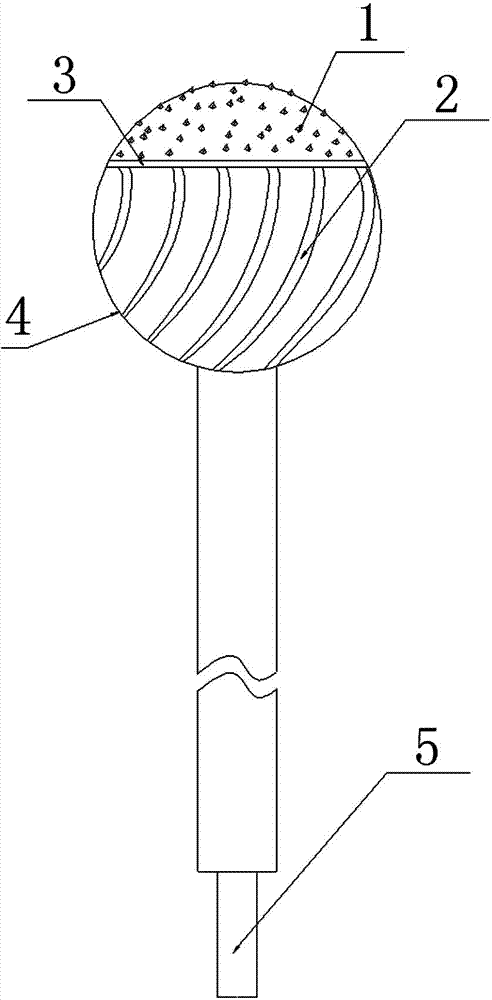

Medical combined operation drill bit

InactiveCN102871701BShorten the timeSolve the problem of repeated replacementSurgeryThree vesselsSpherical form

The invention relates to a medical combined operation drill bit; the operation drill bit is a rod-shaped body, wherein a spherical drill bit is arranged at one end of the rod-shaped body, and a connection handle is arranged at the other end of the rod-shaped body; two different types of cutting edges are arranged on the spherical drill bit and are positioned in different areas of the spherical drill bit and along the axial direction of the rod-shaped body; a first edge area is arranged at the front part of the spherical drill bit and occupies 1 / 5 to 4 / 5 of the spherical drill bit; a second edge area is arranged at the rear part of the spherical drill bit and occupies 2 / 3 to 4 / 5 of the spherical drill bit; a grinding edge or a cutting edge is arranged on the first edge area; and a cutting edge or a grinding edge is arranged on the second edge area. The medical combined operation drill bit can be used not only for punching osseous tissues in operations but also for cutting and polishing osseous tissues in operations, solves the problem that operation drill bits with simplex functions are replaced repeatedly during operations, saves a great amount of time wasted for replacement of drill bits, protects adjacent important nerves and blood vessels and effectively reduces clinical risks.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

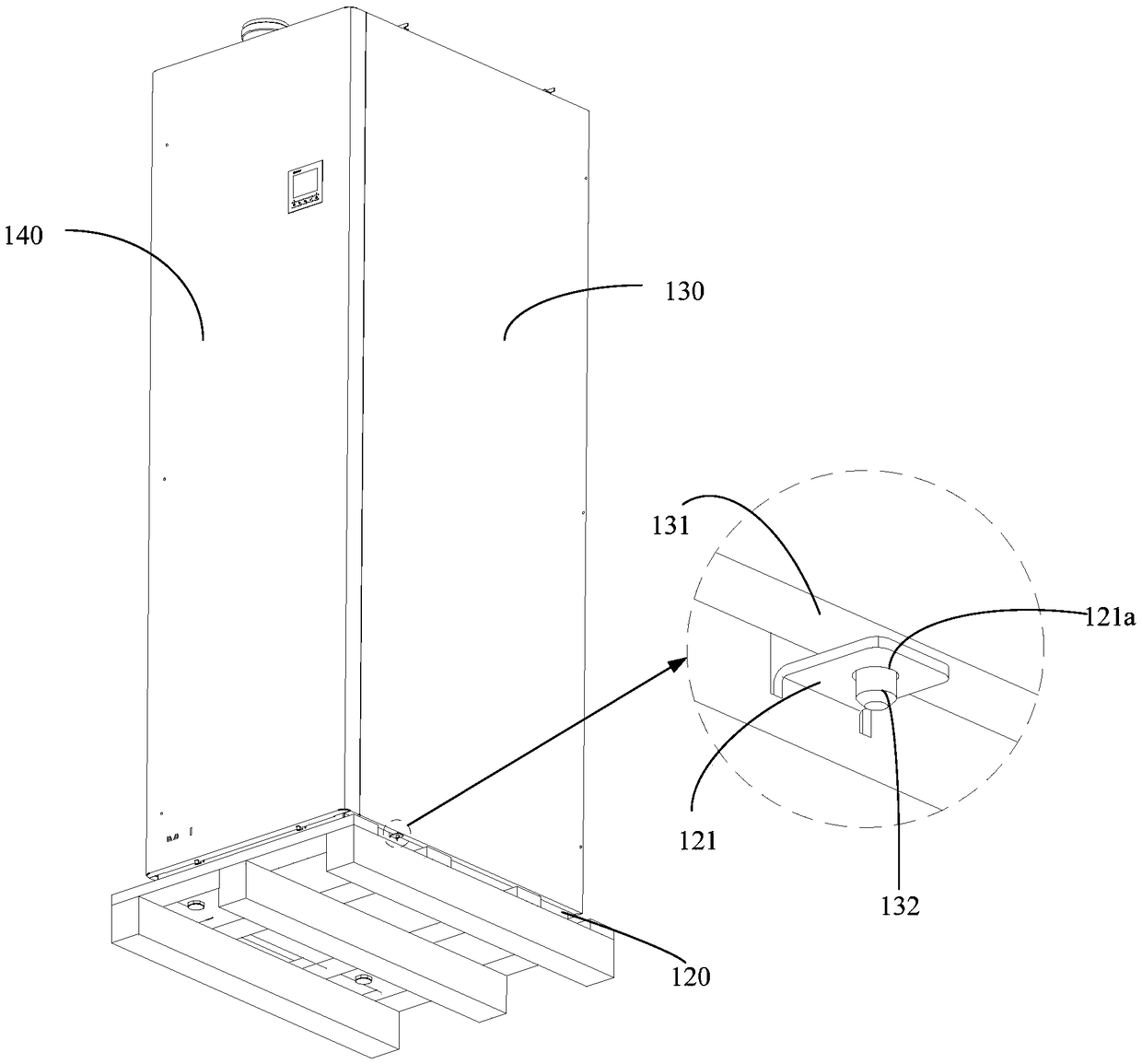

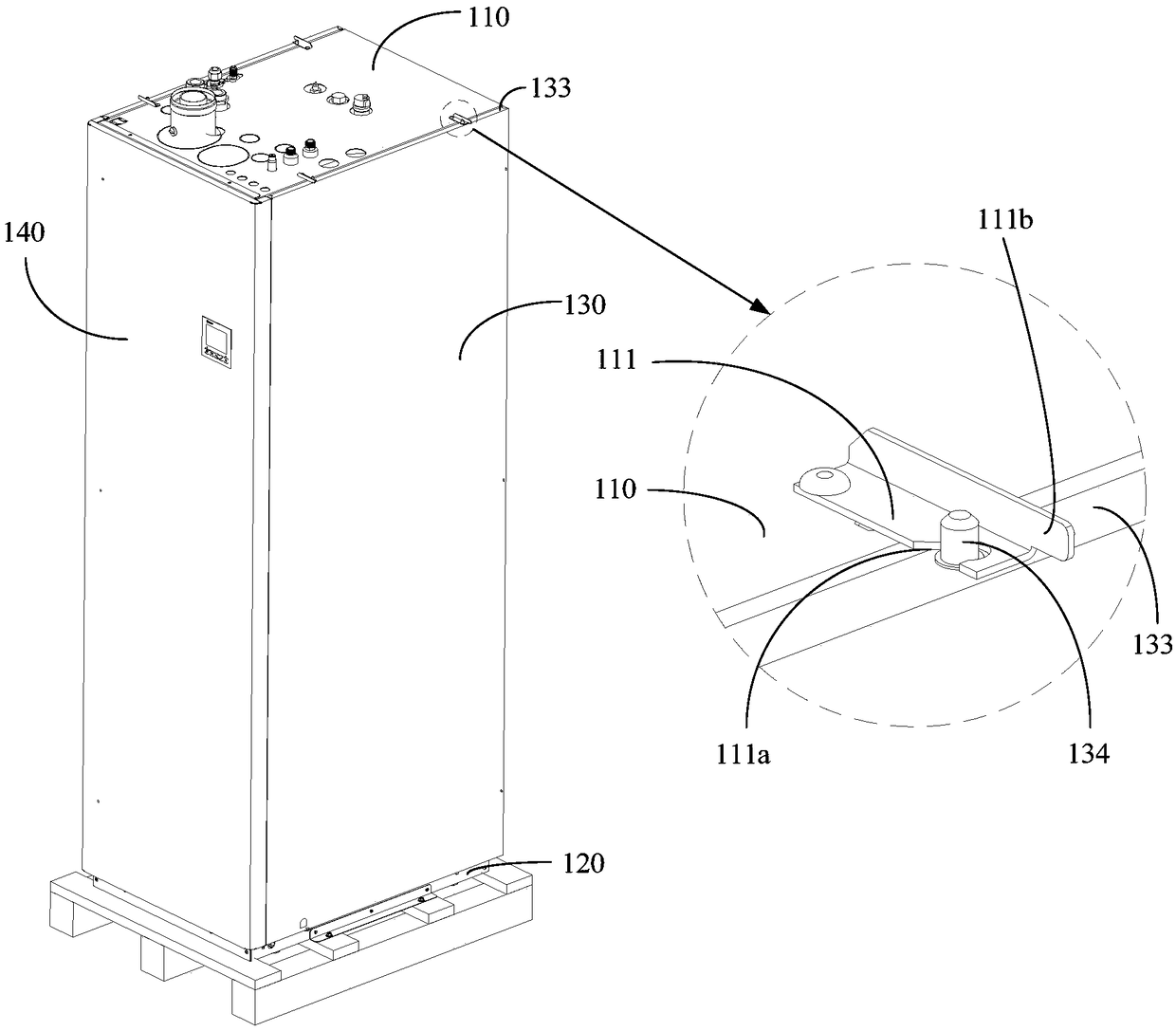

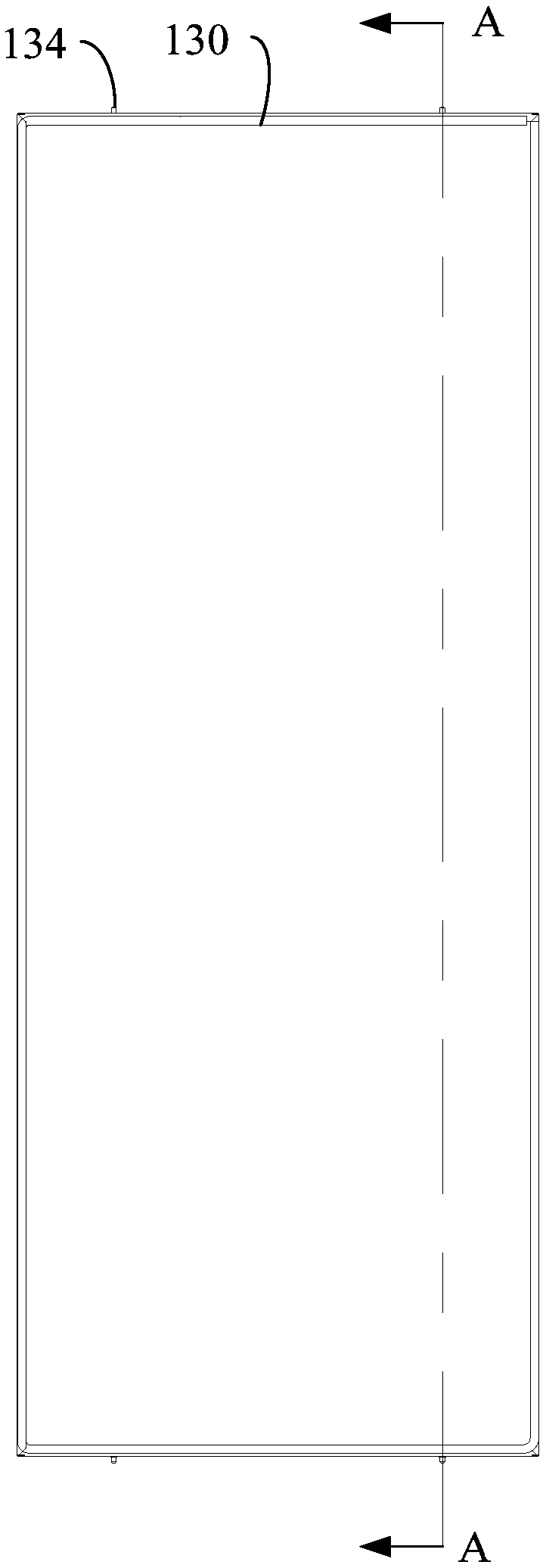

Tank body, composite hydraulic module unit and heat pump system

InactiveCN108800382AReduce complex processEasy to disassembleHeat pumpsSpace heating and ventilation detailsHeat pumpComputer module

The invention discloses a tank body, a composite hydraulic module unit and a heat pump system, wherein the tank body comprises a top cover, a base plate and side plates; the base plate and the top cover are arranged oppositely; the lower ends of the side plates are matched and connected with the base plate in an insertion manner; the upper ends of the side plates are connected with the top cover through clamping hooks; or the upper ends of the side plates are matched with the top cover in an insertion manner; and the lower ends of the side plates are connected with the base plate through the clamping hooks. According to the tank body disclosed by the invention, one end of each side plate is matched and connected with the base plate (or the top cover) in an insertion manner; the other end of each side plate is connected with the top cover (or the base plate) through the corresponding clamping hook; thus, when a worker needs to maintain a component inside the tank body, the worker can implement dismounting of the side plates by firstly opening the clamping hooks and subsequently lifting up (or pulling down) the side plates, or implement mounting of the side plates, and thus a complexprocess for dismounting screws is canceled, and the overall dismounting process is more convenient.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Medical combined operation drill bit

InactiveCN102871701AShorten the timeSolve the problem of repeated replacementSurgeryThree vesselsSpherical form

The invention relates to a medical combined operation drill bit; the operation drill bit is a rod-shaped body, wherein a spherical drill bit is arranged at one end of the rod-shaped body, and a connection handle is arranged at the other end of the rod-shaped body; two different types of cutting edges are arranged on the spherical drill bit and are positioned in different areas of the spherical drill bit and along the axial direction of the rod-shaped body; a first edge area is arranged at the front part of the spherical drill bit and occupies 1 / 5 to 4 / 5 of the spherical drill bit; a second edge area is arranged at the rear part of the spherical drill bit and occupies 2 / 3 to 4 / 5 of the spherical drill bit; a grinding edge or a cutting edge is arranged on the first edge area; and a cutting edge or a grinding edge is arranged on the second edge area. The medical combined operation drill bit can be used not only for punching osseous tissues in operations but also for cutting and polishing osseous tissues in operations, solves the problem that operation drill bits with simplex functions are replaced repeatedly during operations, saves a great amount of time wasted for replacement of drill bits, protects adjacent important nerves and blood vessels and effectively reduces clinical risks.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

Novel construction process for EPS (expandable polystyrene) geotechnical block of onshore wind power plant

InactiveCN110984209AReduce productionReduce dosageFoundation engineeringPre stressArchitectural engineering

The invention discloses a novel construction process for an EPS (expandable polystyrene) geotechnical block of an onshore wind power plant. The process comprises the following steps of placing and fixing a pin in the center of the bottom surface of a foundation pit, then placing a cut EPS block in the center of the bottom surface of the foundation pit, and laying fine aggregate concrete around thebottom of the EPS block; pouring a cushion layer and maintaining the cushion layer; correspondingly carrying out different connection fitting mounting modes on a foundation ring and a pre-stressed anchor bolt type foundation due to different connection modes of the foundation and a tower cylinder; and laying a template, binding steel bars around the block, carrying out encryption, laying a pipeline, pouring concrete, carrying out maintenance, and filling soil for burying after the maintenance is completed. Compared with a traditional onshore fan construction process, the novel construction process for the EPS block has the advantages that the prefabrication, laying and welding work of an original foundation ring support is innovated, and a cushion layer construction mold and a construction mode are improved, so that the construction precision and efficiency are guaranteed.

Owner:SHANXI INSTALLATION GRP CO LTD +1

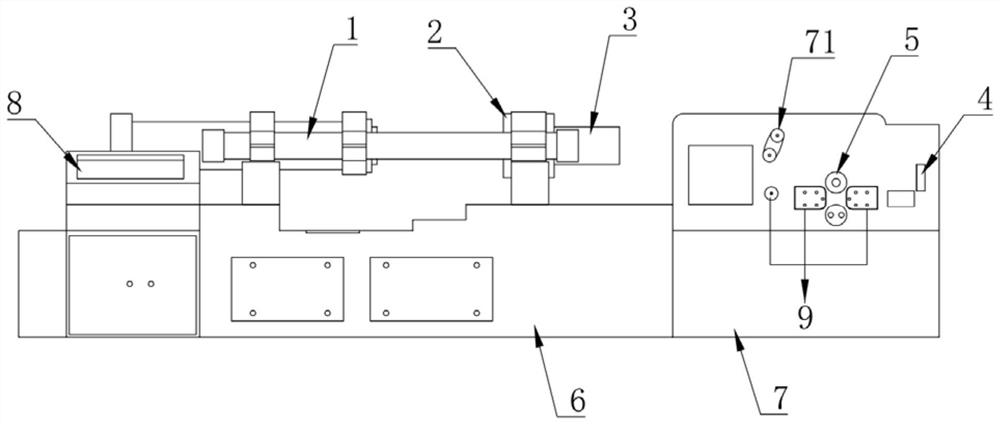

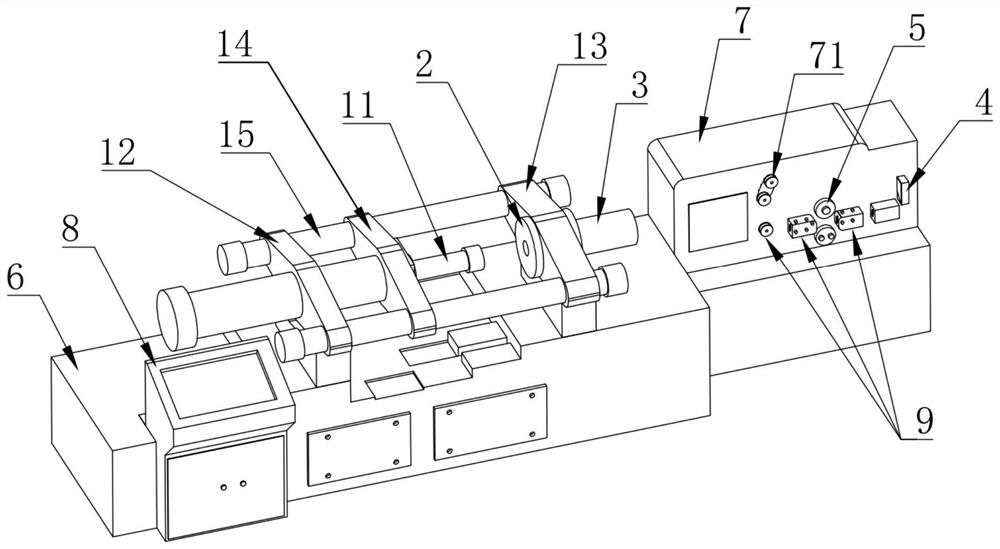

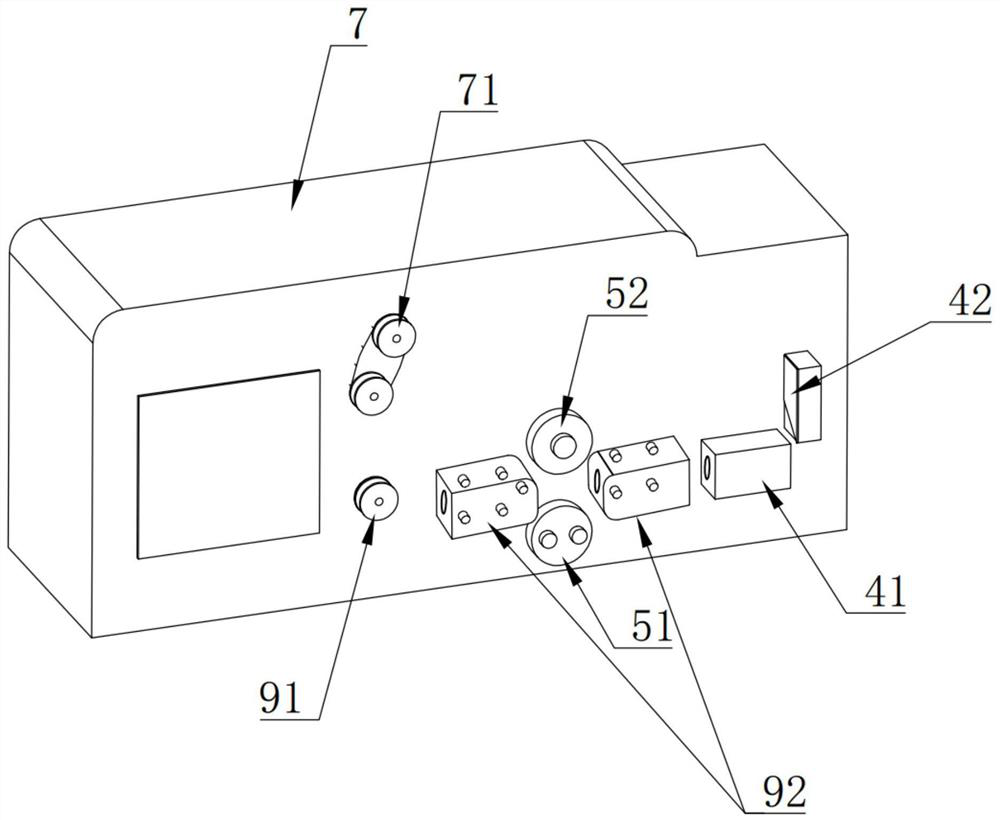

Smooth rectangular soldering tin sheet preparation system and preparation method

The embodiment of the invention discloses a smooth rectangular soldering tin sheet preparation system and a preparation method. The preparation system comprises a pushing and extruding mechanism, a heating device, a rectangular hole mold and a shearing mechanism which are sequentially arranged from left to right, wherein a feeding port for placing a tin column for micro-softening is formed in the portion, on the pushing and extruding mechanism side, of the heating device, the rectangular hole mold is fixed to the heating device, a discharging port is formed in the side, on the shearing mechanism, of the rectangular hole die, the discharging port is communicated with the feeding port; the pushing and extruding mechanism comprises an extruding shaft for extruding the tin column from the heating device to the rectangular hole die, wherein a feeding mechanism for guiding a formed rectangular tin welding wire to the shearing mechanism is further arranged between the heating device and the shearing mechanism. According to the invention, a tin material is heated to a micro-softening stage, extrusion forming is carried out by the pushing mechanism and the rectangular hole mold, and in addition, automatic cutting and connecting production is carried out by combining the shearing mechanism, so that a phenomenon of uneven appearance of a soldering tin sheet caused by the existing production mode is improved, and the piece placing stability of SMT equipment during production is improved.

Owner:铭觉电子科技(苏州)有限公司

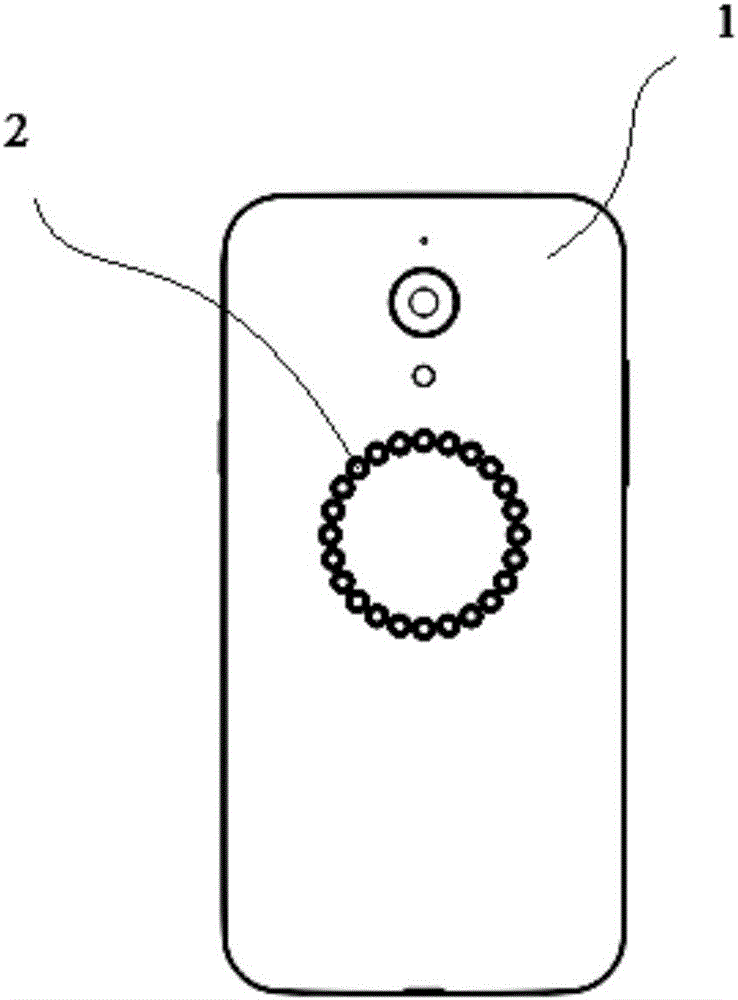

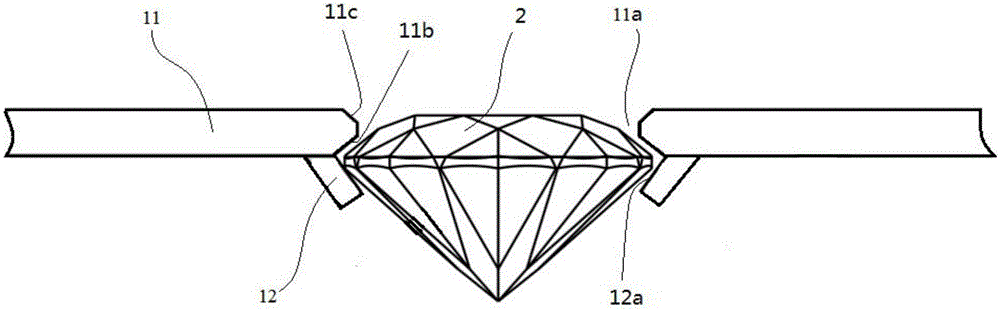

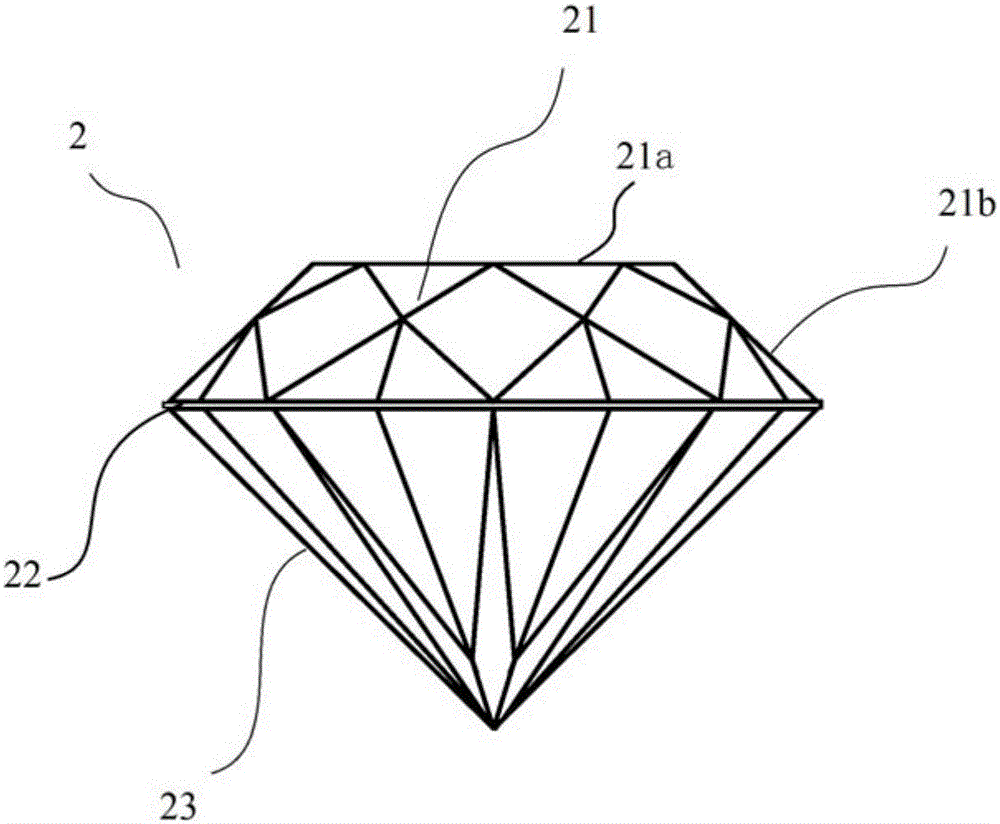

Electronic device

InactiveCN106413320AOmit to useReduce complex processCasings/cabinets/drawers detailsEngineeringElectric equipment

The invention relates to an electronic device. The electronic device comprises a housing and a decoration component. The housing consists of a housing body and a protruding part, both in connection with each other. The protruding part protrudes towards the inner part of the electronic device from the housing body to form a clamping structure with the housing body. The housing body is provided with an installation hole. The decoration component, through the clamping structure, is fixedly arranged in the installation hole. According to the technical schemes of the invention, a metal clamping holder is not needed, therefore, avoiding the time-consuming and complicated processing for the metal clamping holder and saving the manufacturing cost.

Owner:GUANGDONG MAXON COMM

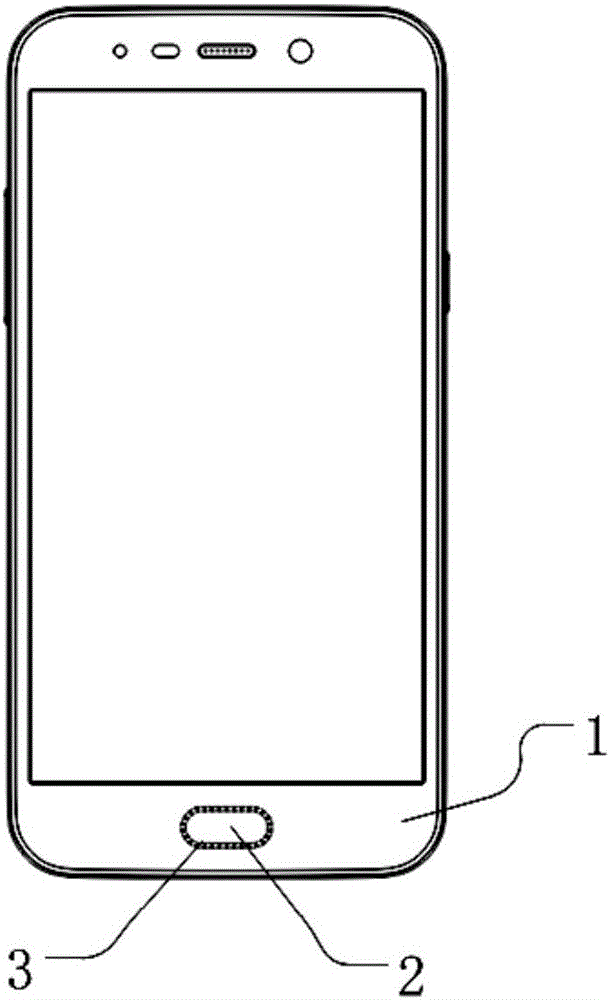

Electronic device and method for inlaying decoration component in electronic device

InactiveCN106790786AOmit to useReduce complex processTelephone set constructionsManufacturing technologyEngineering

The invention relates to the technical field of electronic device manufacturing and particularly relates to an electronic device and a method for inlaying a decoration component in the electronic device. The electronic device comprises a shell, a function part and the decoration component. The function part is mounted in the shell. The function part comprises a function area, a containing space and a limiting part. The function area is used for operating the electronic device. The containing space is located outside of the function area and comprises an opening. The containing space is communicated with the outside world through the opening. The decoration component is contained in the containing space. The limiting part is located outside of the opening and is used for compressing the decoration component. According to the scheme, a metal card tray is eliminated, a complicated technology of processing the metal card tray is eliminated, and the processing cost is saved.

Owner:SHENZHEN TINNO WIRELESS TECH

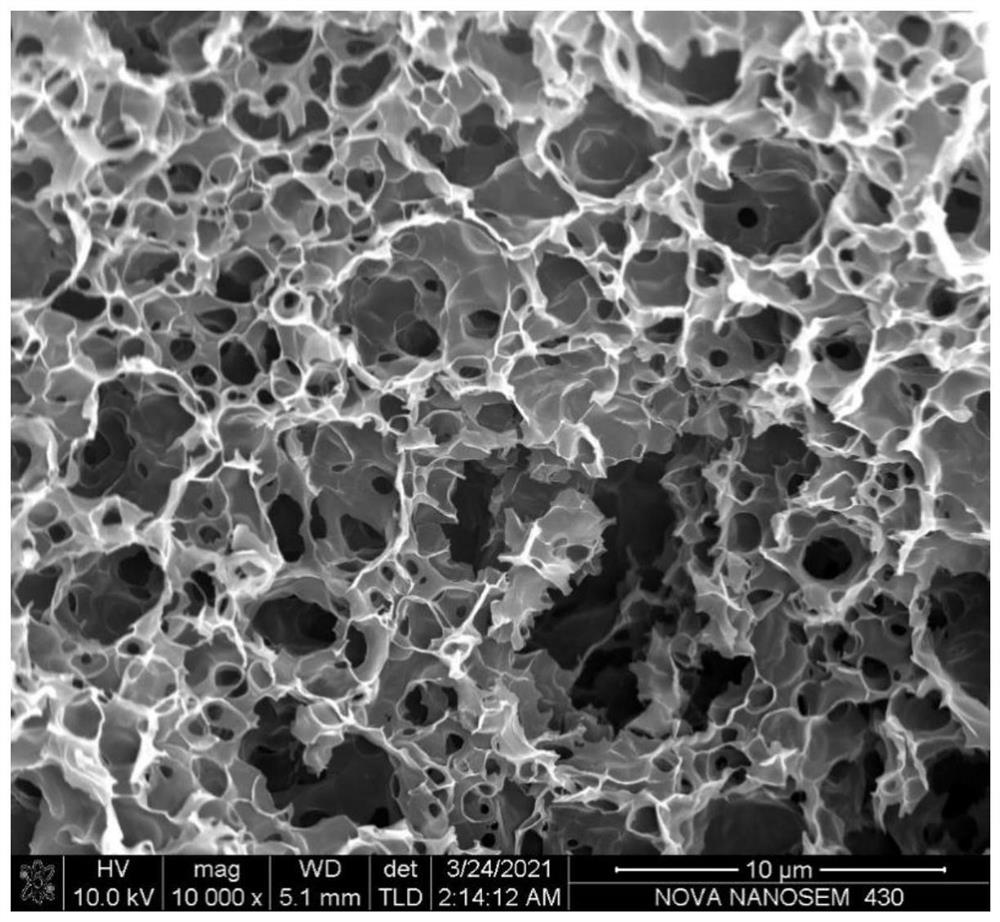

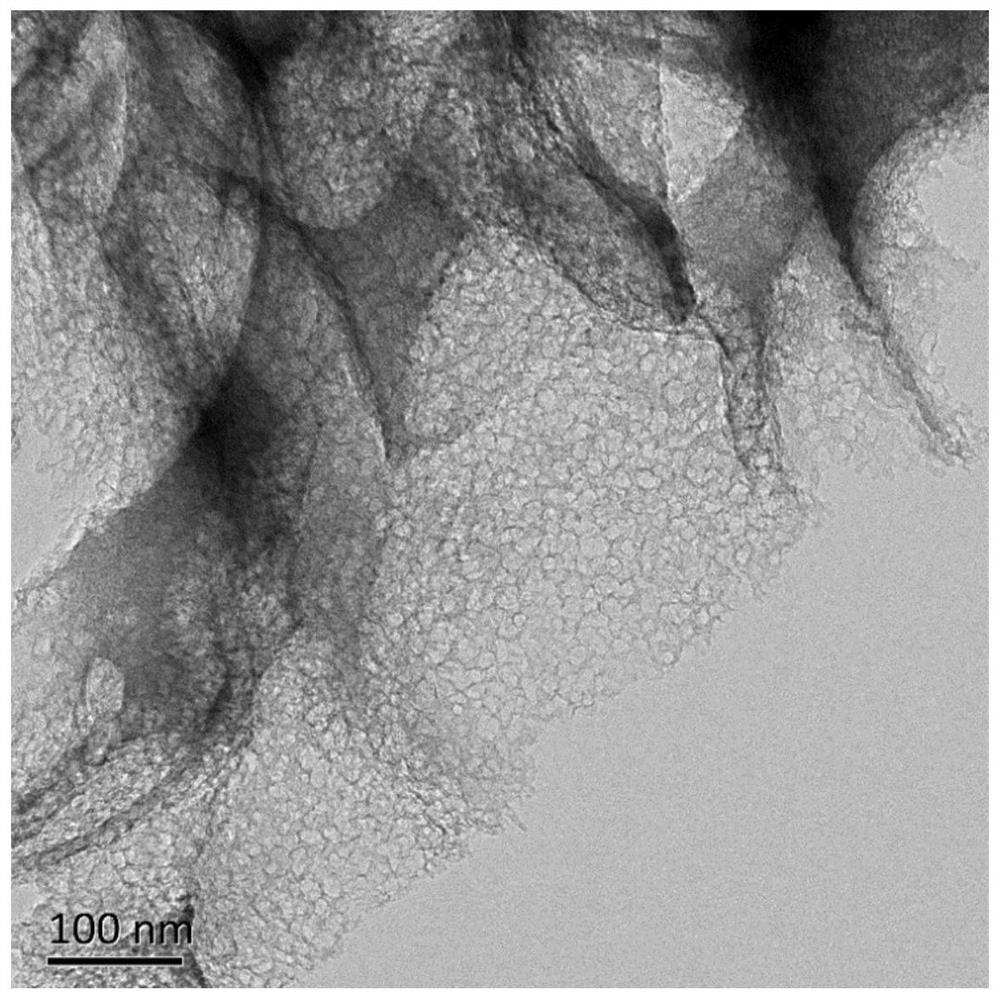

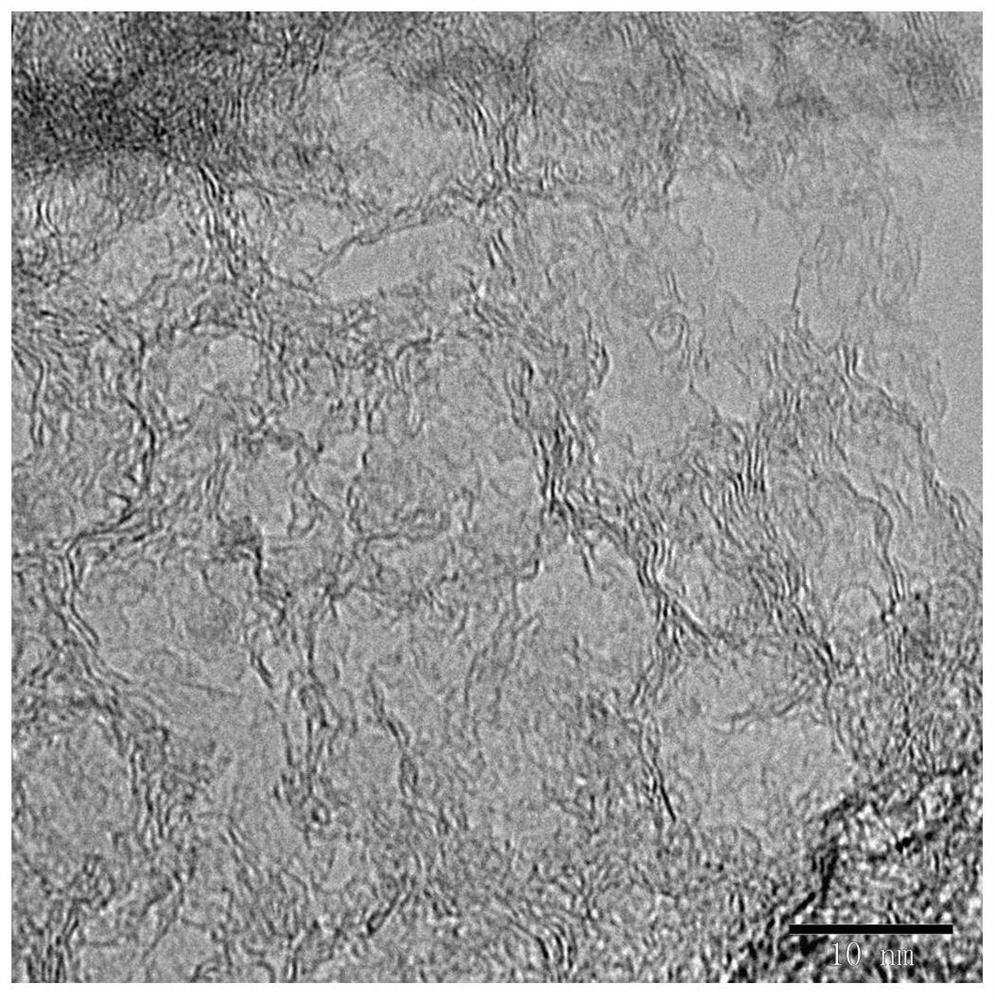

Low-temperature environment-friendly method for preparing in-plane porous few-layer graphene material

The invention discloses a low-temperature environment-friendly method for preparing an in-plane porous few-layer graphene material. The method comprises the following steps: mixing a carbon source, a grinding agent and grinding balls, and grinding with a ball mill; the carbon source is a transition metal organic compound; the grinding agent is a cubic structure crystal with water solubility; under a protective atmosphere, carrying out heating carbonization treatment on the obtained material; adding an acid solution into the obtained material, and washing off metal; and washing and drying the obtained material to obtain the in-plane porous few-layer graphene. The preparation method is simple and easy to implement, small in pollution, low in cost and high in efficiency, the prepared few-layer graphene has a rich in-plane porous structure, the number of layers is 2-20, the specific surface area is 50-1000 m < 2 > / g, the pore diameter is 1-40 nm, and the few-layer graphene can be applied to the fields of conductive agents, catalyst carriers, batteries, supercapacitors, high-performance transistors, sensors and the like.

Owner:SOUTH CHINA UNIV OF TECH

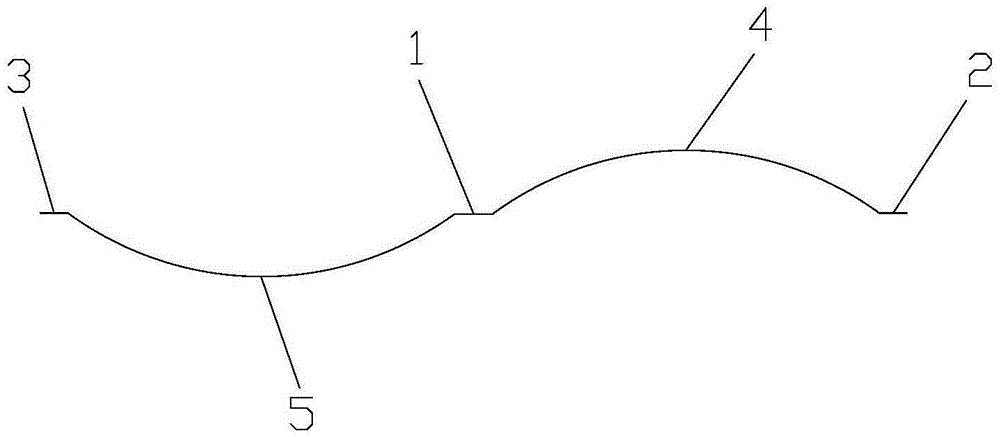

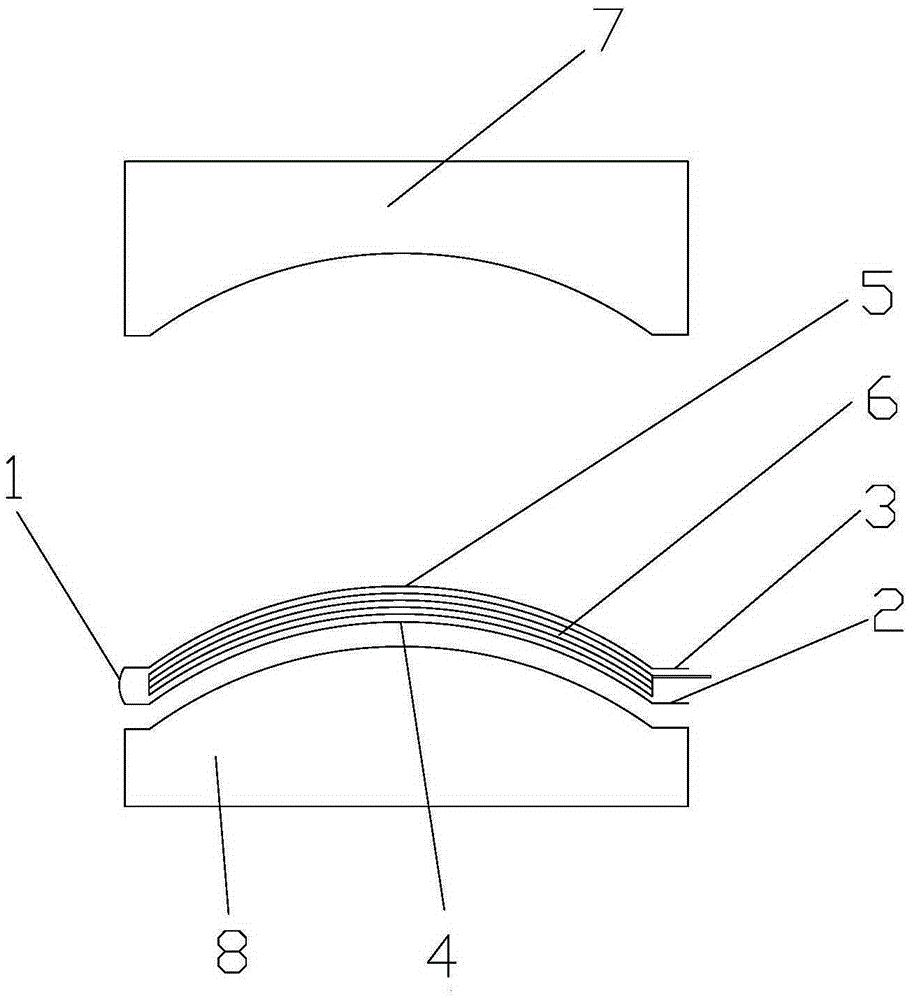

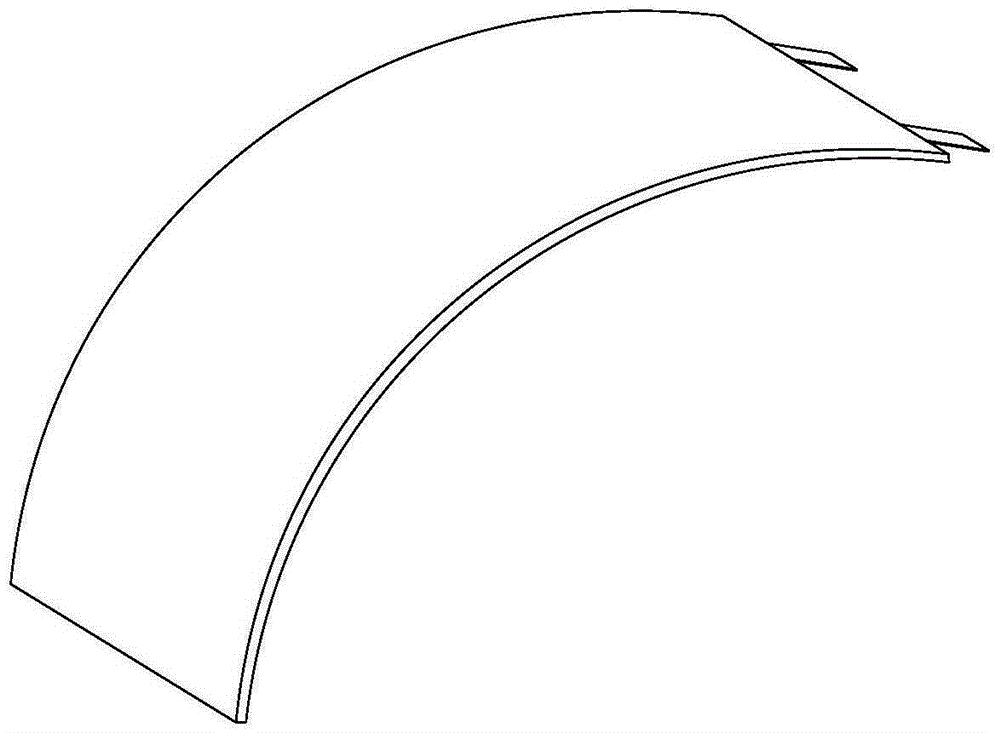

Manufacture method of arc soft-package lithium ion battery

ActiveCN105322236AGood lookingReduce complex processFinal product manufactureSecondary cellsElectrical batteryEngineering

The invention discloses a manufacture method of an arc soft-package lithium ion battery. In a preparation step of a cell, a positive plate with a positive tag and a negative plate with a negative tag are separated by virtue of a diaphragm, the diaphragm is wound surrounding a winding needle, during the winding process, the rotation axial direction of the winding needle is consistent with the axial direction of bending radian of the cell to be prepared, and after the winding is completed, the winding needle is withdrawn; a cell packaging step specifically comprises the following steps: I, preparing an aluminum-plastic shell, wherein the aluminum-plastic shell comprises a left shell and a right shell connected to the left shell, the right shell is provided with a first arc section, and the left shell is provided with a second arc section; II, placing the cell into the first arc section of the right shell, folding the aluminum-plastic shell, and enabling the second arc section to cover the cell; and then hot sealing the folded aluminum-plastic shell. The manufacture process is simple to operate, low in cost, easy to realize, capable of greatly improving the production efficiency and rate of finished products and suitable for preparing various arc soft-package lithium ion batteries in complex shapes.

Owner:XIAN SAFTY ENERGY TECH

Macromolecular nano coating material composite slurry

The present invention relates to one kind of nanometer composite polymer paint slurry, which consists of water 30 wt%, dispersant 0.6 wt%, nanometer polymer assistants 1 wt%, sodium bentonite 2 wt%. heavy calcium carbonate 45 wt%, wollastonite 10 wt%, kaolin 10 wt% and titanium white powder 0-5 wt%, where, the nanometer polymer assistants includes aluminum sulfate 20 wt%, sodium silicate 50 wt%, pentaerythritol 20 wt%, hydroxypropyl methyl cellulose 2.5 wt% and sodium fluosilicate 7.5 wt%. The nanometer composite polymer paint slurry has the crystal structure of the components maintained and narrow size distribution, and can form coating with fire resistance, no smoke in fire, high adhesion to inorganic base material and other advantages.

Owner:赵玉洪

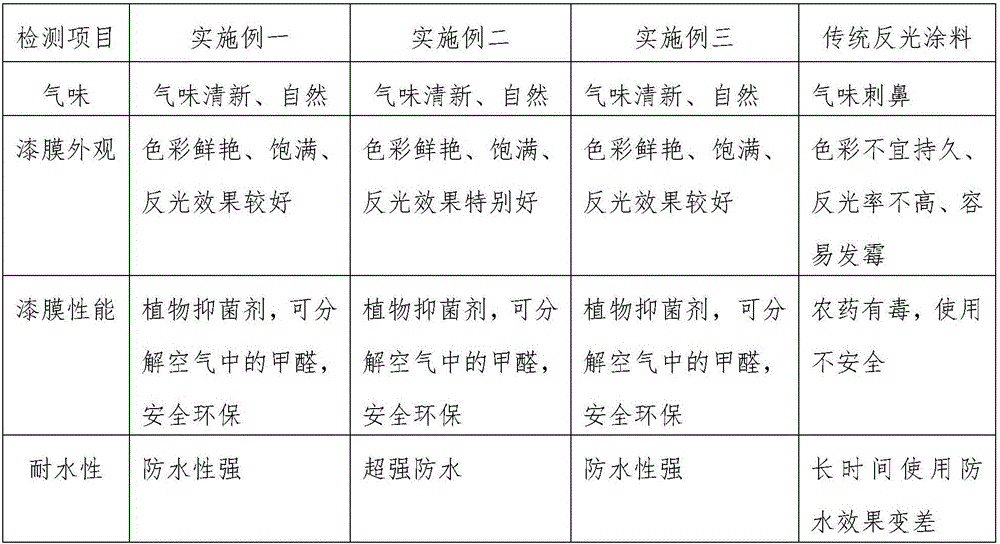

Anticorrosion light reflecting coating

InactiveCN106497429AReduce complex processGood durabilityAntifouling/underwater paintsRosin coatingsRosinNickel oxides

The invention relates to the technical field of coatings, in particular to an anticorrosion light reflecting coating. The anticorrosion light reflecting coating comprises, by weight, 30-35 parts of rosin resin, 25-30 parts of polyamide resin, 20-25 parts of ethylene glycol ethyl ether acetate, 10-15 parts of zinc borate, 6-9 parts of polybenzimidazole, 9-13 parts of ultraviolet light absorbers, 2-6 parts of nickel oxide, 3-7 parts of manganese oxide, 1-4 parts of magnesium oxide, 9-14 parts of organic pigments and 2-5 parts of plant insect-resistant bacteriostatic agents. The anticorrosion light reflecting coating can absorb ultraviolet rays to reflect light and change color, is better in durability and low in manufacturing cost and takes pure-natural plant raw materials as corrosion inhibitors, so that the coating is free from toxicity, environmentally friendly and safe to use.

Owner:FOSHAN JIAMULE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com