Preparation method of lithium ion battery high-nickel cathode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as instability of oxyhydroxides, safety issues, and influence on oxidation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

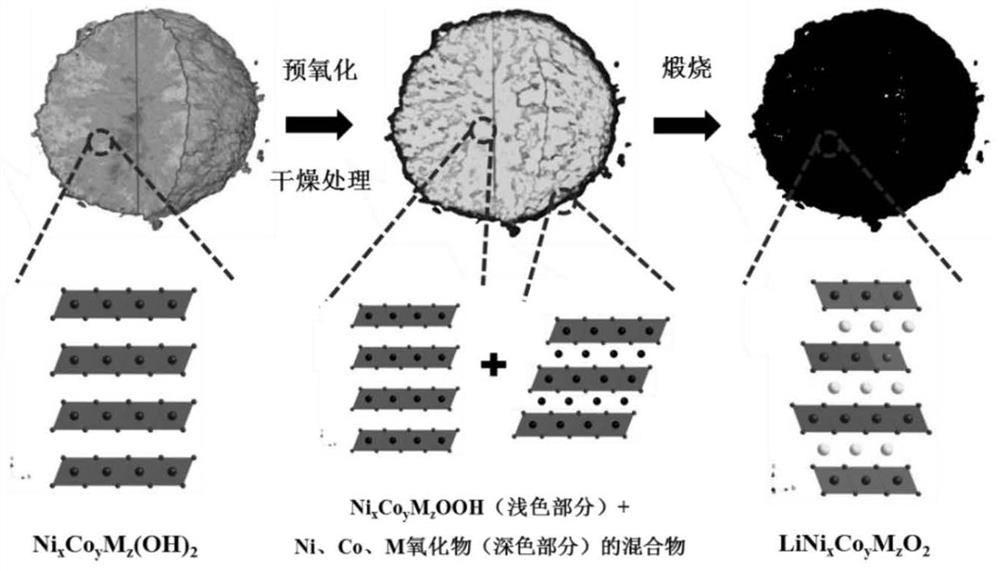

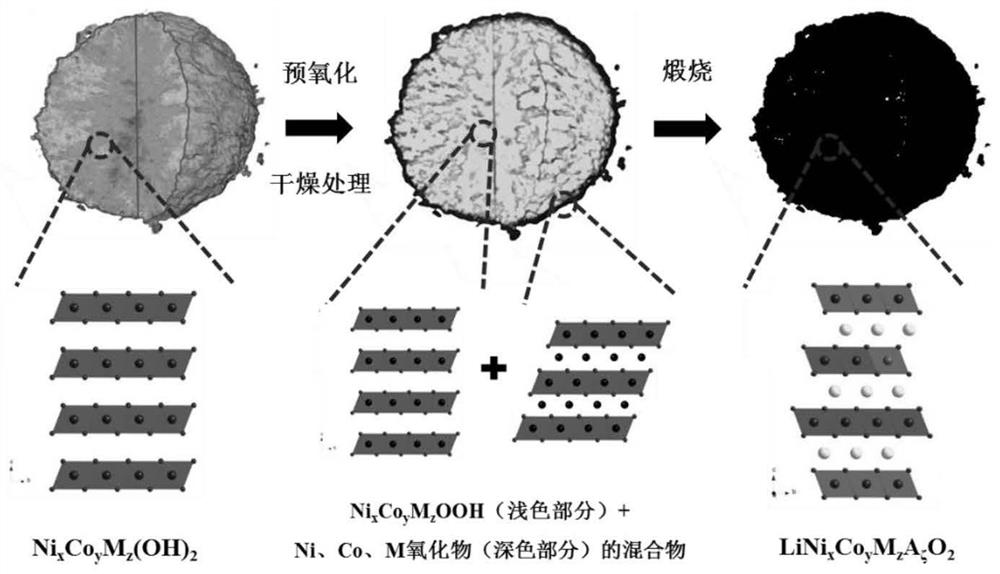

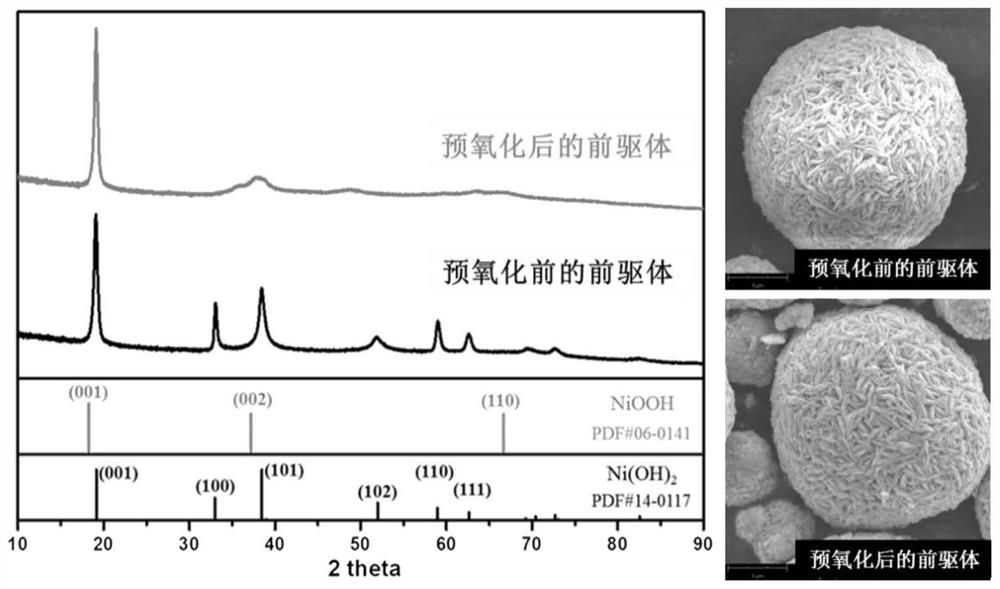

[0056] A method for preparing a high-nickel positive electrode material for a lithium-ion battery, characterized in that it comprises the following steps:

[0057] (1) Preparation of cathode material precursor:

[0058] According to the chemical formula LiNi x co y m z o 2 A salt solution containing a certain stoichiometric ratio of Ni, Co and M elements is obtained under alkaline conditions by adding a complexing agent and using a coprecipitation reaction to obtain a solution containing Ni x co y m z (OH) 2 alkaline slurry.

[0059]In a specific embodiment, where x≥0.6, 0.05≤y≤0.4, 0≤z≤0.4, and x+y+z=1, M is one or more of +4-valent metal elements, preferably One or more of Mn, Ti or Zr. The salt solution of Ni, Co, and M elements is preferably a sulfate salt of Ni, Co, and M elements, which is regulated to an alkaline environment by using NaOH solution, for example, using a NaOH solution with a concentration of 2mol / L to adjust the pH value to 10-14 , the complexin...

Embodiment 1

[0079] The chemical formula of the high-nickel cathode material of the present embodiment is LiNi 0.83 co 0.12 mn 0.05 o 2 , including the following steps:

[0080] 1) Calculate and weigh the sulfate salts of Ni, Co, and Mn based on the ratio of molar ratio Ni:Co:Mn=0.83:0.12:0.05, add deionized water to mix and prepare a solution with a metal concentration of 2mol / L and add it to the reactor , adjust the reaction temperature to 60°C, inject ammonia water to keep the ammonia concentration at 0.5mol / L, inject 2mol / L NaOH solution to adjust the pH value to 11.5, stir at 500r / min, and react for 15h.

[0081] 2) After the reaction is over, add Na to the reactor 2 S 2 o 8 solution, keep Na in the kettle 2 S 2 o 8 The concentration of the solution was 1.2 mol / L, the pH value was adjusted to be kept at 12 by injecting 2 mol / L NaOH solution, the reaction temperature was 40° C., the stirring speed was 400 r / min, and the reaction was carried out for 6 hours.

[0082] 3) Filter...

Embodiment 2

[0085] The chemical formula of the high-nickel cathode material of the present embodiment is LiNi 0.75 co 0.15 mn 0.1 o 2 , including the following steps:

[0086] 1) Calculate with the ratio of molar ratio Ni:Co:Mn=0.75:0.15:0.1 and weigh the corresponding sulfate, add deionized water to mix and prepare a solution with a metal concentration of 2mol / L and add it to the reactor to adjust the reaction The temperature was 60°C, ammonia water was injected to keep the ammonia concentration at 0.5mol / L, 2mol / L NaOH solution was injected to adjust the pH value to 11.2, the stirring speed was 500r / min, and the reaction was carried out for 15h.

[0087] 2) After the reaction is over, add (NH 4 ) 2 S 2 o 8 solution, kept in the kettle (NH 4 ) 2 S 2 o 8 The solution concentration was 0.5 mol / L, the pH value was adjusted to 12 by injecting 2 mol / L NaOH solution, the reaction temperature was 80° C., the stirring speed was 400 r / min, and the reaction was carried out for 6.5 h.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com