Anticorrosion light reflecting coating

A reflective coating and corrosion-resistant technology, which is applied in anti-corrosion coatings, reflective/signal coatings, rosin coatings, etc., can solve the problems of complicated production process of glass beads, unfavorable human health, high price, etc., and achieve strong reflective ability and safe use , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

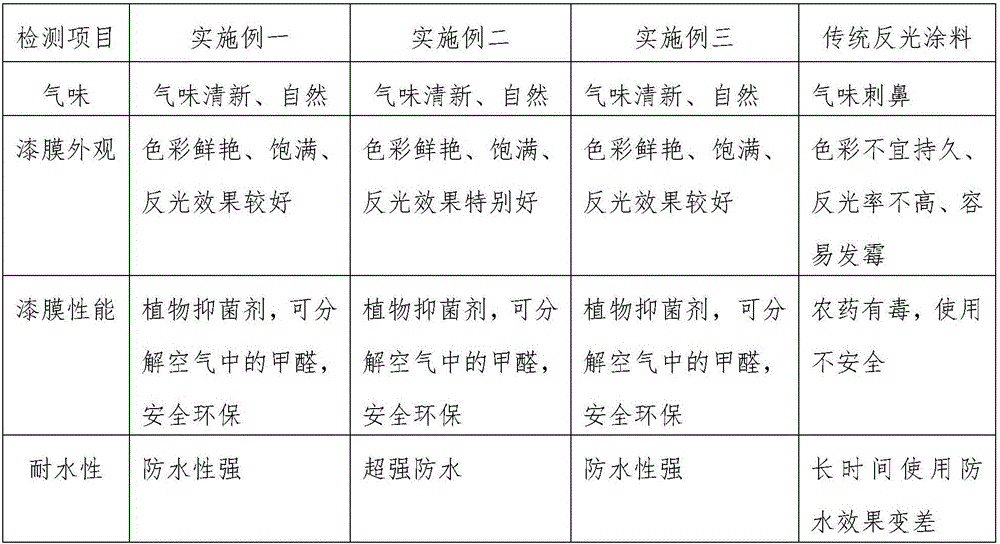

Examples

preparation example Construction

[0025] The preparation method of plant pest control bacteriostatic agent is divided into the following steps:

[0026] S1: Beat mint, garlic, ivy and begonia with a weight ratio of 1.5-2:1.8-2.3:1:2.5-3 into coarse powder, and pass through a 30-mesh sieve;

[0027] S2: Put mint, garlic, ivy and begonia coarse powder into the percolation cylinder, and use 60% hydrous ethanol for percolation extraction. If the weight of raw materials is 1kg, the amount of hydrous ethanol is 10 liters, and the flow rate is 8mL / min. collection of percolate;

[0028] S4: Concentrate the percolation solution with a vacuum film under the conditions of a water bath temperature of 80°C, a vacuum degree of 0.080Mpa, and an inflow rate of 200-250mL / min, and recover ethanol to obtain a concentrated solution containing 1.5g of raw materials per mL;

[0029] S3: Separating and enriching the obtained concentrated solution through a macroporous adsorption resin, followed by gradient elution with water, 35% a...

Embodiment 1

[0031] Get the following materials in parts by weight: rosin resin 30, polyamide resin 25, ethylene glycol ether acetate 20, zinc borate 10, polybenzimidazole 6, ultraviolet absorber 9, nickel oxide 2, manganese oxide 3, magnesium oxide 1 , organic pigments 9, plant insect repellent and bacteriostatic agent 2.

[0032] The preparation method of the plant insect-proof and antibacterial agent is divided into the following steps:

[0033] S1: Beat mint, garlic, ivy and begonia with a weight ratio of 1.5:1.8:1:2.5 into coarse powder, and pass through a 30-mesh sieve;

[0034] S2: Put mint, garlic, ivy and begonia coarse powder into the percolation cylinder, and use 60% hydrous ethanol for percolation extraction. If the weight of raw materials is 1kg, the amount of hydrous ethanol is 10 liters, and the flow rate is 8mL / min. collection of percolate;

[0035] S4: Concentrate the percolation liquid in a vacuum film under the conditions of a water bath temperature of 80°C, a vacuum d...

Embodiment 2

[0038] Get the following materials in parts by weight: rosin resin 33.6, polyamide resin 27.2, ethylene glycol ether acetate 23.4, zinc borate 13.3, polybenzimidazole 7.1, ultraviolet absorber 11, nickel oxide 4, manganese oxide 5.8, magnesium oxide 2.2 , Organic pigment 12, plant pest control and antibacterial agent 3.5.

[0039] The preparation method of the plant insect-proof and antibacterial agent is divided into the following steps:

[0040] S1: grind mint, garlic, ivy and begonia with a weight ratio of 1.8:2.1:1:2.7 into coarse powder, and pass through a 30-mesh sieve;

[0041] S2: Put mint, garlic, ivy and begonia coarse powder into the percolation cylinder, and use 60% hydrous ethanol for percolation extraction. If the weight of raw materials is 1kg, the amount of hydrous ethanol is 10 liters, and the flow rate is 8mL / min. collection of percolate;

[0042] S4: Concentrate the percolation liquid in a vacuum film under the conditions of a water bath temperature of 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com