Low-temperature environment-friendly method for preparing in-plane porous few-layer graphene material

A low-layer graphene and environmentally friendly technology, applied in the field of carbon nanomaterials, can solve problems such as pollution, complex and time-consuming process, and non-environmental protection, and achieve the effects of reducing complex process, fast ion transmission, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]A low-temperature and environmentally friendly method for preparing in-plane porous few-layer graphene is realized by the following steps:

[0046] 1) Weigh 6 g of commercial iron acetylacetonate, 12 g of sodium chloride, and 360 g of zirconia balls. Put the three into a ball mill jar with a volume of 1000mL, then install the ball mill jar on a planetary ball mill, and mill for 4 hours at a speed of 400r / min;

[0047] 2) heating the ball-milled product obtained in step 1) to 700°C at 5°C / min under an argon atmosphere in a tube furnace, and keeping it warm for 4 hours;

[0048] 3) Take out the carbonized product in step 2) and put it into a high-pressure reactor, add 80 mL of hydrochloric acid with a concentration of 3 mol / L, put it into an electric blast drying oven, and pickle it at 80°C for 12 hours;

[0049] 4) The material obtained in step 3) is washed and dried to obtain the in-plane porous few-layer graphene of the target sample.

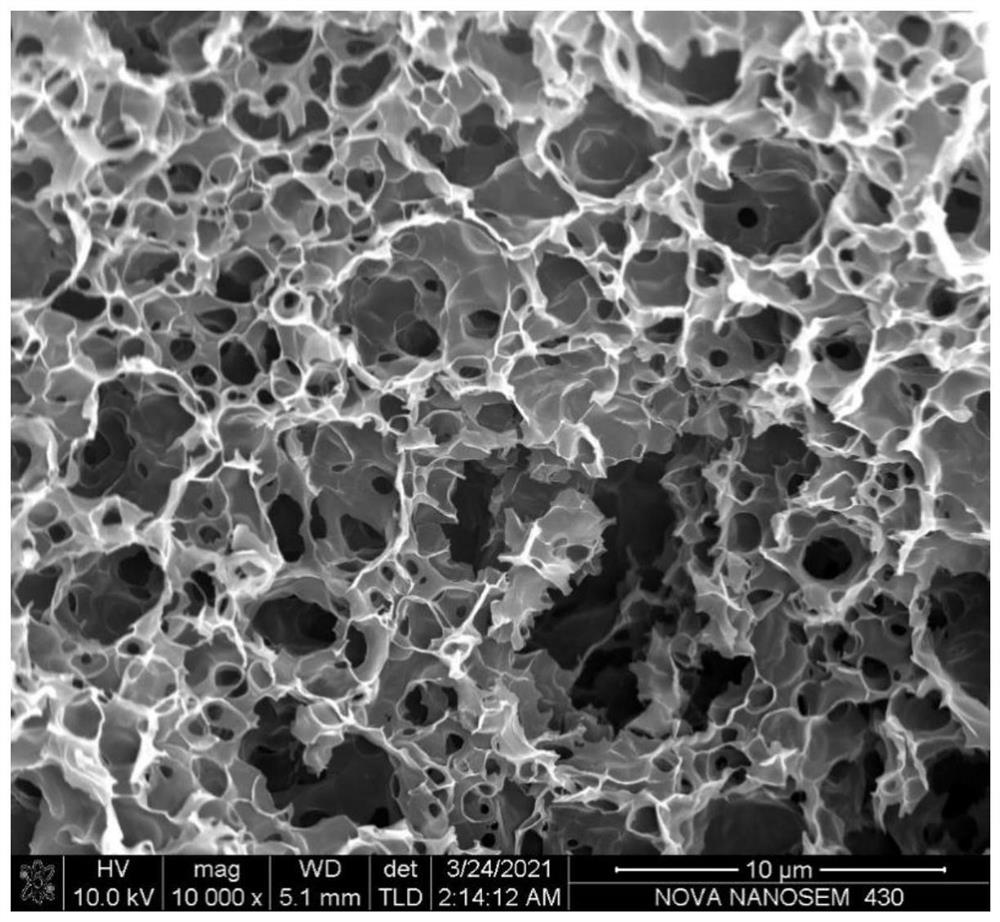

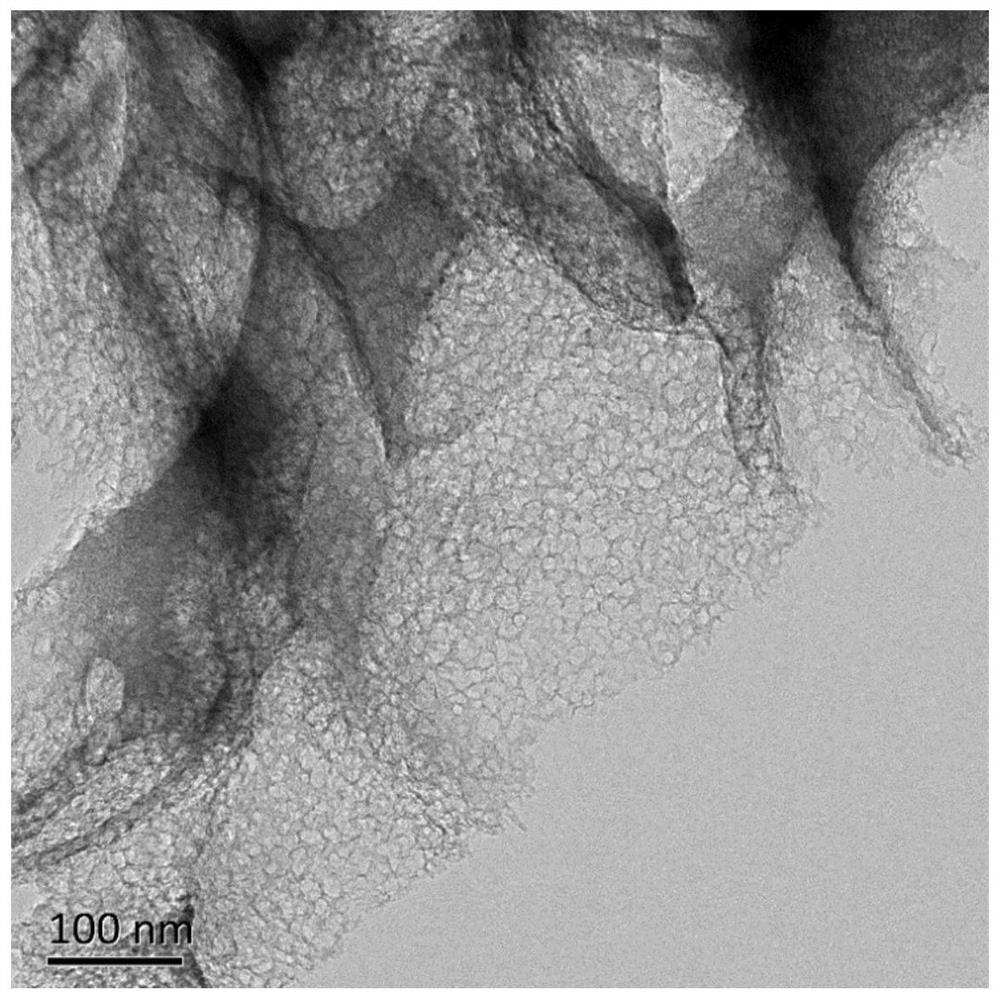

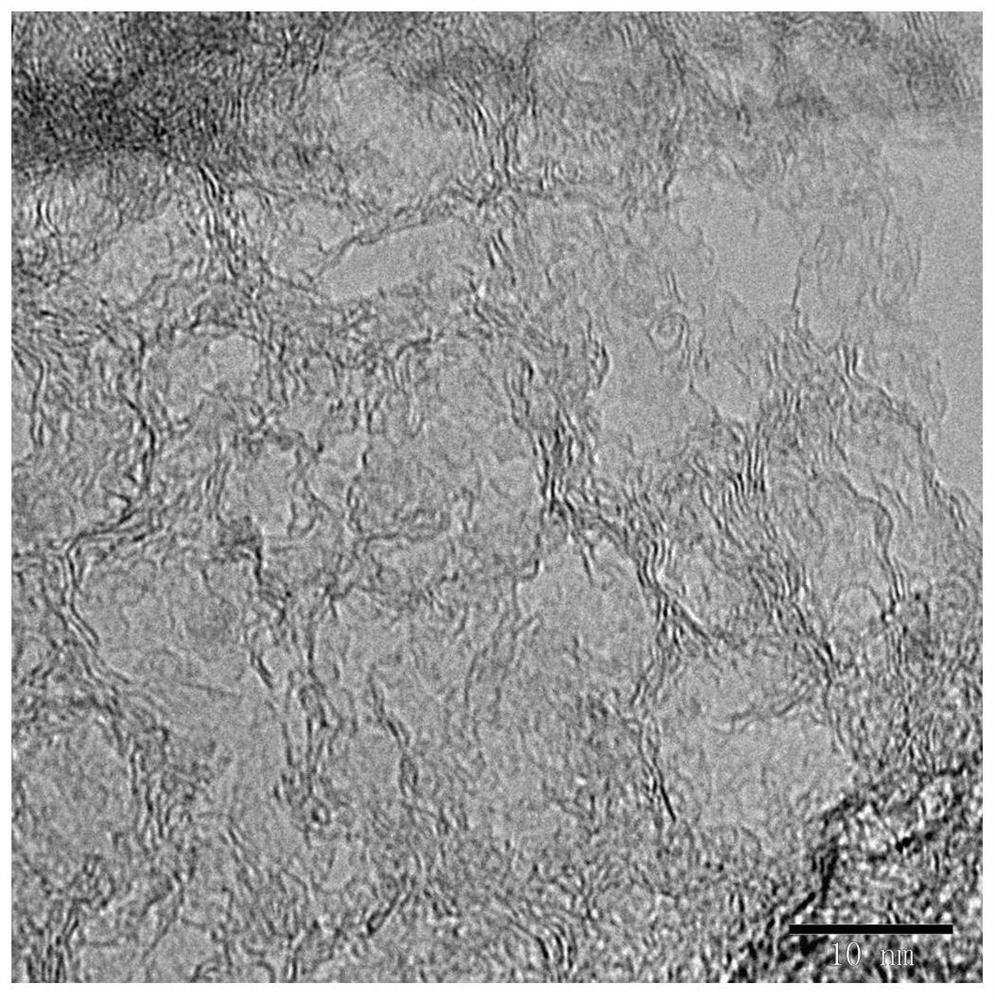

[0050] The in-plane porous few-...

Embodiment 2

[0065] A low-temperature and environmentally friendly method for preparing in-plane porous few-layer graphene is realized by the following steps:

[0066] 1) Weigh 5 g of commercial cobalt acetylacetonate, 7.5 g of potassium chloride, and 200 g of zirconia. Put the three into a ball mill jar with a volume of 1000mL, then install the ball mill jar on the planetary ball mill, and ball mill for 6 hours at a speed of 300r / min;

[0067] 2) heating the ball-milled product obtained in step 1) to 800°C at 8°C / min under an argon atmosphere in a tube furnace, and keeping it warm for 3 hours;

[0068] 3) Take out the carbonized product in step 2) and put it into a high-pressure reactor, add 80 mL of hydrochloric acid with a concentration of 2 mol / L, put it into an electric blast drying oven, and pickle it at 120°C for 15 hours;

[0069] 4) The material obtained in step 3) is washed and dried to obtain the in-plane porous few-layer graphene of the target sample.

[0070] The in-plane po...

Embodiment 3

[0073] A low-temperature and environmentally friendly method for preparing in-plane porous few-layer graphene is realized by the following steps:

[0074] 1) Weigh 5 g of commercial nickel acetylacetonate, 12.5 g of sucrose, and 175 g of zirconia. Put the three into a ball mill jar with a volume of 1000mL, then install the ball mill jar on a planetary ball mill, and mill for 3 hours at a speed of 500r / min;

[0075] 2) heating the ball-milled product obtained in step 1) to 900°C at 10°C / min under an argon atmosphere in a tube furnace, and keeping it warm for 2 hours;

[0076] 3) Take out the carbonized product in step 2) and put it into a high-pressure reactor, add 80 mL of hydrochloric acid with a concentration of 4 mol / L, put it in an electric blast drying oven, and pickle it at 25 ° C for 10 h;

[0077] 4) The material obtained in step 3) is washed and dried to obtain the in-plane porous few-layer graphene of the target sample.

[0078] The in-plane porous few-layer graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com