Spinning and forming device of cylindrical part with inner strengthening and outer thinning

A technology of spinning and forming cylindrical workpieces, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of no similar or similar patents, etc., to solve the problem of forming large straight cylindrical workpieces and reduce complex processes , Enhance the effect of processing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

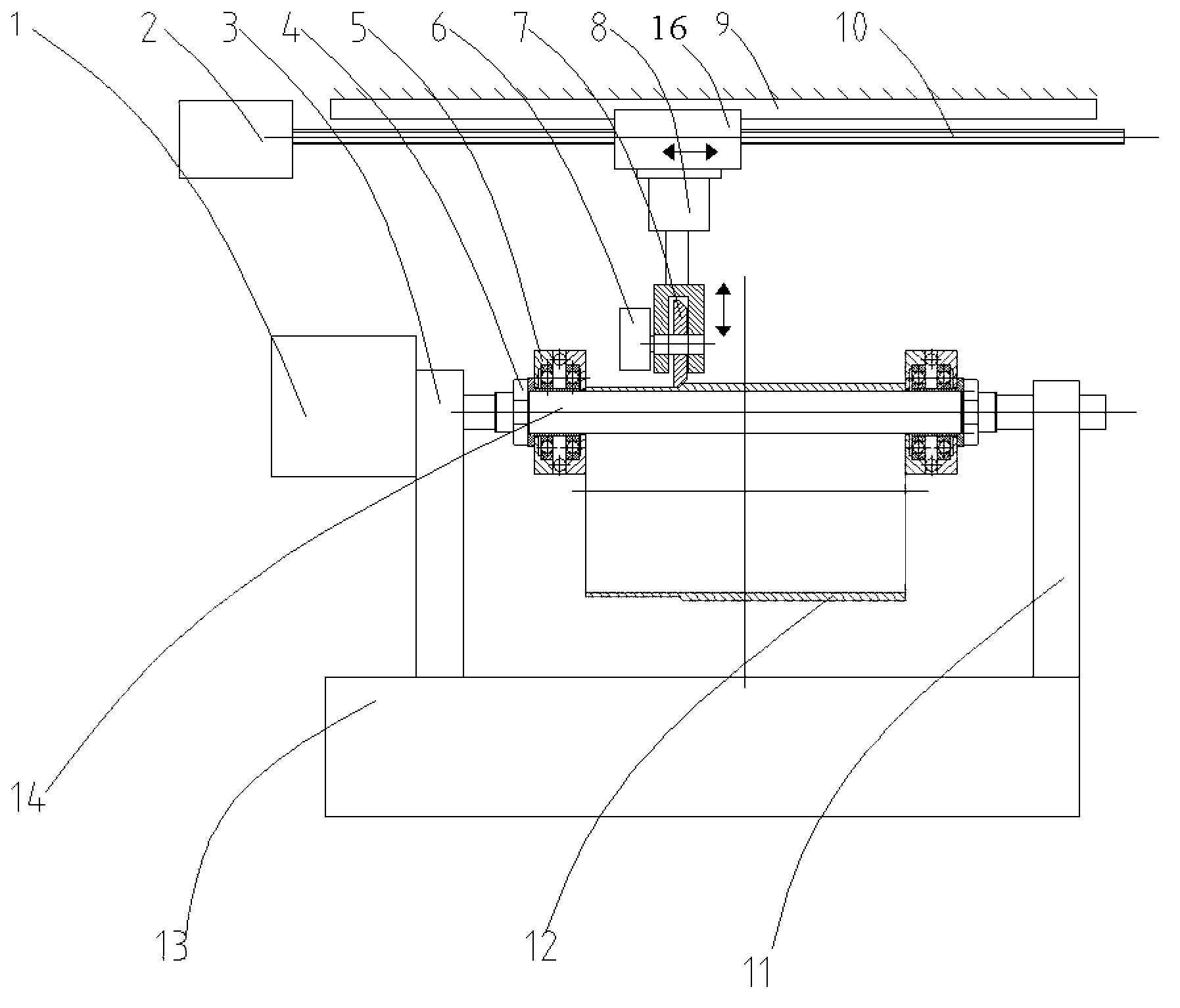

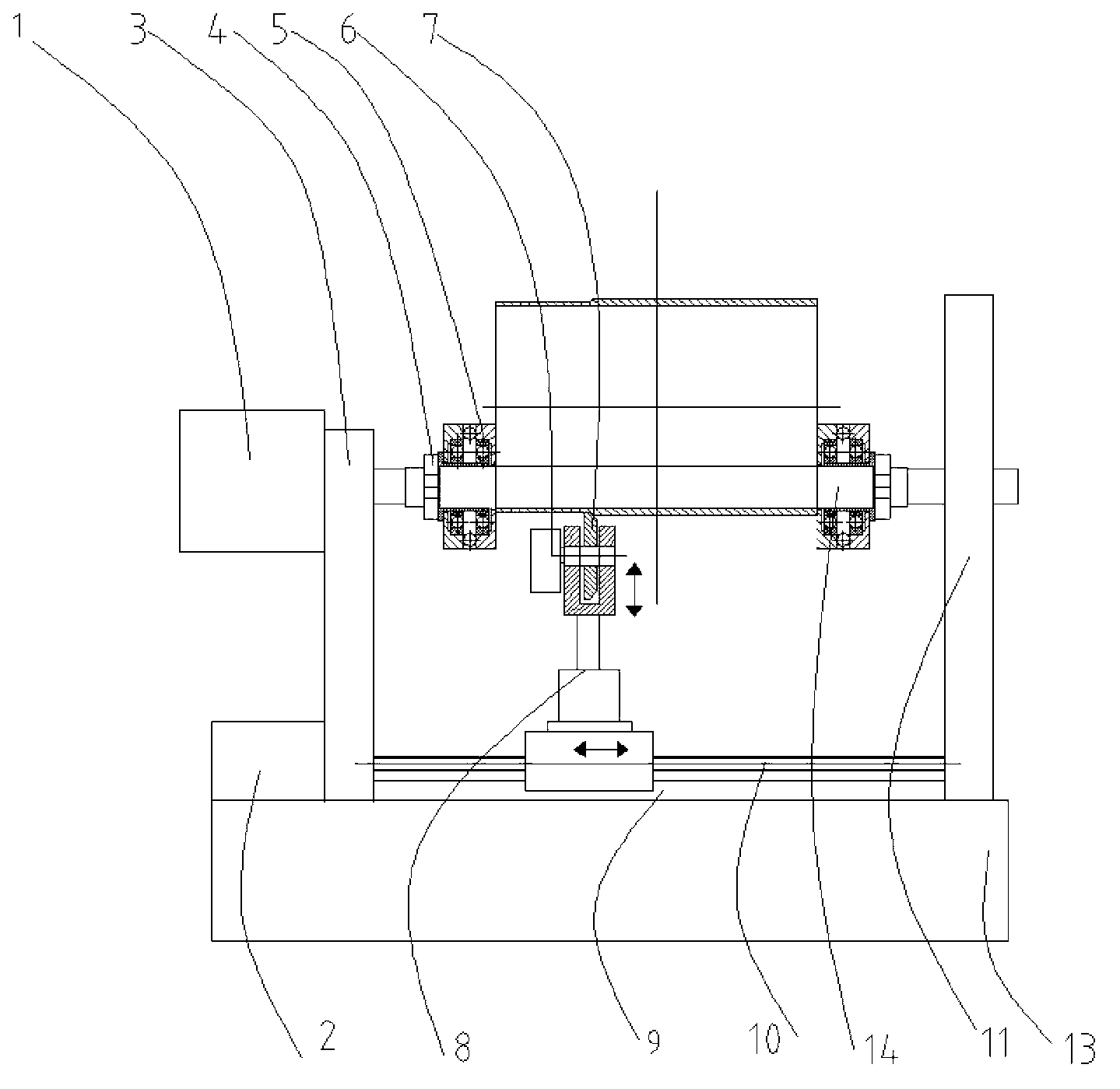

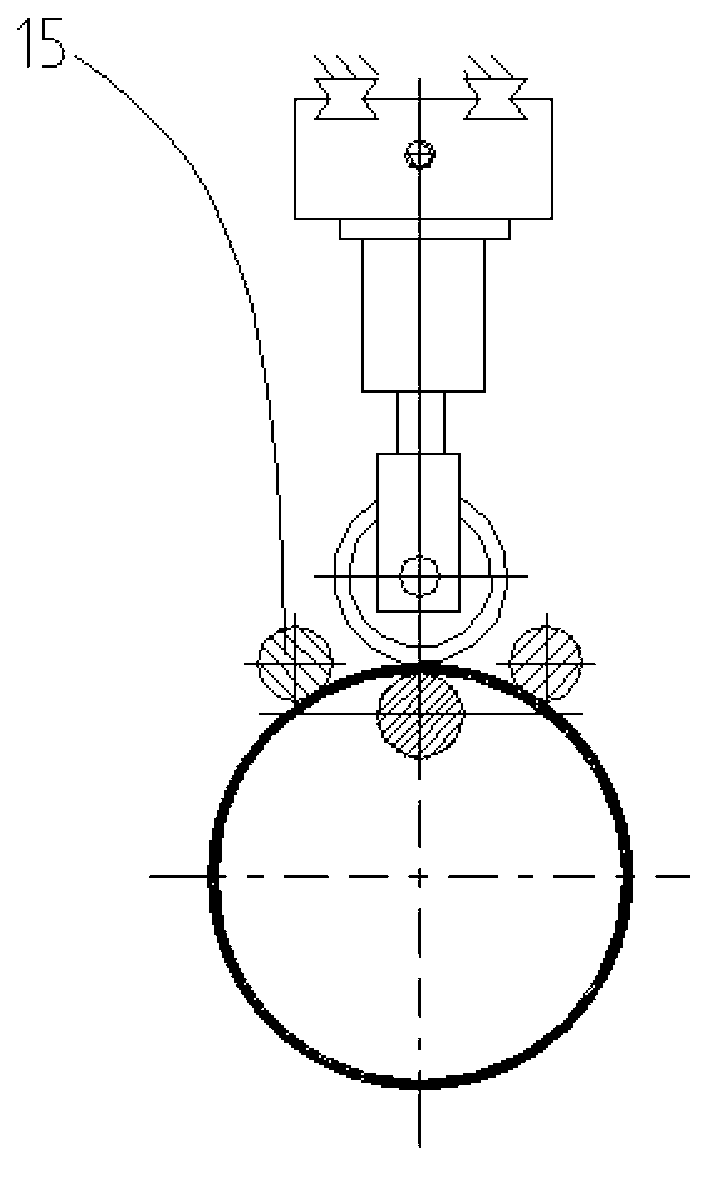

[0027] Referring to the accompanying drawings, the spinning forming equipment for internally reinforced and externally thinned cylindrical parts is mainly composed of a driving device, a clamping device, a feeding device and a working roll. Composed of rollers 7, the main roller 14 is supported by the transmission speed change and reversing mechanism 3 installed on the bed 13 and the tail support seat 11, and is driven to rotate by the driving device I1 through the transmission speed change and reversing mechanism 3, and the bed 13 is equipped with guide rails 9 and the drive shaft 10, the drive shaft 10 is equipped with a slide rail device 16, the drive shaft 10 is driven and rotated by the driving device II2 to make the slide rail device 16 move left and right along the guide rail 9, and the slide rail device 16 is equipped with a radial feed device 8, so The rotary roller 7 is installed on the top of the radial feed device 8, the main roller 14 is equipped with a clamping de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com