Intelligent valve made of zirconium tungstate negative thermal expansion material

A negative thermal expansion material and intelligent valve technology, applied in valve details, diaphragm valves, valve devices, etc., can solve the problems of high cost of valve use, lack of universally used characteristics, and impracticality, and achieve cost savings and good mechanical properties , the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

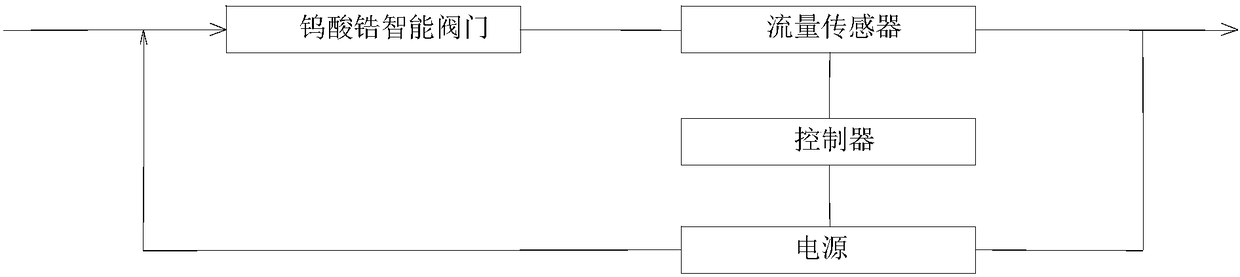

[0012] Such as figure 1 , 2 As shown, this embodiment discloses a new type of negative thermal expansion intelligent material-driven valve, which has the advantages of low cost, wide range of use, not affected by medium performance and environment, good accuracy, and convenient maintenance. At the same time, it can also achieve completely autonomous safety. control.

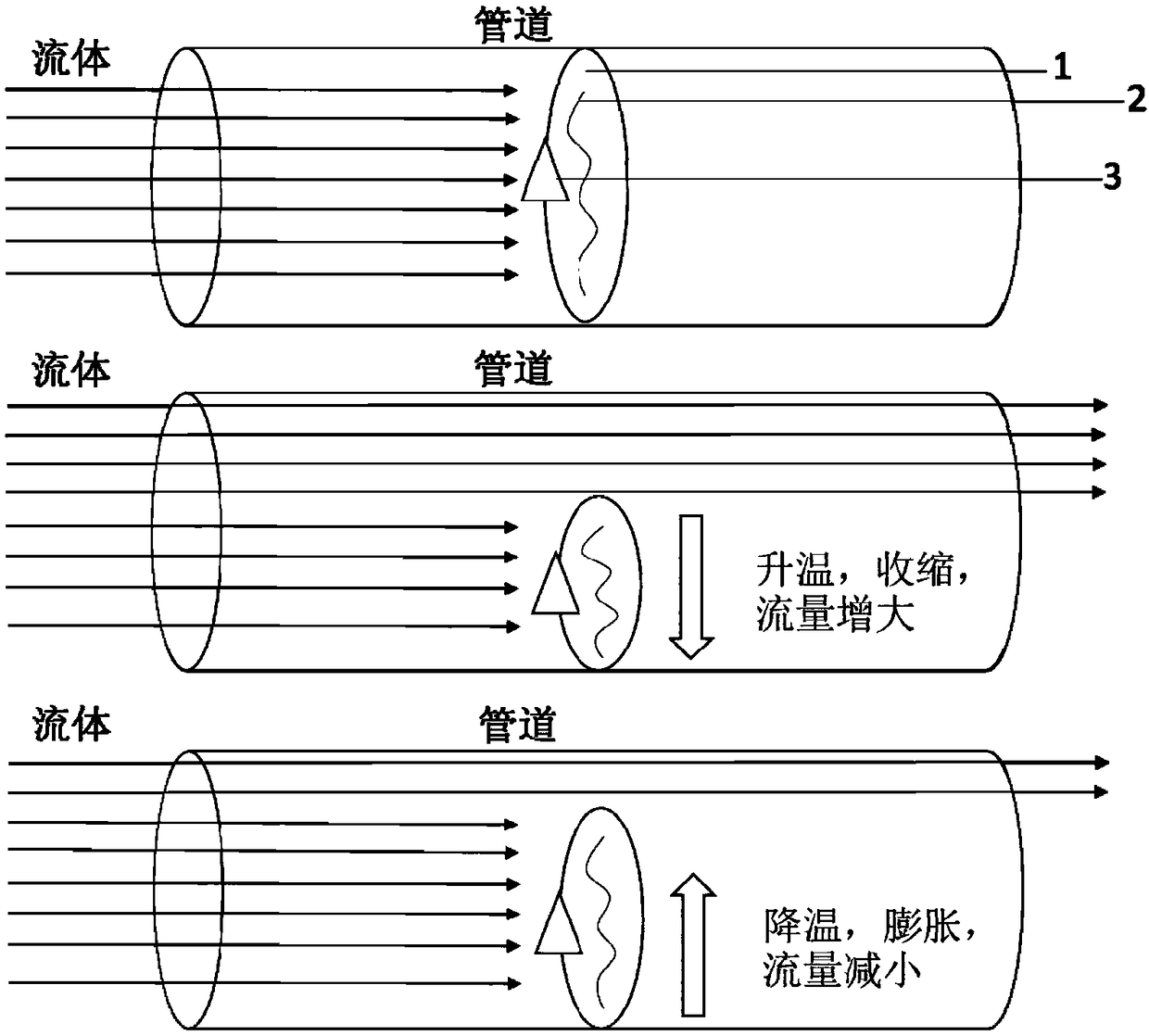

[0013] The following is the use principle and working process of the negative thermal expansion smart material valve:

[0014] Based on the negative thermal expansion material of zirconium tungstate, the combination of zirconium tungstate and ultra-light material graphene makes the valve structure have certain conductivity. The intelligent valve 1 of zirconium tungstate composite material is equipped with a heating wire 2, using 3D printing technology Directly prepare a comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com