Production process of electroacoustic component

An electro-acoustic element and production process technology, applied in the field of electronics, can solve the problems of inability to adapt to the development trend of miniaturization of microphones, complex structure of electro-acoustic elements, difficult to automate production, etc., and achieve simple structure, good conductive effect, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

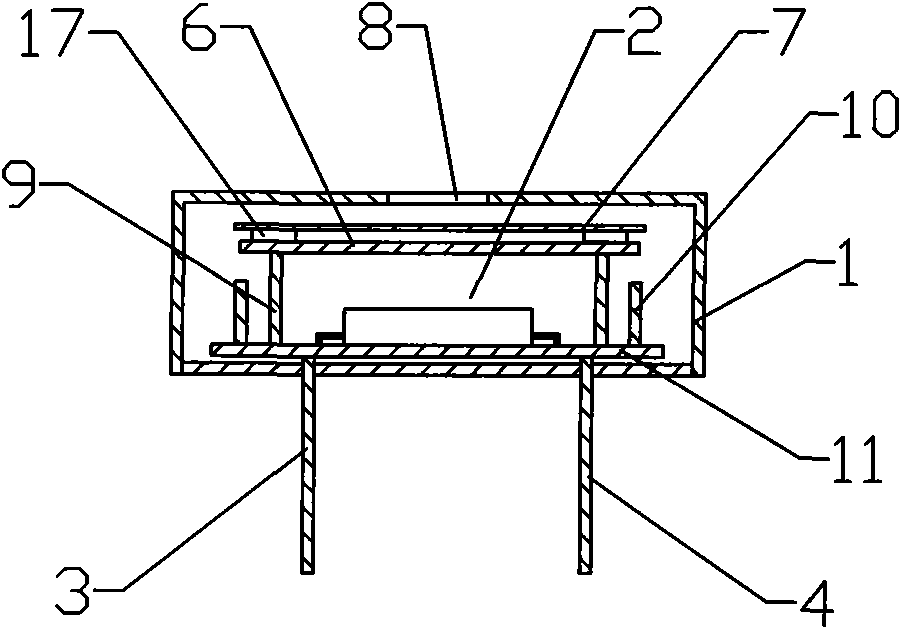

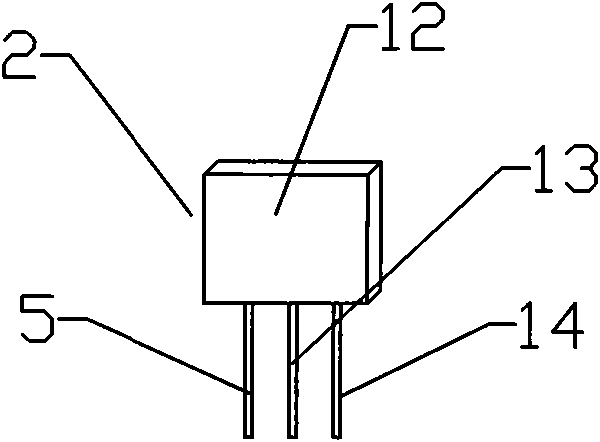

[0044] Embodiment 1, with Figure 4 Schematic diagram of the structure of the electro-acoustic components, attached Figure 5 It is a schematic diagram of the structure of a field effect transistor. The electroacoustic element includes a metal shell 1 with a sound transmission hole 8 on the top, a field effect tube 2 , a pole plate 6 , a vibrating membrane 7 , a first lead pin 3 , a second lead pin 4 and an isolation ring 17 .

[0045] The production process of the above electro-acoustic components includes the following steps:

[0046] 1) Make FET 2:

[0047] The field effect tube 2 is processed into a field effect tube body 12 with an upper surface and a lower surface, a grid 5 carrying an end face is processed on the upper surface of the field effect tube body 12, and a drain is processed on the lower surface of the field effect tube body 12. pole 13 and source 14;

[0048] 2) Assembling the pole plate 6 on the bearing end face of the grid 5;

[0049] 3) Conductive glu...

Embodiment 2

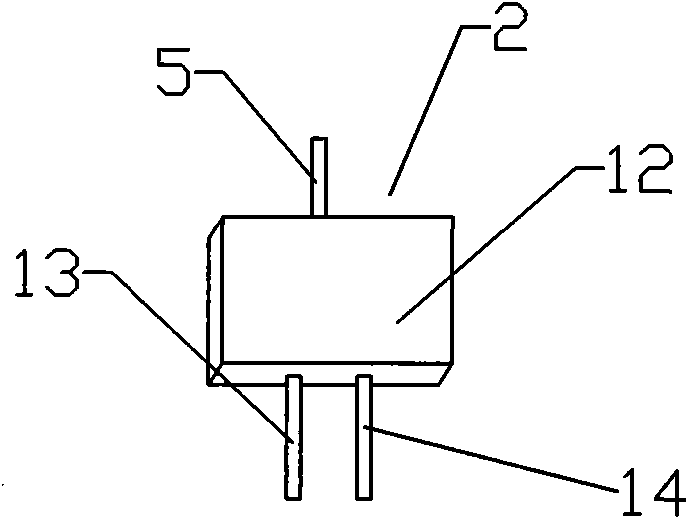

[0053] Embodiment 2, with Image 6 Schematic diagram of the structure of the electro-acoustic components, attached Figure 7 It is a schematic diagram of the structure of a field effect transistor. The electroacoustic element includes a metal shell 1 with a sound transmission hole 8 on the top, a field effect tube 2 , a pole plate 6 , a vibrating membrane 7 , a first lead pin 3 , a second lead pin 4 and an isolation ring 17 .

[0054] The production process of the above electro-acoustic components includes the following steps:

[0055] 1) Make FET 2:

[0056]The field effect tube body 12 is processed into a structure in which the middle is a disc, and its upper surface and lower surface are circular truncated structures. The upper bottom surface 16 of the upper surface circular platform forms the upper surface of the field effect tube body 12. position and process a cylindrical grid 5 with a bearing end face, the lower bottom surface 15 of the lower surface circular platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com