Novel construction process for EPS (expandable polystyrene) geotechnical block of onshore wind power plant

A construction technology and wind farm technology, applied in infrastructure engineering, construction, etc., can solve the problems of low worker efficiency, lagging operation technology, high construction cost, etc., and achieve the effect of simple and convenient construction, good economy, and reduced construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further:

[0036] A new type of EPS geotechnical block construction technology for onshore wind farms of the present invention, specifically:

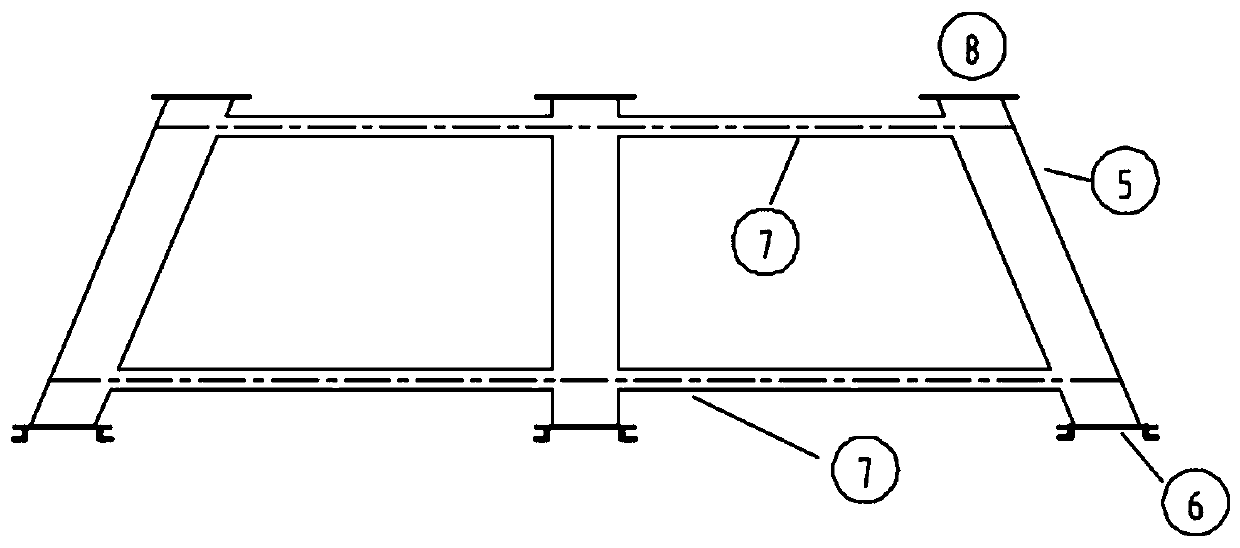

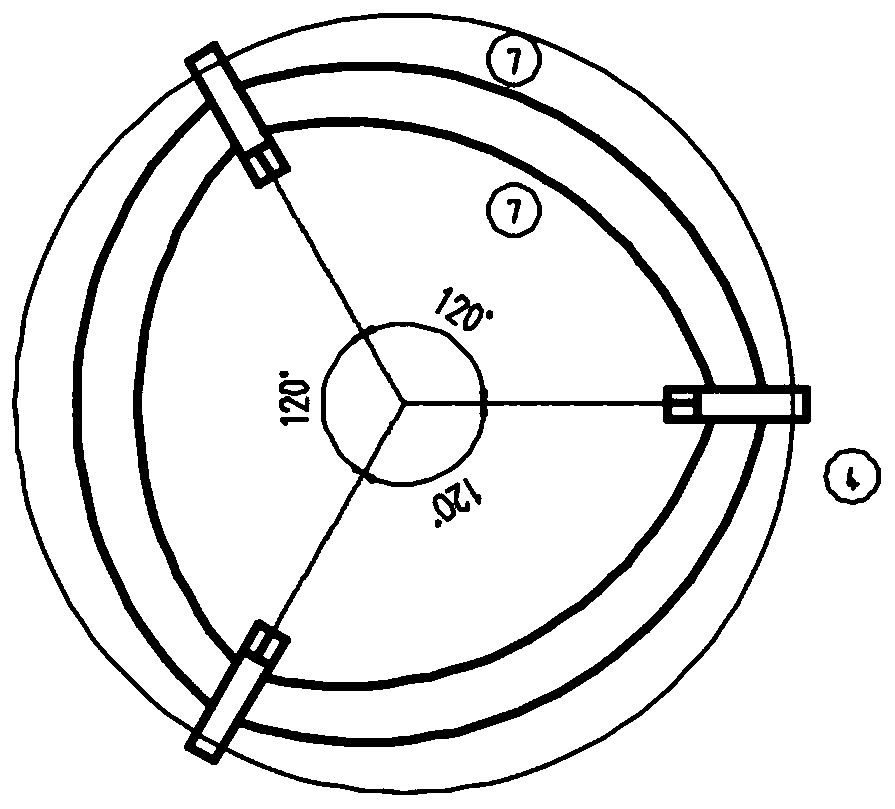

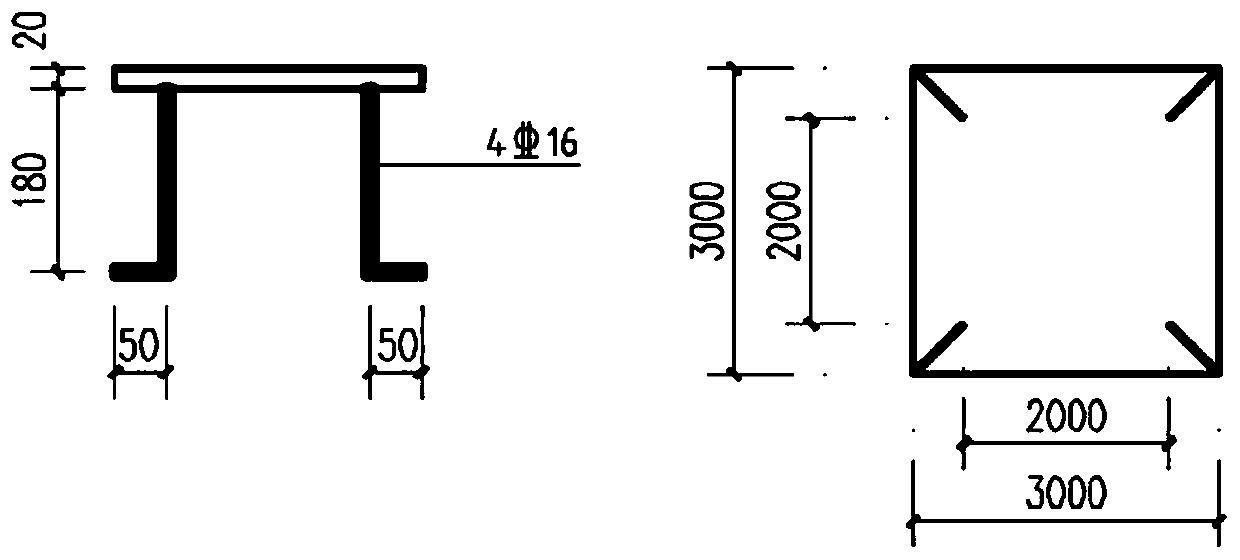

[0037] The foundation pit is excavated, and the slope is carried out at a depth of 2.6-3m, and a slope top plane with a length of 2-3m is reserved; the bottom surface of the foundation pit is cleaned and a pin is installed in the center of the bottom surface of the foundation pit, and the EPS block 1 is placed. Sprinkle 10mm~15mm of C10~C25 fine stone concrete around the bottom surface of EPS block 1; pour the cushion layer and maintain it, and wait for the cushion layer curing to ensure the integration of EPS block 1 and the cushion layer; use a new type of foundation cushion layer mold Carry out formwork support, place prefabricated support device 4 and level it after completion of formwork support, use C15 fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com