Post stress method stake body prestressed antislid stake and construction method

A technology of anti-slide piles and prestressing, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as construction inconvenience, and achieve the effects of convenient conditions, reduced section, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

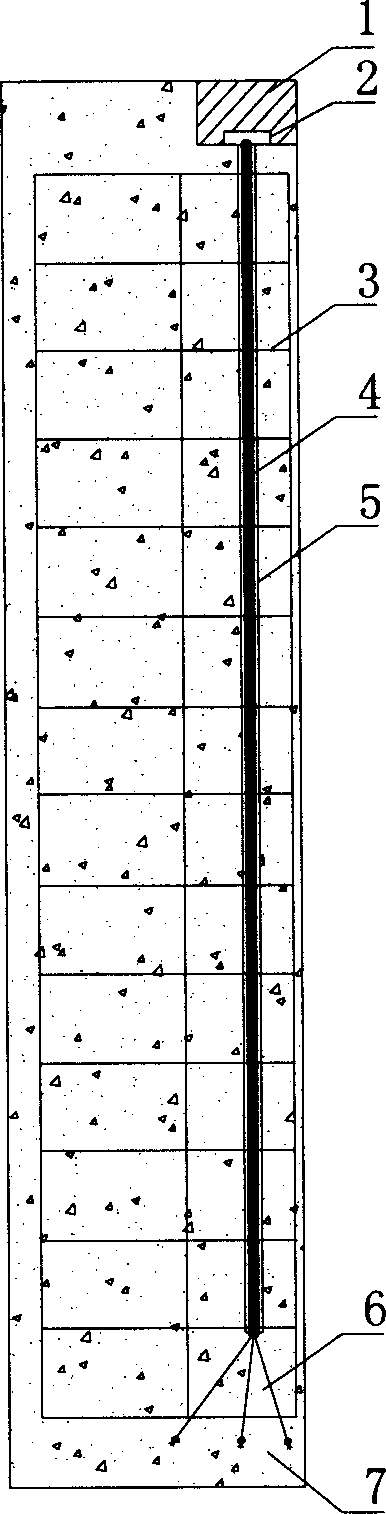

[0027] As shown in the accompanying drawings, there is a reinforcement cage 3 in the first pouring concrete 7, and a bellows 5 is arranged in the cage of the reinforcement cage 3, and a steel strand 4 is placed in the bellows 5, and the two ends of the steel strand 4 protrude from the bellows 5. The lower end of the steel strand 4 is connected with the pile bottom anchoring section anchor 6, and the upper end is connected with the pile top anchor 2, and the upper part of the pile top anchor 2 has the second pouring concrete 1.

[0028] Before making the component of the present invention, according to the actual engineering situation of the landslide, the working conditions and working force of the anti-slide pile are calculated to obtain the selection of the number of prestressed tendons, as well as the number and structure of ordinary steel bars, and the label of concrete.

[0029] The construction method of the present invention: according to the geological conditions of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com