Patents

Literature

31results about How to "Reduced measure fee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

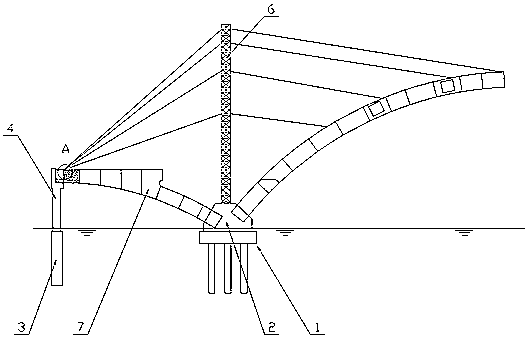

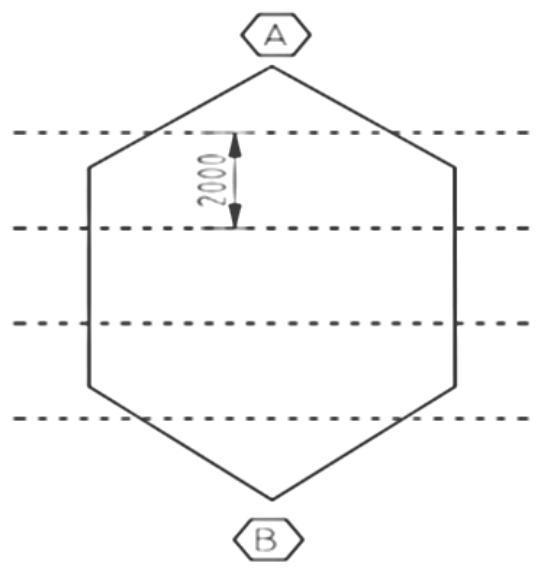

Construction method for integral lifting and batch step-by-step anchoring of spoke type single-layer cable net

InactiveCN106930538AReduced volume and work at heightLower requirementBuilding material handlingHeight differenceIndustrial engineering

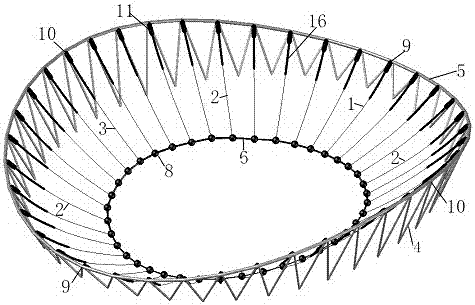

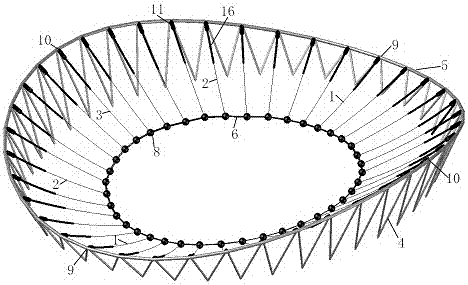

The invention discloses a construction method for integral lifting and batch step-by-step anchoring of a spoke type single-layer cable net. A cable net structure mainly comprises vertical pillars, an outer pressing ring beam, an inner ring cable and radial cables. Obvious height differences exist in the outer end anchoring nodes of all the radial cables. According to the height differences of the anchoring nodes of the outer pressing ring beam, the radial cables are divided into different batches from a structural low point to a structural high point. The number of the batches is determined according to practical conditions. The integral cable net is lifted through a jack, all batches of the radial cables and the outer pressing ring beam are connected and anchored in batches step by step from the low point to the high point in the lifting process, and finally the structure is formed. According to the construction method, the construction support quantity and the upper air operation quantity can be reduced, the requirement quantity of a large-tonnage lifting system is reduced, installation cost is reduced, tool lightening is achieved, the construction period is shortened, and construction efficiency is improved.

Owner:SOUTHEAST UNIV

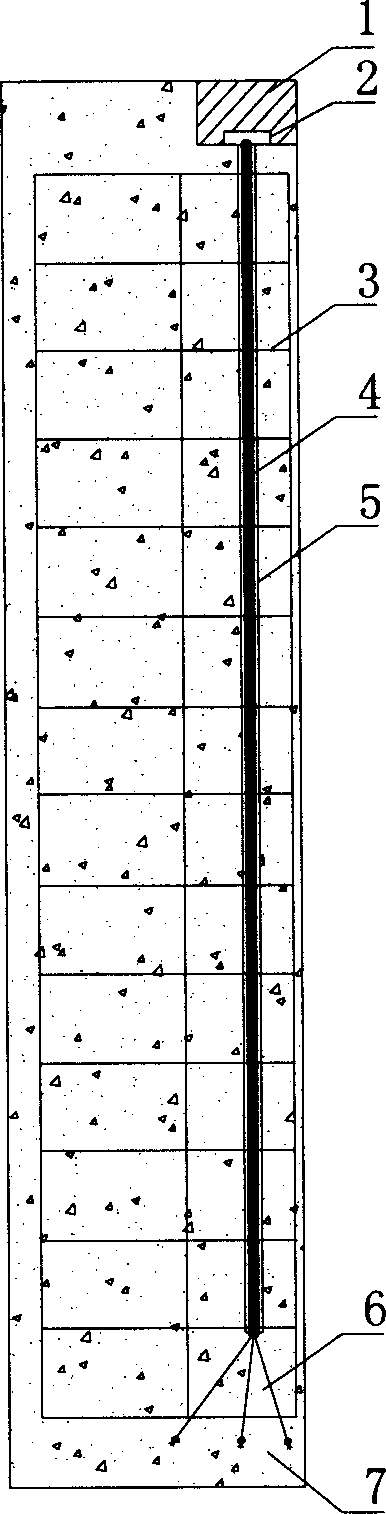

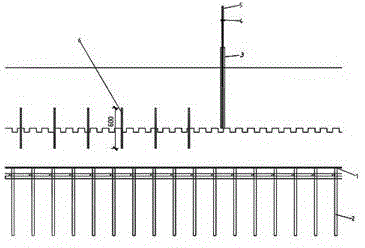

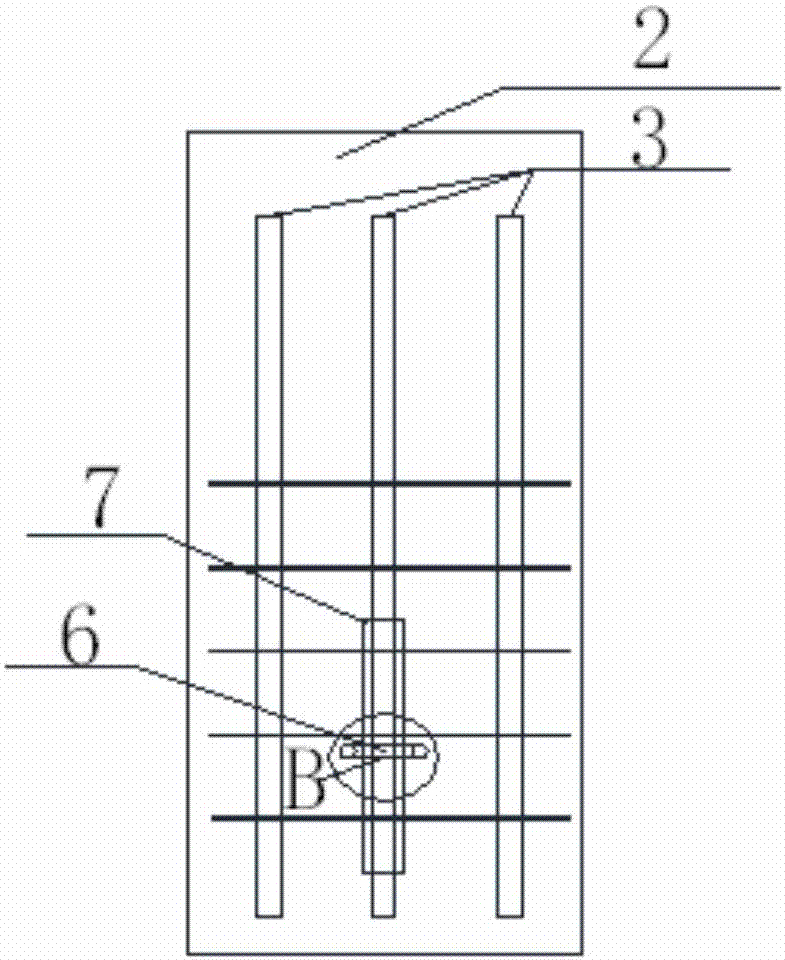

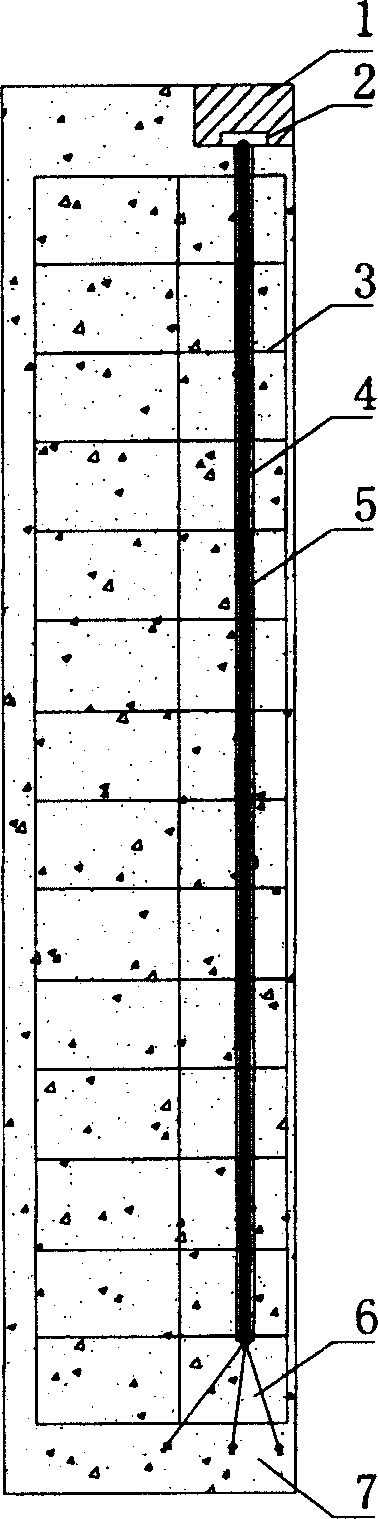

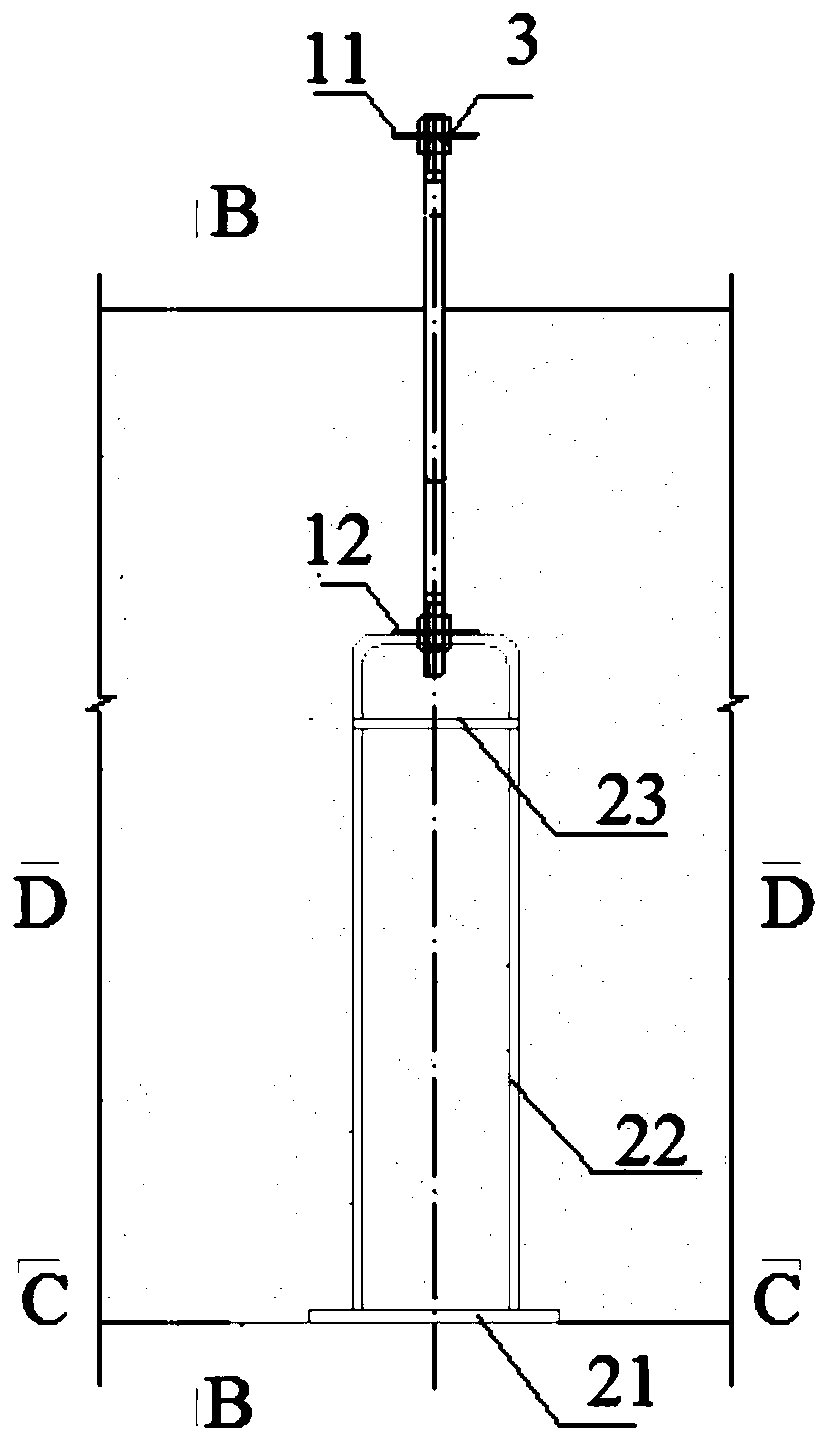

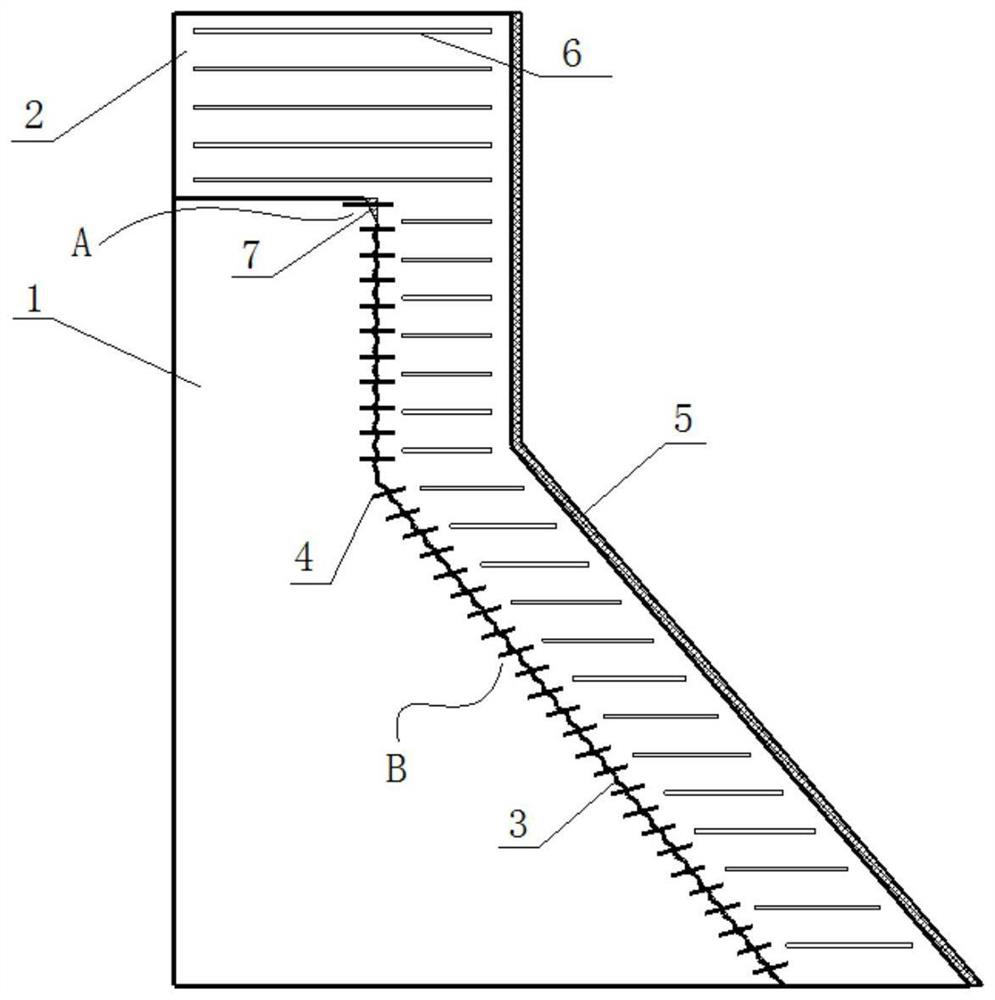

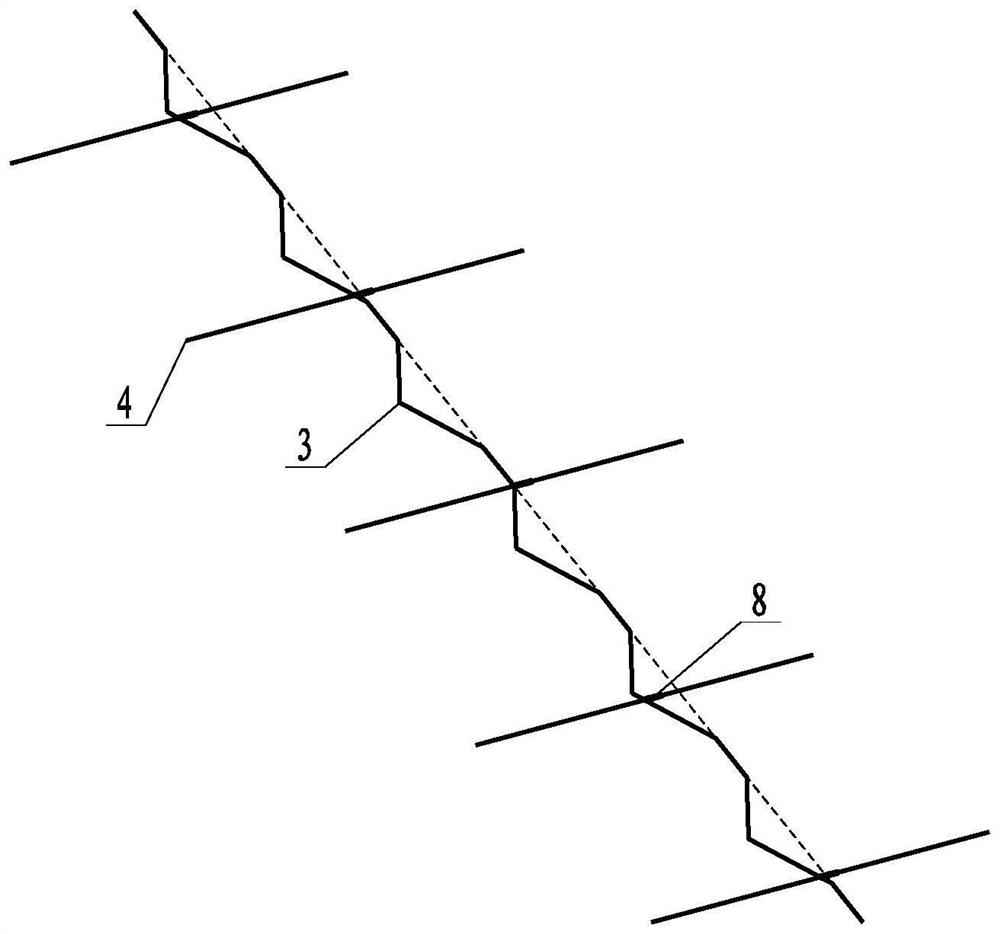

Post stress method stake body prestressed antislid stake and construction method

The present invention adopts construction on ground surface, and makes post-tensional pile-body prestressed anti-slide pile. Its structure is as follows: firstly-poured concrete interior has steel reinforcement cage, cage edge interior has corrugated pipe, in the corrugated pipe interior a stranded wire is placed, two ends of said stranded wire are extended from said corrugated pipe, lower end of said stranded wire is connected with anchorage device of anchored part in the pile bottom, its upper end is connected with anchorage device of pile top, and the upper portion of anchorage device of pile type has secondary poured concrete. Said invention also provides its construction method.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

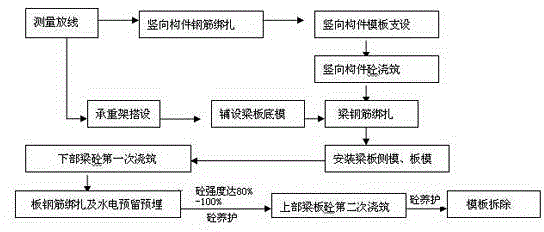

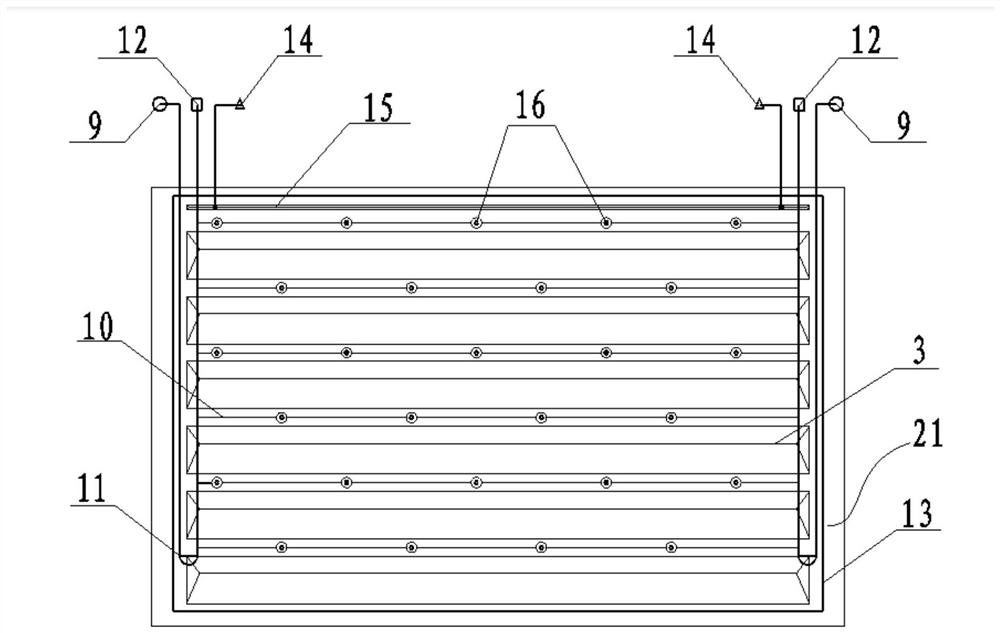

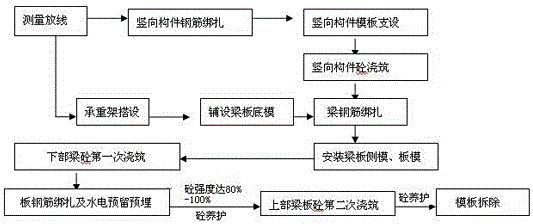

Layered construction method for oversized concrete beam of structural transfer floor of high-rise building

The invention relates to a layered construction method for an oversized concrete beam of a structural transfer floor of a high-rise building. The method comprises the following steps: (1) measuring a construction site and paying off, binding a vertical component reinforcing steel bar, then supporting a vertical component template, and then pouring vertical component concrete; erecting a bearing frame, then laying a bottom die of a beam-slab, and then binding a beam reinforcing steel bar; (2) installing a side die and a plate die of the beam-slab; (3) pouring the lower beam concrete for the first time, then binding a plate reinforcing steel bar and reserving and pre-burying water and electricity lines and maintaining concrete for the first time; and (4) pouring the upper beam plate concrete for the second time, then maintaining concrete, and removing the template. By adopting concrete pouring and reinforcing steel bar binding of the method, the running water beats are reasonable, so that the construction period is shortened, the construction safety is improved, and the construction cost is also lowered.

Owner:ZHEJIANG QINYE COUNSTRUCTION GRP CO LTD

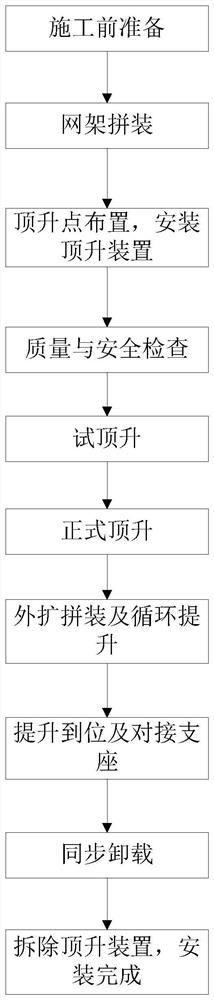

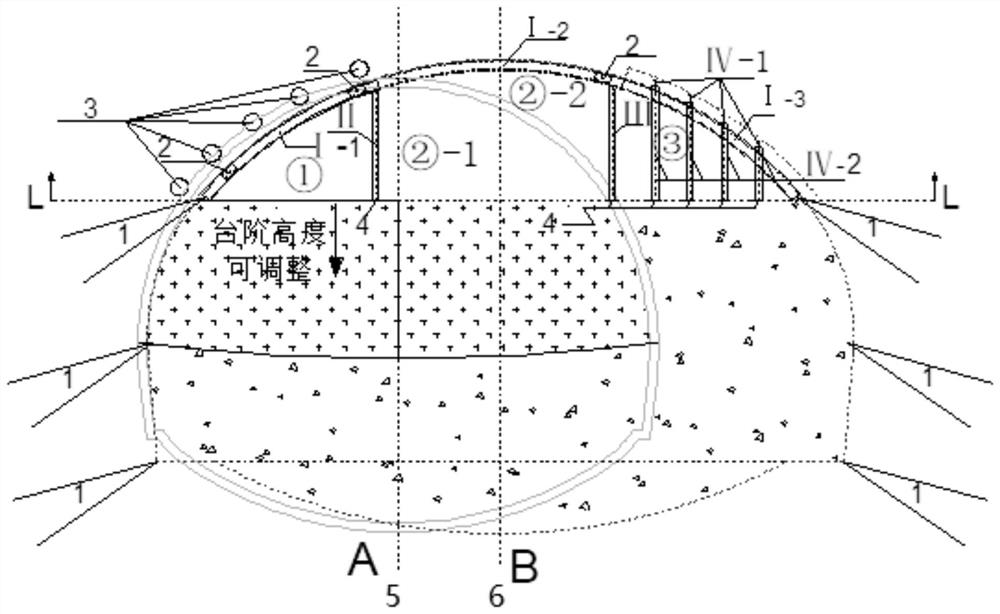

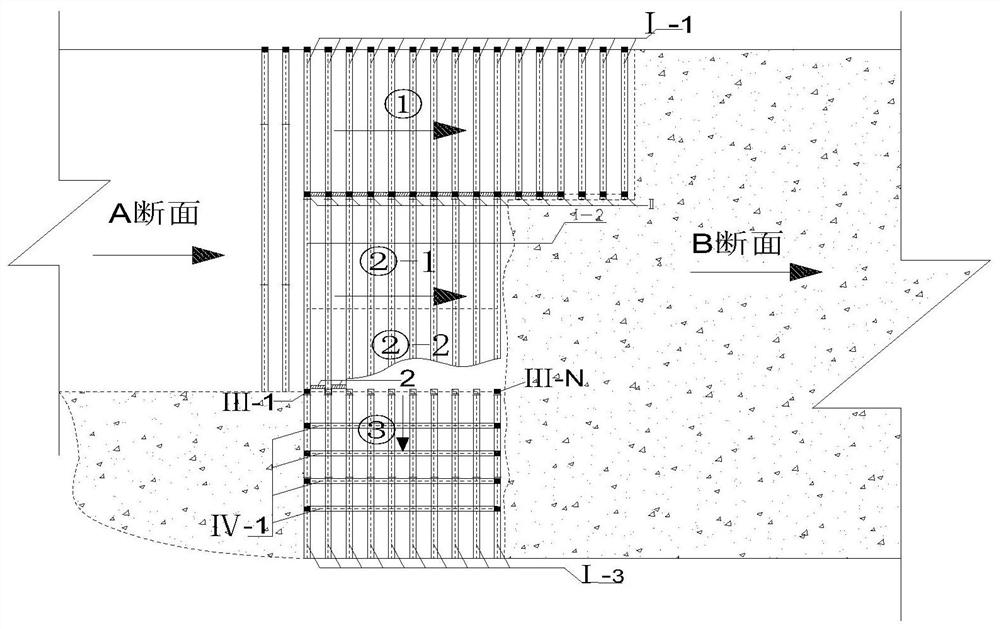

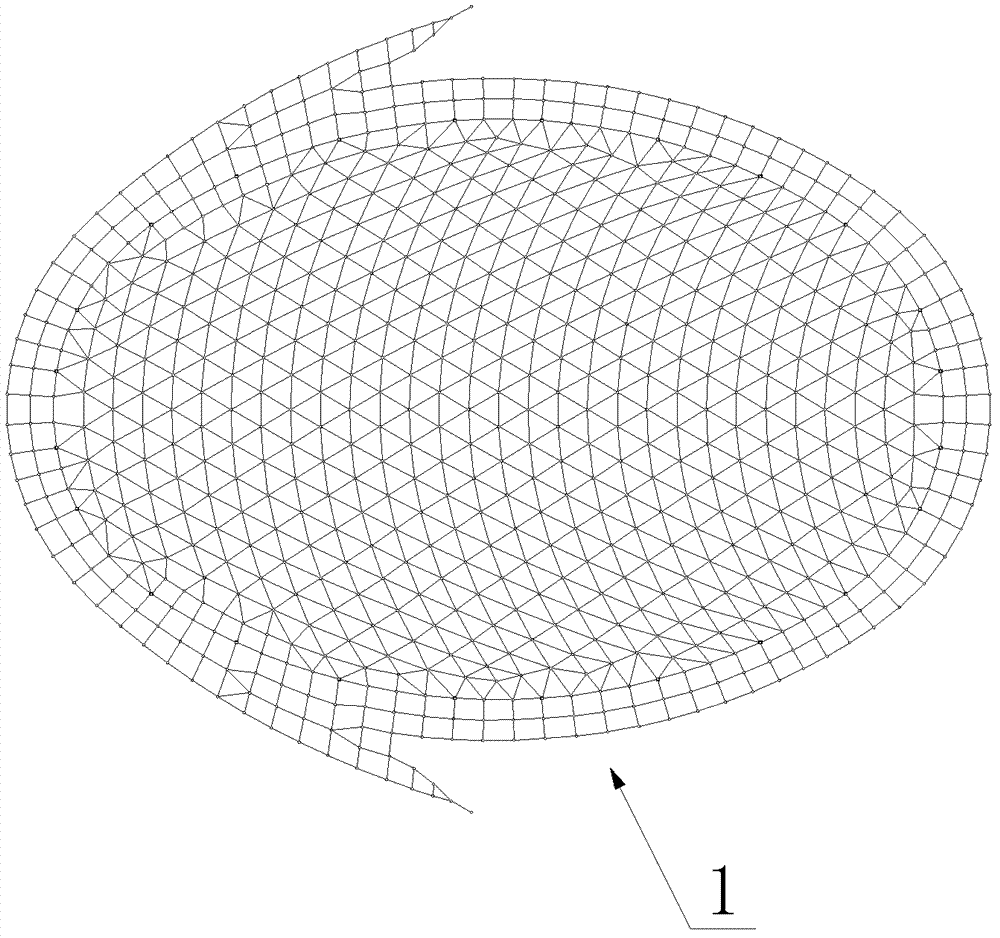

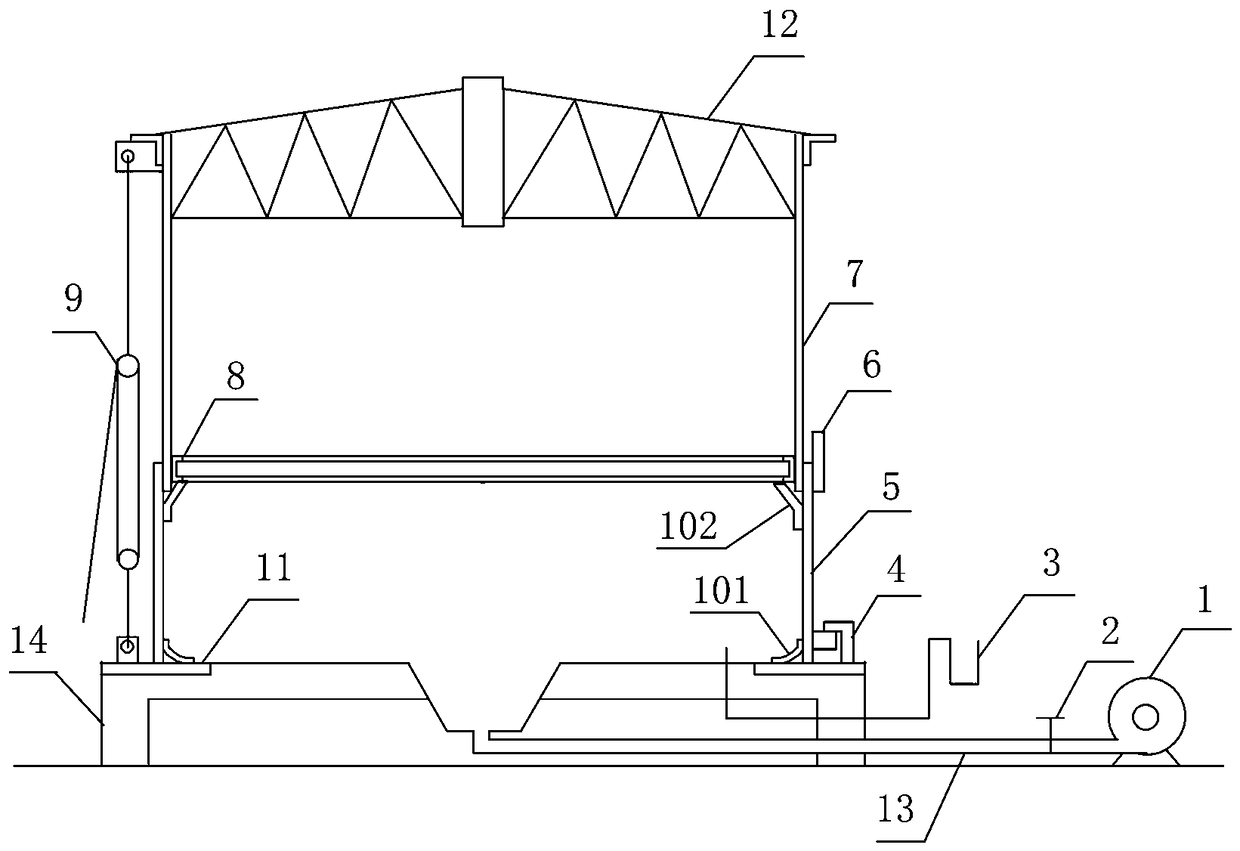

Large-span net rack external expansion assembly integral jacking construction method

InactiveCN111980165ASolve construction problemsControl the durationBuilding material handlingArchitectural engineeringLong span

The invention discloses a large-span net rack external expansion assembly integral jacking construction method, which belongs to the field of building construction. The technical problem to be solvedby the invention is how to reduce the construction difficulty of large-span net rack structures of a spherical shell, a cylindrical shell, a flat plate and various special-shaped stadiums under complex conditions, reduce high-altitude operations, improve safety, and ensure the construction quality. The adopted technical scheme is that the large-span net rack external expansion assembly integral jacking construction method comprises the following steps of: assembly and jacking, that is, the net rack is assembled on the ground, and when the net rack is assembled to a stand position, a jacking bracket is installed, and the jacking work is stopped when the net rack is jacked by using the jacking bracket to a preset height to meet the next grid assembly; symmetrical external expansion assembly,that is, after the jacking work is stopped, symmetrical external expansion assembly is performed on completed space stiffness units from the center of the net rack to make the net rack continue to extend to the surroundings; adjustment of the number and locations of jacking points, that is, when performing expansion assembly outward, the number and positions of the jacking points of the net rackare adjusted according to calculation results; and unloading and dismantling.

Owner:CHINA CONSTR EIGHTH ENG DIV

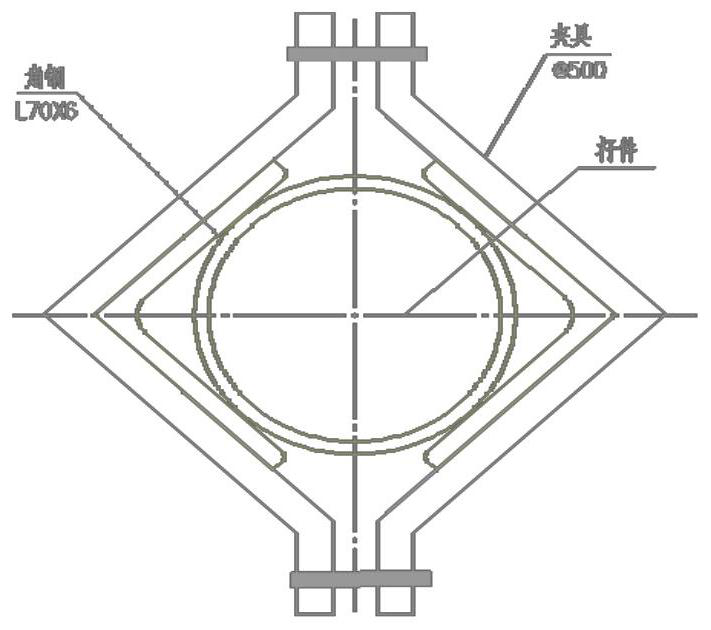

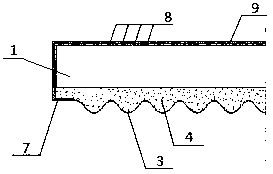

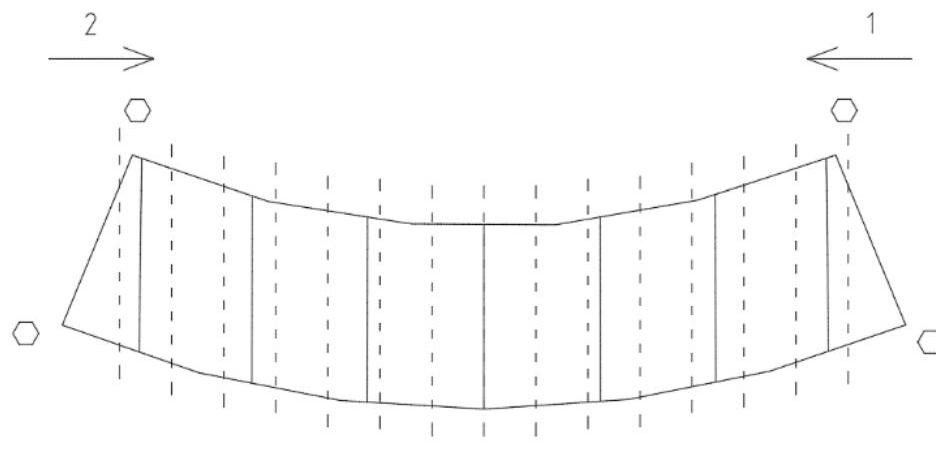

Method for reinforcing open-spandrel masonry arch bridge with corrugated steel plate hoop method

InactiveCN108330847AIncrease the strength design valueImprove bearing capacityBridge erection/assemblyBridge strengtheningCross wallStrength design

The invention discloses a method for reinforcing an open-spandrel masonry arch bridge with a corrugated steel plate hoop method. The open-spandrel masonry arch bridge comprises an arch ring and an arch bridge foundation, wherein the arch ring is arranged on the arch bridge foundation, a spandrel cross wall is arranged on the arch ring, distributed reinforcing steel bars are arranged at the upper end of the arch ring, a mortar protection layer is arranged on the outer side of the distributed reinforcing steel bars, the distributed reinforcing steel bars comprise longitudinally distributed reinforcing steel bars and horizontally distributed reinforcing steel bars, a self-compaction concrete filling body is arranged on the bottom side of the arch ring, a corrugated steel plate is arranged onthe outer side of the self-compaction concrete filling body, and L-shaped distributed reinforcing steel bars are arranged at two ends of the inner wall of the corrugated steel plate and integrally welded and tightened with the corrugated steel plate and the distributed reinforcing steel bars to form a hoop tightened original masonry structure. The strength design value of a material is increased,stone weathering is prevented, the tolerance of the structure to non-uniform tensile stress is improved, limited brackets can be adopted for construction, and the construction progress is acceleratedwhile the measure expense is reduced.

Owner:中顾国际工程咨询有限公司

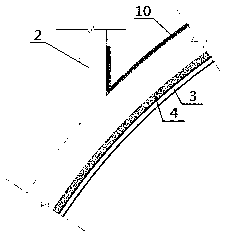

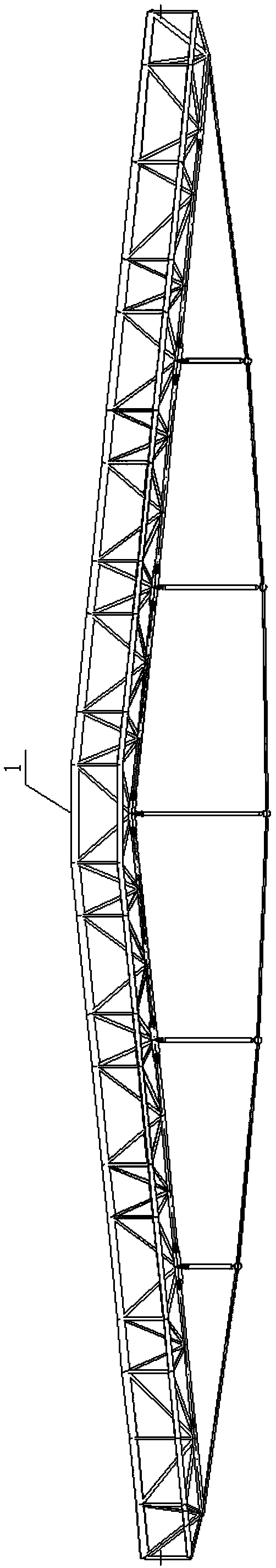

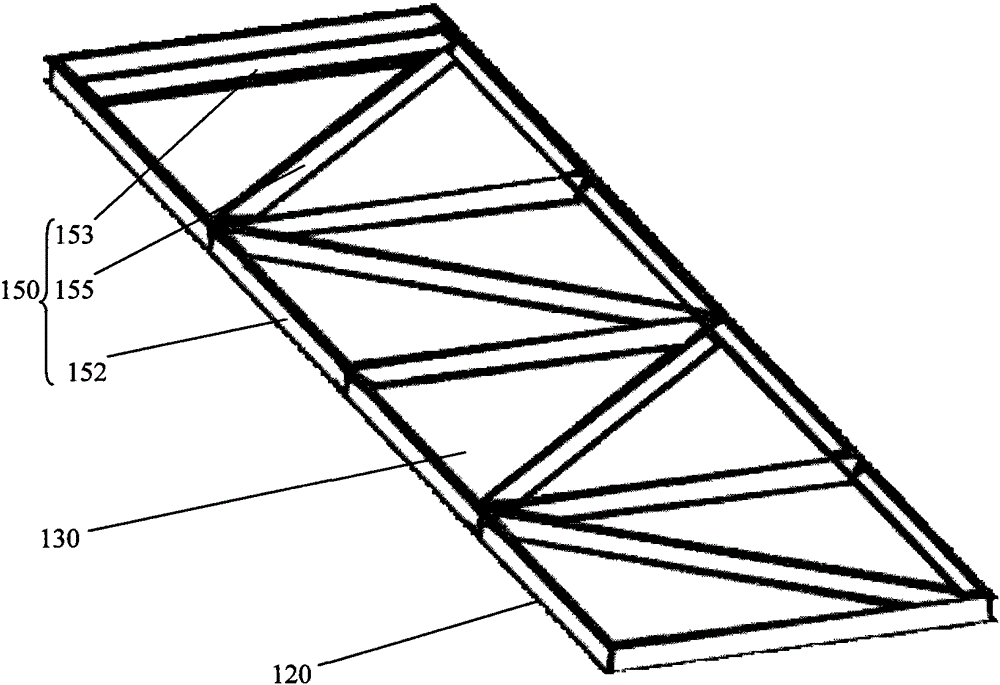

Long-span beam string truss beam off-site construction method

InactiveCN108894496AAvoid entering the venueAvoid problems such as inability to radiateBuilding material handlingArchitectural engineeringLong span

A method for off-site construction of large-span beam string truss beam include such steps as establishing three-dimensional solid model according to construction drawing, automatically lofting and numbering component according to three-dimensional solid model, transporting that component to construction site after factory processing is completed, and removing the component from construction site.According to the span and section form of the beam string truss beam, the assembled tire frame is made on the external surface of the venue, and temporary support frames are respectively made on bothsides of the venue, and the temporary support frames are located at the lower and middle parts of the beam string truss beam; The beam body of a beam string truss beam is divided into two sections and assembled on the assembled jig by the components. The two sections of beams are hoisted on the temporary support frame through the lifting equipment outside the venue, and the whole section of beamsis welded after being adjusted and corrected. The beam string truss beam is constructed by off-site two-machine lifting, which avoids the problems of lifting machinery entering into the stadium or being unable to radiate. The installation of the upper steel structure and the construction of the competition site are carried out simultaneously, which greatly shortens the construction period.

Owner:BEIJING ENG COMPANY LIMITED OF CHINA RAILWAY URBAN CONSTR GRP

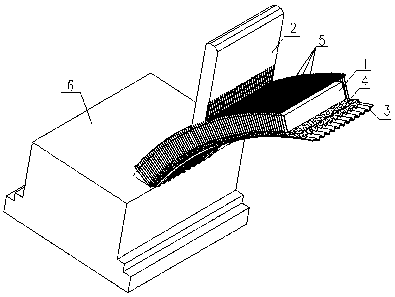

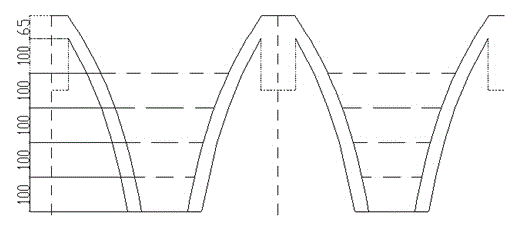

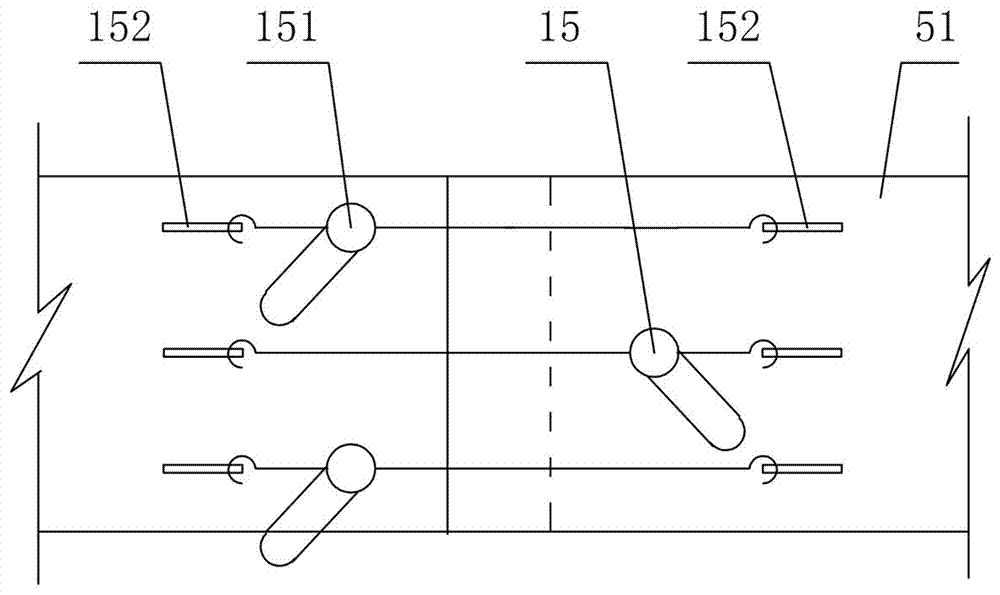

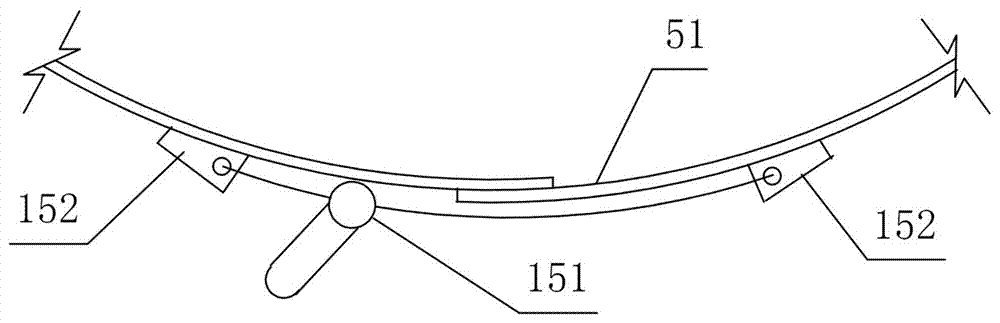

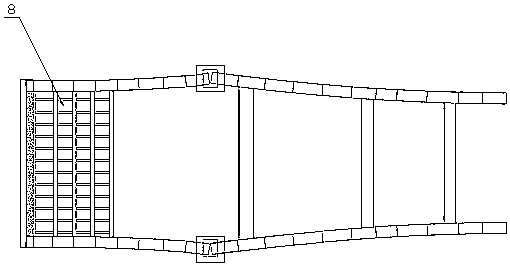

Hyperbolic hopper template and support method thereof of coal storage bunker

InactiveCN104695702AControl construction accuracyGuarantee the construction qualityForms/shuttering/falseworksBuilding material handlingBunkerEngineering

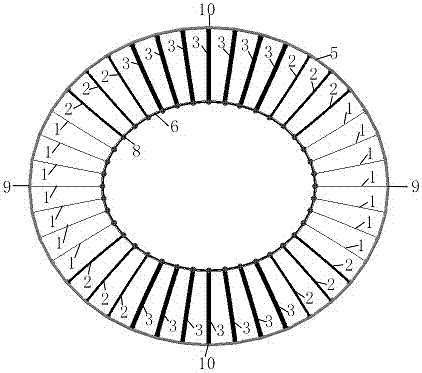

The invention discloses a hyperbolic hopper template and a support method thereof of a coal storage bunker and solves the problems that deviation of a discharge outlet of a hopper is commonly caused, concrete thickness of the hopper is non-uniform and construction quality is affected. The hyperbolic hopper template comprises an inner ring assembly template and an outer ring assembly template, wherein the inner ring assembly template comprises a first inner ring template, a second inner ring template, a third inner ring template, a fourth inner ring template, a fifth inner ring template and a sixth inner ring template, which are sequentially connected from bottom to top, the first to the fifth inner ring templates are 1000 mm thick while the six inner ring templates is 650 mm thick. The outer ring assembly template comprises a first outer ring template, a second outer ring template, a third outer ring template, a fourth outer ring template and a fifth outer ring template, which are sequentially connected from bottom to top.

Owner:CHINA MCC5 GROUP CORP

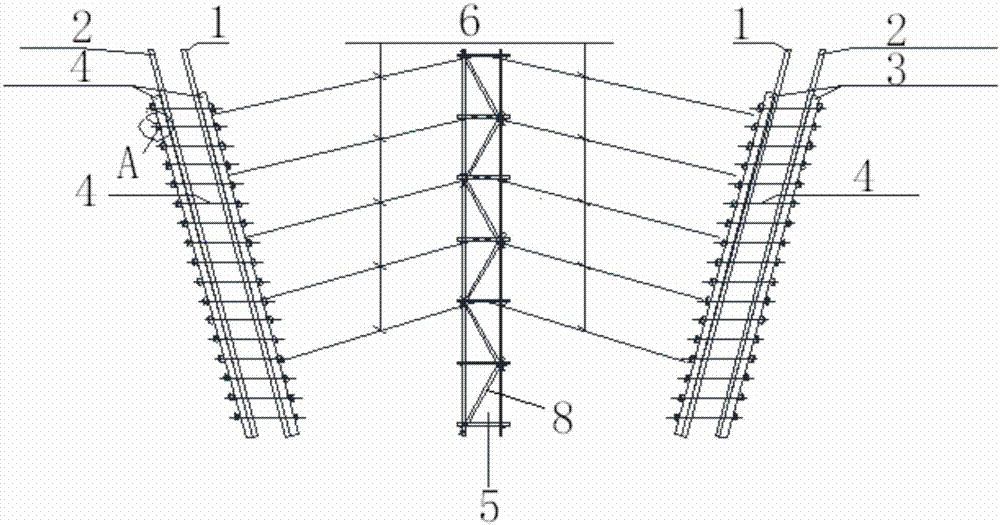

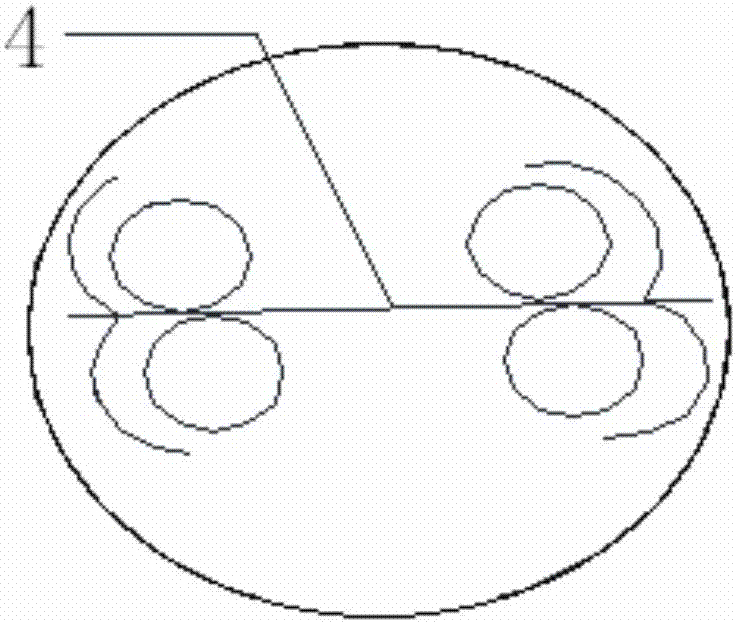

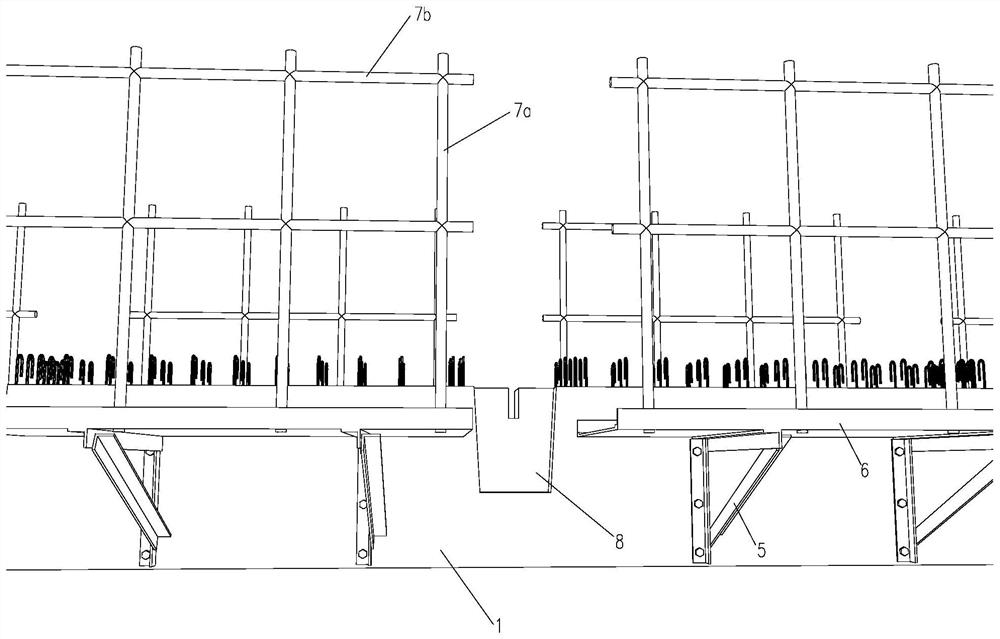

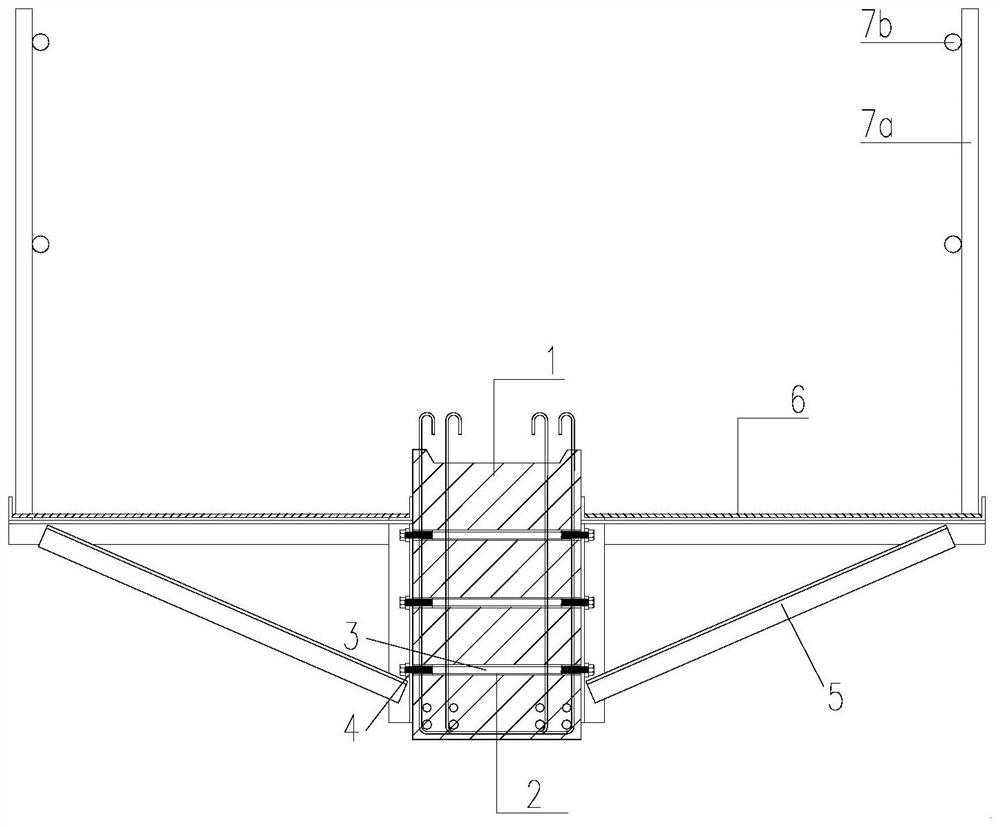

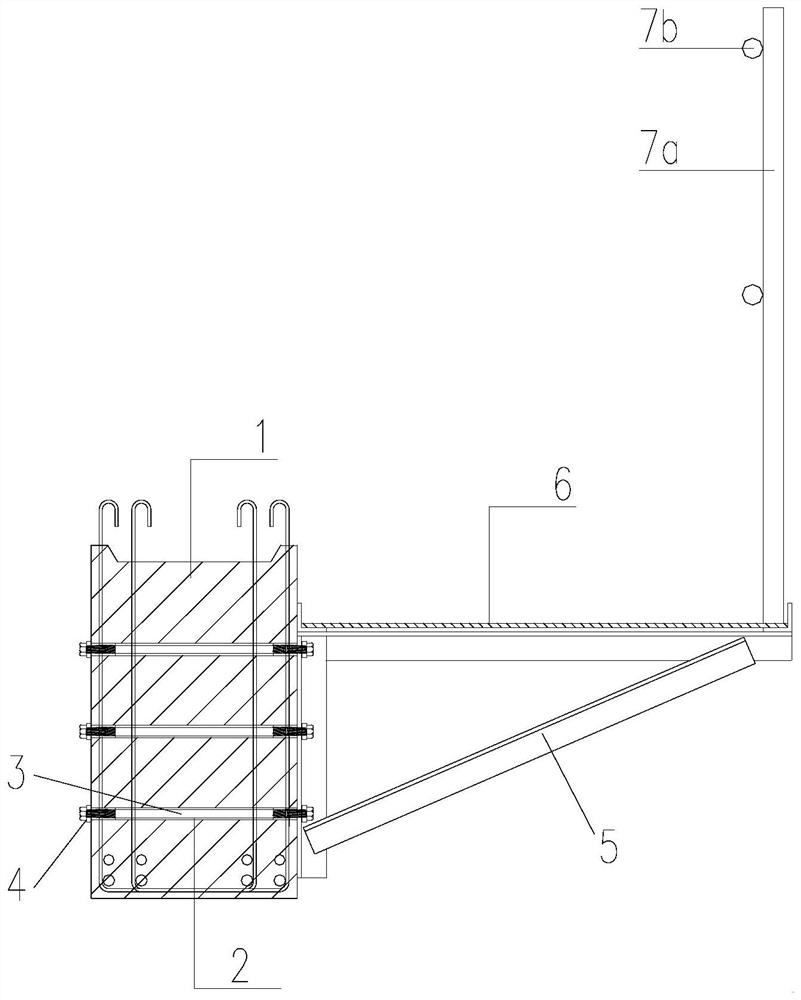

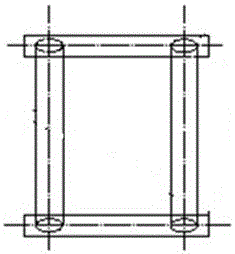

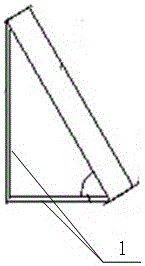

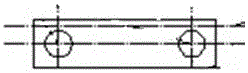

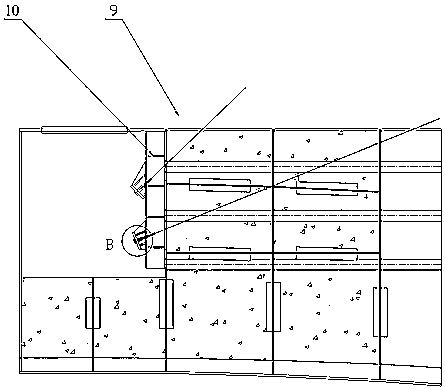

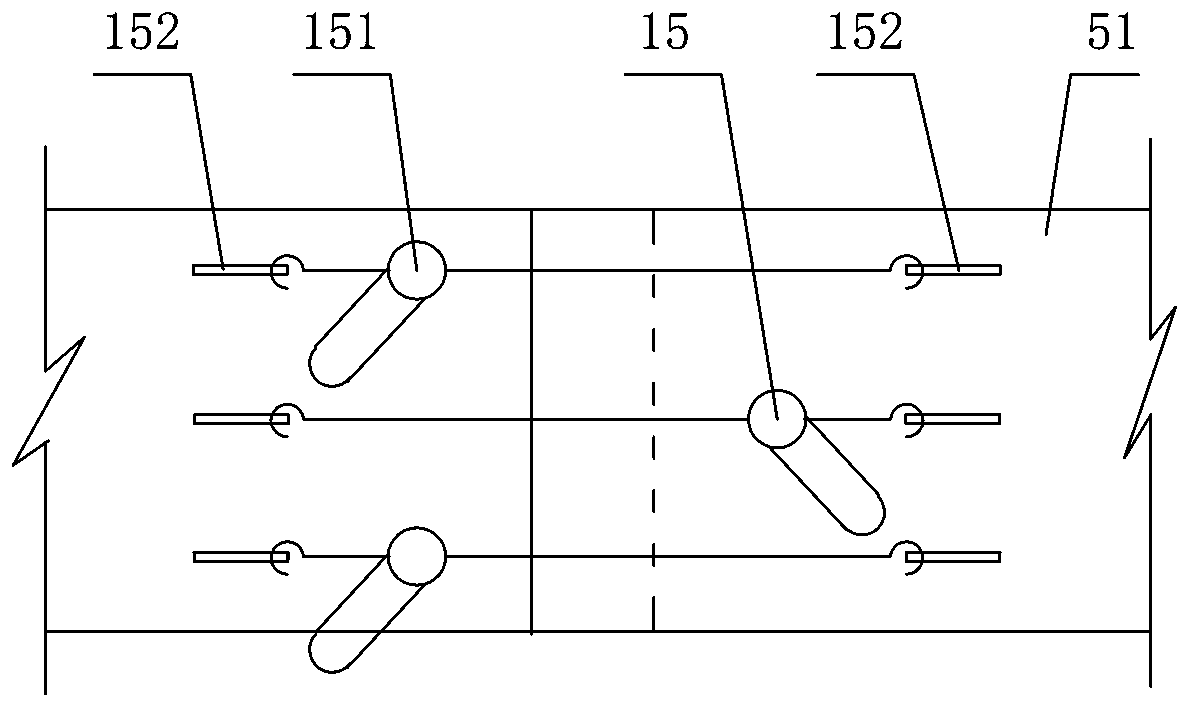

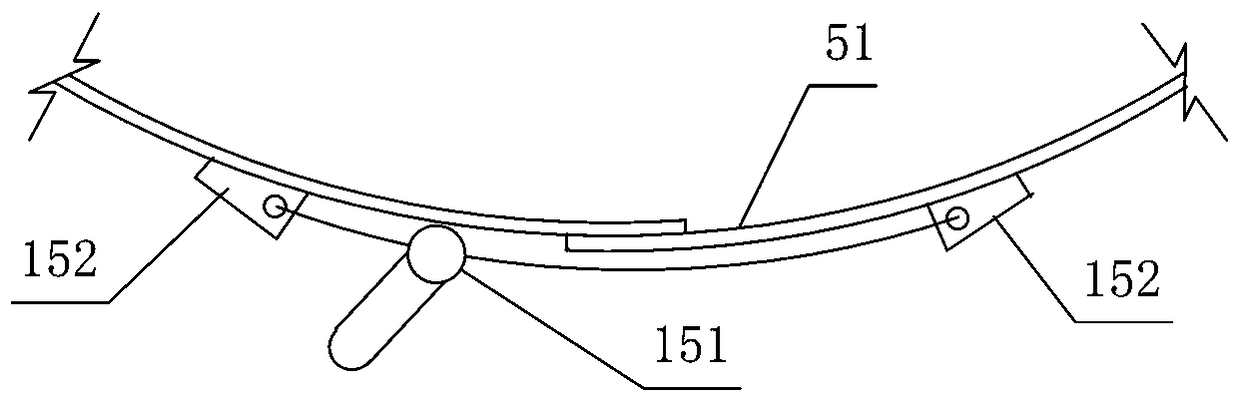

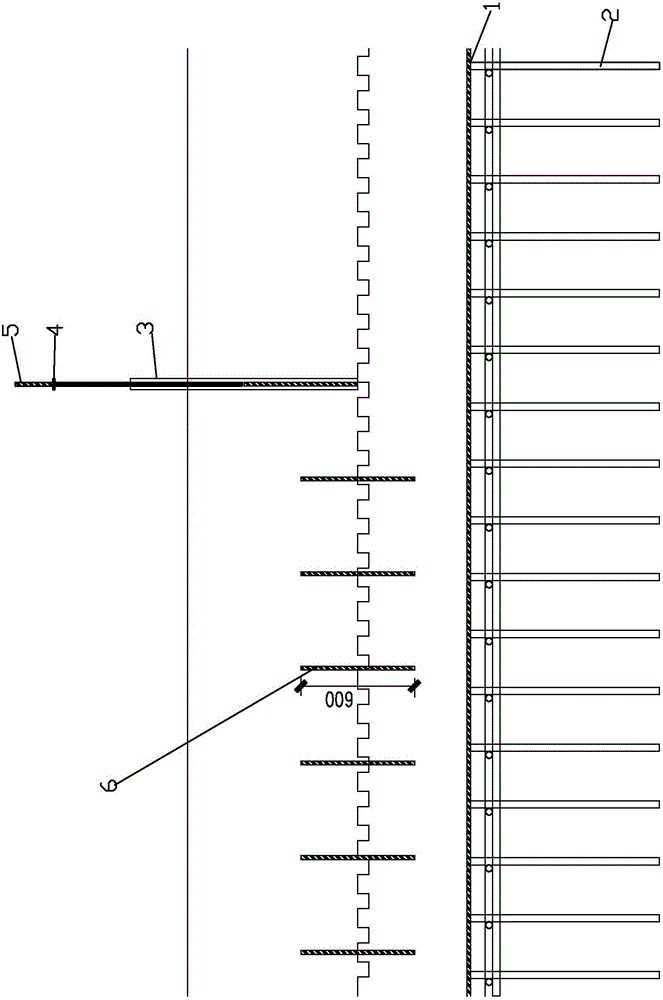

Formwork strengthening and supporting system of inverted-horn-shaped arc-shaped shear wall

InactiveCN107476573AReduce supportReduced measure feeAuxillary members of forms/shuttering/falseworksRebarShear wall

The invention relates to a formwork strengthening and supporting method of an inverted-horn-shaped arc-shaped shear wall. The formwork strengthening and supporting method comprises the following steps that a line is placed according to drawing sizes and an inner formwork is installed; then shear wall reinforcing steel bars is installed; after conceal inspection of the reinforcing steel bars is finished, an outer formwork is installed; square wood bars are installed on the inner formwork and the outer formwork, a plurality of opposite-pulling bolts are installed at intervals, and the square wood bars, the inner formwork and the outer formwork are fixed by the opposite-pulling bolts; a central stand column is erected at an arc-shaped central point by using scaffolding tubes; holes are formed and steel stranded wires penetrate through the inner formwork and the outer formwork, after the steel stranded wires penetrate through the outer formwork, the scaffolding tubes are further arranged on the outer side of the outer formwork, after bypassing the scaffolding tubes the steel stranded wires penetrate back to be fixed on the central stand column by using lock buckles; penetrating of steel stranded wires is repeated symmetrically until all steel stranded wires are run out; and the reinforcing condition of a supporting system is checked and reinforcing for the supporting system is finished. The formwork strengthening and supporting method can greatly reduce supporting or even do not need supporting, so that relative measure fee is reduced.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

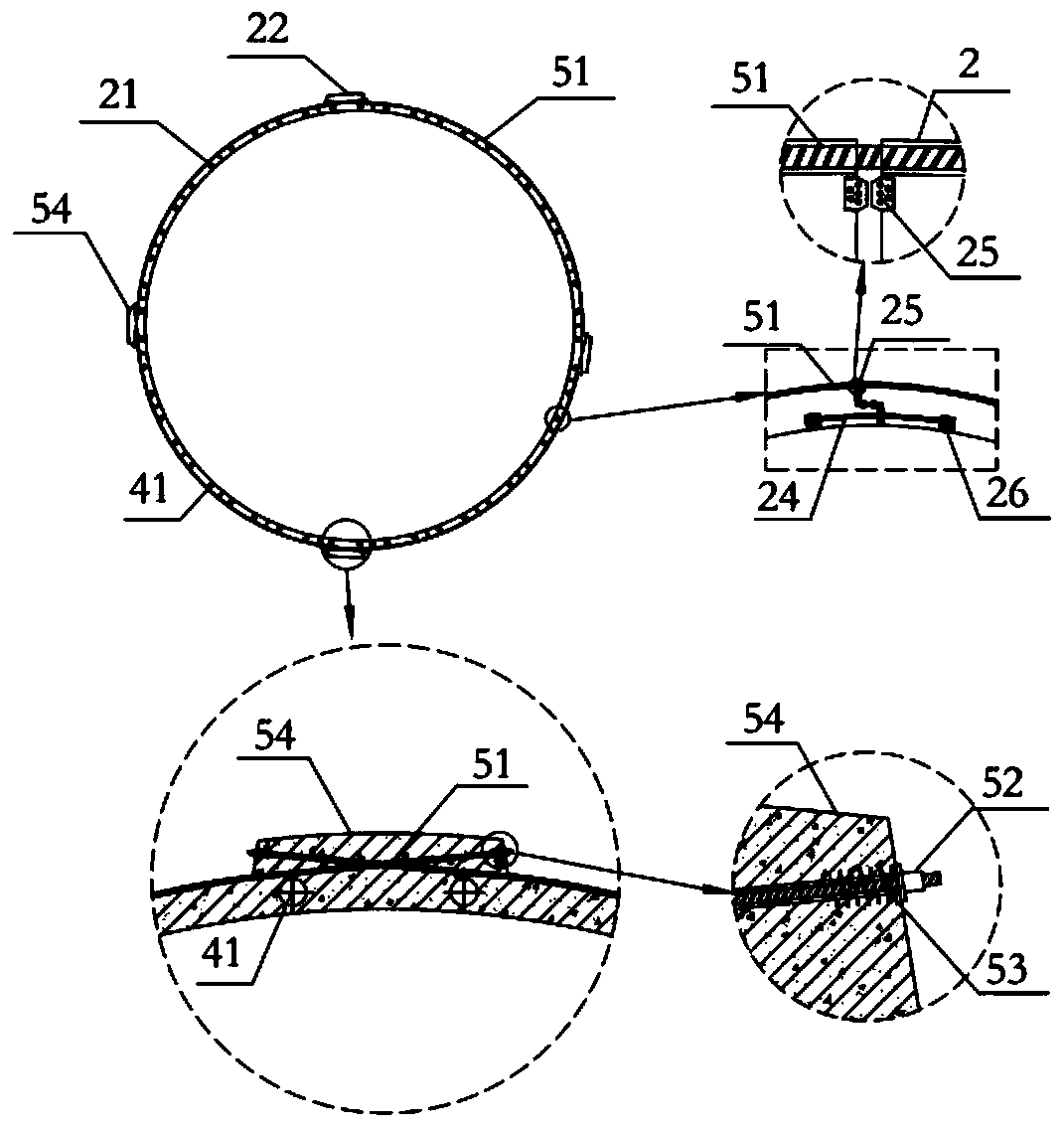

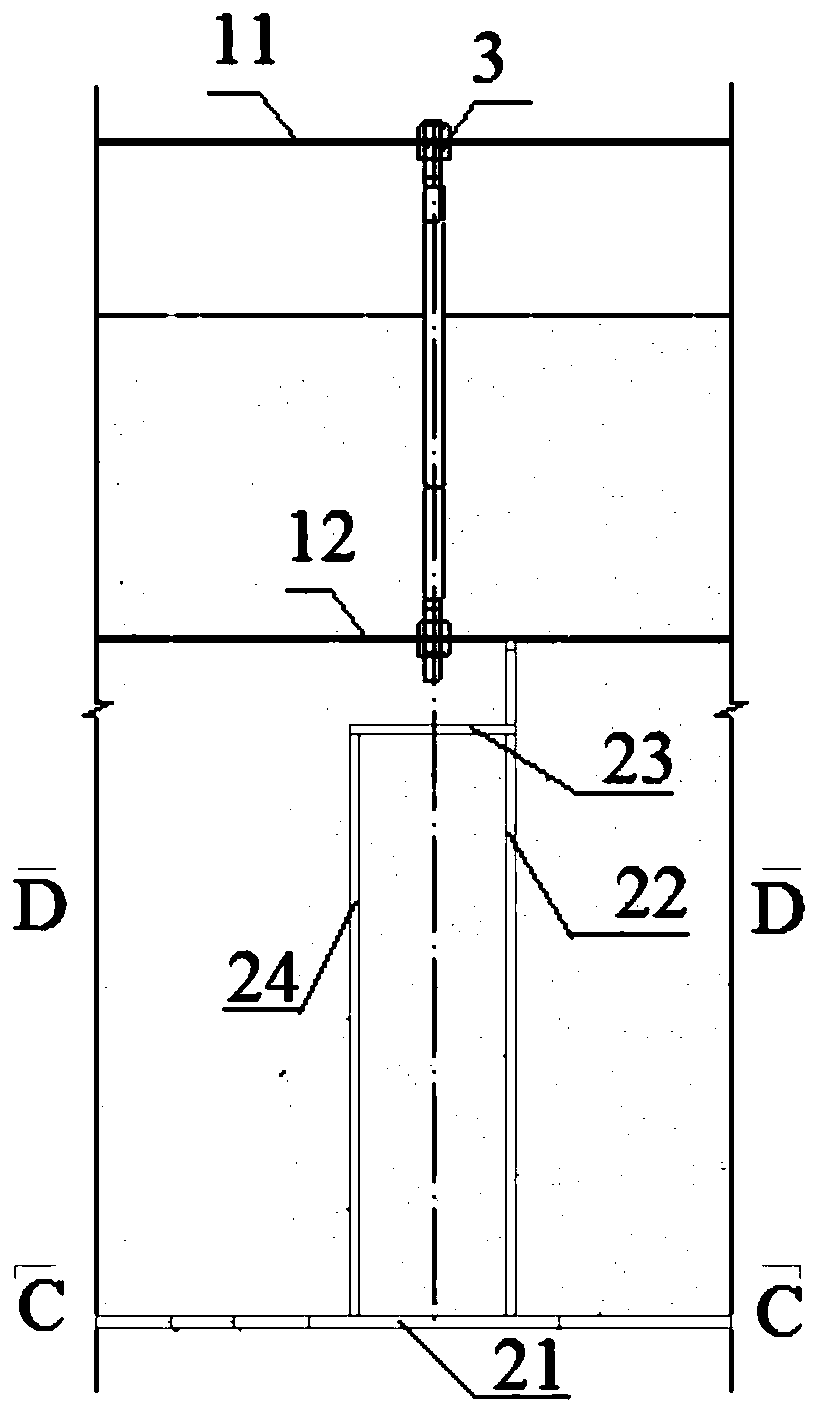

Mixed type connection precast pre-stress concrete round storage bin structure

PendingCN110409900AReduced measure feeImprove pouring qualityBulk storage containerPre stressPre stressing

A mixed type connection precast pre-stress concrete round storage bin structure comprises a bin bottom, and the bin bottom is provided with a bin wall which is provided with a bin top; the bin wall comprises a bin wall base body formed by precast arc-shaped wall plates; the precast arc-shaped wall plates are provided with a vertical pre-stress system; the bin wall base body is provided with an annular direction pre-stress system; the adjacent precast arc-shaped wall plates are connected through long bolts; anchoring platforms are arranged on the four precast arc-shaped wall plates located at the quartering positions of the bin wall; the annular direction pre-stress system comprises an annular direction pre-stress rib composed of four segments of pre-stress ribs; the four segments of pre-stress ribs are correspondingly arranged in the corresponding precast arc-shaped wall plates and encircle the bin wall base body; the two ends of each segment of pre-stress rib penetrate through the corresponding adjacent anchoring platforms, and the pre-stress ribs are tensioned through anchorage devices arranged on the corresponding adjacent anchoring platforms; the bin wall is connected with thebin bottom through common rebars; the bin wall is connected with the bin top through the vertical pre-stress system and concrete poured in the later period; and the advantages that stress is reasonable and anti-seismic performance is achieved are achieved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

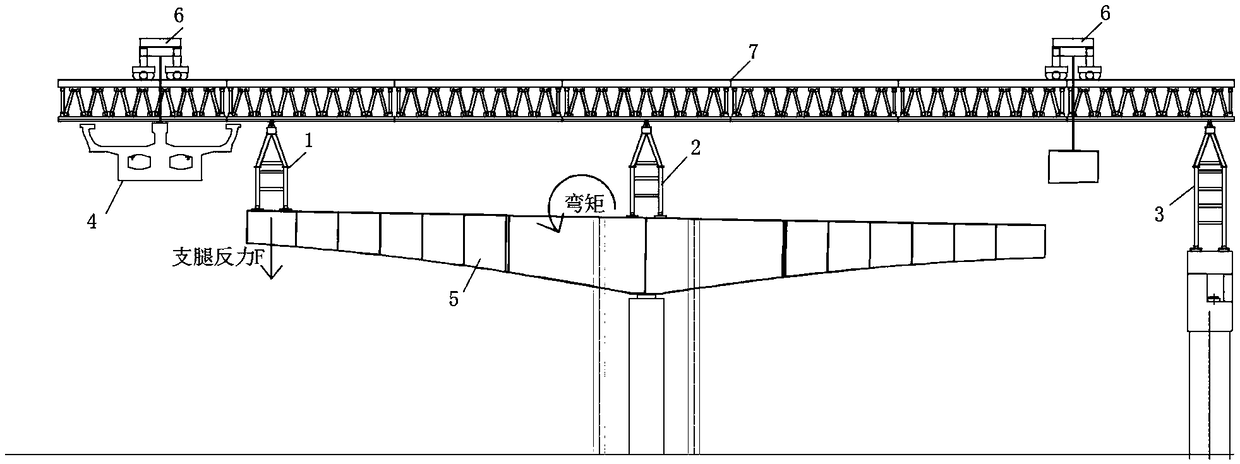

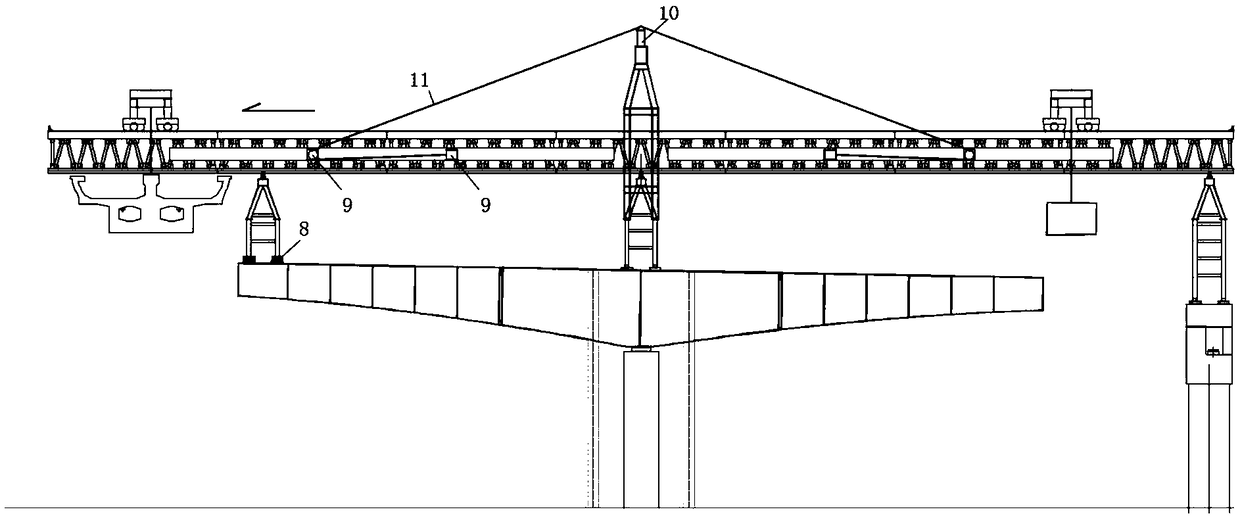

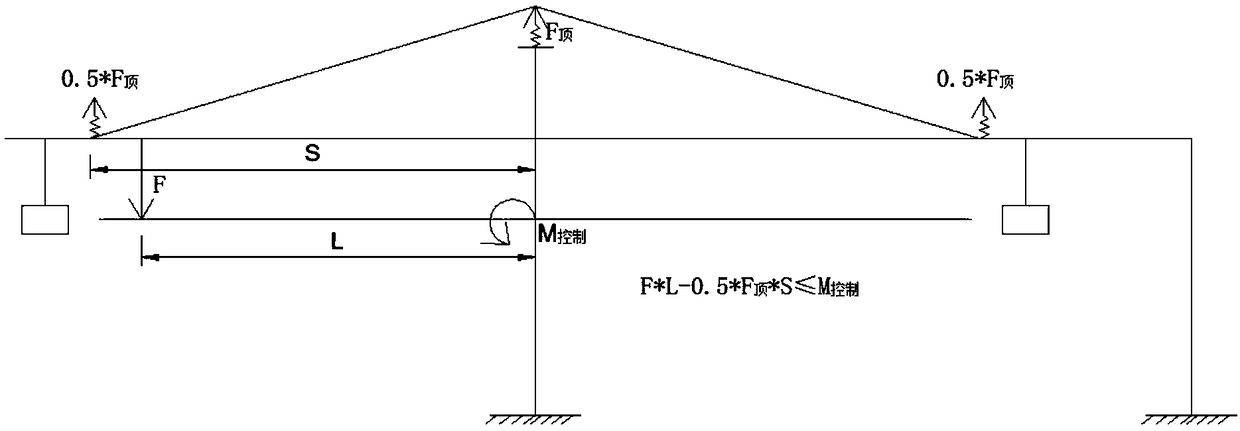

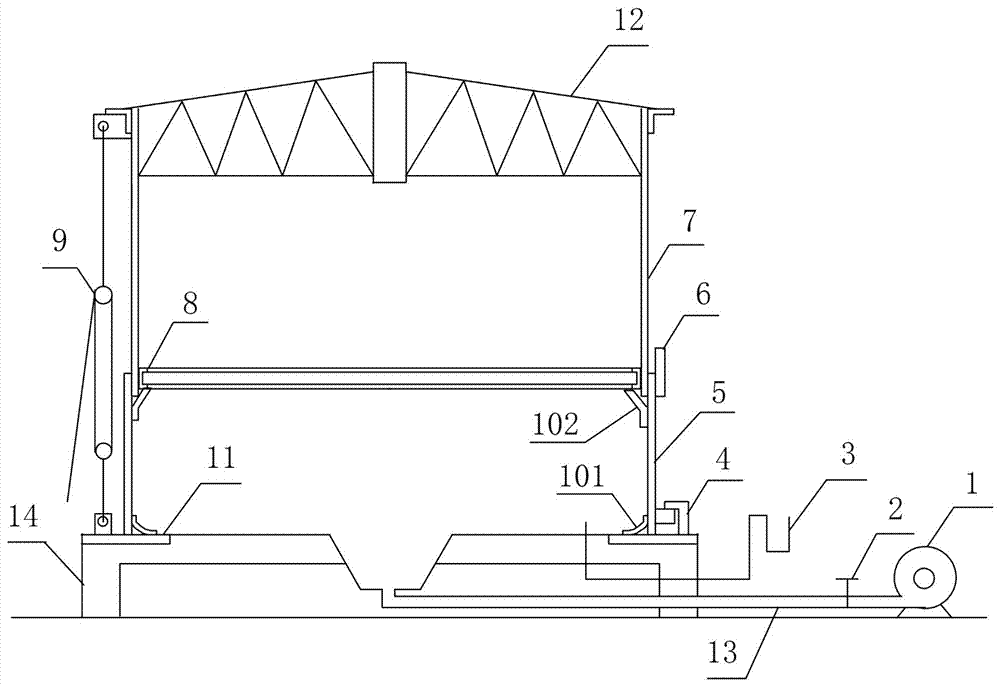

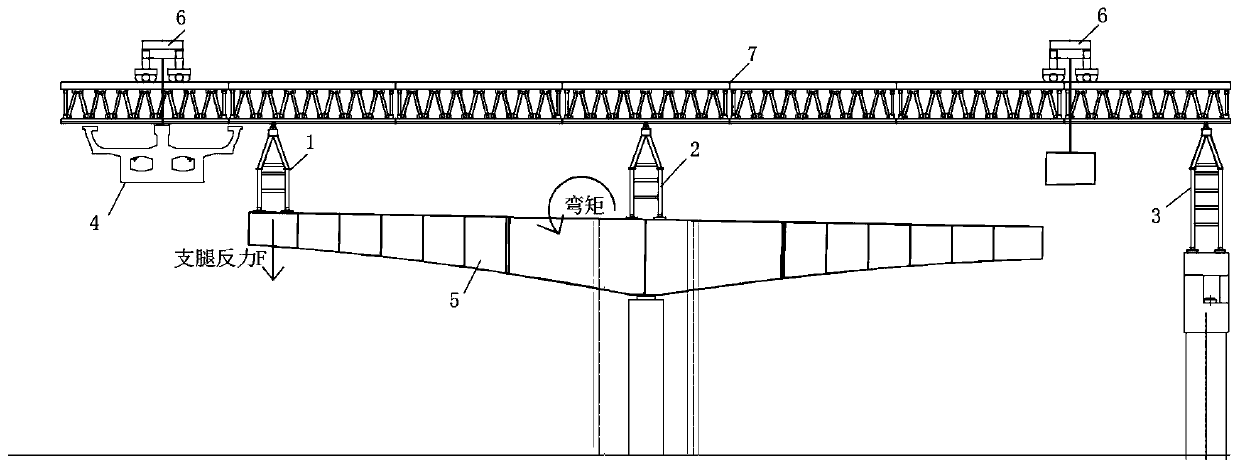

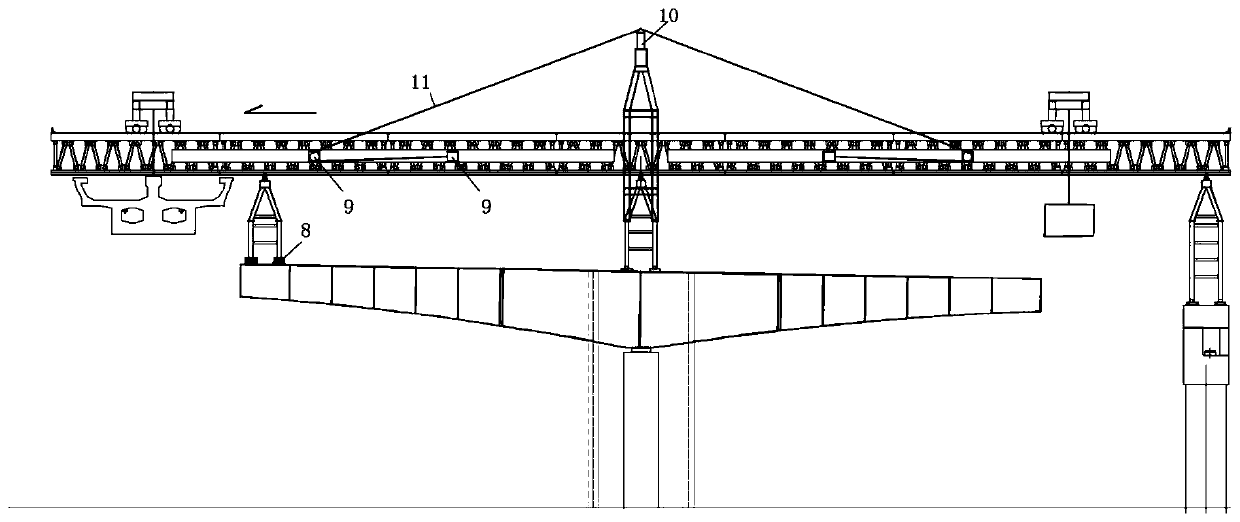

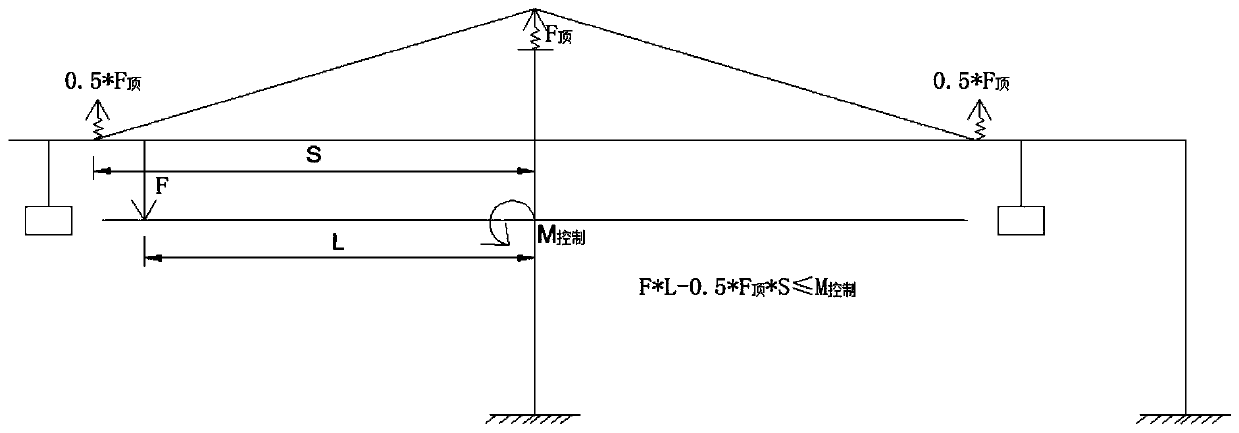

Dead-load control device and method for bridge erection machine

ActiveCN109024308AIncrease the lifting weight limitControllable bending momentBridge erection/assemblyEngineeringLimit value

The invention provides a dead load control device and method of a bridge erection machine. The invention changes the stress form of the traditional bridge erecting machine, the cantilever hoisting load of the bridge erecting machine is transferred to the middle leg, the function of wireless active control of bridge erection machine reaction force is realized, intelligent control is realized, the cantilever load in front of the bridge erecting machine can be adjusted according to the hoisting weight and the hoisting distance, so as to control the front leg reaction force of the bridge erectingmachine to be within the target range, to control the bending moment of the construction beam section caused by the front leg reaction force F of the bridge erecting machine, to improve the stress safety of the construction beam section, to reduce the cost of measures in the hoisting construction, to improve the bending resistance of the main longitudinal beam of the bridge erecting machine, and to increase the original hoisting weight limit value of the bridge erecting machine.

Owner:SHANGHAI CONSTRUCTION GROUP

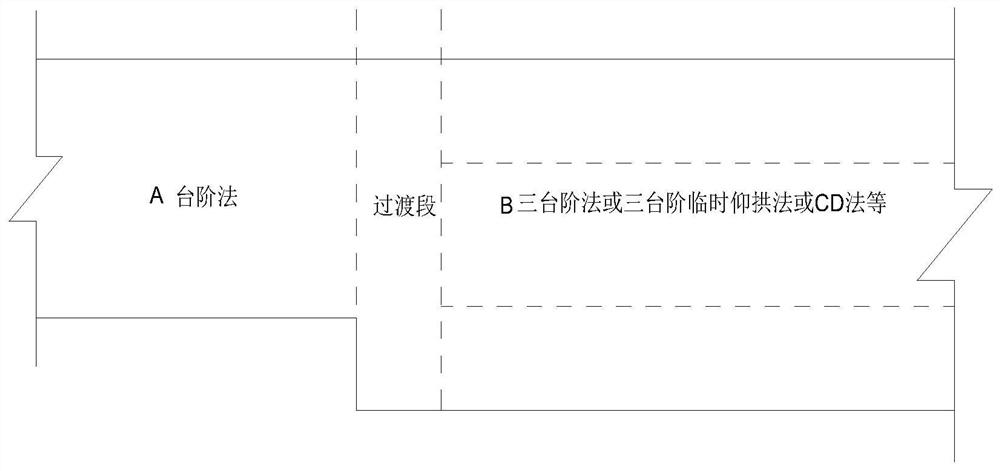

Construction method for transverse expanding excavation conversion when tunnel section suddenly changes to large-span section

PendingCN112814686AStress structure is stableReduced demolition workloadUnderground chambersTunnel liningArchitectural engineeringEngineering

The invention belongs to the field of tunnel engineering, and particularly relates to a construction method for transverse expanding excavation conversion when a tunnel section suddenly changes to a large-span section. According to the construction method, when the tunnel section enters the transition section of the suddenly-changed large-span section, firstly a preceding pilot tunnel is excavated, and then excavation expands towards the arch part of the suddenly-changed large-span section while excavating a following pilot tunnel; then 90-degree straight turning pilot tunnel expanding excavation is conducted in the side wall direction, during expanding excavation, a portal support is added to serve as temporary protection, and a portal cross beam is installed outside the large-span section contour line in the line direction; and after excavation is conducted to the position of a side wall arch foot of the large-span section, an annular arch frame of the large-span section is erected on the lower side of a portal cross beam at a time. According to the construction method, the portal support is large in operation space, high in safety and convenient to construct, meanwhile, the portal cross beam is arranged on the outer side of a main tunnel primary support arch frame, extension or erection of the main tunnel annular arch frame is not affected, the portal cross beam and upright end wall portal vertical supports at the junction of the two sections can serve as permanent primary supports, and the dismantling workload of the temporary portal is reduced.

Owner:CHINA RAILWAY 20 BUREAU GRP

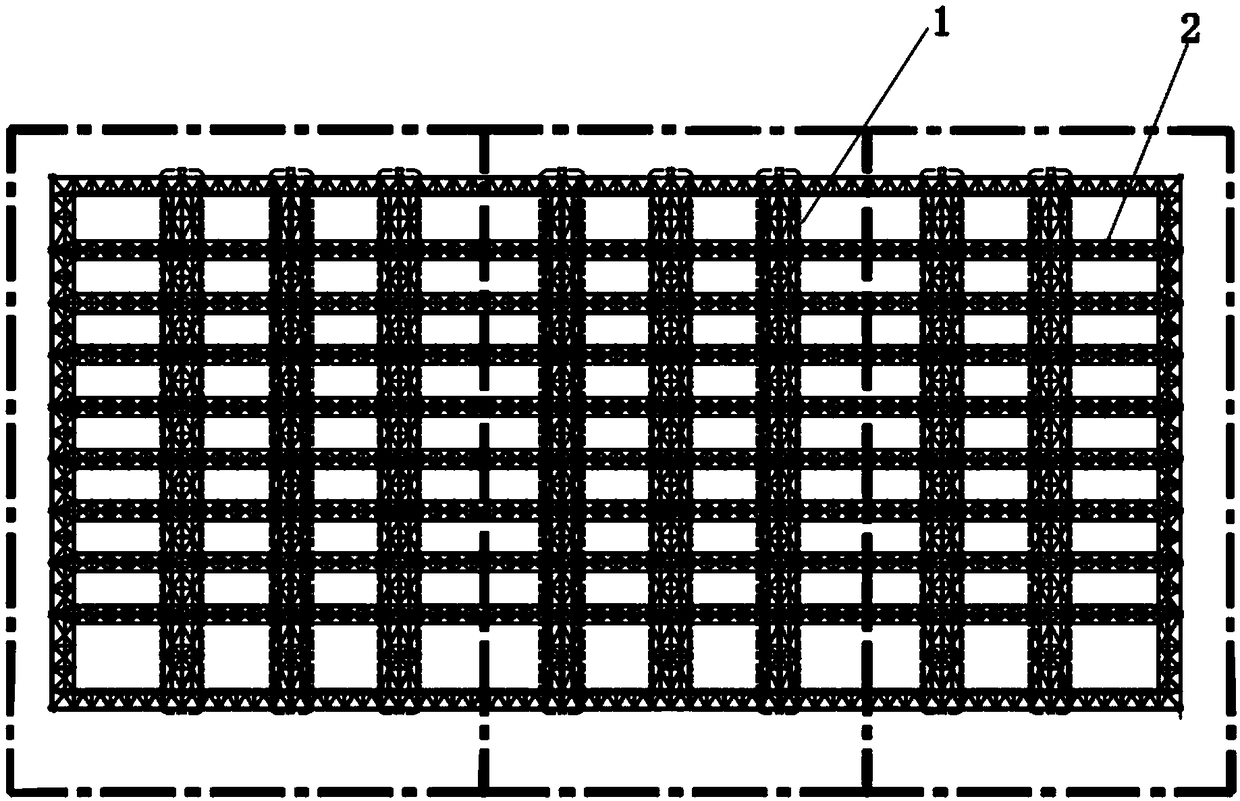

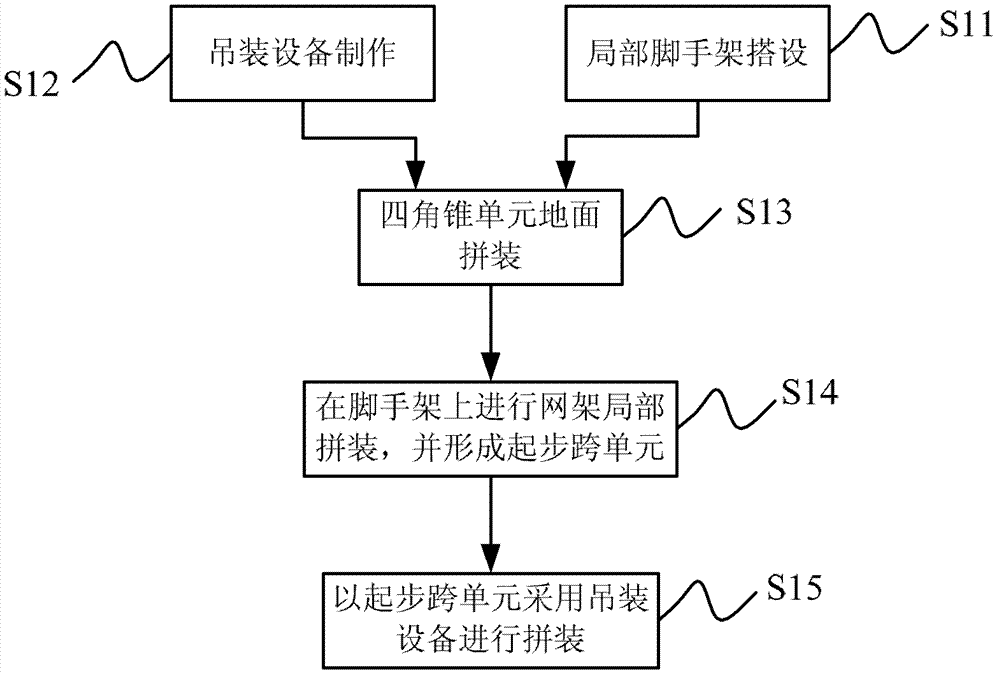

High-altitude bulk process of bolt ball net frame

ActiveCN102345393BSave turnover materialsSimple and fast operationBuilding material handlingEngineeringUltimate tensile strength

The invention discloses a high-altitude bulk process of a bolt ball net frame, comprising the steps: 1) erecting local scaffolds; 2) assembling square pyramidal units on the ground; 3) carrying out local assembly of the net frame on the local scaffolds and forming a net-frame start crossing unit; and 4) assembling the start crossing unit by adopting lifting equipment, wherein the lifting equipment is fixed to the start crossing unit; the square pyramidal units are lifted to high altitude by the lifting equipment and are symmetrically overhung, expanded and assembled from the middle of the net-frame start crossing unit to the two sides thereof till the assembly of the whole bolt ball net frame is finished. The high-altitude bulk process provided by the invention is applicable to installation and construction of various large-span bolt ball net frame roof structure systems; and according to the high-altitude bulk process, large construction machines are not needed, the operation is simpler, and only few supporting scaffolds need to be erected, thus greatly improving the labor efficiency and reducing the labor intensity.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

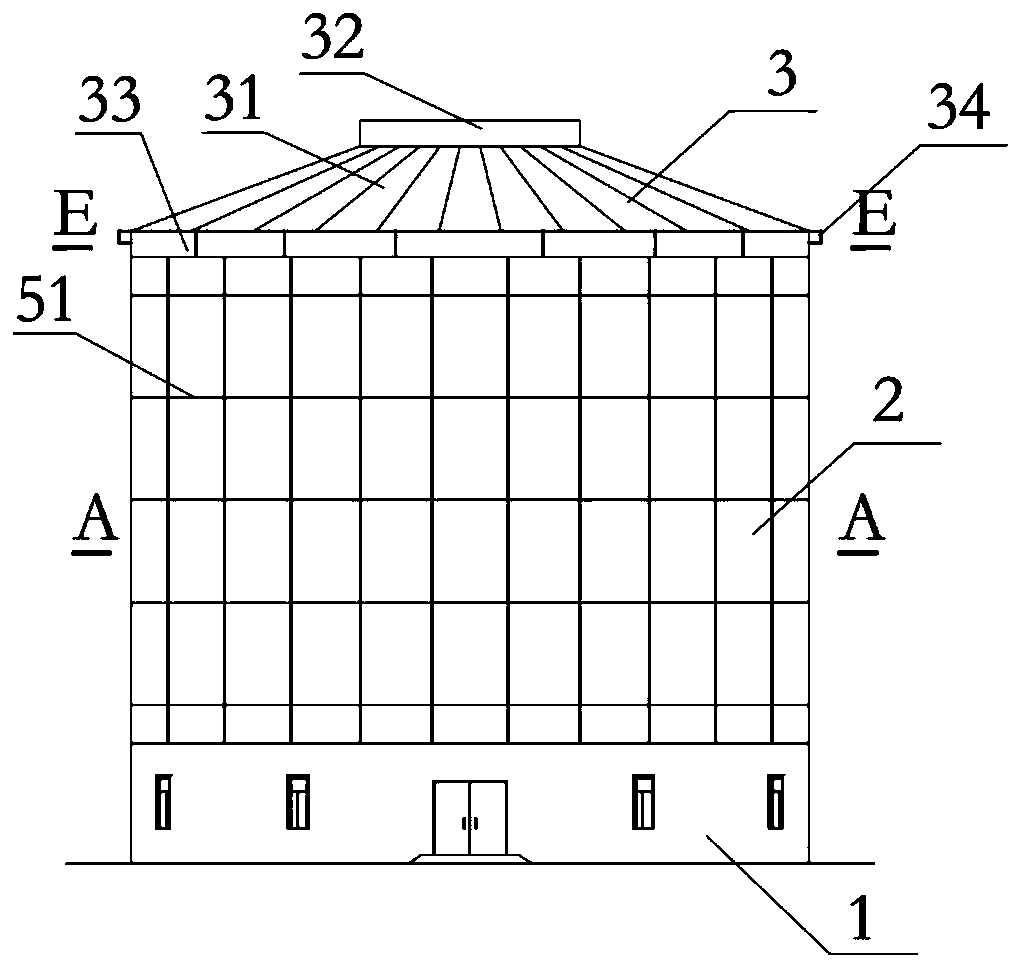

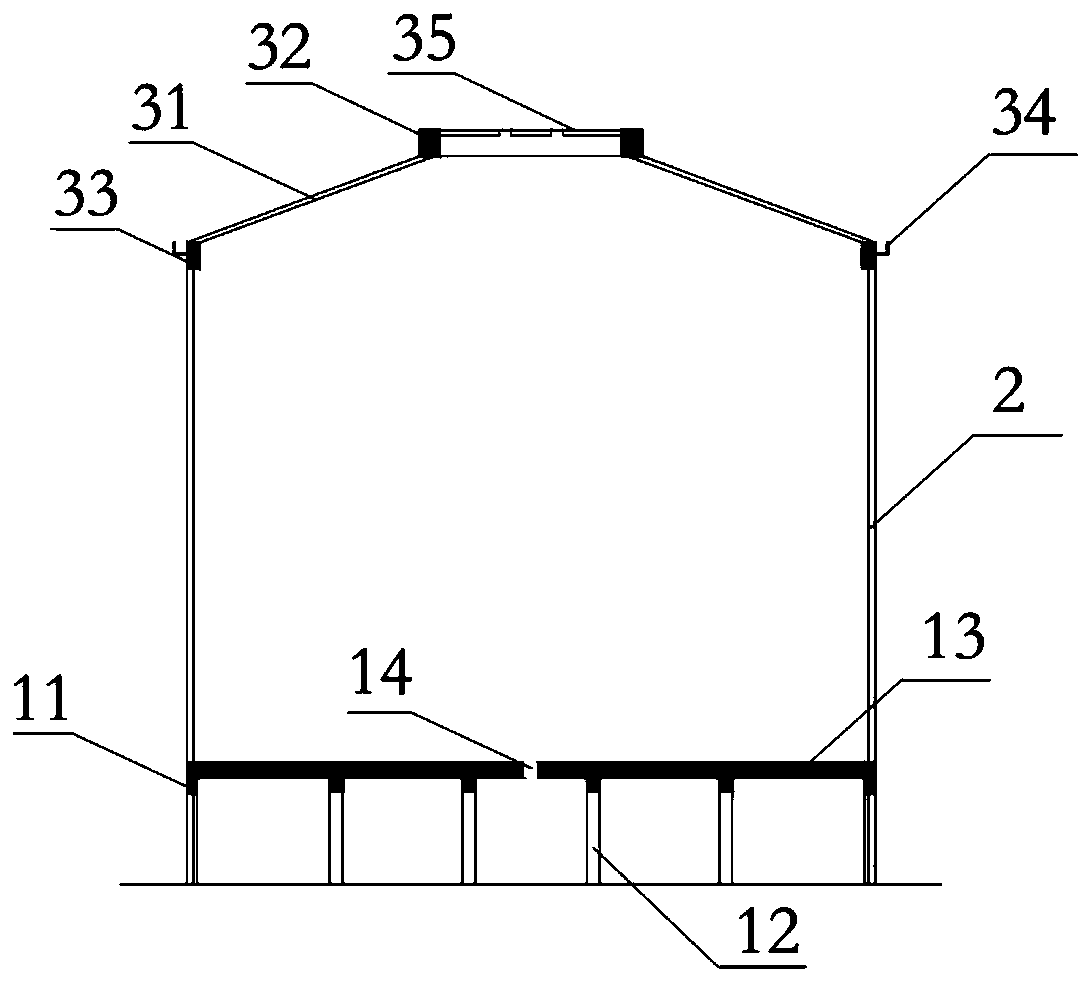

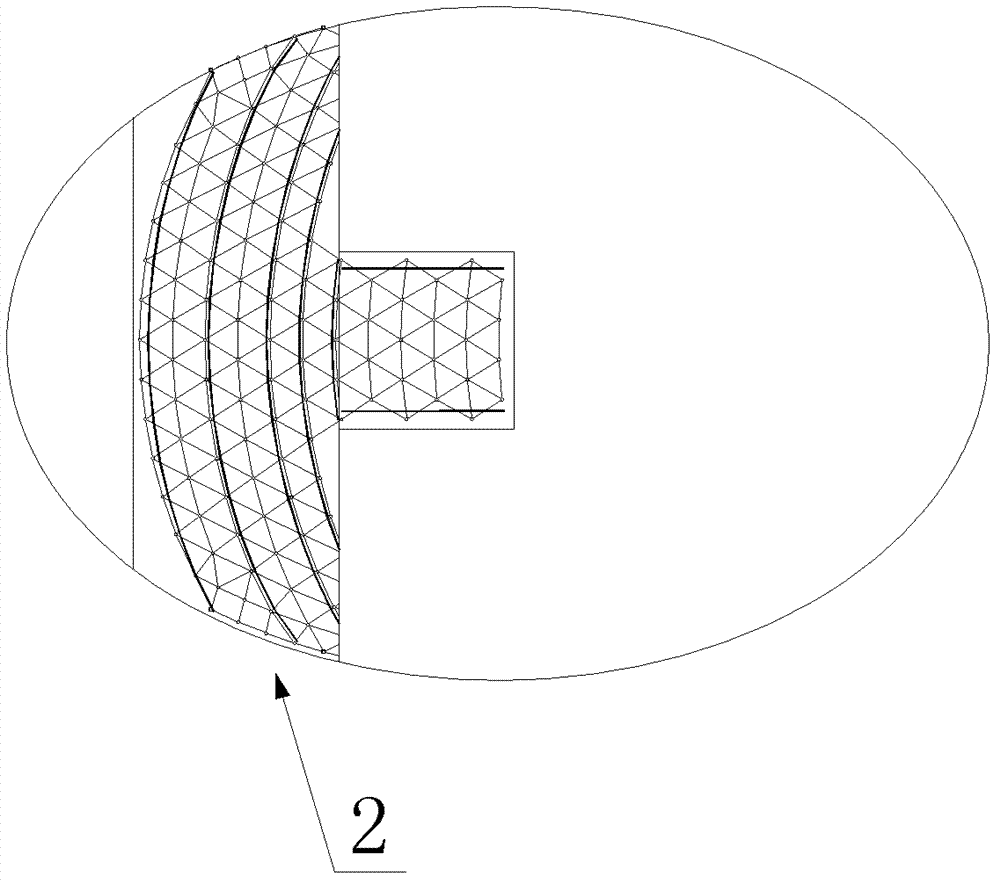

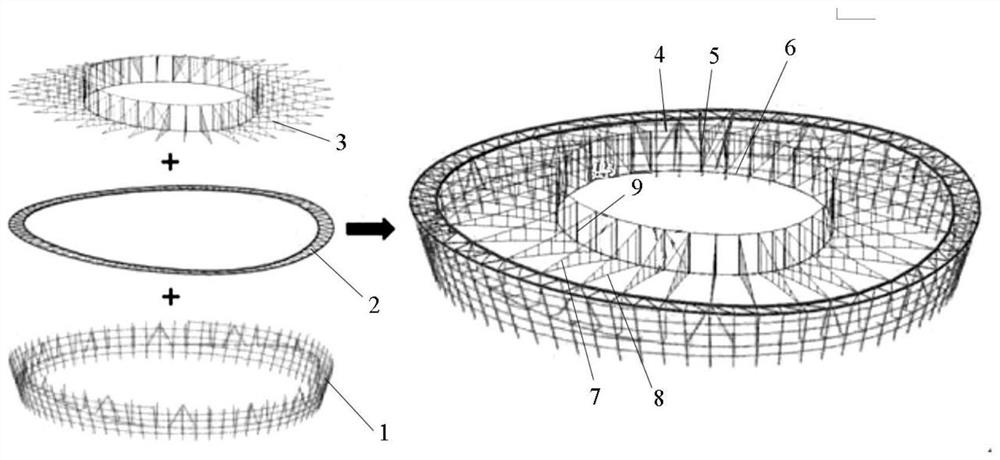

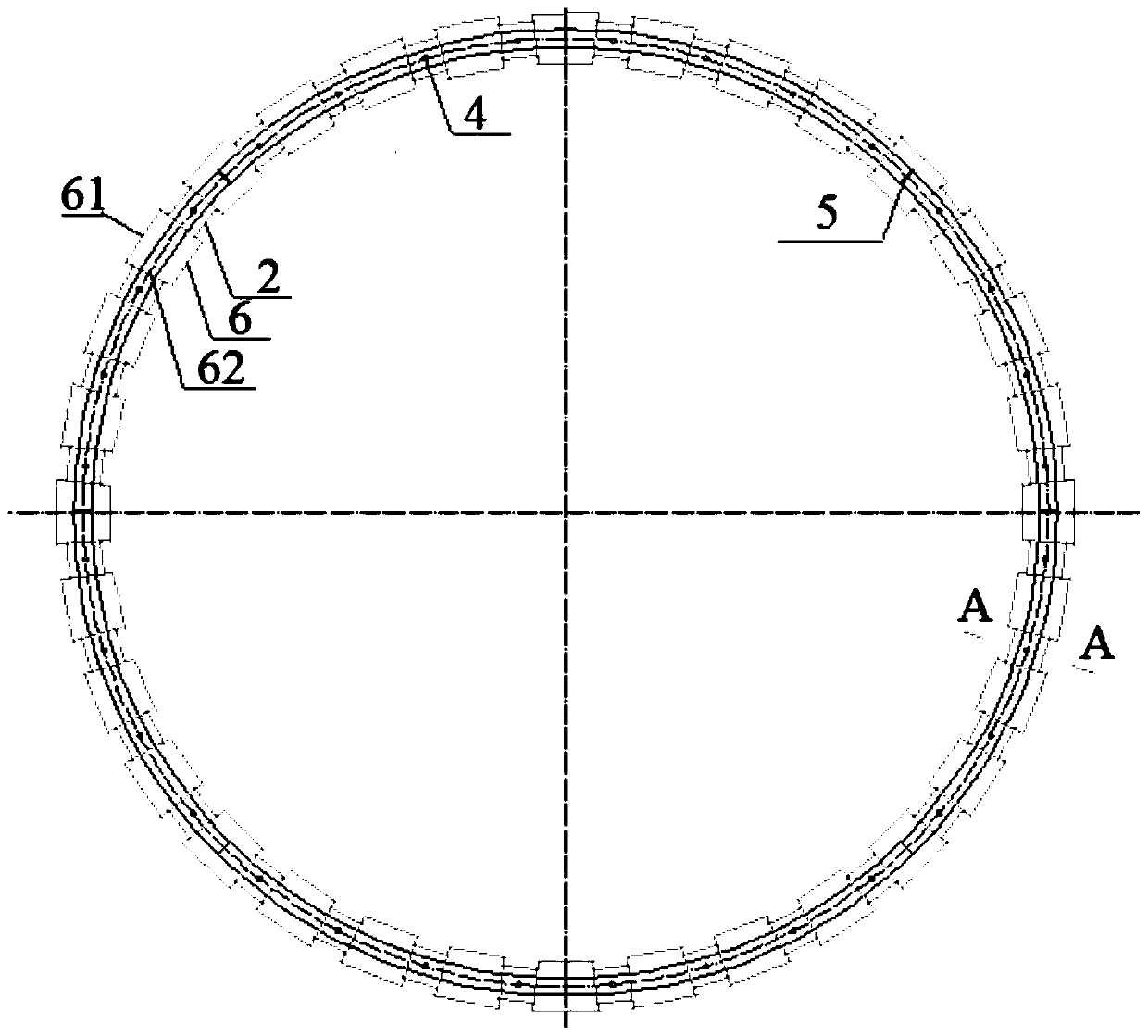

Stadium ultra-large-span hub type double-layer cable structure and mounting method thereof

PendingCN112392303AReduce usageReduced measure feeBuilding roofsGirdersArchitectural engineeringCable net

The invention discloses a stadium ultra-large-span hub type double-layer cable structure and a mounting method thereof. The stadium is composed of a steel frame structure, a roof cable net structure and an outer pressing ring horizontal truss, wherein the width of the outer pressing ring horizontal truss is 12-13 m, the outer pressing ring horizontal truss is supported on inner ring vertical steelpipe columns, A-shaped steel pipe columns and outer ring inclined steel pipe columns, the specification of a horizontal pressed truss inner chord is P1600 * 50 mm, the specification of a horizontal pressed truss outer chord is P1200 * 32 mm, the inner ring steel columns are hinged and supported at the tops of concrete stand columns, and the outer ring steel columns are hinged and supported on a 6m elevation concrete structure. By the adoption of the hub type design, long materials and short materials obtained after steel components are cut are utilized to the maximum extent, particularly, the project adopts a structural design Ansys and Revit data fusion technology, the whole process from design to construction is controlled, strict measurement, calculation and control are realized, industrialized production is realized, the length is fixed, so that the measure cost in general similar engineering total cost is greatly reduced, and the cost of labor, materials and the like is saved.

Owner:CHINA CONSTR FOURTH ENG DIV

Post stress method stake body prestressed antislid stake and construction method

InactiveCN1298938CMature construction equipmentConstruction conditions are ripeBulkheads/pilesPre stressArchitectural engineering

The present invention adopts construction on ground surface, and makes post-tensional pile-body prestressed anti-slide pile. Its structure is as follows: firstly-poured concrete interior has steel reinforcement cage, cage edge interior has corrugated pipe, in the corrugated pipe interior a stranded wire is placed, two ends of said stranded wire are extended from said corrugated pipe, lower end of said stranded wire is connected with anchorage device of anchored part in the pile bottom, its upper end is connected with anchorage device of pile top, and the upper portion of anchorage device of pile type has secondary poured concrete. Said invention also provides its construction method.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Cement grinding mill foundation suspension type reserved hole embedding method

ActiveCN104452800AHigh quality and precisionImprove embedded precisionFoundation engineeringCement grindingSteel tube

The invention discloses a cement grinding mill foundation suspension type reserved hole embedding method. The problems that existing reserved hole embedding construction is high in cost, large in difficulty, prone to excursion and the like are solved. The embedding method includes the following steps: (1) preparing reserved hole model sets, wherein a foundation at the feeding end of a cement grinding mill and a foundation at the discharging end of the cement grinding mill are each provided with N reserved holes, and the reserved holes are divided into 2 / N reserved model sets, and N is an even number; (2) installing suspension type reserved hole supports outside the foundations; (3) arranging longitudinal central steel wires and transverse central steel wires of reserved hole models at the upper portions of the structural steel supports of the feeding end grinding foundation and the discharging end grinding foundation; (4) setting up a level gage measurement platform used for measuring the elevations of the reserved hole models of the feeding end grinding foundation and the discharging end grinding foundation at the positions of pegs through scaffold steel tubes, and gradually measuring the elevations of the reserved hole model sets when the reserved hole model sets are installed; (5) installing the reserved hole model sets, wherein the reserved hole model sets are installed on the suspension type reserved hole supports; (6) the reserved hole model sets are hoisted and fixed.

Owner:CHINA MCC5 GROUP CORP

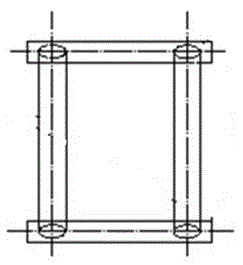

Diffusion wheel pressure reinforcement plate for floor construction on hoisting machinery

ActiveCN102817483BReduced measure feeLoad-engaging girdersBuilding repairsFalseworkBuilding construction

The invention relates to a diffusion wheel-pressure reinforcement construction method for a floorslab on hoisting machinery. The method comprises the following steps of: step 1, confirming if the floorslab through which the hoisting machinery passes needs to be diffused and wheel-pressed or not, if yes, carrying out step 2, and if not, carrying out step 4; step 2, confirming the thickness of earthing soil on the floorslab and the thickness of a reinforcement plate on the earthing soil according to the type of the hoisting machinery; step 3, paving the earthing soil and the reinforcement plate on the floorslab according to the thicknesses confirmed by the step 2; and step 4, loading the floorslab by the hoisting machinery. The embodiment of the invention also provides a diffusion wheel-pressure reinforcement plate applied in the construction method, the reinforcement plate comprises a frame and a top plate arranged on the frame. Compared with reinforcement only through earthing or a scaffold, the construction method and the reinforcement plate are capable of saving more measure fee.

Owner:CHINA CONSTR SCI & IND CORP LTD

Installation and construction method of large steel silo

ActiveCN105484549BLow costImprove construction efficiencyBuilding material handlingBulk storage containerSiloBuilding construction

The invention discloses an installation and construction method of a large steel material bin. The installation and construction method comprises steps as follows: a bottom plate is installed on a foundation platform firstly, a first cylindrical shell section is installed on the bottom plate, a conic vertex is installed on the first cylindrical shell section to form a bell jar structure, then a second cylindrical shell section is assembled on the periphery of the first cylindrical shell section, a vertical seam splicing port without tight splicing is reserved in the second cylindrical shell section and is taken as an open port, gaps between the second cylindrical shell section and the bottom plate as well as between the first cylindrical shell section and the second cylindrical shell section are sealed with rubber plates, a blast apparatus is adopted to blast air to the bell jar structure, the bell jar structure ascends to be higher than the second cylindrical shell section, the open port of the second cylindrical shell section is retracted, the first cylindrical shell section and the second cylindrical shell section are assembled and spliced, remaining cylindrical shell sections are installed sequentially with the same method, and the installation of the large steel material bin is completed finally. According to the installation and construction method, working at heights is changed into working in lower positions, the safety of construction can be improved, resources and constriction cost are saved, the working efficiency is improved, and the construction period is shortened.

Owner:THE FIRST ENG CO LTD OF THE 23TH METALLURGICAL CONSTR GRP MINMETALS

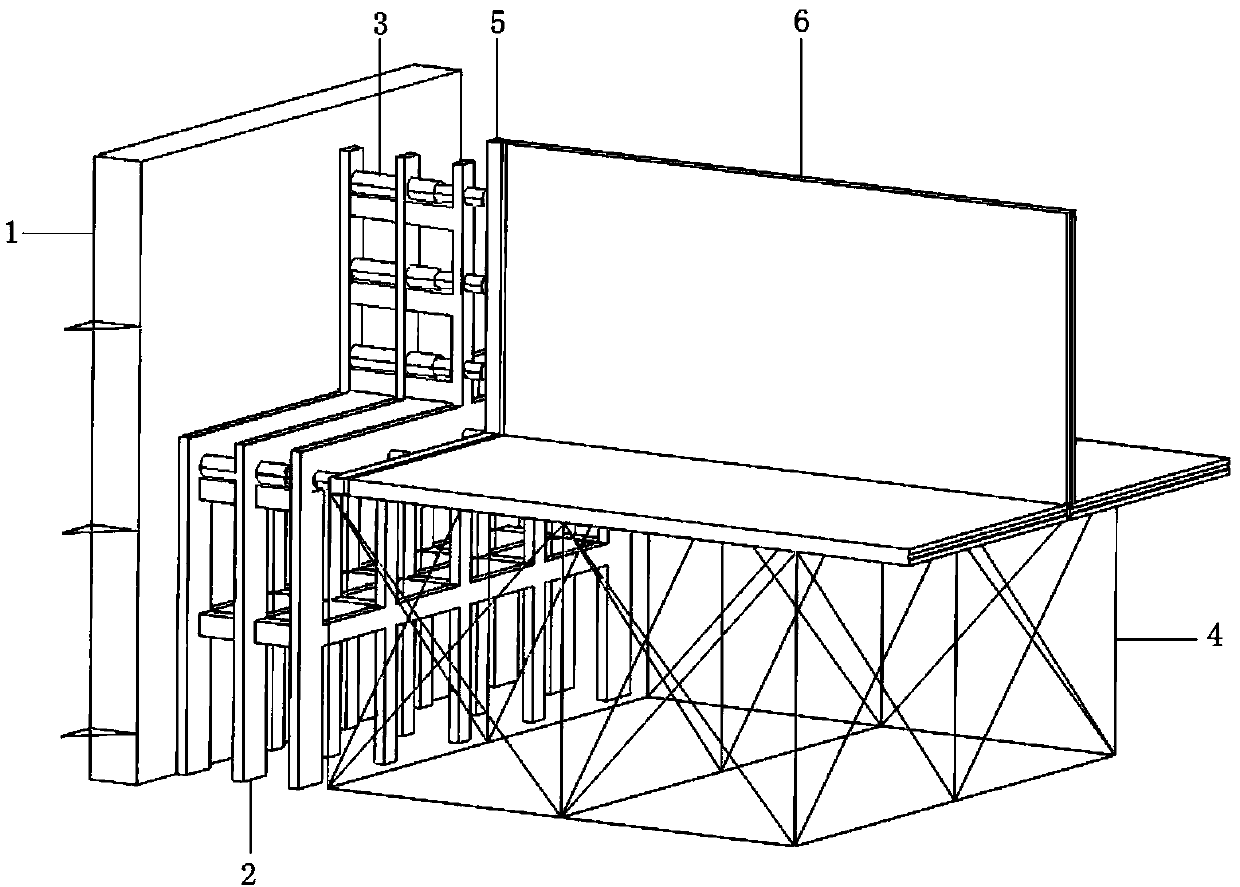

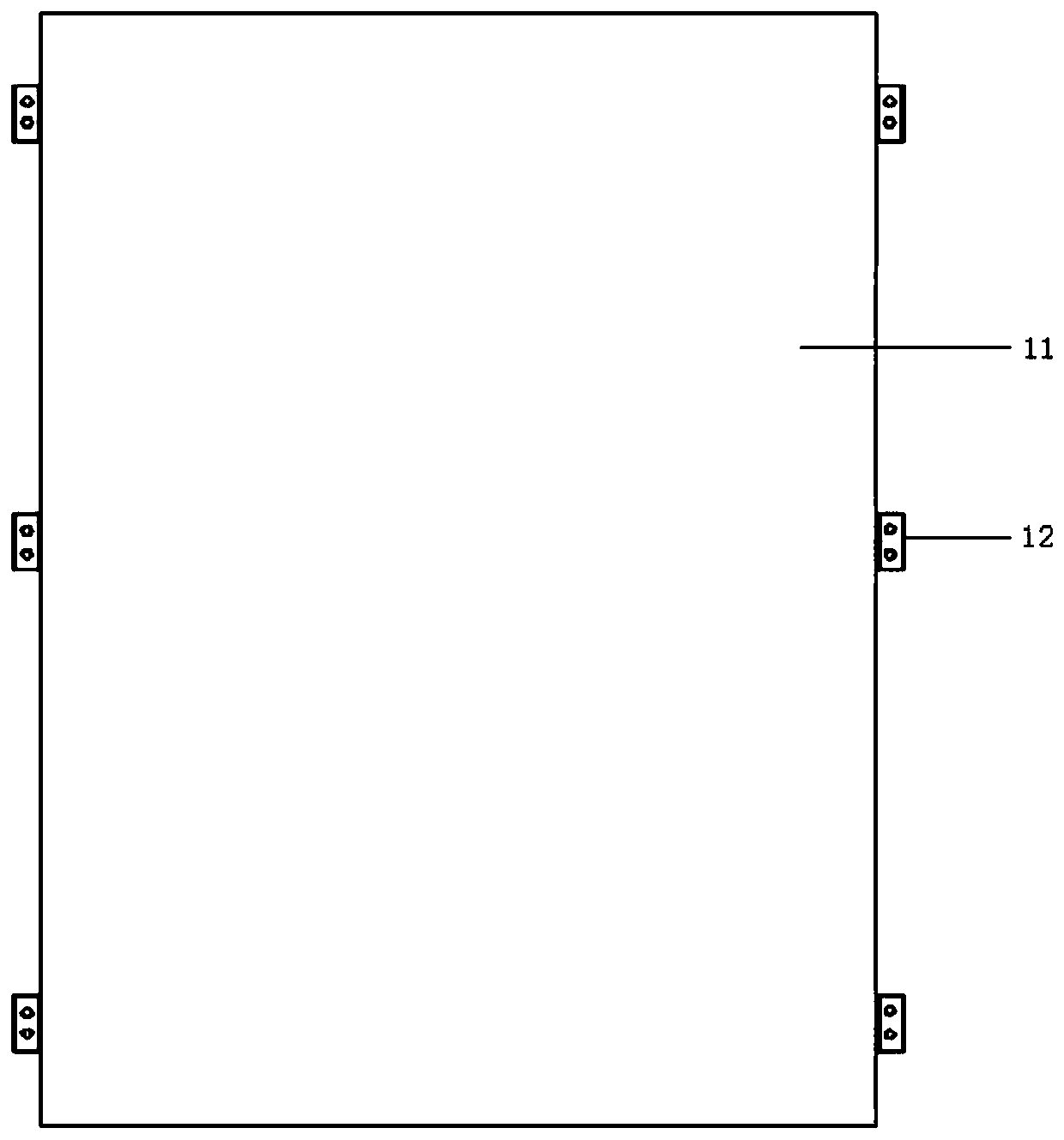

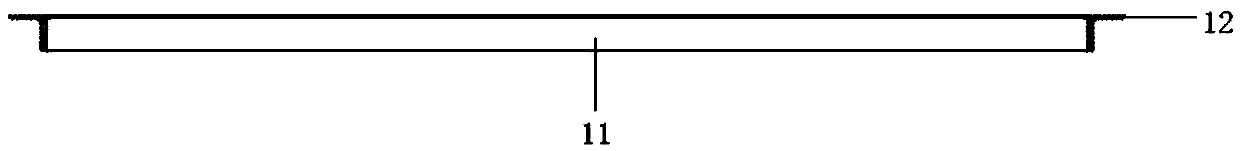

Fabricated construction platform of horizontal superimposed structure

PendingCN112376880ARealize synchronous hoistingFast constructionScaffold accessoriesBuilding support scaffoldsConstruction engineeringFloor level

The invention relates to a fabricated construction platform of a horizontal superimposed structure. The platform comprises a precast beam, a supporting truss, platform plates, handrails, and protective parts. A plurality of groups of connecting parts are arranged at one side or two sides of the precast beam, and the connecting parts are arranged along the extending direction of the precast beam; the supporting truss is arranged on the connecting parts of the precast beam; the platform plates are provided with reinforcing structures, are placed on the supporting truss and are fixed with the supporting truss; each handrail comprises a handrail upright post and a handrail horizontal rod, and the handrails are mounted outside the platform plates; and the protective parts are arranged in the areas, where the platform plates are not arranged, of a secondary beam connecting structure of the precast beam, and the connection of the adjacent platform plates is achieved. The fabricated construction platform of the horizontal superimposed structure has the beneficial effects that mounting and dismounting are convenient, hoisting is conducted together with a prefabricated element, and the construction speed of a main body structure can be increased; a construction platform is prevented from being erected from a lower floor to a construction working face of the floor, and project measure cost is remarkably saved; and meanwhile, the equipment installation, the decoration and other procedures can be conveniently carried out on the lower floors as soon as possible, and the engineering construction progress is accelerated.

Owner:FCEC PREFABRICATED BUILDING RES INST CO LTD

Cement Mill Foundation Hanging Reserved Hole Embedding Method

ActiveCN104452800BHigh quality and precisionImprove embedded precisionFoundation engineeringCement grindingMaterials science

Owner:CHINA MCC5 GROUP CORP

Method for establishing buckling and hanging system by using arch rib structure of edge span

The invention discloses a method for establishing a buckling and hanging system by utilizing an arch rib structure of an edge span. The method is characterized by sequentially carrying out the following steps: firstly, the construction of arch abutment foundation and arch abutment is carried out, the foundation of cover beam and the construction of cover beam, and then the embedded parts of the buckling tower foundation are embedded at the top of the arch base, the first section of the side span arch rib is installed before the concrete of the arch abutment is poured, When the concrete strength of the arch abutment meets the requirements, tensioning the stranded wire in the first segment and grouting, Consolidate that first segment with the arch abutment, then the buckling tower is installed on the arch base by the crane, At that same time, the side span arch rib and the transverse longitudinal beam correspond to the side span arch rib are installed by the support method, Remove the bracket of the side span arch rib, set anchor device of anchor point at one end of the side span arch rib located at the cover beam, bury anchor cable pipeline and position in the anchor device, pour the pressure concrete in the side span arch rib and the end beam, and pour the pressure concrete at the anchor device after the anchor device is removed.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP 1ST ENG

A sub-unit installation and construction method of a large-span double-layer PTFE membrane structure roof

ActiveCN111851745BEasy to installImprove construction qualityClimate change adaptationHeat proofingInsulation layerLong span

A kind of large-span double-layer PTFE membrane structure roof sub-unit installation and construction method of the present invention comprises the following steps: S1, roof structure is modeled, and roof is divided into several units; S2, pack unit film, will according to unit shape Each finished unit membrane is packaged from the center to both sides, and a paper tube is added at the bend; S3, on-site inspection of the unit membrane to check whether it is damaged and check the quantity; S4, installation of the outer mold; S5, installation of the waterproof membrane; S6, installation of the inner membrane Membrane installation; S7, insulation layer installation. The invention utilizes the self-designed large-span hemispherical double-layer PTFE membrane structure roof sub-unit installation and construction technology to ensure that the tension of the double-layer membrane roof membrane is in place, and the overall construction quality is better.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

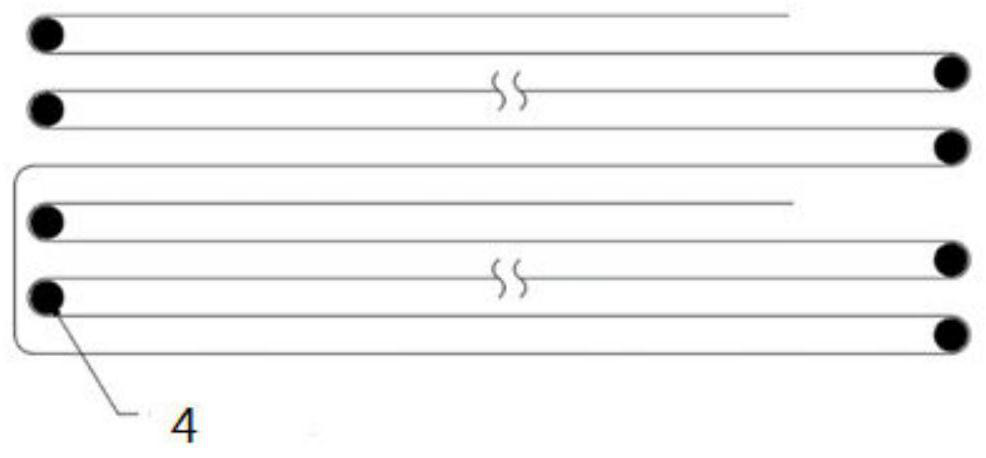

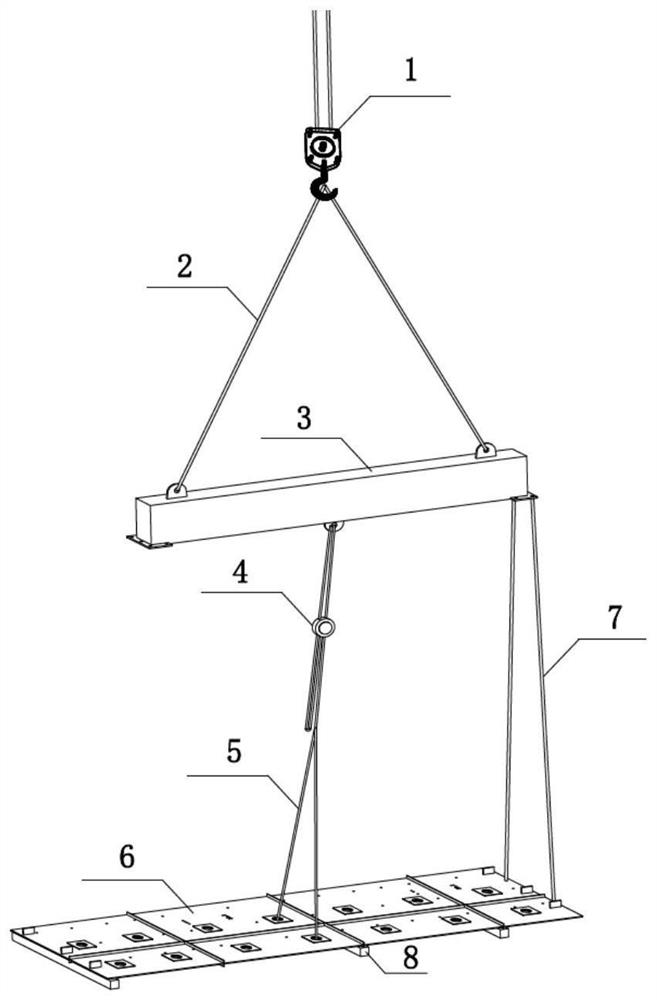

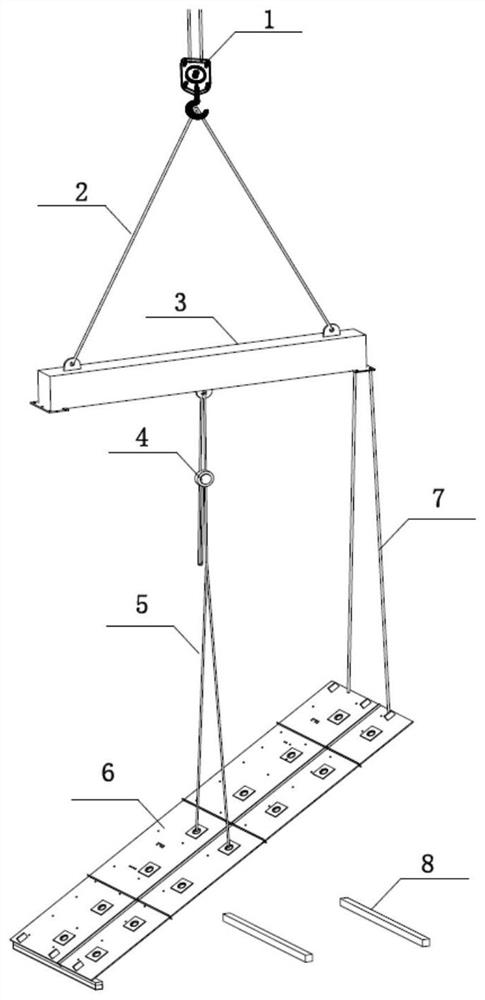

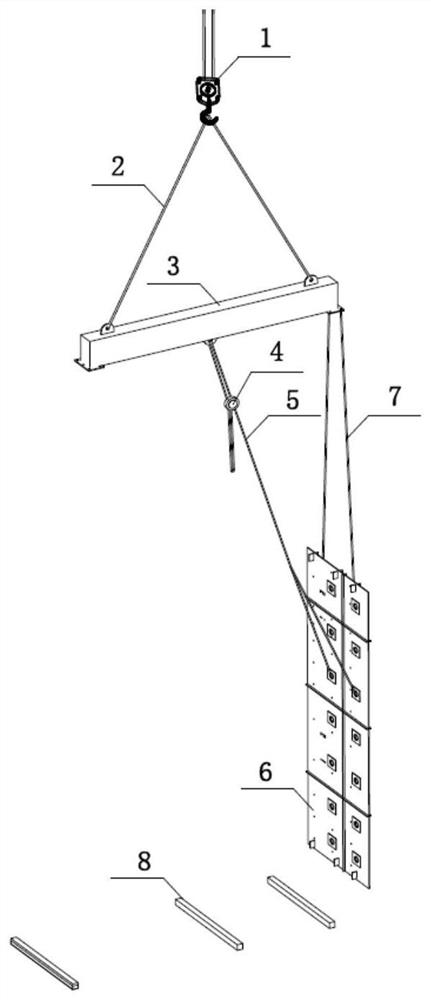

A hoisting device and hoisting method for an ultra-thin steel plate shear wall in the blind area of a tower crane

InactiveCN108862002BRealize multiple reuseWill not be caused by green construction requirementsLifting devicesLoad-engaging elementsSheet steelClassical mechanics

The invention relates to the technical field of hoisting equipment, in particular to a tower crane blind area ultrathin steel plate shear wall hoisting device and a hoisting method thereof. The towercrane blind area ultrathin steel plate shear wall hoisting device comprises a shoulder pole beam, two shoulder pole beam riggings used for being connected with one end of a steel plate shear wall areconnected with one end of the lower surface of the shoulder pole beam, an electric hoist is arranged in the middle of the lower surface of the shoulder pole beam, a hook of the electric hoist is connected with two electric hoist riggings used for being connected with the middle of the steel plate shear wall, and the two ends of the upper surface of the shoulder pole beam are connected with two hoisting riggings connected with a lifting hook of a swing arm tower crane. The tower crane blind area ultrathin steel plate shear wall hoisting device and the hoisting method thereof are easy, convenient and rapid to operate, low in cost, safe and reliable and high in stability, and plastic deformation does not occur on the steel plate shear wall in the hoisting process.

Owner:CCCC FIRST HARBOR ENG +1

Full-section jacking system and jacking method for underground excavation of comprehensive pipe gallery sub-storage structure

The invention discloses a full cross section jacking system for an underground excavation utility tunnel sub carbon structure. The system comprises a reaction force back system, a jacking force system support frame, a jacking force system, a guide rail, a force transmission reverse T beam and a resistance reduction system. The invention also discloses a jacking method of the jacking system. According to the method, firstly, the integral stage length selection and integral prefabrication of a reverse T sub cabin structure are performed; then, the reaction force back system, the jacking force system support frame, the jacking force system and the guide rail are installed in a node well; in addition, the resistance reduction system is arranged on a small longitudinal beam in a utility tunnel; then, the force transmission reverse T beam is installed; the jacking force system is opened; sectioned reverse T sub cabin structures takes place one by one; finally, the seam filling and leveling are performed in a seam position of the reverse T sub cabin structure and the utility tunnel, and the sub cabin structure jacking is completed. The system and the method provided by the invention solve the problems of construction complexity, narrow and small operation space and the like of the non-excavation process utility tunnel sub cabin structure; the construction efficiency of the conventional sub cabin structure can be obviously improved.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

Jack-up installation construction structure of large steel silo

ActiveCN105672735BLow costImprove construction efficiencyBuilding constructionsBulk storage containerEngineeringSilo

The invention discloses a mounting construction structure for a large-sized steel material cabin. The mounting construction structure comprises a basic platform, a first cylindrical section, a cone roof, a second cylindrical section and a bottom plate, wherein the first cylindrical section is arranged on the bottom plate; the cone roof is hermetically connected to the top of the first cylindrical section to form a bell jar structure; the second cylindrical section is arranged outside the first cylindrical section in a sleeving manner and formed by splicing a plurality of arc plates; a vertical gap which is not spliced temporarily is reserved as a movable joint; the two arc plates at the joint have lapping allowance of a certain length; a movable joint tensioning device is further arranged between the two arc plates at the joint; a first seal rubber plate for sealing a gap between the second cylindrical section and the bottom plate is arranged in the first cylindrical section; the mounting construction structure further comprises an air blowing device and a limiting device; and a second seal rubber plate for sealing a gap between the first cylindrical section and the second cylindrical section is arranged on the first cylindrical section. According to the mounting construction structure, the high-altitude operation can be changed to the low-altitude operation, the safety of construction can be enhanced, resources and construction expenses can be saved, the working efficiency can be improved, and the construction period can be shortened.

Owner:THE FIRST ENG CO LTD OF THE 23TH METALLURGICAL CONSTR GRP MINMETALS

A ring-arranged pre-embedded bolt fixing structure and installation method for CDQ coke oven body

ActiveCN107267165BNot easy to moveSave temporary support materialBuilding constructionsProduction lineArchitectural engineering

The invention discloses a dry coke quenching furnace annular arrangement pre-embedded bolt fixed structure and an installation method thereof, which belong to the fields of industrial building dry quenching or similar industrial production line equipment base, and chimney base pre-embedded bolt installation engineering. The dry coke quenching furnace annular arrangement pre-embedded bolt fixed structure comprises a connection board, bracing frames and connecting pieces, the connection boards are arranged at the top of the bracing frame, bolt holes are arranged on the connection board, the connecting piece is arranged at the bottom of the bracing frame, the adjacent two bracing frames are connected together, the bracing frame comprises a bottom crossbeam, columns 1, crossbeams and columns 2, the bottom of the bracing frame is the bottom crossbeam, a pair of the columns 1 and a pair of the columns 2 are respectively arranged on the relative position of the bottom crossbeam, and the top of the columns 1 and the columns 2 are connected together through the crossbeam. Aiming at the integral deviation problem of the bolt installation due to vibration when the concrete is vibrated in the prior art, the bolt is strictly prohibited to connected with the basic steel bar without interference, so that displacement is not easily generated.

Owner:马鞍山钢铁建设集团有限公司

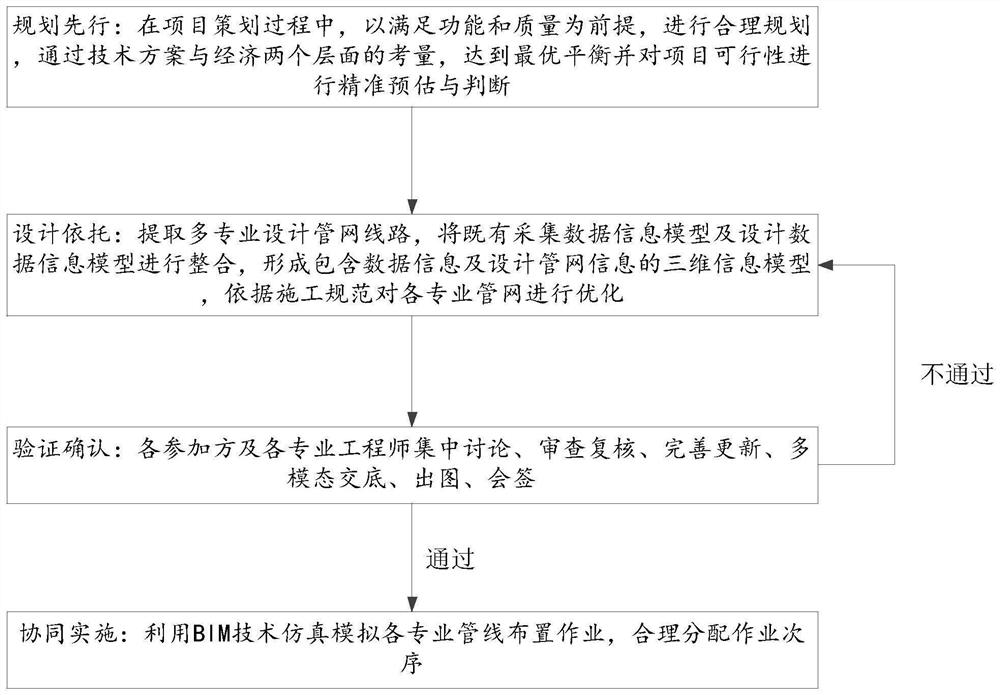

PDVI-based multi-specialty complex large-scale commercial complex pipe network optimization method

PendingCN114692354AReduce drawing timeVerify maturityGeometric CADDesign optimisation/simulationProfessional engineerData information

The invention discloses a PDVI-based multi-specialty complex large-scale commercial complex pipe network optimization method, which comprises the following steps: planning in advance: in a project planning process, carrying out reasonable planning on the premise of meeting functions and quality, and establishing a project planning plan by considering two aspects of a technical scheme and economy; optimal balance is achieved, and project feasibility is accurately estimated and judged; design support: extracting a multi-specialty design pipe network line, integrating the acquired data information model and the design data information model to form a three-dimensional information model, and optimizing each specialty pipe network according to construction specifications; verification and confirmation: each participant and each professional engineer intensively discusses, reviews and rechecks, perfects and updates, multi-modal disclosure, drawing and countersigning; and collaborative implementation: simulating each professional pipeline arrangement operation by using a BIM technology, and reasonably distributing an operation sequence. By using the novel method, the time for waiting for drawing of a design institute is reduced, and the early planning time is shortened.

Owner:SHANXI INSTALLATION GRP CO LTD

Construction method of gravity dam heightening structure with limited combination of rear upper

PendingCN114351655AReduced measure feeRaise the ratioFoundation engineeringGravity damsTemperature controlArchitectural engineering

The invention discloses a construction method of a gravity dam heightening structure with limited combination of a rear upper. The method comprises interface processing, structure processing and temperature control processing. By means of interface treatment, structure treatment and temperature control treatment measures, the gravity dam heightening structure with the limited combination of the rear wall is formed, a certain combination proportion is achieved between an old dam body and a new dam body, and it is guaranteed that the effect of combined stress is achieved between the old dam body and the new dam body. The problem that the new dam body and the old dam body are difficult to connect into a whole or completely separate when the dam is heightened is solved; the method has the advantages that the old dam body and the new dam body are combined in a certain proportion, and the effect of combined stress between the old dam body and the new dam body can be guaranteed.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES +1

Layered Construction Method of Concrete Oversized Beams in Transfer Story of High-rise Buildings

The invention relates to a layered construction method of concrete super-beams in transfer floors of high-rise building structures, which includes the following steps: (1) measuring and setting out the construction site, binding the steel bars of the vertical components, and performing formwork support of the vertical components after binding Then pour the concrete of the vertical components; erect the load-bearing frame, lay the bottom formwork of the beam slab, and then bind the beam reinforcement; (2) install the side formwork and formwork of the beam slab; One-time pouring, after the first pouring, slab reinforcement binding and water and electricity reservation and pre-embedding, and then the first concrete curing; (4) The second pouring of the upper beam and slab concrete, and concrete curing after the pouring is completed , After the concrete curing is completed, the formwork can be removed. The present invention has a more reasonable flow rhythm arrangement for pouring concrete and binding steel bars, shortens the construction period, improves construction safety, and reduces construction costs at the same time.

Owner:ZHEJIANG QINYE COUNSTRUCTION GRP CO LTD

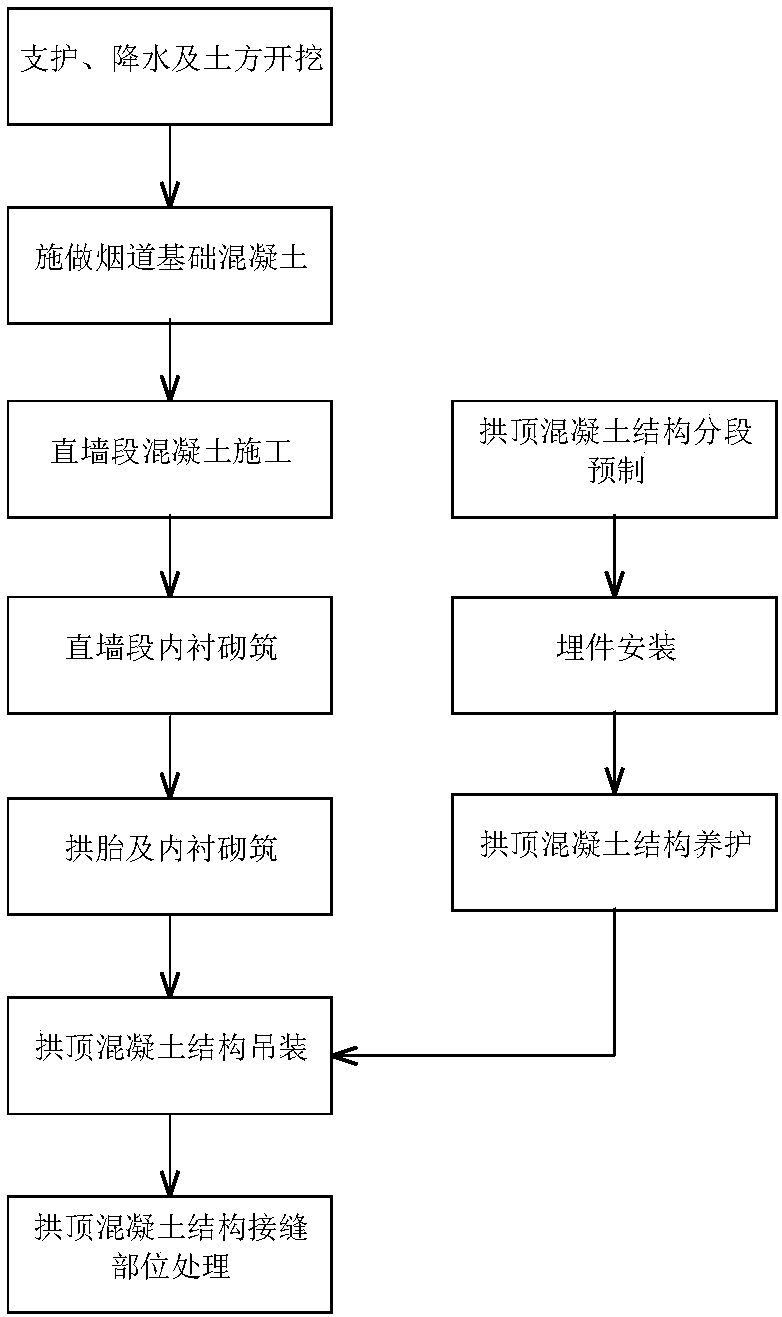

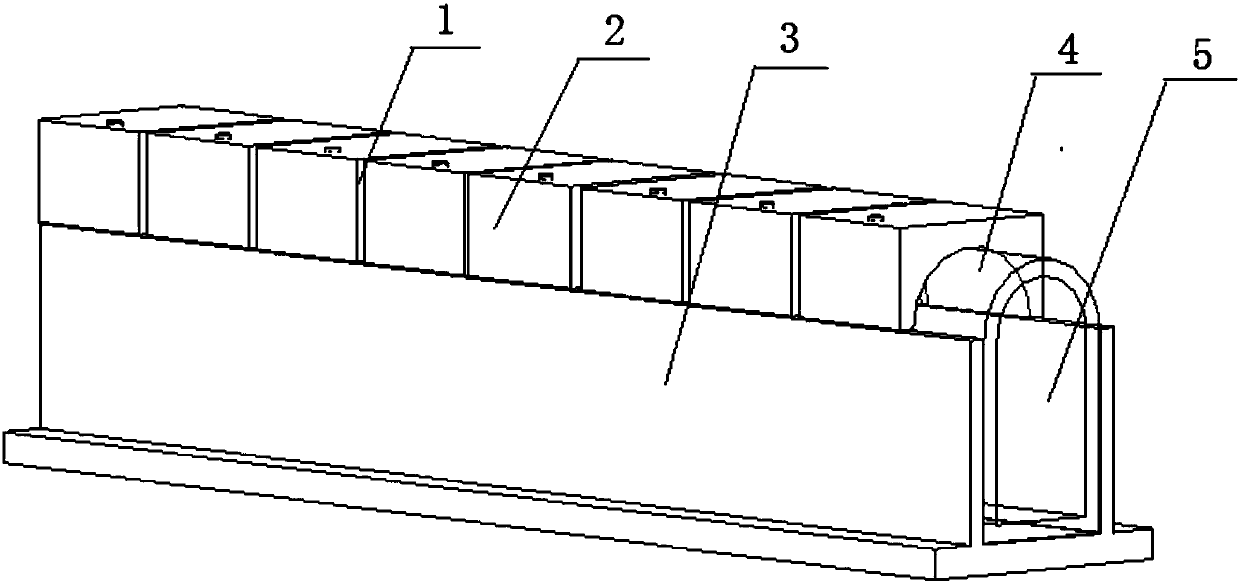

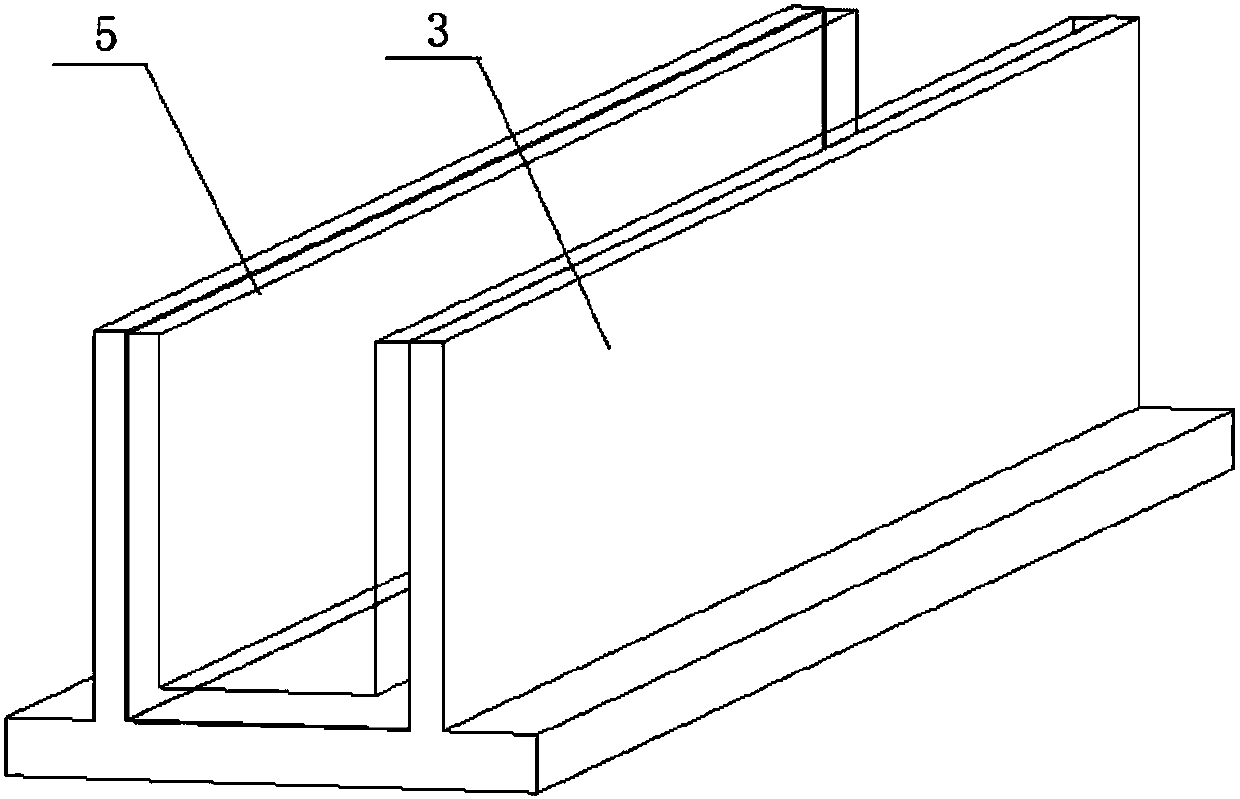

Flue top plate rapid construction method

InactiveCN107829560AShorten the construction periodImprove manufacturing precisionBuilding material handlingVertical ductsWall segmentFlue

The invention provides a flue top plate rapid construction method. A flue top plate is preliminarily fabricated in a sectional mode, and in a construction period, flue top-plate sectional pre-fabrication processing, straight-wall-section concrete construction, straight-wall-section lining masonry construction, and arch-moulding-bed and vault lining masonry construction are conducted at the same time, so that the construction period is effectively shortened. Compared with the prior art, the flue top plate rapid construction method has the advantages that the construction of a flue top-plate segment and the construction of a lower straight wall segment are conducted simultaneously, so that the construction period is shortened; a vault concrete structure is preliminarily fabricated in an off-site mode, so that the fabrication accuracy is high, and the quality is easily ensured; a vault mould can be fabricated by being divided into small segments and can be recycled, so that measure expenses are saved.

Owner:CHINA THIRD METALLURGICAL GRP

Constant load control device and method of bridge erecting machine

ActiveCN109024308BIncrease the lifting weight limitControllable bending momentBridge erection/assemblyEngineeringLimit value

The invention provides a dead load control device and method of a bridge erection machine. The invention changes the stress form of the traditional bridge erecting machine, the cantilever hoisting load of the bridge erecting machine is transferred to the middle leg, the function of wireless active control of bridge erection machine reaction force is realized, intelligent control is realized, the cantilever load in front of the bridge erecting machine can be adjusted according to the hoisting weight and the hoisting distance, so as to control the front leg reaction force of the bridge erectingmachine to be within the target range, to control the bending moment of the construction beam section caused by the front leg reaction force F of the bridge erecting machine, to improve the stress safety of the construction beam section, to reduce the cost of measures in the hoisting construction, to improve the bending resistance of the main longitudinal beam of the bridge erecting machine, and to increase the original hoisting weight limit value of the bridge erecting machine.

Owner:SHANGHAI CONSTRUCTION GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com