Layered Construction Method of Concrete Oversized Beams in Transfer Story of High-rise Buildings

A technology of structural transfer layer and layered construction, which is applied in building structures, beams, buildings, etc., can solve the problems of great influence on the quality of poured beams and slabs, large investment of formwork steel pipes, and large hydration heat and temperature rise. To achieve the effect of reasonable flow rhythm arrangement, construction quality assurance, and reduction of pouring and ramming sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

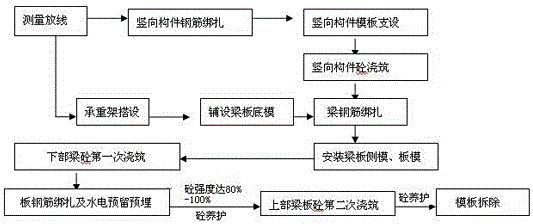

[0027] like figure 1 and figure 2 Shown, the layered construction method of high-rise building structure transfer layer concrete super-beam of the present invention may further comprise the steps:

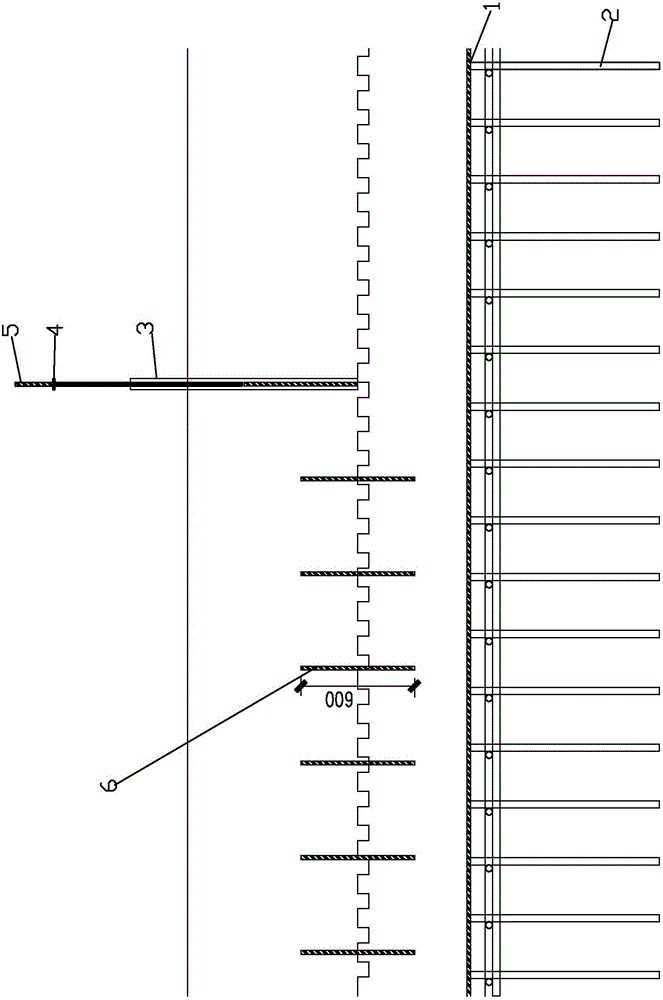

[0028] (1) Measure and lay out the construction site, and then bind the steel bars of the vertical members on the one hand, and then set up the formwork 1 of the vertical members after binding, and then pour the concrete of the vertical members, that is, pour the wall columns at the lower part of the transfer beam , the concrete strength of the wall column at the lower part of the transfer beam is ≥80%; on the other hand, the load-bearing frame is erected, and the load-bearing frame is a load-bearing formwork steel pipe 2, and the calculated load required for the erection of the load-bearing formwork accoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com