Installation and construction method of large steel silo

A construction method and technology of steel materials, applied in the processing of building materials, large-capacity bulk material storage, building types, etc., can solve the problems of high-altitude operations, high cost of machinery use, high risk, etc., to achieve short construction period and save Construction cost, effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

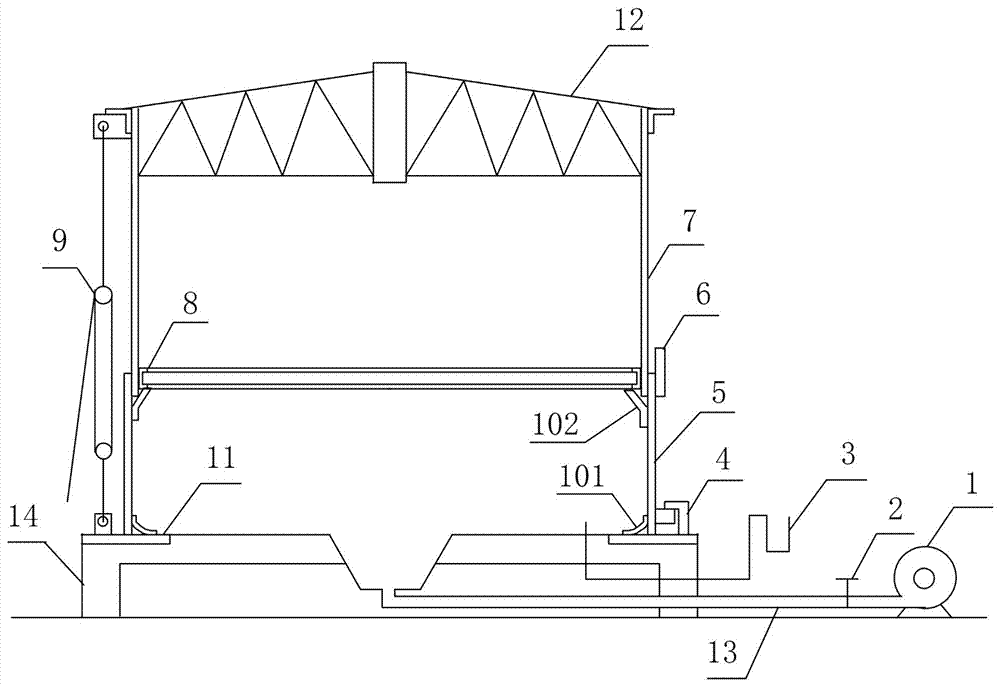

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Take the installation and construction of a 16,000t alumina large-scale steel silo in a factory as an example. The model of the large-scale steel silo is Φ30m×27.4m, the diameter of the cylinder is 30m, and the height is 27.4m. The cylinder is composed of 14 sections. The total weight of the steel silo is 586t, the maximum gas lifting weight is 458t, and the maximum gas lifting pressure required is 768mmH 2 O, that is 0.0768atm or 0.0768Kgf / cm 2 .

[0027] Such as figure 1 As shown, the installation and construction method of the above-mentioned large steel silo specifically includes the following steps:

[0028] (1) Installation of the bottom plate 11, the first barrel section 7 and the cone top 12:

[0029] On the top of the foundation platform 14, a plurality of arcuate plates are spliced piece by piece to form an annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com