Jack-up installation construction structure of large steel silo

A steel, large-scale technology, applied in the field of jack-up installation construction structure, can solve the problems of high risk, high cost of mechanical use, high-altitude operation, etc., to achieve the effect of short construction period, saving construction cost and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

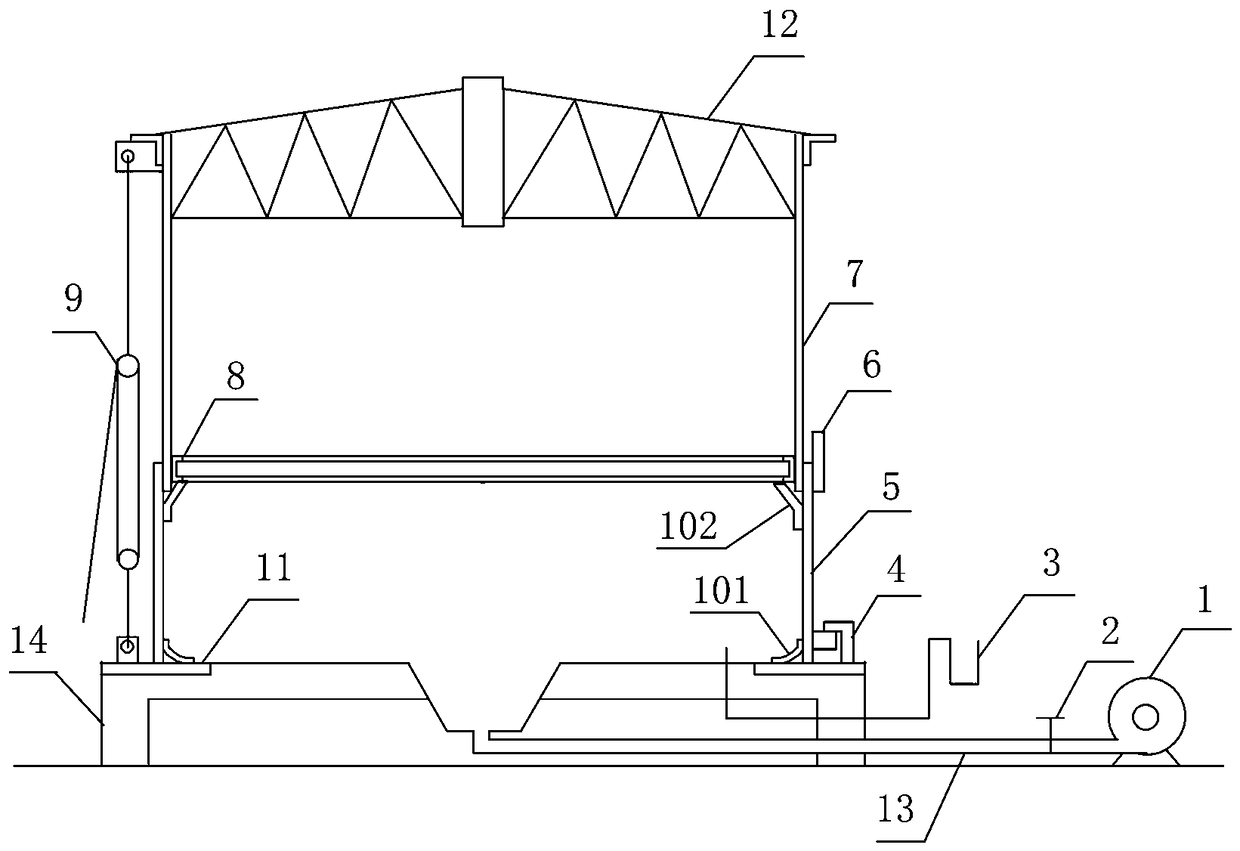

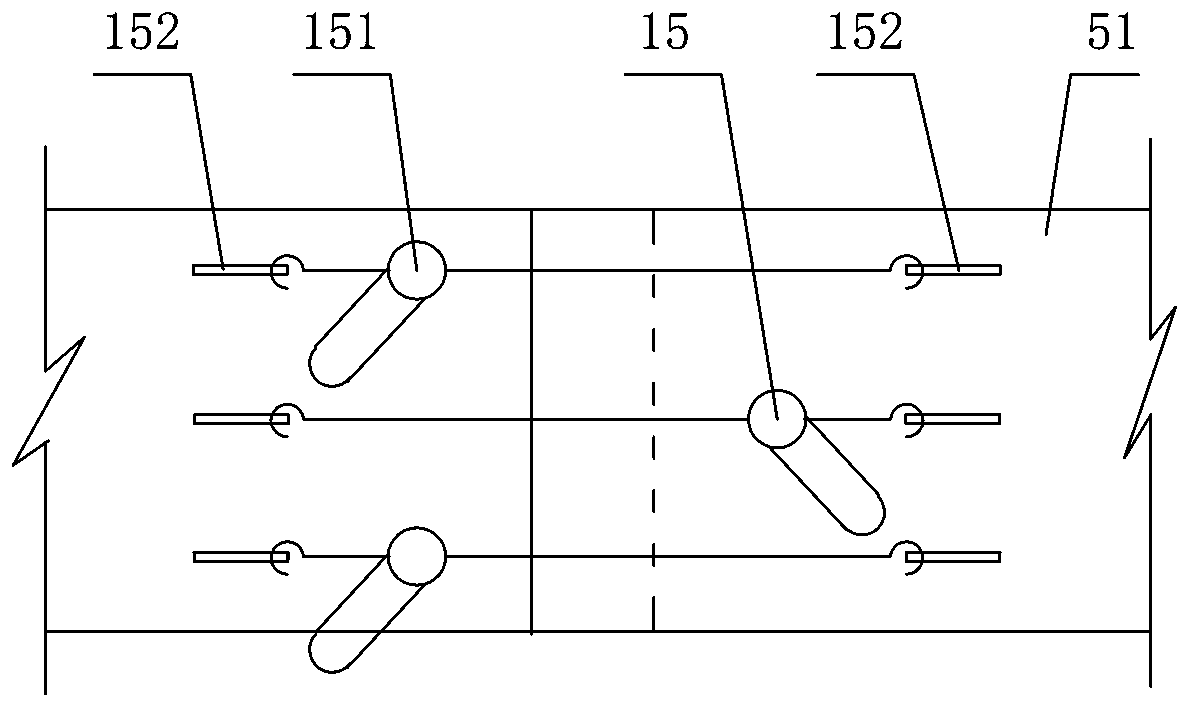

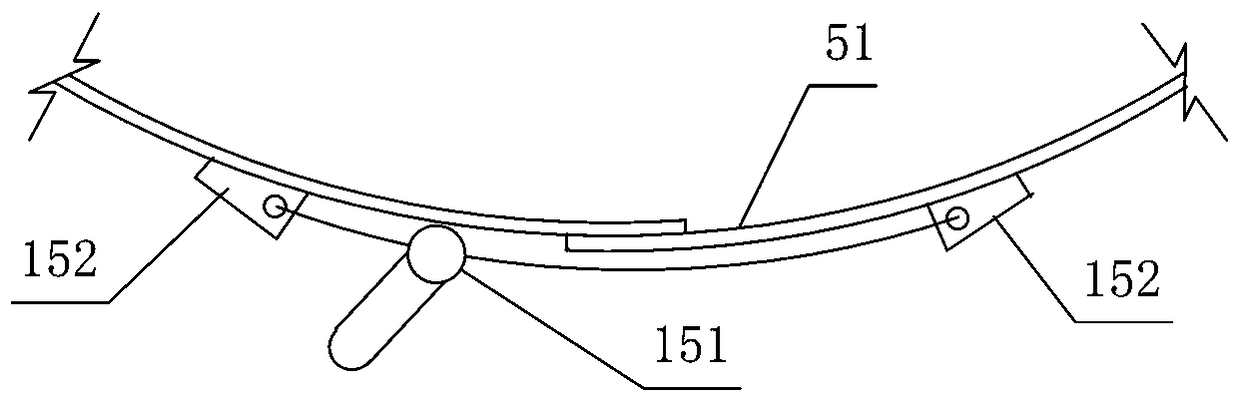

[0021] like figure 1 As shown, the jack-up installation construction structure of the large-scale steel silo in this embodiment includes a foundation platform 14, a first section cylinder section 7 and a second section cylinder section 5, and a bottom plate 11 is installed on the foundation platform 14. In this embodiment, The bottom plate 11 is an annular plate, which is spliced by 48 arcuate plates; the second cylindrical section 5 is placed on the bottom plate 11, and the first cylindrical section 7 is sleeved inside the second cylindrical section 5 and close to the second The inner side wall of the cylindrical section 5 is sealed with a conical top 12 on the top of the first cylindrical section 7 and forms a bell structure. The second section of the cylinder section 5 is spliced by a plurality of arc-shaped plates 51 and a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com