Cement grinding mill foundation suspension type reserved hole embedding method

A hole-reserved, suspended technology, applied in infrastructure engineering, construction, etc., can solve problems affecting construction quality, construction period, eccentric wear of sliding shoe bearings, offset of reserved holes, etc., to shorten the construction period, pre-embedded High accuracy and the effect of reducing the cost of measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

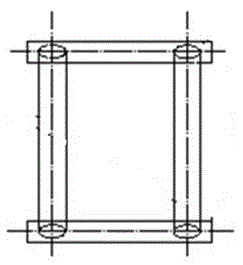

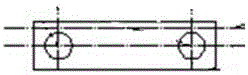

[0041] like figure 1 As shown, this embodiment provides a method for embedment of cement mill foundation suspended reserved holes, in which a bracket is installed outside the foundation, and a method of hanging the reserved holes is used on the bracket; and the existing reserved holes are changed For the method of burying alone, according to the pre-embedding method and difficulty, the reserved hole model is made in groups as a whole4.

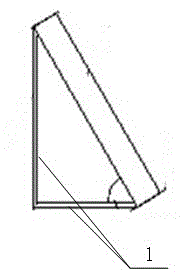

[0042] When implementing the above method, it is first necessary to make 4 groups of reserved hole models, which are specifically as follows: N reserved holes are respectively set on the foundation of the feed end and the discharge end of the cement mill, and are divided into 2 / N groups of reserved model groups, N is an even number, in this embodiment, N=24. like Figures 1 to 6 As shown, for a model with an inclination angle, according to the size and angle of the drawing, carry out lofting on the ground production platform, and make and as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com