Mixed type connection precast pre-stress concrete round storage bin structure

A prestressing and concrete technology, which is applied in the field of hybrid connection prefabricated prestressed concrete circular storage warehouse structure, can solve the problems of poor concrete density and structural waterproof performance, sharp increase of engineering construction costs, insufficient vibration, etc., to reduce The effect of material consumption and construction cost, improvement of labor intensity and environment, and improvement of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

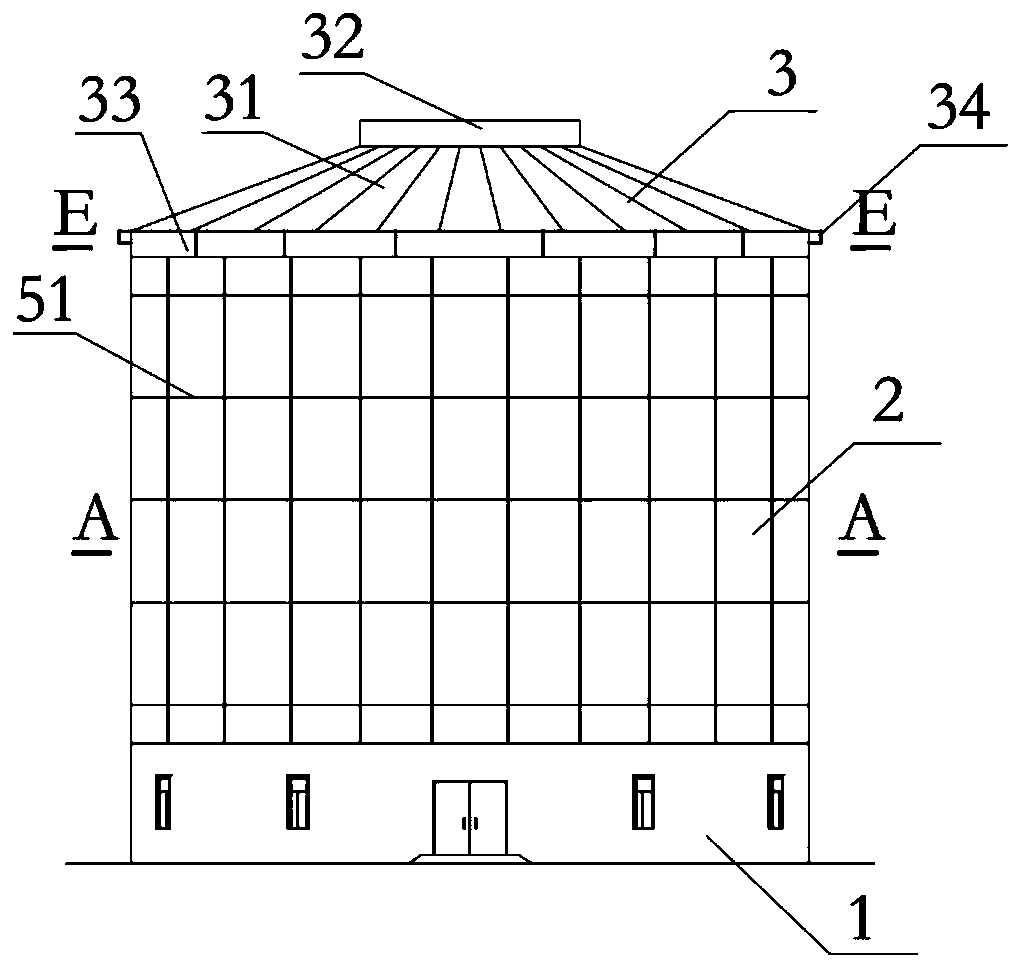

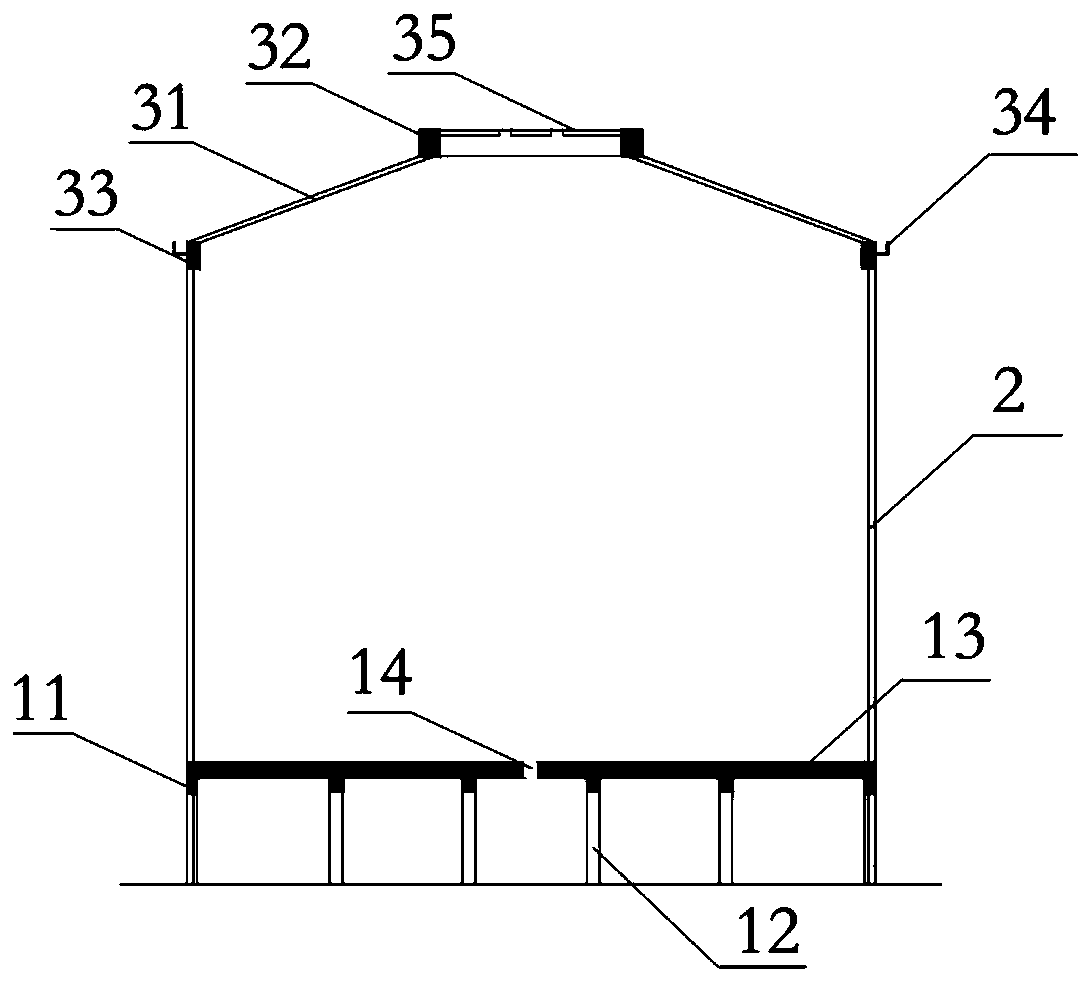

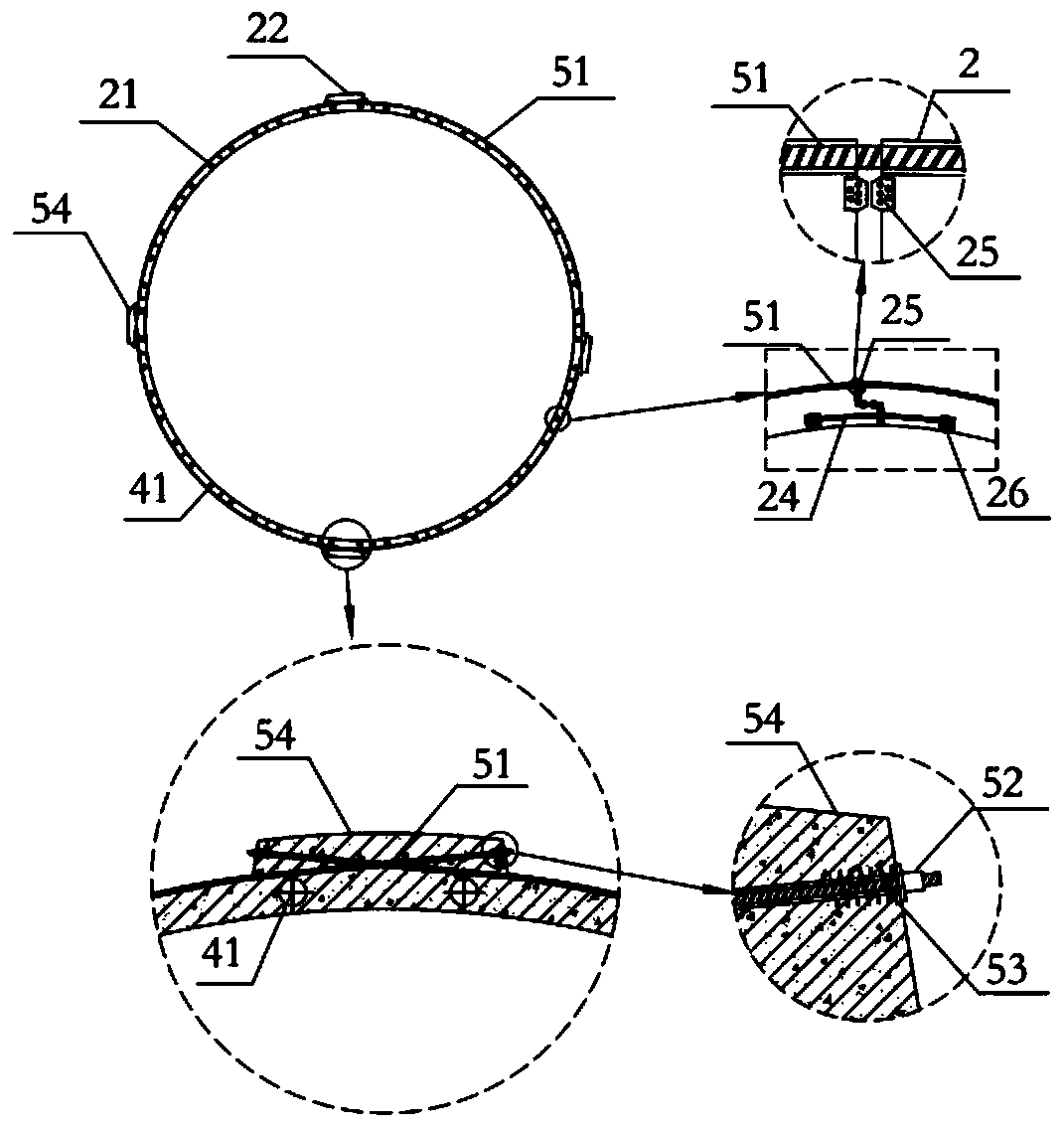

[0022] A hybrid connected prefabricated prestressed concrete circular storage silo structure, comprising: a silo bottom 1, a silo wall 2 is arranged on the silo bottom 1, a silo roof 3 is arranged on the silo wall 2, and the silo wall 2 includes The tongue-and-groove prefabricated arc-shaped wall panels 23 are enclosed to form the warehouse wall matrix, and the vertical prestressing system 4 is arranged on the prefabricated arc-shaped wall panels 23, and the circumferential prestressing system 5 is arranged on the warehouse wall matrix, adjacent to The prefabricated curved wall panels 23 are connected by long bolts 24 and are used for the pre-fixation of the prefabricated curved wall panels 23. An anchoring platform 54 is arranged on the four prefabricated curved wall panels located at the four equal parts of the warehouse wall. The prestressing system 5 includes a circumferential prestressing tendon 51 composed of 4 sections of prestressing tendons, and the 4 sections of prest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com