Flue top plate rapid construction method

A construction method and flue technology, applied in the direction of vertical pipes, building components, buildings, etc., can solve the problems of high cost of measures, long construction period, long process flow, etc., to save cost of measures, save construction period, and high manufacturing precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

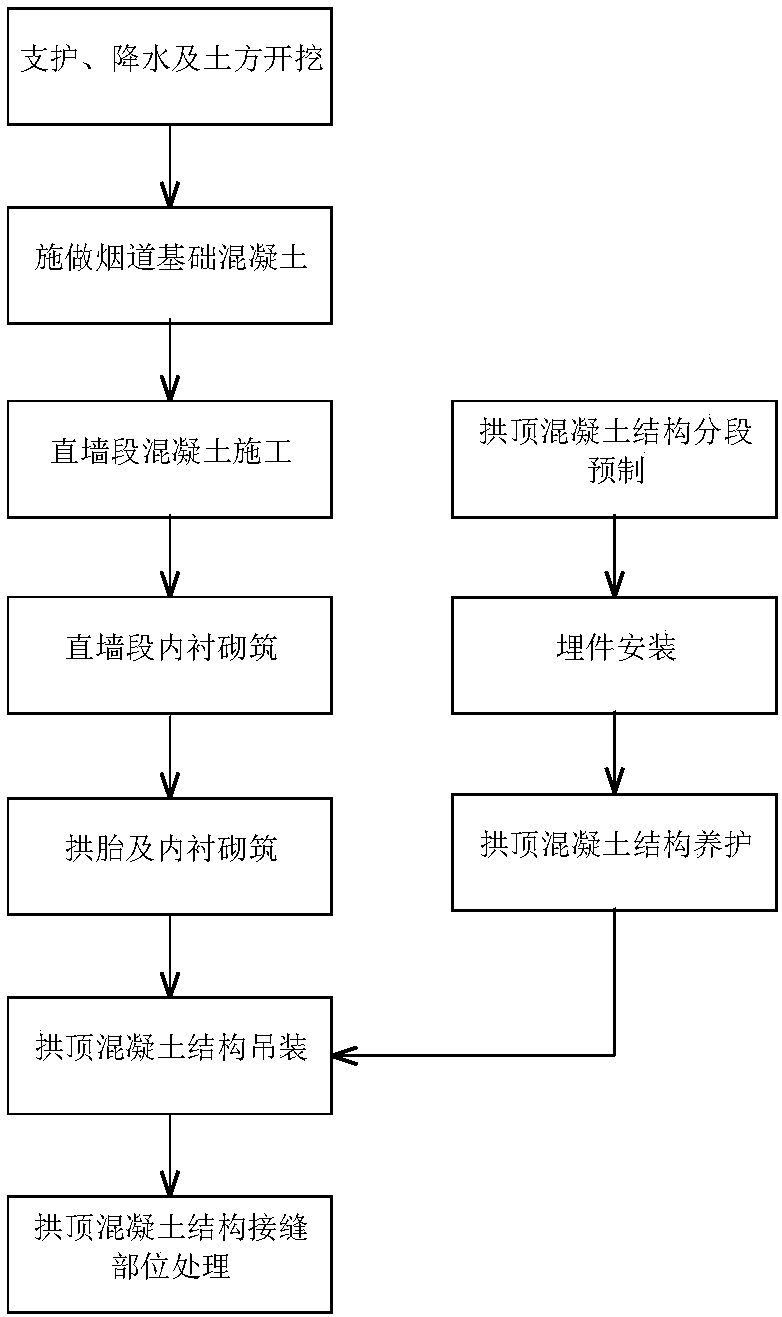

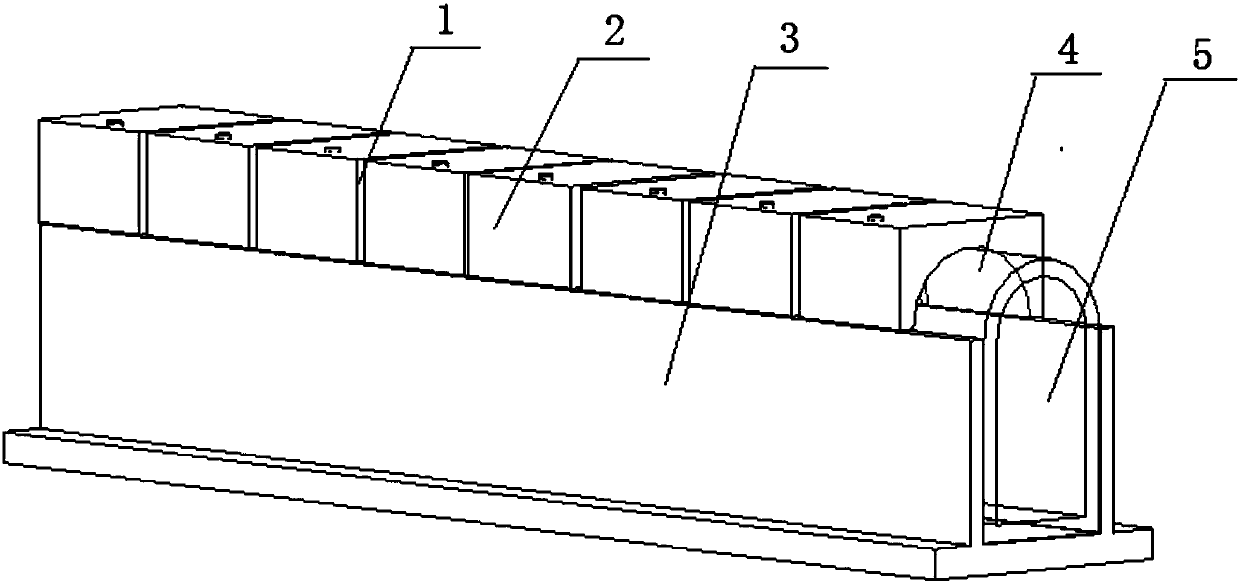

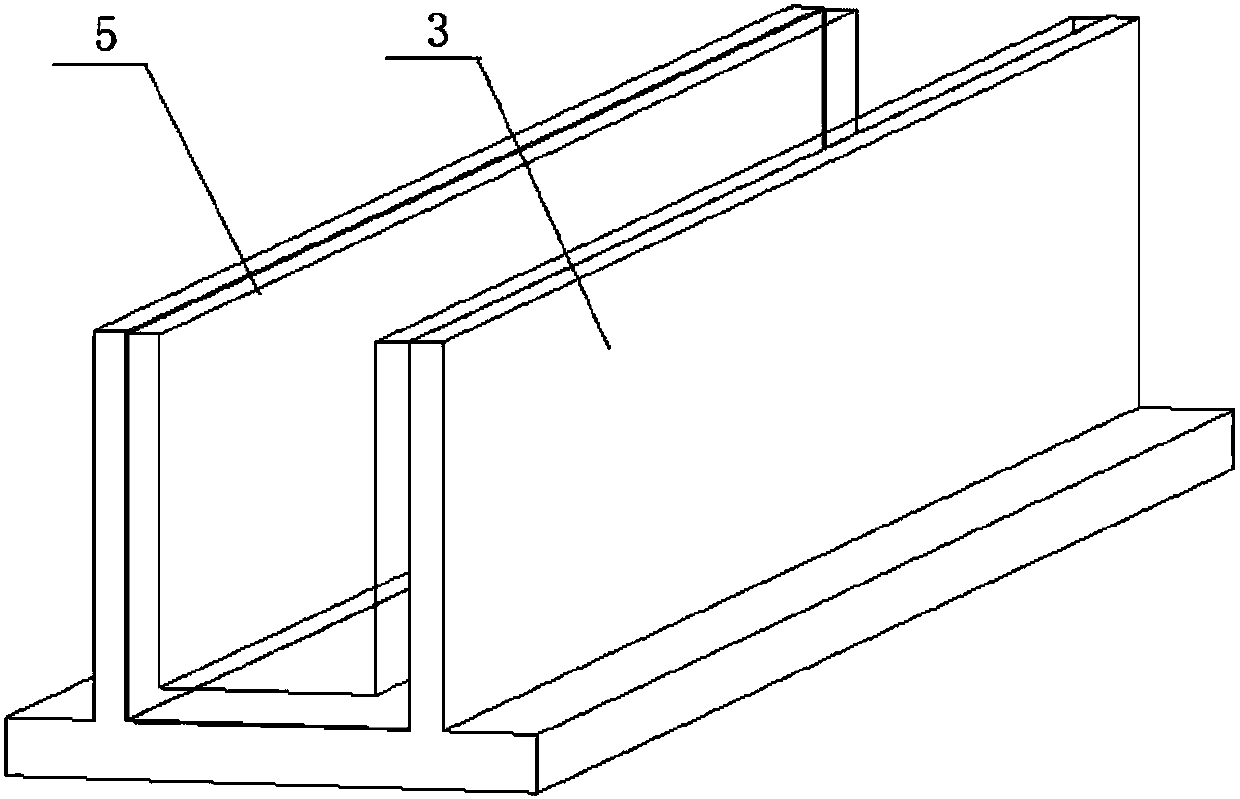

[0024] Such as Figure 1-Figure 4 As shown, a rapid construction method for the flue roof, the flue roof is prefabricated in sections, and in the construction period, the section prefabrication of the flue roof and the concrete construction of the straight wall section, the lining of the straight wall section, and the arch The construction of tire and vault lining is carried out at the same time, which effectively shortens the construction period; the specific steps are as follows:

[0025] 1) Carry out support, precipitation and earthwork excavation according to the normal sequence of construction, and then apply concrete for the flue foundation;

[0026] 2) Carry out segmental prefabrication of the vault concrete structure, and at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com