Large-span net rack external expansion assembly integral jacking construction method

A construction method and overall jacking technology, which is applied in the direction of construction, building structure, and building material processing, etc., to achieve the effects of easy installation, good social benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

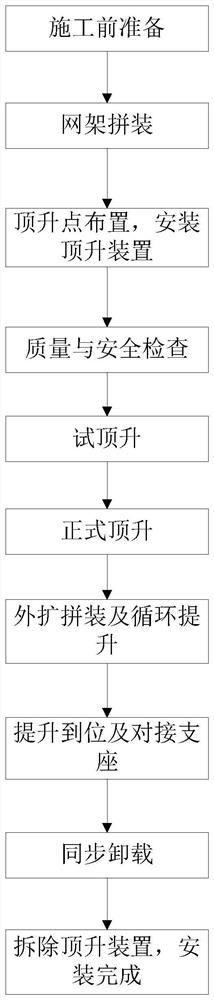

[0098] The overall jacking construction method of the large-span network frame external expansion assembly of the present invention, the construction method is specifically as follows:

[0099] (1) Assembling and jacking: the net frame is assembled on the ground, and the jacking bracket is installed when it is assembled to the position of the stand, and the jacking bracket is used to lift the net frame to a set height (each jacking height is different, determined according to the civil engineering situation) When the next grid assembly is satisfied, stop the jacking work;

[0100] (2) Symmetrical expansion assembly: After the jacking work stops, the space rigidity unit that has been assembled is symmetrically expanded from the center of the network frame, so that the network frame continues to extend around;

[0101] (3) Adjust the number and position of the jacking points: when splicing outwards, adjust the number and position of the jacking points of the grid according to th...

Embodiment 2

[0104] as attached figure 1 As shown, the overall jacking construction method of the large-span network frame external expansion assembly of the present invention, the technical process of the construction method is as follows:

[0105] S1. Preparations before construction; details are as follows:

[0106] S101. Check the grid materials that have entered the field, and stack the balls and poles separately, and check the processing dimensions of the balls and poles to ensure the installation accuracy, otherwise they cannot be used;

[0107] S102. The debris piled up on the site must be cleaned up to ensure the smooth progress of the project construction;

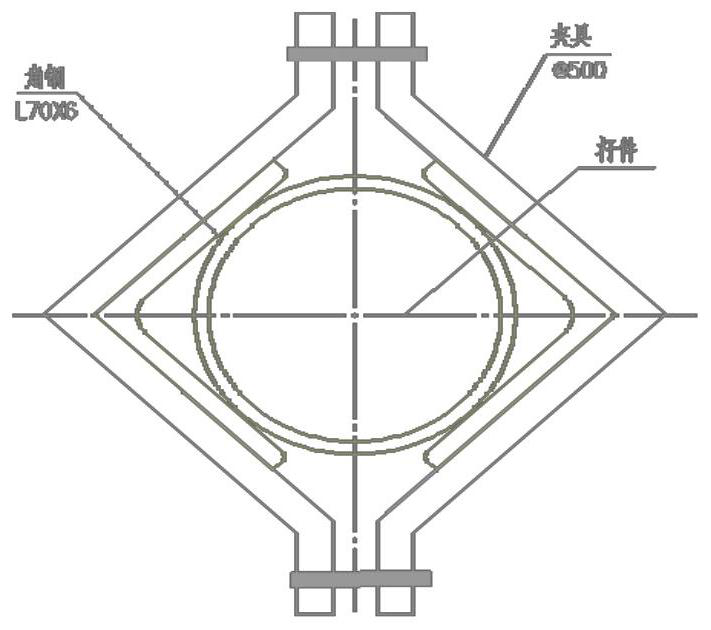

[0108] S103. Use MIDAS to calculate the number and position of jacking frames according to the site conditions and structural shape, and perform stress and deformation calculations; after the network frame is checked and calculated, if any overstressed rods are found, temporarily reinforce them, that is, use clamps on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com